ELECTRIC, WITH AN EDGE

Daelim’s 2500 kva transformers are available in three styles, pad mounted transformer, dry-type transformer and mini substation transformer. Daelim has been producing and selling 2500kva transformers for over 15 years. Rich design experience can meet your various application needs of transformers.

At the same time, daelim’s 2500kva transformer has passed a number of international certifications, including: IEC, IEEE, ANSI, CSA. Ensure that the transformers you purchase can be installed and operated smoothly in the United States, Canada, Mexico, Ecuador, Spain and other countries.

The 2500KVA transformer is especially suitable for use in places like Bitcoin mines that require large-scale electricity consumption, which can save you a lot of electricity expenses and improve the efficiency of use.

2022 Ultimate Pad Mounted Transformer Guide

-FIND THE BEST PAD-MOUNTED TRANSFORMER GUIDE ON THE WEB ALL IN ONE PLACE. SEE OUR LIST OF 14+FAQ RIGHT HERE.

Ultimate 1250kVA Transformer for Guide

-This article discusses the 1250kVA transformer’s specifics, Properties, ratings, uses, and FAQs. Read on!

3500 kva three phase pad mounted transformer

-The 3500 kVA pad mounted transformer refers to a three phase pad-mounted industrial transformer with a power of 3500 kVA.

Wholesale 2500 kva transformers are prominent components in power distribution systems. These transformers are engineered to either step up or step down voltage levels, enabling efficient power transmission. Let’s delve into the pricing details of these transformers:

To comprehend the price range of Wholesale 2500 kva transformers, it’s crucial to explore the different types available in the market. Here is an overview of the various types and their respective price ranges:

IEC Standard Factory Price 2500 KVA 3150KVA 35KV 33KV 20KV Electrical Distribution Transformer:

2500 Kva Dry Type Transformer:

Wholesale 2500 kva Electrical Transformer:

22 Kv 2500 kVA 250kVA Three Phase Step Down Distribution Transformer:

Please note that the aforementioned prices are based on the suppliers found on Alibaba and Made-in-China. Prices may vary depending on specific features and specifications. To obtain a more accurate quote, it’s recommended to directly contact the supplier.

Transformer Type Price Range IEC Standard Factory Price 2500 KVA 3150KVA 35KV 33KV 20KV Electrical Distribution Transformer $9,000.00 – $9,600.00 2500 Kva Dry Type Transformer $100.00 – $2,000.00 Wholesale 2500 kva electrical transformer Prices not specified 22 Kv 2500 kVA 250kVA Three Phase Step Down Distribution Transformer $500 – $20,000

The various types of Wholesale 2500 kva transformers offer distinct features, and their differences stem from factors such as insulation grade, model and loss standard, and styles. Let’s explore these variations:

Insulation Grade: The insulation grade of a 2500 kva transformer may differ based on individual plant design. Varied insulation grades can impact the transformer’s performance and safety.

Model and Loss Standard: The model and loss standard of a 2500 kva transformer can vary based on the manufacturer and desired application. Each manufacturer may employ unique models and adhere to specific loss standards.

Styles: Renowned supplier Daelim offers three styles of 2500 kva transformers, including pad-mounted, dry-type, and mini-substation transformers. Each style possesses distinct features and specifications to fulfill diverse installation requirements.

For a comprehensive understanding of the variations between Wholesale 2500 kva transformers, it’s advisable to consult manufacturers or suppliers. They can provide detailed information on features, specifications, and applications tailored to their respective transformers.

The Wholesale 2500 kva transformer stands as an indispensable and versatile asset in the power distribution industry. Its pricing varies based on the type and specific requirements. As a potential buyer, it is crucial to comprehend these distinctions and make an informed decision according to your unique needs and budget.

Remember, conducting thorough research, comparing different options, and selecting the best value for your investment are key factors in making a wise purchase. Happy shopping!

Please note that the information provided in this guide is generated using AI and data from various sources. Prices mentioned are subject to market conditions and supplier policies, thus are subject to change.

