ELECTRIC, WITH AN EDGE

With economic development, electricity consumption in the paper industry continues to rise. To better energy-saving production, the selection of distribution transformers for paper-making enterprises is particularly important. Common dry-type distribution transformer and Oil-immersed distribution transformer.

Take a large paper-making company as an example.

There are a total of 52 10/0.69 (0.4) kV power distribution transformers installed, and the installed capacity of the transformer is 129,000 kVA; reducing the power consumption per unit product can not only reduce costs but also contribute to energy conservation and environmental protection.

Therefore, it is of great significance to improve the operating efficiency of distribution transformers and reduce the loss of the distribution network.

Distribution transformers are one of the most commonly used equipment in power grids. Distribution transformers run through all links of the power system.

In the factory substation and distribution network, the number and total capacity of distribution transformers are very large.

Generally speaking, it takes 3 to 5 times of voltage conversion process from power generation to power consumption. In this process, the Distribution transformers will produce various losses, including active power loss and reactive power loss.

Common Distribution transformers are divided into oil-immersed Distribution transformers and dry-type Distribution transformers.

At this stage, the conventional 10 kV oil-immersed Distribution transformers on the market mainly include S9, S11, and S13 series;

Dry-type Distribution transformers include SCB9, SCB10, SCB11, SCB13, SCBH15, SGB9, SGB10, SGB11, SGB13 and SGBH15 series.

Detailed explanation of the difference between dry-type transformers and oil-immersed transformers

S9 series transformers began production in the 1990s, using high-quality magnetic and conductive materials and a new structure, and the transformer core adopts a three-stage joint structure.

This effectively reduces the no-load loss;

The coil compression adopts laminated wood, which increases the compression area of the coil end surface and enhances the short-circuit resistance of the product.

S11 series transformers were produced in 2005. The transformer core is made of high-quality cold-rolled silicon steel sheets laminated with multi-layered fully oblique joints, which reduces the leakage magnetic loss caused by the joints during the operation of the transformer.

The high and low-voltage windings are made of oxygen-free copper.

Continuous winding makes full use of the orientation of the silicon steel sheet. The improvement of this process greatly reduces the loss, improves the power factor, and reduces the power grid line loss.

S13 series transformers are three-phase wound core fully sealed oil-immersed power transformers.

It is currently the energy-saving distribution transformer product with the best performance index. The S13 open-type three-dimensional wound core transformer is a new product launched based on the S11 wound core energy-saving transformer.

The cores of the S13 series transformers are arranged in a triangle shape with no seams. They are wound on special equipment, which greatly reduces the magnetic resistance, reduces the no-load current by 70% to 85%, improves the power factor, and reduces the power grid loss.

The wound core structure is in a natural tightening state, no clamps are required to tighten, which avoids performance deterioration due to clamping, and reduces no-load loss by 20% to 45%.

At the same time, the wound core itself is a seamless whole, and the structure is compact, and the noise level is reduced by 7 to 10 dB.

