ELECTRIC, WITH AN EDGE

We use transformers in a wide range of residential and industrial applications. They help improve the security and efficiency of power systems by raising or lowering voltage levels as required. In a world highly reliant on electrical systems, it is important to know how these devices work.

This article by Daelim will discuss one specific type, the main power transformer, to guide you in electrical systems.

Daelim is a leading Chinese brand for electrical components and solutions. If you’re looking for quality, well-made products that can deliver impressive results, you should check them out.

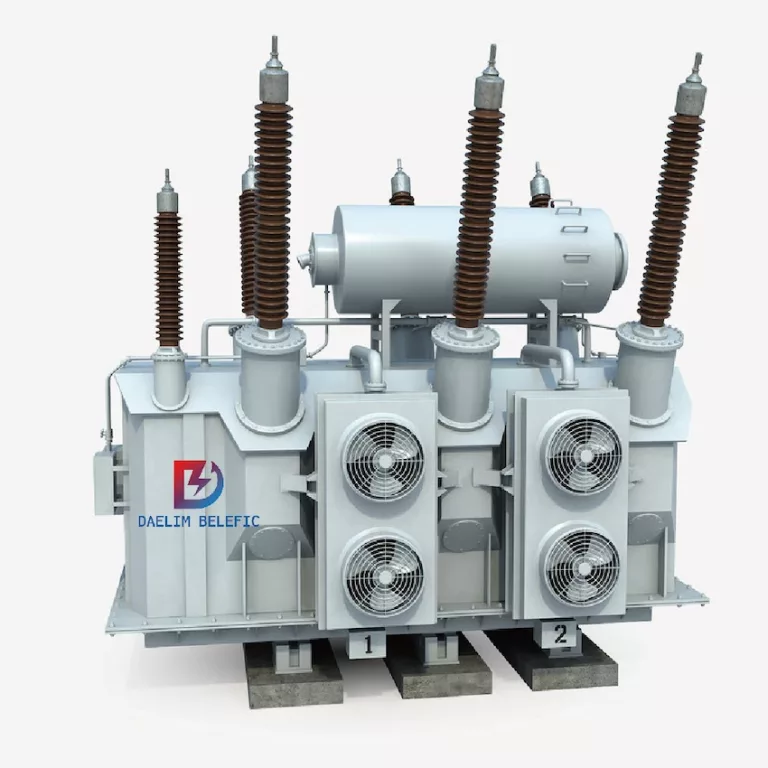

Daelim Belefic is a leading manufacturer of high-quality electrical equipment, specializing in the design, engineering, and production of power transformers. Our “DAELIM EDGE+ ADVANTAGE” concept ensures that we provide our clients with multiple standards, cutting-edge service, and professional customization skills, setting us apart from other power transformer manufacturers.

Our investment in research and development allows us to provide efficient and professional transformer product solutions through improved products and innovative ways to help clients reduce costs and create new values. We have a strong R&D team with more than 20 years of transformer design experience, making them experts in international transformer standards such as IEC, IEEE / ANSI, CSA, and more.

We take quality seriously, which is why we strictly implement the ISO 9001 quality management system. We conduct three different quality tests to ensure that our transformers meet the highest standards. Type tests ensure the reliability and safety of new product types before they go into production, FAT tests are standard production tests, and inspection tests are carried out by SGS, CSA special inspection service, or according to customer requests.

Our dedicated customer service, product innovation, engineering excellence, and strong social and environmental responsibility have made us a trusted power solutions partner for the global electric industry. We are committed to meeting our customers’ needs and winning their trust by being a reliable and trustworthy partner to them.

So, if you’re looking for a power transformer manufacturer that provides high-quality products, professional customization, cutting-edge service, and multiple standards, look no further than Daelim Belefic. Choose us as your partner, and we’ll help you reduce costs and create new values for your business.

The main power transformer is a device used to change the AC voltage using electromagnetic induction means. It has a main member or the primary coil, the secondary coil, and a core.

The function of this transformer includes voltage conversion, current conversion, impedance transformation, isolation, and regulation.

The industry divides transformers into plenty of other types to suit different transformer functions.

A main power transformer is a critical component in power generation and distribution. It is an electrical device that is used to transfer electrical energy from one circuit to another through electromagnetic induction. They are designed to handle high voltages and currents and are used to step up or step down the voltage of electricity to the desired level. Power transformers can be used in a variety of applications, including substations, solar projects, and other energy-intensive operations.