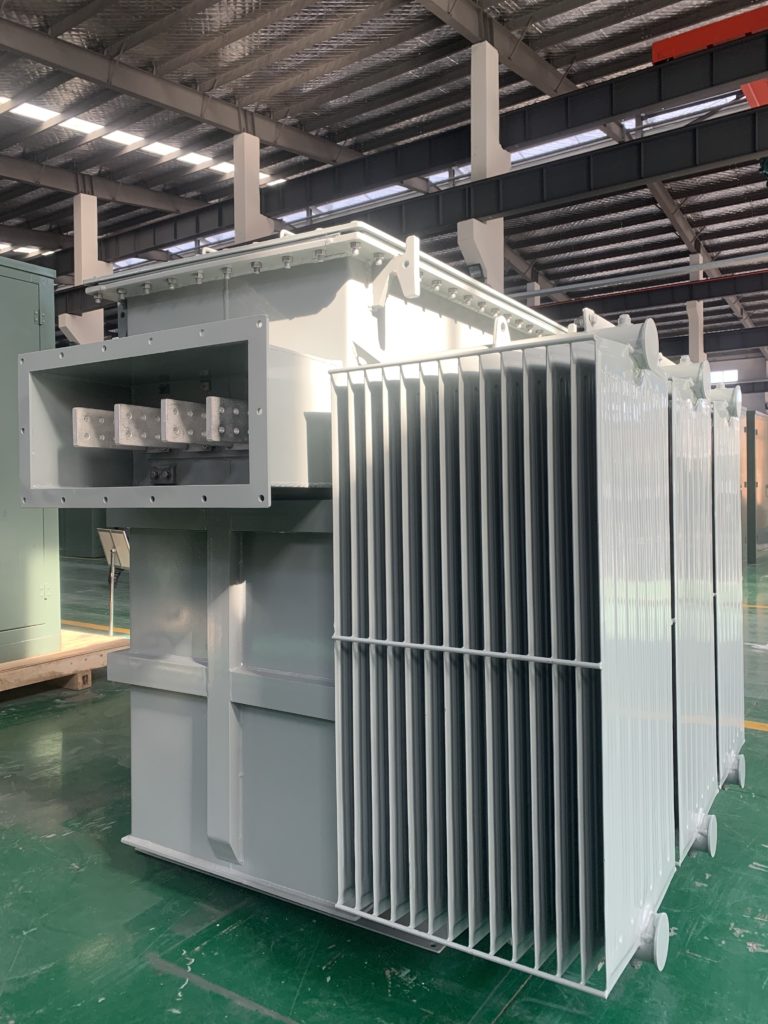

2500 kva refers to a distribution transformer with a rated capacity of 2500 kva. A transformer with a capacity of more than 2000kva is a large-capacity transformer. The most widely used type of 2500kva transformer on the market is a pad mounted transformer. The vacuum butterfly valve used on the transformer radiator.

The lower part of the transformer housing is provided with a device for jacking the transformer, and the lower part should be provided with a horizontal traction device to facilitate the towing, pulling and jacking of the transformer without lifting equipment.

Ability to withstand short-circuit: The transformer should be able to withstand the short-circuit current supplied by the infinite power supply on the 10kV power supply side when the three-phase short-circuit on the low-voltage bushing side occurs, and the duration is 2 seconds without component damage, winding deformation or no discharge trace.

2500 kva pad-mounted transformer weight:

Oil Weight: 1020 kg

Total Weight: 8865 kg

2500 kva pad mounted transformer dimensions:

