ELECTRIC, WITH AN EDGE

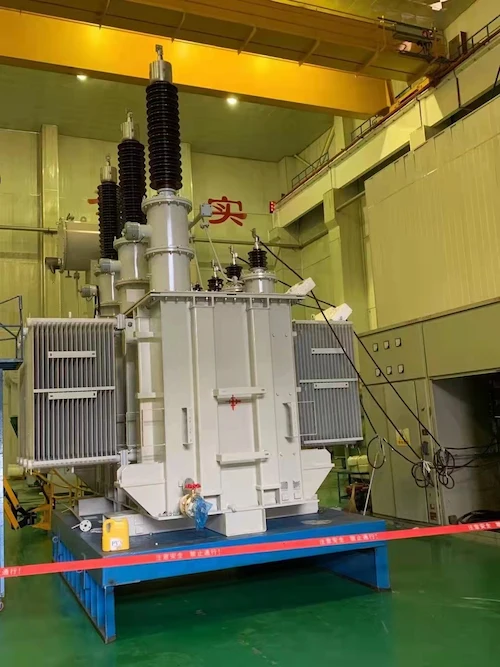

The normal operation of the 500kV transformer requires reasonable temperature control, it is necessary to choose a suitable cooling method to help the transformer cool down.

In the actual operation of the 500kV transformer, there is more or less iron loss and copper loss. These losses will eventually be transformed into heat and radiated to the outside world. The existence of this heat energy causes the temperature of the transformer to continue to rise during operation.

In order to avoid the phenomenon of excessive temperature, it is necessary to select a suitable cooling method.

Cooldown the transformer to maintain its normal operation and service life.

This type of 500kV transformer cooling method is to uses an oil pump to pump the hot oil from the upper part of the 500kV transformer to the inside of the cooler. After the hot oil flows through the cooling tube, it transfers the heat carried by itself to the cooling tube, and the cooling tube dissipates the heat. Into the air.

The airside needs to draw in air through the operation of the 500kV transformer fan. After the air flows through the air pipe, it absorbs the corresponding heat, and finally blows out the cooler to achieve the goal of cooling the transformer. The oil flow through the winding is a kind of thermal convection cycle.

This type of 500kV transformer cooling method also uses an oil pump to suck the hot oil from the upper part of the 500kV transformer inside the cooler.

When the hot oil flows through the cooling tube, it transfers heat to the cooling tube, and the cooling tube transfers the heat to the air.

Then the airside draws in air through the operation of the transformer fan.

When the air flows through the air pipe, the heat is absorbed by the air pipe and discharged to the outside of the cooler, thereby helping the 500kV transformer to cool down, but the oil flow through the winding is a forced directional circulation.

This type of transformer cooling method is also called oil-immersed self-cooling. Its essence is the natural convection cooling of the internal oil. Transformer oil is cooled by natural convection.

The transformer oil tank will gradually be heated during the operation of the oil-immersed transformer, the density will decrease accordingly, and the oil flow will gradually increase.

In this process, the heat is gradually transferred out with the help of the heat sink or the wall of the fuel tank. At this time, the oil temperature of the 500kV transformer will gradually decrease, the density will gradually increase, and the oil flow will gradually flow downward. Circulating this process, the most prominent advantage of this method is that the noise value is small.

A Complete Guide to Oil Immersed filled Distribution Transformer

This type of oil-immersed transformer cooling method is essentially the natural circulation of transformer oil.

The air used for cooling is blown onto the radiator with the help of a fan. Because the airflow rate is relatively high, the heat transfer on the airside is increased. Compared with ONAN’s transformer cooling method, the convective heat transfer rate of the ONAF radiator surface will be increased by 2 to 3 times.

In OFAF’s transformer cooling method, the oil flow is a form of heat convection circulation during the process of flowing inside the winding.

When the transformer oil flows in the coil, the main reason is the heating of the coil itself.

The flow of transformer oil flowing through the coil changes with the load and has no direct relationship with the transformer oil flowing through the cooling facility drawn by the oil pump.

When the load increases, the temperature difference will gradually increase, and the cycle efficiency will gradually increase.

In ODAF’s transformer cooling method, the flow of transformer oil flowing through the coil is a forced directional circulation.

The flow of transformer oil in the coil is achieved by the pressure of the submersible pump and the oil pipe, and there is not much correlation with the load of the transformer.

In the process of using the ODAF method to cool the transformer, it is affected by the driving of the guiding device.

The flow speed of transformer oil will increase accordingly. When the transformer oil flows through various solid insulating parts such as turn insulation and insulating plates inside the winding, corresponding static electricity will be generated due to the strong friction between each other. .

In the case of continuous accumulation of electric charge, it will cause problems such as the increase of electric field and electric field distortion in the local area of the transformer, and then the corresponding oil current charging problem will be caused when the discharge volume of the insulation part increases.

The existence of this problem has a significant impact on the safe and stable operation of 500kV transformers. In recent years, there have been some faults caused by oil flow static electricity. This problem has received widespread attention from society.

There is a close relationship between the electrification of the oil flow and the speed of the oil flow. In the case of using ONAF’s transformer cooling method, the oil flow through the winding is a kind of thermal convection cycle. Therefore, the oil and the insulator The relative speed has been significantly reduced, and there is no need to worry about the problem of oil flow electrification.

All transformer oil in the ODAF transformer cooling mode is directly injected into the coil, which also causes any impurities that can enter the oil to enter the coil.