Selection of Power Distribution Main Transformer in 110kV Substation Design

Though all follow the same principles, the construction of transformers has different methods. There are several types of transformers used in the electrical power system. We can classify transformers by voltage levels, core medium, winding arrangement, use and installation place, etc.

Below we discuss different types of transformers and their purpose.

Selection and Capacity Calculation of Transformers Used in Substations

These are the most common transformer types used in the industry for all applications. They’re categorized as step-up and step-down transformers, depending on the voltage ratio from the primary to secondary windings.

This transformer type converts the primary voltage level to a lower voltage across the secondary output. You can achieve this output by the ratio of primary and secondary windings. For step-down transformers, the amount of windings is higher across the first side than the secondary side. Therefore, overall, the winding ratio remains more than 1.

Professionals use step-down transformers to convert high voltages to low voltages in an electrical distribution system. They reduce the cost and loss of electricity and provide a long-distance power delivery solution.

Step-up transformers are just the other step-down transformers. It increases the low primary voltage to a high secondary voltage. For the Step Up transformer, the ratio of the primary and secondary winding remains less than 1. That means there are more turns in the secondary winding than in the primary.

Electricians use step-up transformers in stabilizers and inverters where low voltage is converted to a much higher voltage. Furthermore, it is in high demand in an electricity distribution grid. Power distribution-related applications require high voltage to function efficiently.

Transformer type is determined by the medium between the primary and secondary winding. Air core transformers are great for light loads, while iron core transformers can handle heavy loads.

The air-core transformer does not require a physical magnetic core. Instead, it uses the air to provide its flux linkage.

Faraday’s law of induction states that a magnetic field will cause induction in a coil placed inside a magnetic field. Using an air-core transformer, the primary coil produces an alternating current, which induces a voltage in the secondary coil. This reaction then powers the load.

Ferrite cores are ferromagnetic materials that have high magnetic permeability. Professionals use them to reduce losses in high-frequency applications because of this property. Furthermore, they are prominent devices in switch-mode power supply (SMPS) and other digital circuitry.

Ferrite core transformers also offer different types of shapes and sizes, counting on the appliance requirement. It is more common in electronics rather than electrical applications. The most popular shape in the ferrite core transformer is the E core.

Their winding order classifies the transformers, usually the number of individual windings around the core. One of the types is Auto Winding Transformers, which are very popular.

What are the types of transformer windings ? What are the types of concentric windings?

This transformer has two windings, one for the input and one for the output. The input is an AC power source, while the second is connected to a load. These are electrically isolated but magnetically coupled.

Changing magnetic flux causes the current to produce the induced EMF within the secondary winding. This voltage is simply because of induction. The voltage is mostly based on the windings ratio, but it can raise or lessen the input voltage.

The center-tapped node is movable in auto-winding transformers while the primary and the secondary coil are connected in series. Depending on the center-tapped position, you can change the secondary voltage.

This section discusses transformers based on their role in an electrical system.

Power transformers are large and powerful, transmitting high voltage power from generators to distribution centers. Their size and insulation make them perfect for all kinds of power generation stations and transmission substations.

Professionals use these transformers for power distribution to remote locations. These devices are for the distribution of electricity at low voltage.

Voltages can be less than 33KV for industrial purposes and 440v-220v for domestic purposes.

Several factors determine the type of distribution transformer you need, such as:

A measurement transformer is a device that allows for the measurement of power. Electricians use this instrument to measure the phase, current, and voltage of the actual power line.

The potential transformer has two coils, one on the primary side and one on the secondary side. The primary coil is connected to the HV line. Meanwhile, the secondary coil is connected to all other meters and instruments used to measure electricity.

The transformer uses the primary winding to decrease the voltage level to a certain limit, otherwise known as a point. This model has a grounded secondary winding which functions to protect the circuit from electrical shock.

The current transformer is a measuring instrument that acts as a high-current transformer. Once it senses a situation where the current in the circuit is too high, it uses transformers to lower the current and send it to the desired value in the circuit.

There are three types of current transformers: wound, toroidal, and bar type.

Selection of Power Distribution Main Transformer in 110kV Substation Design

We can connect the primary winding of the transformer in series physically by using the conductor. This conductor then carries the measured current within the circuit. The secondary current is mainly dependent on the transformer’s turns ratio.

This transformer doesn’t have a primary winding and instead has a hole through which the current flows. Some of them also have an internal split-core that allows for easier installation and removal.