| Dimension(mm) | ||

| W | D | H |

| 3070 | 1650 | 2330 |

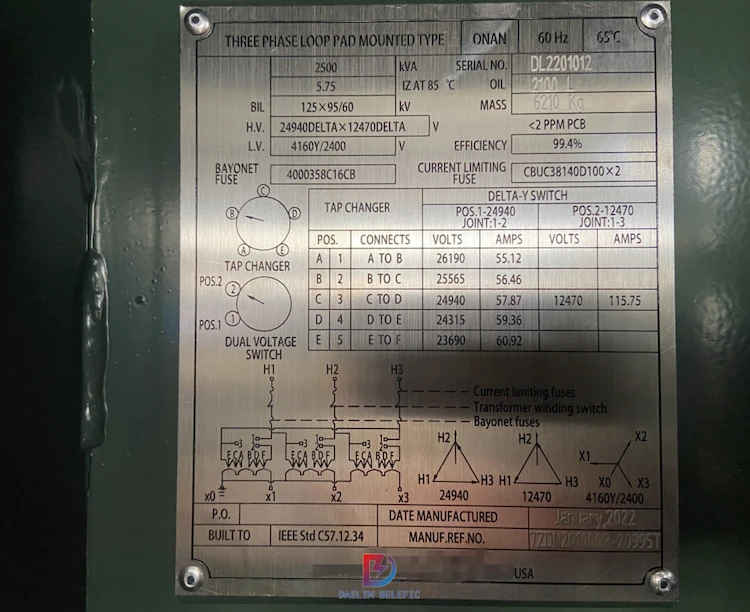

The picture shows the nameplate of a pad mounted transformer sold by Daelim to the United States.

What information content and key performance parameters of the transformer can be seen from the factory nameplate?

From the factory nameplate in the picture, you can see the product specifications, short-circuit capacity, rated current, rated frequency and number of phases, connection group model, cooling method, application standard, characteristic impedance working voltage, insulation level, etc. of the pad mounted transformer.

The basic parameters of the factory nameplate of the pad mounted transformer are introduced in detail below.

The product specification of the pad mounted transformer in the picture is Three phase loop pad mounted type.

This pad mounted transformer is a three-phase transformer.

Loop refers to Internal Loadbreak Switches as Loop-Feed Switches or Loop-Radial Switchese.

The volume of the transformer in the figure is 2500kVA, and the volume levels of the transformer are 630, 800, 1000, 1250, 1600, 2000, 2500, 3000, 3500kVA, etc.

The oil volume of the Pad mounted transformer is: 2100L

The rated frequency of the power supply system in my country is 60Hz.

The rated frequency in the figure is 60Hz, and the number of phases is three-phase.

Generally, a three-phase transformer is selected, unless the single-phase electrical load accounts for a very large proportion of the load.

In order to better reduce the three-phase unbalance, a three-phase transformer is independently set to supply the single-phase electrical load power supply system.

The rated current of the Pad mounted transformer in the figure is 24940DELTA X 12470 DELTA V on the high-voltage side, and the rated current on the low-voltage side is: 4160Y/2400V.

It shows that the tap switch on the high-voltage side of the transformer has three parts, and the rated current on the low-voltage side is 4160Y/2400V.

The current is 4160Y/2400V.

The purpose of setting the tap power switch on the high-voltage side of the transformer is to adjust the working voltage level of the power supply system of the transformer.

If the DC voltage of the machinery and equipment is high, change the tap power switch to 5% of the tap connector to reduce the DC voltage of the machinery and equipment;

If the DC voltage of the machinery and equipment is slightly lower, change the tap power switch to to -5% of the sub-connector to increase the DC voltage of the machine equipment.

The connection group model of the Pad mounted transformer in the picture is DELTA-Y-SWITCH. Dyn11 wiring and yyn0 wiring distribution transformer comparison.

The full load loss and load loss of the former one are slightly larger than the latter one.

The former has a slightly higher compressive strength for the primary side winding of the insulating layer than the latter.

At present, there are more and more electronic products in the load, which will cause environmental pollution of high-order harmonics to the power grid.

Compared with Dyn11 wiring and yyn0 wiring distribution transformer, when the primary winding is connected into a three-phase shape, it can make the third and non-negative integer high-order harmonics generate electric field, so the former one is beneficial to the protection of the superior power grid for the third and non-negative integers. higher harmonics;

The zero-sequence characteristic impedance of Dyn11 wiring is much smaller than that of yyn0 wiring, so the former one is beneficial to the removal of common faults of single-phase grounding;

yyn0 wiring transformer stipulates that the low-voltage neutral point current does not exceed 25% of the rated voltage of the low-voltage winding.

The low-voltage neutral point current of the Dyn11 wiring transformer is allowed to be more than 75% of the rated voltage of the low-voltage winding.

