ELECTRIC, WITH AN EDGE

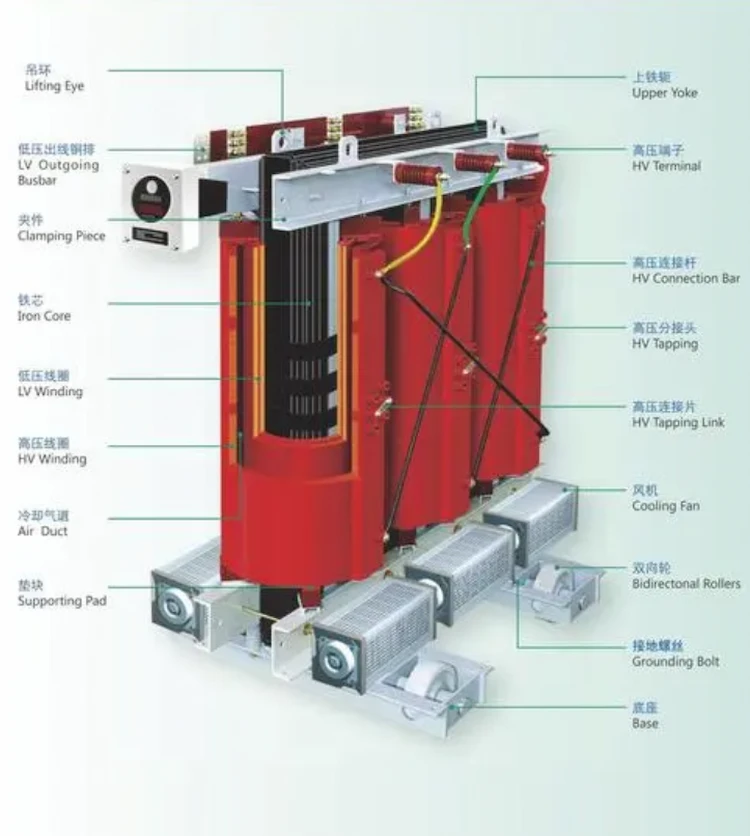

The dry-type transformer must be used in complex buildings (basements, floors) and crowded places. The oil-immersed transformer is used in an independent power transformation occasion. The transformer in the box transformer usually uses a dry type transformer.

With more than 15 years of experience in transformer design and production, Daelim provides you with high-quality transformer solutions.

Daelim’s transformers have obtained CSA, IEEE, IEC, ANSI and other certifications, which can provide you with uninterrupted power guarantee and reduce your procurement costs.

Use oil-immersed transformers as electricity in passive places in the wild. When setting up equipment and deploying, choose between dry and oil changes according to the space. When the space is large, you can choose the oil change, and when the space is more crowded, you can choose the dry change.

The weather in the area is relatively humid and sultry, and it is easy to use oil change. If you use dry change, you must be equipped with forced air cooling equipment.

Some differences between dry-type and oil-immersed transformers:

Two types of transformers are widely used in medium-scale power distribution.

The advantages of each type depend on the target location, project/end user, transformer size/capacity requirements, loss and cost requirements.

Indoor locations are likely to use dry-type transformers, even if they are usually larger (less space) because the requirements for compliance with fire safety regulations are less stringent.

Areas with higher load requirements and outdoor power distribution can benefit from oil-immersed installations.

In order to make full use of these two types, it is recommended to consider the use of non-flammable or non-flammable liquid transformers.

This will enable companies to circumvent certain fire safety regulations while benefiting from durable and long-lasting transformers.

The oil immersed transformer-definition is 1000kVA and above, and an outdoor thermometer type signal should be installed, and then a long-distance signal should be installed.

Oil-immersed transformer gas relays and pressure protection devices should be installed for 800kVA and above.

For 800kVA transformers, oil-immersed transformers can also be equipped with gas relays in accordance with the following requirements and in consultation with the manufacturer.