The transformer oil flow in OFAF transformer cooling mode is mainly distributed inside the coil, and it is difficult for impurities to enter the coil. This method plays a vital role in maintaining the cleanliness of key insulation parts.

The coil in the ODAF transformer cooling mode has a stronger cooling effect, and the temperature difference between the upper and lower parts is also small.

From a theoretical point of view, the difference between the hot spot temperature and the average value of the coil temperature is also small. From this point of view, the average value of the coil temperature allows the temperature increase value to be appropriately increased.

In the ICE standard, the coil temperature increase limit for the ODAF transformer cooling mode is 70K, and the temperature increase limit for the OFAF transformer cooling mode is 65K.

In fact, the oil flow inside the transformer is more complicated. If the speed of the oil flow is too fast, the controllability will become worse and worse.

The calculation software currently developed is based on an idea and simplified model, which leads to greater uncertainty.

During the normal operation of the transformer, the following two transient operating conditions usually occur:

Short-term super-nameplate operation and sudden loss of cooling operation.

For the former, it is similar to the steady-state operation. Under the premise of high design reliability, the two transformer cooling methods of ODAF and OFAF have certain guarantees in performance.

One thing to pay attention to is to make clear regulations on the short-term super-nameplate running time.

For the latter, the coil cooling in OFAF transformer cooling mode itself relies on the heating of the coil itself, and the pump only plays an indirect role.

After the oil pump stops working, the cooling condition of the coil itself will continue for a while.

The coil cooling in the ODAF transformer cooling mode is completely dependent on the pump. After the oil pump stops working, the cooling condition of the coil will change in real-time.

Through the comparison of these aspects, it is not difficult to see that ODAF is significantly better than OFAF in terms of the cooling effect of the transformer.

In the ICE standard, the coil temperature increase limit for ODAF transformer cooling mode is 70K, and the temperature increase limit for OFAF transformer cooling mode is 65K.

From the perspective of the current 500kV transformer cooling system, there are mainly the following problems:

First, the main and backup power signals are faulty.

It can only reflect the tripping and tripping actions that occur in the lower circuit of the two AC incoming air circuit breakers.

When in the state of the air switch, due to human misdivision, the upper mouth and the loop failure of the power supply terminal.

This causes the previous air switch to trip, which cannot be reflected in the monitoring background. In addition, the problem that the operating personnel cannot be in time will cause the cooling fan to stop and trip the exit delay.

If the cold control loses power and trips the pressure plate of the three-side switch, an alarm will be issued in the background and the three-side trip of the main transformer will result in loss of processing opportunities.

Second, the working signal of the fan or oil pump will only be reflected on the panel of the air-cooled control box.

This makes the operator unable to control in real-time. Regarding the characteristics of the two relying on temperature load to start, in some special situations and in the case of high load peaks, it is necessary to manually check whether the cooler is started or not.

The existence of this work will reduce the efficiency and degree of automation of comprehensive substations with a higher level of automation. At the same time, it also laid potential safety hazards for the stable and safe operation of the entire substation.

In view of the above-mentioned transformer cooling system problem, the following solutions are proposed:

First, the solution to the failure of the main and backup AC power signal response.

It can be solved by adding time relay, specific model, and access method.

Choose according to on-site construction conditions, but one thing to note is that the selected time relay can avoid the simultaneous closing time of the AC contactor when the dual power supply is in the automatic switching state in the case of a short-term loss of power, which is generally about 3 seconds.

Second, to solve the problem that the working signal of the fan or the oil pump can only be reflected on the panel of the air-cooled control box, the empty terminal connected with the moving and closing contact of the corresponding relay can be connected to the inside of the monitoring background.

During the operation of the 500kV transformer, in order to prevent malfunctions caused by overheating and damage to the service life, it is necessary to use a suitable cooling method to help it cool down.

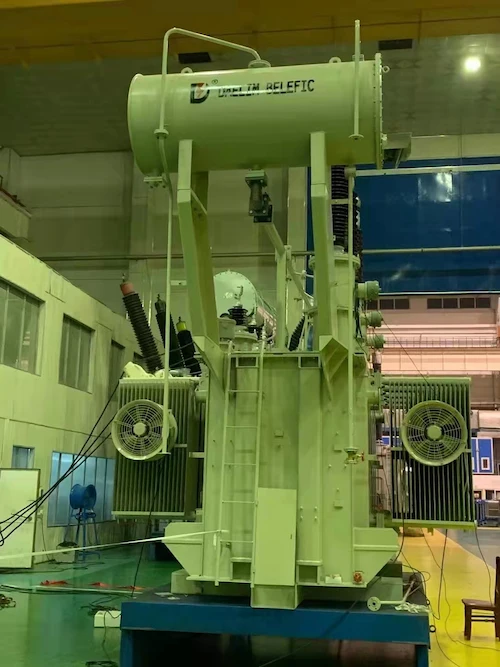

For 500kV transformers, the most commonly used cooling methods are OFAF and ODAF. This article compares the two from the five aspects of circulation, oil flow charging, and oil flow impurities. The effect of ODAF is significantly better than that of O- FAF and ODAF cooling methods are bound to be widely used.

When you find that although there are many 500kv transformers on the market, none of them can meet your requirements. Please contact Daelim. Daelim can provide you with customized services. 15 years of experience in designing and producing transformers can be your reliable guarantee.

Download Resource

ELECTRIC, WITH AN ENGE-- DAELIM BELEFIC