Therefore, Dyn11 wiring transformer is beneficial to improve the working ability of single-phase power imbalance.

The cooling method of the Pad mounted transformer in the picture is ONAN, which indicates the over-temperature protection method of the Pad mounted transformer.

There are also oil-to-air cooling (ONAF), oil immersion cooling (ODWF), and forced oil circulation system cooling (ODAF) for Pad mounted transformer cooling methods.

The picture shows the outdoor Pad transformer mounted.

Under normal circumstances, the outdoor is an oil-transformer transformer, and the indoor is an oil-immersed transformer.

Other information content also includes the net weight of the transformer, the information content of the manufacturer.

High-pressure side 2500/10/1.732=144A

Low-pressure side 2500/0.4/1.732=3608A

A 2500 kVA transformer can withstand up to 2700KW.

If the power factor is 0.9, it can be rated to carry an active load of 2250kW.

However, the transformer has the capability of short-circuit emergency overload.

Generally, it can carry a 20% emergency overload, and can withstand a maximum of 2700KW, but it does not exceed 2 hours. Two hours is the limit of the transformer.

If the temperature of the transformer is too high for more than two hours, the insulation will be damaged, and serious consequences such as insulation breakdown and short circuit will occur.

The method for determining the rated capacity of the high and low voltage sides of the transformer is as follows:

The transformer capacity should be selected according to the calculated load.

For a single transformer that supplies power with a stable load, the load rate is generally about 85%.

Namely: β=S/Se In the formula:

S——calculated load capacity (kVA);

Se——transformer capacity (kVA);

β——load rate (usually 80% to 90%).

Add the load power of each phase of A-phase, B-phase and C-phase independently.

For example, the total power of the A-phase load is 10kW, the total power of the B-phase load is 9kW, and the total power of the C-phase load is 11kW, and the maximum value is 11kW.

(Note: The power of each single-phase device is calculated according to the maximum value on the nameplate, and the three-phase device power is divided by 3, which is equal to the power of each phase of this device)

For example:

C-phase load total power = (computer 300W X10 units) + (air conditioner 2kW X4 units) = 11kW

11kW X 3-phase = 33KW (transformer three-phase total power)

The three-phase total power/0.8 is the most important step.

Currently, more than 90% of the transformers on the market have a power factor of 0.8, so it needs to be divided by the power factor of 0.8.

33KW / 0.8 = 41.25kW (total transformer power)

41.25KW / 0.85 = 48.529KW (transformer power that needs to be purchased), then you can choose a 50kVA transformer when purchasing.

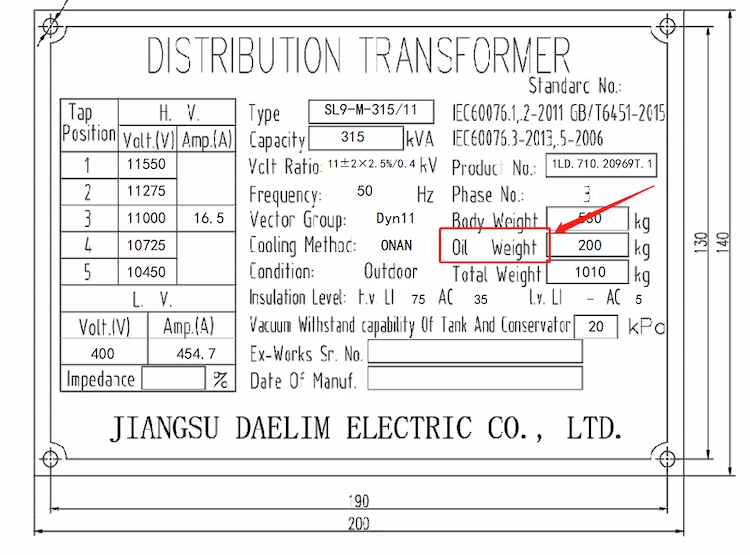

Determine the total amount of oil that the transformer body should have according to the transformer nameplate.

Generally speaking, the amount of transformer oil is proportional to the rated capacity of the transformer.

The larger the rated capacity, the larger the transformer oil volume.