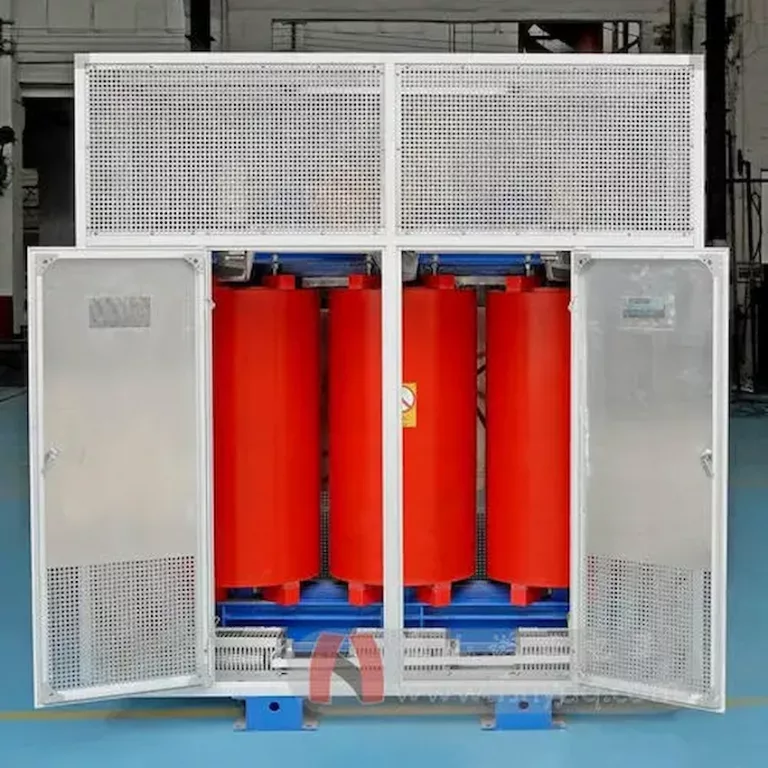

Compared with oil-immersed distribution transformers, dry-type distribution transformers refer to transformers in which the core and windings are not immersed in insulating oil.

At present, dry-type distribution transformers are used more and more in the development of the electric power field. Due to different cooling methods, it can be divided into natural air-cooled dry-type distribution transformers (AN) and forced air-cooled dry-type distribution transformers (AF);

Due to different insulating media, it can be divided into SCB series epoxy resin cast dry-type distribution transformers (using epoxy resin as the insulating medium) and SGB series insulated non-encapsulated dry-type distribution transformers (insulating material is Nuomac paper DuPont paint);

Due to different core materials, it can be divided into silicon steel sheet core dry type distribution transformers (SCB, SGB series) and amorphous alloy core series dry-type distribution transformers (SCBH, SGBH series).

SCB series distribution transformers are dry-type distribution transformers manufactured through a casting process. Because of their oil-free, flame-retardant, non-polluting, intelligent, low loss, safety, explosion-proof, maintenance-free, small size, and lightweight characteristics, they can go directly to the load center for power supply.

Dry-type distribution transformers generally have the following characteristics:

A Complete Guide to Three Phase Epoxy-resin Dry Type Distribution Transformer

Large and medium-sized papermaking enterprises have a relatively large electricity load, with electricity load ranging from 40 to 120 MW.

Paper-making enterprises have continuous production for 340 days or 8160 hours throughout the year, and the continuous load accounts for more than 90% of the electricity load. Under normal production conditions, load fluctuations are small.

At this stage, most of the motors of large and medium-sized paper-making enterprises often use a 690 V voltage level, which reduces the number of 10(6) kV voltage level motors and increases the number of distribution transformers.

There are two types of distribution transformers: oil-immersed distribution transformers and dry-type distribution transformers. Its advantages and disadvantages include the following aspects.

Many substations of papermaking enterprises are arranged in the building attached to the craft workshop. Affected by the height of the operation floor of the craft workshop, the height of the oil-immersed transformer room may not meet the ventilation requirements, and two floors are required;

In addition, oil-immersed distribution transformers require a separate distribution transformer room due to fire protection requirements, which occupies a large building area and increases civil construction costs.

The dry-type distribution transformer can be placed in the same room with the low-voltage power distribution panel, and there is no special requirement for the height of the room.

The calorific value of the distribution transformer is generally estimated at 1%~1.5% of the distribution transformer capacity.

Dry-type distribution transformers are generally insulated with dry resin and are cooled by natural air. Large-capacity transformers need fan cooling; if the room is the same as the low-voltage power distribution room and the room has temperature requirements, the air conditioning and ventilation system need to consider the heat generation of the transformer, adding additional Power consumption.

Oil-immersed distribution transformers rely on radiators to dissipate heat, and no need to add any ventilation devices when meeting the window area.

Dry-type distribution transformers have no possibility of catching fire, while oil-immersed distribution transformers may have oil sprayed or leaked when they fail, causing a fire.

