ELECTRIC, WITH AN EDGE

A dry-type cast resin transformer is used in various commercial, utility, and industrial applications due to its many benefits.

The growing technological advancements in this type of transformer will make electrical devices more efficient in the coming years.

According to recent data, the global market is predicted to increase at a compound yearly growth rate of 3.83% from 2021 to 2026.

The dry-type transformer market will reach a value of $7.531 billion in 2026, compared to 2019’s $5.790 billion.

DAELIM is one of the leading transformer manufacturers that provide top-notch dry-type transformers.

It has different dry-type transformers with low loss, compact and lightweight, low noise level, high mechanical strength, and flame resistance.

Having stated that, what makes this type of transformer unique?

How does it work, and what are its benefits?

Here you’ll read the best information to answer those questions.

Three Phase Epoxy-resin Dry Type Distribution Transformer Manufacturer

-If you’re looking for a professional Epoxy-resin Three Phase Dry Type Distribution Transformer Manufacturer, Daelim can be your best supplier.

Detailed explanation of the difference between dry-type transformers and oil-immersed transformers

-This article will compare the difference between dry-type transformers and oil-immersed transformers in terms of price, model, application.

What is The Alarm Temperature of The Dry-type Transformer?

-Introduced the dry-type transformer temperature standards, mainly including the temperature of the dry-type transformer’s coil, the temperature of the iron core, metal parts, and adjacent materials, and what is the alarm temperature of the dry-type transformer.

Normal liquid-type transformers rely on hazardous materials such as oil or fire-resistant liquid dielectric. In contrast, dry-type transformers don’t use liquids.

A dry-type cast resin transformer is a static device with no moving parts that uses ecologically beneficial temperature insulation techniques.

The term “dry” means that the system is cooled by natural ventilation, classified as “voltage changing.”

It doesn’t use oil, silicone, or any liquid to cool the coils and electrical core.

With that in mind, the transformer’s housing is highly vented to allow air to go in. Furthermore, these transformers have epoxy resin-encased windings.

The epoxy layer protects it from dust and rust that goes inside with the natural air.

These transformers are often smaller in size and less in weight. Moreover, almost all dry-type transformer diagram is the same.

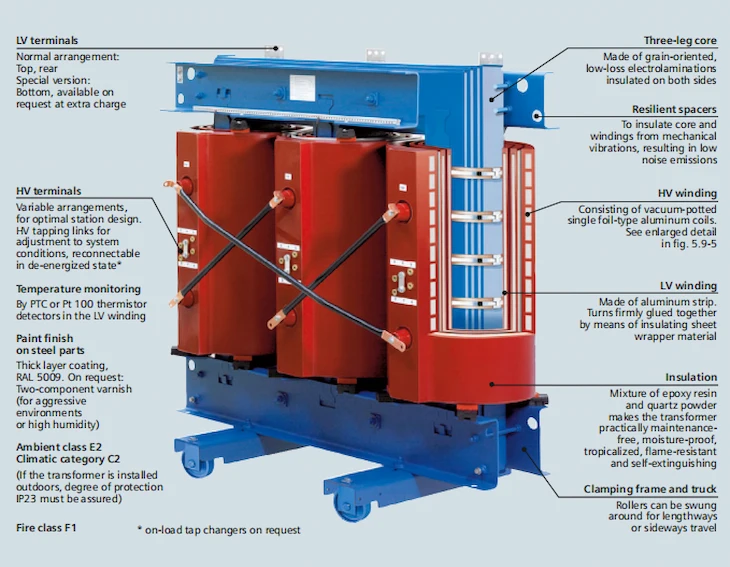

It’s almost the same with other transformers. Here are the different components of the said transformer

:

Correspondingly, DAELIM dry-type transformers have insulation classifications that range from the following:

A dry-type cast resin transformer can be utilized in many different settings and applications.

You can use it in both outdoor and indoor situations.

These transformers are primarily used in low and medium-voltage distribution networks.

You can see these networks in places like schools, hotels, stadiums, and retail malls.

There is also this kind of transformer in either aboveground and underground substations of interior cities.

Different industries like chemical, oil, and gas use dry-type transformers.

Also, these transformers are used in environmentally sensitive water protection zones.

Moreover, you may have bumped into one in a forest or near one.

It works well in that kind of environment as a fire-risk area.

There are also dry-type transformers in coastal industries like renewable energy generation in offshore wind turbines.

There are different types of dry-type transformers.

A DAELIM dry-type transformer has specifications in adherence to IEC726, GB6450, GB/T10228-1997.

To get you acquainted, here are the usual kinds of dry transformers out there:

A VPI transformer is commonly used in both industrial and commercial settings.

The transformer is made of components that can withstand high temperatures as it has the highest insulation rating.

Moreover, the transformer is also a moisture-resistant polyester sealant commonly applied using a vacuum pressure impregnation procedure.

The sealant is typically administered with a vacuum pressure impregnation process hence the transformer’s name. VPI transformers are generally rated up to 30 MVA.

VPI transformers are similar to Vacuum Pressure Enclosed (VPE) transformers.