However, the specific oil volume of the transformer is related to the voltage, manufacturer, and external dimensions of the transformer.

Transformers with the same rated capacity have different oil volumes.

Oil-immersed transformer equipment uses oil as the main insulation method for transformers.

It is used for the connection between two-level power grids and between two regional power grids. The windings of oil-immersed transformer equipment are immersed in transformer oil, and the insulating medium is oil. Generally, it will be identified by the oil level indicator of the oil pillow. Generally, a large power transformer will have a pointer to display the oil level.

Of course, the oil level will also change with the oil temperature, as long as it conforms to the relevant curve.

A 2500 kVA transformer can withstand up to 2700KW.

If the power factor is 0.9, it can be rated to carry an active load of 2250kW.

However, the transformer has the capability of short-circuit emergency overload. Generally, it can carry a 20% emergency overload, and can withstand a maximum of 2700KW, but it does not exceed 2 hours.

Two hours is the limit of the transformer.

If the temperature of the transformer is too high for more than two hours, the insulation will be damaged, and serious consequences such as insulation breakdown and short circuit will occur.

The output power of the transformer is the apparent power, and the relationship with the active power (KW) is: apparent power = active power × power factor.

Calculated with an average power factor of 0.8, a 2500KVA transformer can provide (2500KVA×0.8) 2000KW of active power for the load.

The price of the transformer is mainly affected by four aspects, model, material, voltage level, capacity, of course, except for special requirements.

So, how much can a 2500kva transformer be purchased?

We judge the approximate price of the transformer according to the four conventional price influences. Such as: s9, s11, s13, scb10 models;

Copper core and aluminum core material; 2500kva capacity; high voltage side 10kv, low voltage side 0.4kv voltage level;

That is, how much are s9-2500/10/0.4, s11-2500/10/0.4, s13-2500/10/0.4, and scb10-2500/10/0.4 copper core and aluminum core transformers?

S9, s11, s13 copper core transformers are between 47000~52000usd, and the price of aluminum core transformers is between 23614~27000usd.

The cost of the 2500 kVA transformer is affected by many aspects, such as the type of transformer (e.g. the dry kind or those that are oil filled) as well as the materials used to construct it and the complexity of its design, and the company’s pricing strategy. In addition market conditions, like supply and demand, could influence the cost of a transformer.

The specifications for the 2500 kVA transformer may differ based on the manufacturer and the particular model. But, the most common specifications include an 11kV primary voltage with an additional voltage of 415V and 50Hz frequency. The transformer could also incorporate cooling methods, like air or oil cooling to reduce heat that is generated in operation.

500 kVA transformers are able to be purchased from different suppliers and manufacturers. The most well-known brands comprise ABB, Siemens, and Schneider Electric, Daelim Belefic .

Additionally, there are many online marketplaces, such as Alibaba and IndiaMART, where you can find a wide range of 2500 kVA transformers for sale from various suppliers.

Amperage for a 2000 kVA transformer is calculated by using the formula: Amperage equals kVA multiplied by 1,000 Voltage. In this case, for example that you have a secondary voltage of 415V then the amperage would be 6023A.

The cost of a 2500 kVA pad-mounted transformer could vary greatly based on the company and its specifications and market conditions. It is best to speak with manufacturers or suppliers directly for most up-to-date and accurate price information.

Like the pad-mounted transformer, the cost of a dry type transformer varies greatly. Again, contacting manufacturers or suppliers directly is the best way to obtain accurate pricing information.

The dimensions of a 2500 kVA transformer can vary depending on the design and the manufacturer. However, a typical 2500 kVA transformer might measure approximately 2.5m x 1.5m x 2.5m. It’s important to check the specific dimensions with the manufacturer or supplier before purchasing.

The price of a 2500 kVA transformer can be influenced by various factors, including changes in the cost of raw materials, fluctuations in demand, and developments in transformer technology. For example, advances in materials and design can lead to more efficient transformers, which can command higher prices. Conversely, increases in production efficiency can lead to lower prices.

In addition to the factors mentioned above, the price of a 2500 kVA transformer can also be affected by factors such as the cost of labor, the cost of energy, and the cost of complying with regulations and standards. Additionally, the location of the manufacturer and the destination of the transformer can also impact the final price due to shipping and import/export costs.