Dry-type transformers should be installed by the manufacturer, temperature measuring devices, and more generally for 630kVA transformer devices.

Products are classified according to the number of phases.

Single transformers can be divided into three-phase transformers and single-phase transformers.

In the three-phase power system, the general application of three-phase transformers can also be composed of three single-phase transformer groups when the large transportation conditions are affected by the three-phase power system.

Dry-type transformers need an insulation system to promote air circulation and keep them cool.

Therefore, the unit is larger and uses a larger coil (with the same voltage/capacity rating) than the oil-filled model.

In addition, the dry variant uses more materials, leading to higher costs.

In terms of performance, power distribution devices operate at higher temperatures because the natural cooling mechanism is not always constant and is easily affected by the surrounding environment.

These shortcomings lead to a shortened service life (the service life of dry-type transformers is 15 to 25 years, while that of liquid transformers is 25 to 35 years).

From a maintenance point of view, keeping dry stations in optimal working condition requires continuous inspections.

The operator must carefully check and clean the grille, shutters or slits to ensure that they are not blocked.

Ignoring this step may cause the machine to overheat.

The advantage of this aspect of dry-type transformers is that no conventional oil analysis is required (more on this later).

Since dry-type transformers have many limitations, why are they still there?

Dry-type transformers are especially suitable for indoor places and areas that are prone to fire risks.

In addition, these workstations have fewer regulatory requirements for installation, operation, and maintenance, and these requirements require their own set costs.

This includes fewer fire safety guidelines to worry about during operation and storage.

In addition, since the risk associated with fire is less, dry power distribution can be installed closer to the target area, thereby reducing costs (less materials/cables required for connection).

Examples of such densely populated locations include hospitals, airports, underground power distribution systems, hospitals, shopping malls, etc.

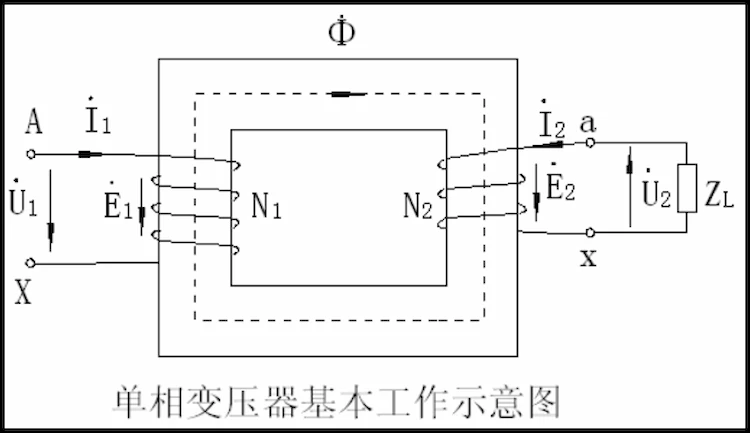

Two high and low voltage windings with turns N1 and N2 are respectively wound on the same iron core.

Among them, the AX winding that is connected to the power source and absorbs electric energy from the grid is called the primary winding (primary winding), and the ax winding that is connected to the load and outputs electric energy to the external circuit is called the secondary winding.

When a voltage U1 is applied to the primary winding, a current I1 flows through the primary side, and an alternating main magnetic flux Φ with the same frequency as U1 is generated in the iron core.

The main magnetic flux is linked to the primary and secondary windings at the same time, according to the law of electromagnetic induction , Will generate induced potentials E1 and E2 in the primary and secondary windings, and the secondary side will generate load current I2 under the action of E2 to output electrical energy to the load.