This transformer uses the bus bar of the major network like the primary winding. Furthermore, it is protected from the high voltages of the network and generally bolted toward the device which carries current.

Phase design is the wiring principle which the transformers use to transform electricity. There are two popular phase designs which are single-phase and three-phase transformers.

The working principle of a transformer is to create an alternating current by converting electrical energy into mechanical torque. A single-phase transformer creates AC power using two windings, primary and secondary. The primary winding provides the AC supply, whereas the load is connected to the secondary winding.

Meanwhile, the three 1-phase transformers function by connecting them using three primary windings. You can also connect their three secondary windings like one secondary winding. This configuration creates the 3-phase supply, which is prominent in generating, distributing, and transmitting electric power.

The assemblage of this transformer is not expensive, and the connection works through Star and Delta type.

You should note that transformers do not generate electrical power but simply convert it. Below are the key parts of a transformer and their function:

The input side of the transformer is called the primary. It is where the main electrical power to transform connects.

The output side of the transformer is where the power is sent to the load. Depending on demand, the incoming electric power will either be increased or decreased.

Transformers have two windings that either deliver or receive power. The primary winding is the coil that sends power to the load. Meanwhile, the secondary winding is the coil that receives power from the source. Manufacturers subdivide these two coils into several smaller coils to reduce flux creation.

The transformer core provides a controlled path for the magnetic flux generated in the transformer. The core is made of many thin laminated steel sheets. This design allows for cooling by using fewer materials.

We can find two main types of windings in a transformer: the core-type and the shell-type. Core-type windings surround the laminated core, while shell-type windings are inside the laminated core.

A power transformer is an electrical device experts use to transfer power from one circuit to another. It doesn’t change the frequency, and it can provide several different AC supplies at various voltages. Power transformers have a main member or the primary coil, the secondary coil, and a core.

Transformers allow the flow of electrical energy from one circuit to another and transform its voltage. Professionals employ electric circuits to change the current flow, voltage, and electromotive force depending on the current direction.

Laminated core transformers are the most common type of transformer used in power transmission and appliances, converting input voltage to low voltage to power electronic devices.

Daelim has been in the transformer business for over a decade and is one of the most trusted brands. With a reputation for high-quality transformers, it’s your go-to brand when looking for something reliable.

If you’re looking for electrical products and solutions, Daelim Belefic is your innovative and reliable partner. From main power transformers to other electrical transformer types, Daelim has it all. Contact Daelim today to learn more.

There are several types of main power transformers based on their application and construction. Here are some of the most common types of main power transformers:

Three-Phase Transformers: This is the most commonly used type of main power transformer, designed to transform high voltage electrical power from the primary winding to a lower voltage in the secondary winding. The three-phase transformer consists of three single-phase transformers assembled together.

Autotransformers: An autotransformer is a type of transformer that has a single winding with two end terminals, used to step up or down the voltage in a single circuit. In an autotransformer, a part of the winding is used for both primary and secondary voltage transformation.

Distribution Transformers: Distribution transformers are used to transform high voltage electricity from the transmission lines to a lower voltage, suitable for distribution to end-users.

Power Transformers: Power transformers are used in substations to step up or step down the voltage level of power for transmission or distribution.

Instrument Transformers: Instrument transformers, such as current and voltage transformers, are used to measure the high-voltage and high-current power flow in the electrical network.

Rectifier Transformers: Rectifier transformers are used in the electrical power industry to supply power to the DC circuits of large industrial operations, such as electrolysis plants, aluminum smelters, and steel mills.

Understanding the different types of main power transformers is important for selecting the right transformer for a particular application. It’s also crucial to ensure that the chosen transformer meets the required standards and regulations for safety, efficiency, and performance.

The role of a main power transformer in a substation is to step up or step down the voltage of the electric power, depending on the requirements of the power system. When electricity is generated at the power plant, it is produced at a relatively low voltage, usually ranging from 2.4 kV to 33 kV. However, the power grid requires high-voltage electricity to reduce the power loss and improve the efficiency of transmission.

This is where a main power transformer comes in. It steps up the voltage of the electricity before it is transmitted over long distances through the transmission lines. The transformer increases the voltage to a level that is suitable for efficient transmission and reduces the current, which in turn reduces the amount of power loss. At the receiving end of the transmission line, another transformer steps down the voltage to a level that is suitable for distribution to households and businesses.

