ELECTRIC, WITH AN EDGE

Currently, one dominant categorization of transformers revolves around their cooling design. Dry-type power transformers and oil-cooled transformers are the prevalent cooling designs available in the market today.

In this article, you’ll specifically learn about dry-type power transformers. How does it function, what makes it different, and all relevant information; you can read all below.

Speaking of dry-type power transformers and electrical products, Daelim is one reputable brand to take note of. Daelim Belefic is an electrical manufacturer that highlights the importance of high-quality yet cost-efficient products.

Jiangsu Daelim Electric Co.Ltd launched Daelim Belefic with experts and professionals in the field of electrical manufacturing. The company sees that every product is of high quality and follows international electrical standards.

Three Phase Epoxy-resin Dry Type Distribution Transformer Manufacturer

-If you’re looking for a professional Epoxy-resin Three Phase Dry Type Distribution Transformer Manufacturer, Daelim can be your best supplier.

Selection And Maintenance of 10 kV Dry-type Transformer

-This article analyzes the selection of 10 kV dry-type transformer and further elaborates the maintenance work of the Cast Resin Dry-type Transformer.

Three Phase Epoxy-resin Dry Type Distribution Transformer Manufacturer

-If you’re looking for a professional Epoxy-resin Three Phase Dry Type Distribution Transformer Manufacturer, Daelim can be your best supplier.

A dry-type power transformer simply requires normal air ventilation to cool the electrical core and coils. It does not need liquid or oil for its cooling system.

An air-tight transformer is a type of dry-type transformer that functions without the use of an insulating liquid. Instead, manufacturers enclose the windings and core inside the air pressurized tank.

Dry type-transformers can step up the voltage to a higher rating or step down for a lower one.

Furthermore, a dry-type transformer must comply with CSA and UL for environment safety and recognized high-temperature insulation systems.

This compliance extends the transformer’s lifespan, which saves both time and money in the long run.

Dry-type transformers have several efficiency benefits that reduce the risk of fires and electrical outages, leading to high financial costs.

Additionally, transformers also reduce a building’s reliance on fireproof vaults, basins, and venting to keep up with the safety requirements.

Transformer replacement isn’t a particularly complex process. However, it does require the transportation of the replacement unit directly to the customer for installation and testing.

The transport can be a high cost to any company or transformer owner.

Experts suggest fire-resistant dry-type transformers for high-rise buildings, hospitals, underground tunnels, schools, steel factories.

It is advisable to any places where fire safety is a great concern because of rising temperatures.

Dry-type uses air as a coolant, while liquid-type uses oil. In other words, the main distinction between the two is in the type of cooling medium they use.

Cooling mediums are vital for transformer safety. Whether you’re transforming heavy loads or just trying to get the device functioning, overheating is inevitable. The solution lies in using cooling mediums like heat exchangers, which you can install on transformers for fast cooling.

Dry-type transformers are highly efficient and safe to use from a fire safety perspective. Additionally, they are very resistant to chemical contaminants. This condition means that you will not need to inspect the transformer every time there is a minor accident. Repairs can be much faster and easier.

In terms of costs, however, oil-filled transformers are often cheaper than the dry-type variant. Nevertheless, there are still a few deviants from this rule. Also, oil-filled transformers are quieter than dry-type ones.

Lastly, oil-filled transformers are more efficient than their dry-type counterparts. They can easily handle overloads and provide higher voltage ratings. Dry-type can become an overheating risk in cases of overload, and remember that their performance is limited during overload. As a consequence, dry-type transformers can become expensive to maintain.

There are different types of transformers, each with its advantages and considerations.

In most cases, their differences spring from different protection and installation requirements.

For example, if you are looking for radiance protection, choose a VPI dry-type transformer with the Radiance Protection feature.

Meanwhile, if you need superior mechanical power, then opt for a cast coil transformer.

Below are the popular types of dry-type power transformers available in the market:

Even in harsh environmental conditions, cast coil transformers endures.

You don’t have to worry about them being damaged by the elements.

Furthermore, they are easy to maintain and can last for a lifetime.

Cast-coil transformers are popular for building interiors, tunnels, ships, mining services, manufacturing plants, and nuclear power plants.

Open wound transformers are made up of a high-performance core surrounded by a protective outer cover.

This protective cover barriers the internal cores from corrosion and other environmental damages.

Vacuum pressure encapsulated transformers excels in insensitivity to alkalinity, chlorides, and acids.

Because of their thick varnish and superior resistance, they offer an ideal alternative to traditional vacuum-encapsulated transformers.