When purchasing a 2500 kVA transformer, you should consider factors such as the transformer’s specifications, the reliability of the manufacturer, the transformer’s efficiency, and the after-sales service provided by the manufacturer. Additionally, it’s important to consider the total cost of ownership, which includes not only the purchase price but also the costs of installation, operation, maintenance, and disposal.

To get the best price when purchasing a 2500 kVA transformer, it can be helpful to compare quotes from several different manufacturers or suppliers. Additionally, consider the total cost of ownership rather than just the purchase price. A transformer with a higher purchase price but lower operating and maintenance costs may be more cost-effective in the long run.

Future trends in the price of a 2500 kVA transformer will likely be influenced by factors such as developments in transformer technology, changes in the cost of raw materials and energy, and fluctuations in demand. For example, advances in materials and design could lead to more efficient transformers, which could command higher prices. Conversely, increases in production efficiency could lead to lower prices.

Maintenance requirements can vary depending on the type of transformer. For instance, oil-filled transformers require regular checks of the oil level and quality, while dry-type transformers might require periodic cleaning to remove dust and debris. Regular inspections to check for any signs of wear and tear, overheating, or other potential issues are also important. These maintenance requirements can impact the total cost of ownership. The expected lifespan can be a significant factor in determining the value of the investment. Some transformers may contain materials that are harmful to the environment and must be disposed of properly.

Safety considerations can include the risk of electrical shock, fire, and exposure to hazardous materials. Transformers should be installed, operated, and maintained in accordance with all applicable safety standards and regulations.

Different manufacturers may offer different pricing structures for their transformers. This can be due to a variety of factors, including differences in manufacturing costs, brand reputation, product quality, and after-sales service. It’s important to consider all of these factors, not just the initial purchase price, when choosing a manufacturer.

Installation requirements can vary depending on the type and model of the transformer. Factors to consider include the physical size of the transformer, the need for a concrete pad or other foundation, the availability of suitable electrical connections, and the need for any additional equipment such as cooling systems or protective devices. The cost and complexity of installation can significantly impact the total cost of ownership.

Warranty terms can vary depending on the manufacturer. A warranty might cover defects in materials and workmanship for a certain period of time after purchase. Some warranties might also cover certain types of damage or failure under specific conditions. Understanding the warranty terms can help you assess the potential future costs and risks associated with the transformer.

Due to their size and weight, transporting 2500 kVA transformers can be a complex and potentially costly process. Factors to consider include the distance from the manufacturer to the installation site, the availability of suitable transportation infrastructure, and any special requirements such as cranes or other heavy lifting equipment for installation.

The global market can significantly affect the price of a 2500 kVA transformer. Factors such as fluctuations in the price of raw materials, changes in labor costs, and shifts in supply and demand can all impact the price. Additionally, global events such as economic crises or natural disasters can also have an effect.

The type of insulation used in a transformer can significantly affect its price. High-quality insulation materials can improve the transformer’s performance and lifespan, but they can also increase the cost. Some transformers use oil as an insulator, while others use solid insulation materials. Each type has its own advantages and disadvantages, and the choice can impact the transformer’s price.

The efficiency of a transformer refers to the percentage of the input power that is successfully converted to output power. More efficient transformers tend to be more expensive, but they can also lead to lower energy costs over time. Therefore, when considering the price of a transformer, it’s important to also consider its efficiency.

Transformers are designed to operate within a specific frequency range. If you need a transformer that can handle a wider frequency range, you may need to pay more. Conversely, a transformer with a narrower frequency range might be less expensive.

The physical size of a transformer can affect its price. Larger transformers require more materials to manufacture and can be more expensive to transport and install. However, they can also handle larger loads and may be more efficient, which can lead to cost savings over time.

Transformers can produce noise during operation, and this noise level can vary depending on the design and quality of the transformer. Transformers that are designed to operate more quietly can be more expensive, but they may also be more desirable in certain settings, such as residential areas or workplaces.

ELECTRIC, WITH AN ENGE-- DAELIM BELEFIC