Therefore, the oil-immersed distribution transformer should be placed in a separate transformer room. The fire resistance level of the transformer room should be Class I, the lower part of the transformer should be equipped with an oil storage tank, and the door of the transformer room should also be a Class A fire door.

Dry-type distribution transformers mainly rely on the transformer to dissipate heat. When the rated current is exceeded, the distribution transformer coil will overheat and cannot be dissipated, and the internal temperature will rise.

If the overload is within the allowable range of the distribution transformer, it will only affect the service life of the transformer. If it exceeds the allowable range of the transformer, it may catch fire or even cause an explosion.

Therefore, generally, dry-type distribution transformers should be operated under rated capacity, while oil-immersed distribution transformers have better overload capacity and allow longer overload time. The overload capacity of oil-immersed and dry-type distribution transformers is shown in the table.

| Overload capacity of oil-immersed and dry-type Distribution transformers | ||

| Overload multiple/time | Transformer allowable duration/min | |

| Dry-type transformer | Oil-immersed transformer | |

| 1.1 | 180 | |

| 1.2 | 60 | 150 |

| 1.3 | 45 | 120 |

| 1.4 | 32 | |

| 1.5 | 18 | |

| 1.6 | 5 | 45 |

| 1.75 | 45 | |

| 2 | 7.5 | |

For distribution transformers of the same capacity, the purchase price of dry-type distribution transformers is much higher than that of oil-immersed distribution transformers.

Taking 2000 kVA distribution transformers as an example, the price of dry-type distribution transformers is 1.3~1.5 times higher than that of oil-immersed distribution transformers.

Dry-type distribution transformer SGB series of insulating non-encapsulated dry-type distribution transformers are made of Nomak paper DuPont paint, which is non-flammable, non-polluting, low loss, safety, maintenance-free, strong overload capacity, and long service life. Features such as small size and lightweight.

The price of SGB series dry-type distribution transformers is not much different from that of SCB series dry-type distribution transformers.

The S9 series of oil-immersed distribution transformers have higher losses. Except for the transformers that are in operation, this type of transformer is basically not selected for new projects. The products currently selected are mostly the S11 and S13 series.

Medium and large pulp and paper enterprises have a large electricity load. The 690 (400) V distribution transformer uses about 20000 kW.

The loss of the distribution transformer is the smallest, but it will increase the number of distribution transformers.

The main production workshops of large pulp and paper enterprises have a working time of 24 hours and continuous operation for 330 to 340 days, so load fluctuations are small.

The load factor of the distribution transformer is selected between 0.55 and 0.65, and various losses are relatively small.

If the distribution transformer is selected according to the load factor, it will increase the number of transformers, so it is not recommended to choose according to this condition.

Although dry-type distribution transformers increase procurement costs, compared with oil-immersed transformers, civil construction costs are reduced, which is conducive to the layout of power distribution devices and reduces the possibility of fire.

However, the dry-type transformer and the low-voltage power distribution panel are arranged in the same room. The heat output of the transformer is generally 1% to 1.5% of the transformer capacity, and the indoor temperature is required, which requires an increase in air-conditioning costs.

Reasonable selection, configuration, and management of distribution transformers have great potential in terms of energy-saving and consumption reduction. With the growth of electrical load, the number and capacity of distribution transformers have gradually increased. In addition to adopting new energy-saving materials and choosing new energy-saving transformers to reduce losses when preparing transformers, it is also necessary to strengthen the management of distribution transformers and fully tap the loss reduction measures of distribution transformers.

When you need to find more than just existing transformers, Daelim’s Transformer Service Center can help you design and produce distribution transformers that meet your unique needs.

We have our own factory and a professional team of engineers, which can design and modify application requirements that meet all your conditions.

Download Resource

ELECTRIC, WITH AN ENGE-- DAELIM BELEFIC

After filling in the contact information, you can download the PDF.