The main transformers are:

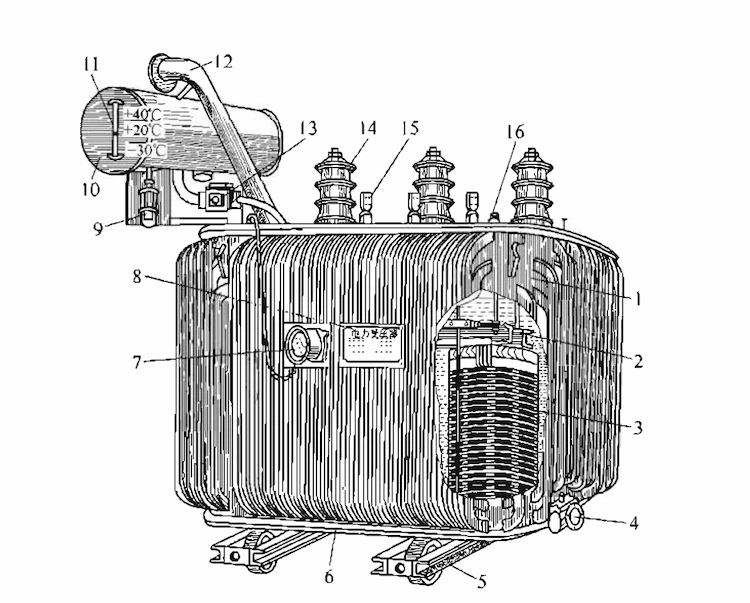

It consists of iron core, windings, fuel tank, accessories, etc.

The iron core is the magnetic circuit part of the transformer.

It consists of an iron core column (winding on the column) and an iron yoke (connecting the iron core to form a closed magnetic circuit).

In order to reduce eddy current and hysteresis loss, and improve the magnetic permeability of the magnetic circuit, The iron core is made of silicon steel sheets with a thickness of 0.35mm~0.5mm, which are coated with insulating varnish, and then interlaced.

The cross section of the small transformer core is rectangular or square, and the cross section of the large transformer core is stepped. This is to make full use of space.

The winding is the circuit part of the transformer, which is made of copper wire or aluminum wire.

The primary and secondary windings are concentrically sleeved on the iron core column.

In order to facilitate insulation, the low-voltage winding is generally inside and the high-voltage winding is outside.

However, for large-capacity low-voltage and high-current transformers, considering the difficulty of the lead-out process, the low-voltage winding is often sheathed outside the high-voltage winding.

The body refers to the whole of the iron core and windings.

The oil tank is equipped with the body and transformer oil.

In order to facilitate heat dissipation, some tank walls are welded with radiating pipes.

The role of transformer oil is insulation and cooling.

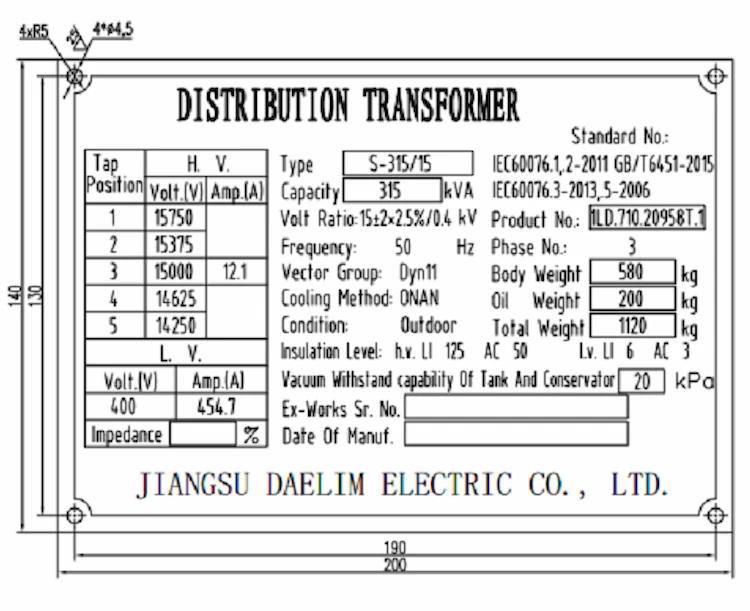

Each transformer has a nameplate on which the model, rating and other data are marked to facilitate users to understand the operating performance of the transformer.