However, they are made of silicon-based resin rather than polyester. The resin produces a thicker varnish by as much as a factor of four in most cases.

A thicker varnish makes it particularly resistant to salt, moisture, and high humidity.

Creating this resin coating incorporates many dip processes to enclose the coil assembly.

After that, the coating is cured in an oven. Due to its high resiliency, it’s an excellent choice for harsher environments.

They are employed in locations where alkalis, chlorides, and acids are present.

An open wound transformer got its name from its manufacturing procedure which is the “dip-and-bake” technique.

With this process, the coils are heated, dipped in high-temperature varnish, and then baked in this procedure.

A dry-type cast resin transformer (CRT) is highly suitable in high moisture environments.

What’s great with this kind of dry-type transformer is its low maintenance.

That’s why it’s perfect for tunnels, offshore platforms, onboard ships, mining services, production plants, and nuclear plants.

Its popularity in a harsher environment is because its primary and secondary windings are enclosed in epoxy resin.

This coating aids in preventing moisture from penetrating and affecting the winding substance.

This cast resin encapsulation provides complete protection, allowing the transformer to operate without interruption in a high-moisture environment.

As a result, this transformer is non-hygroscopic.

Moreover, a CRT is available in ratings ranging from 25 KVA to 12,500 KVA, with an insulation class of F.

A dry-type cast resin transformer has many benefits and advantages.

The transformer is a versatile device that you can use for many different applications.

It’s an ideal choice for those who need a low-cost solution for large-scale systems and those looking to move from small-scale indoor applications to outdoor systems.

Nonetheless, here are the remarkable benefits of this type of transformer:

Completely encapsulating the transformer’s primary and secondary windings in epoxy resin prevents moisture from penetrating the windings.

The cast resin is highly resistant to adverse weather conditions.

Moreover, these transformers can run without interruption at 100% humidity.

The transformers can also endure rapid temperature changes from -25oC to +40oC.

You can reduce substation construction and installation expenses by adopting dry-type transformers.

The transformers can be installed near the load center without risk of fire or explosion.

It reduces expensive repairs caused by fires.

Likewise, the overall civil works are decreased because these transformers do not necessitate the construction of particular fiber brick walls or oil pits.

Furthermore, because LT cables are not required, there are cost savings from expensive cable laying activities.

Because these transformers do not use oil, there is no chance of oil leakage contaminating groundwater.

Moreover, cast resin transformers help to conserve our natural resources.

Its design and functioning are environmentally friendly.

Because a cast resin transformer simply requires air to cool, liquid testing is no longer required.

Even in the most extreme conditions, its smooth coil surface eliminates massive dirt build-up.

Only technical staff are required to clean and visually inspect it.

Because the windings of cast resin transformers are enclosed in resin, they can manage short-time overloads significantly better than oil-cooled devices.

It is because the effects of axial and radial forces under high current loads are minimized.

As their names suggest, the two are completely different but function the same.

A dry-type transformer uses natural ventilation to cool its system.

On the other hand, an oil-type transformer uses oil as its cooling medium.

Sometimes electrical rooms get crowded, and you can’t fit your dry-type transformer indoors.

There’s nowhere else to put it but outside.

Dry-type transformers can be placed outside because it’s moist and weather resistant.

However, you may need a special setup for the transformer.

Although it’s resistant to harsh climates and environments, you need to place it inside a case for maximum protection.

It’s very hard to find a transformer that’s perfect in all aspects.

However, it’s easier to look for near-perfect ones like what DAELIM offers.

Dry-type transformers still have their disadvantages.

For one is the repair. Dry-type transformers are very sturdy, but it’s very difficult to fix once it’s been damaged.

Nonetheless, remember, many advantages still trump a handful of disadvantages.

Manufacturers like DAELIM do rigorous testing before releasing a dry-type transformer to their client or even on the market.

However, clients should do routine tests such as winding resistance, voltage ratio, and phase displacement.

Other special tests include winding hot-spot temperature-rise measurements, low-temperature tests, and vibration floor testing.

Dry-type cast resin transformers will be an essential component of electric systems in commercial, residential, and industrial applications.

Furthermore, continual technical advancements and a growing emphasis on replacing traditional insulated systems are expected to drive demand.

The demand will propel the dry-type cast resin transformer market forward in the coming years.

DAELIM makes sure to ride that upward trajectory and ensure that the transformers they produce are of the highest quality.

It believes that a well-functioning quality system is a key to a healthy market.

The company has prioritized ensuring that it becomes a leader in product quality and customer satisfaction.

If you find that the existing distribution transformer types or power cannot meet your requirements. You can choose to tell Daelim. Daelim has a team that has always had a wealth of design transformers, and can give you a specific design plan in the shortest time.

Daelim’s distribution transformers comply with IEEE, ANSI, CSA, IEC certification, and are used in North America (such as Canada, the United States, Mexico), South America (such as Ecuador, Chile), Europe (such as Spain, Lithuania) and some Asian countries. Daelim even has a professional installation team that can provide you with installation services.

ELECTRIC, WITH AN ENGE-- DAELIM BELEFIC