Furthermore, vacuum-encapsulated transformers are ideal for applications in hazardous environments and resistant to salt, water, and humidity.

Manufacturers design this type considering high temperature and moisture-resiliency.

They build them with components that can bear high temperatures and moisture-resilient polyester sealant.

Manufacturers apply the vacuum pressure impregnation method for this design.

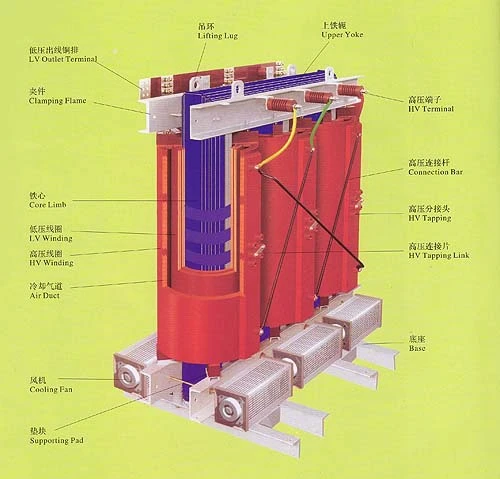

A transformer comprises parts that function in different ways to enhance a transformer’s overall functions.

Below are the standard parts for every dry-type power transformer.

Variations in design are highly possible depending on manufacturer specifications.

The cast resin transformers are normally cooled by natural ventilation.

However, some cases require the use of fans for cooling with forced air.

The fan ensures that the transformer cools down to a certain temperature.

The ventilation openings must be kept clear to allow the natural dissipation of heat generated from the transformer.

The core supports the transformer windings and enables a low reluctance path to the magnetic flux.

Typically, manufacturers make them out of the laminated soft iron core to reduce energy losses.

Transformer designers use insulating materials like papers to isolate the windings and the transformer core.

Also, they make these windings of copper because of their high ductility and conductivity.

Additionally, the high conduction properties reduce the amount of copper and energy losses.

As a result, high ductility enables bending of the conductor into a tight winding around the core.

A tap changer is a switch that has a position of variable voltage.

It serves to change the output voltage of a transformer.

By altering the position of the tap changer, you will change the ratio between the output voltage and medium voltage.

Depending on your device, tap changers can be either de-energized tap changer DETC or an on-load tap changer LTC.

Windings are a form of electrical wire used in transformers’ inductors and coils.

Manufacturers can group them depending on their ease of manufacturing and their use in electric power systems.

Typically, professionals classify windings with voltage range into primary or secondary windings.

Primary windings are based on supply, while secondary windings connect on voltage range.

Note that these are just the main parts. Different manufacturers can design their products differently with varying parts or features.

Typically dry-type transformers have a lower kVA rating than their oil-cooled counterpart.

Below are the common kVA thresholds evident on popular market brands like Schneider dry-type transformers and Daelim Belefic’s products.

As always, please do note that variations may exist depending on the manufacturer.

For example, in Schneider’s Dry Type Transformer product Resiglas, the kVA ratings range from 63kVA to 5,500kVA.

Most of their dry-type transformers are typically three-phase, but single phases are also available upon special request.

Meanwhile, Daelim has a kVA range of 30-2500 kVA for their Three Phase Epoxy-resin Dry-type Transformer for three-phase systems.

These are typically just standard ratings, and higher-rated specialties are also available for customization.

Dry-type transformers are environmentally friendly, durable, and do not create pollution.

Additionally, they find applications in contaminated and damp areas.

Their installation process is easy and is durable, with low thermal properties.

Their cables won’t allow short circuit currents or overloads due to their high resistance and low side clearance.

Lastly, they can withstand overloads with the help of certain safety components.

Dry-type transformers pose less of a fire hazard.

They are also ideal for indoor applications like hospitals or universities, where there is a lot of traffic.

Most dry-type transformers last for 25 years.

Some well-ventilated and regularly maintained transformers can even last for more than 35 years, even 50+ years.

Dry-type transformers will still be essential for generations to come.

With modern technologies and continuous technological advancements, dry-type transformers will improve and progress to the future.

For reliable dry-type power transformers, you may visit Daelim Belefic.

Daelim produces quality dry-type power transformers following multiple standards like ANSI, IEEE, and CSA.

Daelim is your partner for innovative electrical solutions and services. Electricity with an edge.

When you need to find more than just existing transformers, Daelim’s Transformer Service Center can help you design and produce distribution transformers that meet your unique needs.

We have our own factory and a professional team of engineers, which can design and modify application requirements that meet all your conditions.

Download Resource

ELECTRIC, WITH AN ENGE-- DAELIM BELEFIC