It is the guaranteed value of the output capacity of the transformer under rated working conditions, and is the rated apparent power, in volt-ampere (Vâ¢A) or kilovolt-ampere (kVâ¢A) or megavolt-ampere (MVâ¢A).

Generally, those with a capacity below 630kVA are small power transformers; those with 800~6300kVA are medium-sized power transformers; those with 8000~63000kVA are large-scale power transformers; and those with 90,000kVA and above are super-large power transformers.

The rated voltage U1N/U2N refers to the line voltage.

The primary side rated voltage U1N refers to the rated voltage applied to the primary winding by the power supply; the secondary side rated voltage U2N refers to the terminal voltage of the secondary winding when the primary side is added to the rated voltage and the secondary side has no load.

The unit is: volts (V) or kilovolts ( kV).

The rated current I1N/I2N refers to the line value current.

The rated current of the primary and secondary side refers to the current that is allowed to pass for a long time at the rated capacity and rated voltage, and the unit is: ampere (A).

Basic code, rated capacity, rated voltage and structural performance characteristics.

For example, the model is: SL7-630/10, where “S” represents three-phase, “L” represents aluminum wire, “7” represents the design number, “630” represents the rated capacity of 630kVâ¢A, and “10” represents the high-voltage winding rating The voltage is 10kV.

Various transformer series products produced by Daelim include: S7, SL7, S9, SC8, etc. Among them, SC8 type is epoxy resin

Cast dry-type transformer.

N1 and N2 are the turns of the primary and secondary windings respectively; U1 is the power supply voltage;

I0 is the primary no-load current; Φm and Φs1 are the main flux and leakage flux respectively; E1, Es1, E2 are the primary induced potential, Leakage inductance potential and secondary side induced potential;

U20 is the secondary side no-load voltage.

The leakage magnetic flux Φs1 only accounts for (0.1~0.2)% of the main magnetic flux.

The main magnetic flux Φm and i0 are in a non-linear relationship and can transfer energy to the secondary side;

While the leakage magnetic flux Φs1 and i0 are in a linear relationship.

Cannot transfer energy to the secondary side.

1) Classification by winding: Divided into two types: dry-type transformers with encapsulated windings and dry-type transformers with non-encapsulated windings. A dry-type transformer with one or several windings encapsulated by solid insulation is called a dry-type transformer with encapsulated windings. Dry-type transformers whose windings are not encapsulated with solid insulation are called non-encapsulated winding dry-type transformers.

2) Classified by shell: There are four types of dry-type transformers: sealed, fully enclosed, enclosed and non-enclosed dry-type transformers. The sealed dry-type transformer has a sealed protective shell, and the shell is filled with air or some kind of gas. The sealing performance of the shell prevents the gas inside and outside the shell from being exchanged.

The fully enclosed dry-type transformer has a fully enclosed shell. The air inside and outside the shell can be exchanged, but the outside air cannot cool the core and windings in a circulating manner. Closed dry-type transformer with a closed shell, the outside air can cool the core and windings in a circulating manner.

The non-enclosed dry-type transformer does not have a casing, and the outside air can cool the core and windings in a circulating manner.

3) Classified according to the temperature resistance class of the insulating materials used: Divided into Class A, Class B, Class C, Class E, Class F, and Class H insulating dry-type transformers. At present, the common ones are Class B, Class F, and Class H dry-type transformers.

4) According to the classification of dry-type transformers: divided into SC (epoxy resin pouring encapsulation type), SCR (non-epoxy resin pouring solid insulation encapsulation type), SG (open type).

5) Classified according to the insulating material selected for the transformer.

ELECTRIC, WITH AN ENGE-- DAELIM BELEFIC

After filling in the contact information, you can download the PDF.