In addition to voltage transformation, main power transformers also provide other important functions in a substation. They act as a physical and electrical barrier between different voltage levels in the power grid, providing insulation and protection to the substation and the transmission lines. They also regulate the voltage and provide reactive power compensation to maintain power quality and stability in the power system. Overall, main power transformers play a critical role in the efficient and reliable operation of the power grid.

Main power transformers play a crucial role in solar power projects. They are responsible for transforming the electrical energy generated by the solar panels into a voltage suitable for use by the electrical grid. The power generated by the solar panels is typically in the range of 400-600V DC. This voltage is not suitable for use by the electrical grid, which requires a much higher voltage level.

The main power transformer in a solar project steps up the voltage of the generated power to a higher level. This higher voltage is then fed into the substation and ultimately the electrical grid. The transformer works by using the principle of electromagnetic induction to transform the voltage level of the electrical energy.

When an electrical current passes through a conductor, it creates a magnetic field around the conductor. The strength of this magnetic field is proportional to the amount of current passing through the conductor. Similarly, when a magnetic field moves through a conductor, it induces an electrical current in the conductor. The strength of the induced current is proportional to the rate of change of the magnetic field.

In a transformer, two coils of wire are wound around a magnetic core. The primary coil is connected to the power source, and the secondary coil is connected to the load. When an alternating current flows through the primary coil, it creates a magnetic field that changes direction with the alternating current. This changing magnetic field induces an alternating current in the secondary coil, which is then fed to the load.

The ratio of the number of turns in the primary coil to the number of turns in the secondary coil determines the voltage transformation ratio of the transformer. For example, if the transformer has a 10:1 voltage transformation ratio, and the primary voltage is 400V DC, the secondary voltage will be 4000V DC. This is a simplified explanation, as transformers used in solar projects are typically more complex than this, and may have multiple windings, taps, and other features to control voltage and current.

In summary, the main power transformer in a solar project is responsible for stepping up the voltage of the electrical energy generated by the solar panels to a higher level suitable for use by the electrical grid. The transformer works by using the principle of electromagnetic induction to transform the voltage level of the electrical energy.

When choosing a main power transformer, there are several factors that should be considered to ensure the right selection. Here are some key factors to keep in mind:

Voltage requirements: The transformer should be able to handle the voltage levels required by the specific application. This includes both primary and secondary voltages.

Power rating: The transformer should be rated to handle the power requirements of the application. This includes both the maximum and continuous power ratings.

Efficiency: Higher efficiency transformers can help reduce energy consumption and operating costs. It is important to consider the transformer’s efficiency when making a selection.

Size and weight: The size and weight of the transformer should be appropriate for the application. This includes both the physical space available and any weight restrictions that may be in place.

Cooling requirements: Transformers generate heat during operation, and it is important to ensure that the cooling requirements are met for the application. This includes both the type of cooling required (such as air or oil) and the cooling capacity needed.

Environmental considerations: Depending on the application, it may be important to consider the environmental conditions the transformer will be exposed to. This can include factors such as temperature, humidity, and exposure to moisture or dust.

Quality and reliability: The transformer should be of high quality and designed for reliable performance. This includes factors such as the quality of materials used, the manufacturing process, and any testing and quality control measures that have been implemented.

Cost: Finally, cost is an important consideration when choosing a main power transformer. It is important to balance the upfront cost of the transformer with its long-term operating costs, including efficiency and maintenance requirements.

There are several leading main power transformer manufacturers, including ABB, Siemens, and Daelim Belefic. Each manufacturer has its own strengths and areas of expertise, and it is important to choose a manufacturer that can provide a transformer that meets your specific requirements. Daelim Belefic, for example, has over 15 years of experience in designing, engineering, and producing high-quality electrical equipment, including power transformers, and has a strong focus on research and development to provide cutting-edge solutions to its customers.

In conclusion, main power transformers are critical components in power generation and distribution and can be used in a variety of applications, including substations, solar projects, and other energy-intensive operations. It is important to choose the right transformer for your specific needs and to choose a reputable and experienced manufacturer, such as Daelim Belefic, to ensure the quality and reliability of the transformer.

Daelim currently has 69KV class, 138kv class, and 220kv class main power transformers.

If you find that these main power transformers cannot meet your requirements, you can tell us your requirements and we can provide you with customized services. Our main power transformer has been applied in more than 20 countries all over the world.

Download Resource

ELECTRIC, WITH AN ENGE-- DAELIM BELEFIC