ELECTRIC, WITH AN EDGE

This article describes in detail the selection of dry-type distribution transformers in the process of configuring the public building power grid.

From the economic considerations of long-term operation, more efficient and energy-saving dry-type distribution transformers should be used first.

Daelim is a transformer manufacturer with 16 years of experience in the design and production of dry-type distribution transformer. It can provide transformer solutions for your public building grid.

Daelim’s professionalism and efficiency have been recognized by customers in dozens of countries and regions around the world.

DAELIM’s dry-type distribution transformer has obtained IEEE, ANSI, CSA, and IEC certifications.

Can provide the most professional transformer solutions for your power grid construction.

Distribution Transformer Selection of An Office Building

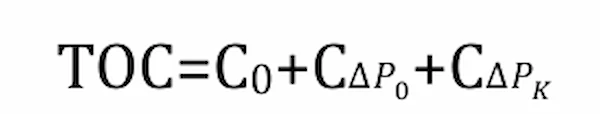

-The author compared the economic evaluation indices of commonly used dry-type transformer and SCBH15 amorphous alloy transformer by the calculation of total owning cost ( TOC).

Wiring method of Dry-type Transformer

-Introduced the common wiring methods of dry-type transformers, how to connect the input and output terminals of the transformer, and what are the low-voltage outlet methods of dry-type transformers.

Selection And Maintenance of 10 kV Dry-type Transformer

-This article analyzes the selection of 10 kV dry-type transformer and further elaborates the maintenance work of the Cast Resin Dry-type Transformer.

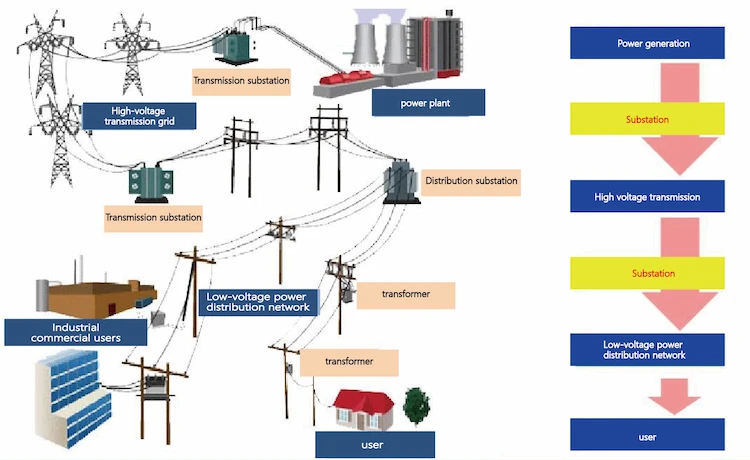

Public buildings are a high-density area of building energy consumption at this stage. Public building area accounts for less than 4% of the total urban building area, but its energy consumption accounts for 22% of the total building energy consumption.

Public buildings are densely populated, and power dry-type distribution transformersare important equipment for public buildings. The installed density is several times higher than that of other buildings, and dry-type distribution transformer are mostly used.

When designing the power supply and distribution of public buildings, it is necessary to analyze the safety, economy, and energy saving, and finally determine the dry-type transformer model.

Due to the continuous improvement of magnetic materials, the no-load loss value of dry-type distribution transformer is constantly adjusted down.

But so far, the conductivity improvement of copper has only increased by 3%, unlike the magnetic material that has undergone four generations of improvement in permeability.

Therefore, in the later period, the latest energy-saving models only reduce no-load loss, and their load loss has not changed.

This is because under the current material, design, and technological level, to reduce load loss, the only way to greatly increase the use of winding copper wire, resulting in increased dry-type transformer costs, increased volume, and lower cost performance.

Daelim uses the most advanced technology on the market to produce a three-phase epoxy dry-type transformer.

This dry-type transformer greatly reduces no-load loss while reducing load loss. Save you a lot of electricity, save energy and money.

Rated Capacity(kVA) | No-load loss (W) | Load loss/W | Short circuit resistance (%) | ||

B(100℃)) | F(120℃)) | H(145℃)) | |||

30 | 220 | 710 | 750 | 800 | 4 |

50 | 310 | 990 | 1060 | 1130 | |

80 | 420 | 1370 | 1460 | 1560 | |

100 | 450 | 1570 | 1670 | 1780 | |

125 | 530 | 1840 | 1960 | 2100 | |

160 | 610 | 2120 | 2250 | 2410 | |

200 | 700 | 2510 | 2680 | 2870 | |

250 | 810 | 2750 | 2920 | 3120 | |

315 | 990 | 3460 | 3670 | 3930 | |

400 | 1100 | 3970 | 4220 | 4520 | |

500 | 1310 | 4860 | 5170 | 5530 | |

630 | 1510 | 5850 | 6220 | 6660 | |

630 | 1460 | 5940 | 6310 | 6750 | 6 |

800 | 1710 | 6930 | 7360 | 7880 | |

1000 | 1990 | 8100 | 8610 | 9210 | |

1250 | 2350 | 9630 | 10260 | 10980 | |

1600 | 2760 | 11700 | 12400 | 13270 | |

2000 | 3400 | 14400 | 15300 | 16370 | |

2500 | 4000 | 17100 | 18180 | 19460 | |

1600 | 2760 | 13000 | 13700 | 14500 | 8 |

2000 | 3400 | 15900 | 16900 | 18000 | |

2500 | 4000 | 18800 | 20000 | 21400 | |

| Rated Capacity(kVA) | No-load loss (W) | Load loss/W | Short circuit resistance (%) | ||

| B(100℃)) | F(120℃)) | H(145℃)) | |||

| 30 | 190 | 670 | 710 | 760 | 4 |

| 50 | 270 | 940 | 1000 | 1070 | |

| 80 | 370 | 1290 | 1380 | 1480 | |

| 100 | 400 | 1480 | 1570 | 1690 | |

| 125 | 470 | 1740 | 1850 | 1980 | |

| 160 | 540 | 2000 | 2130 | 2280 | |

| 200 | 620 | 2370 | 2530 | 2710 | |

| 250 | 720 | 2590 | 2760 | 2960 | |

| 315 | 880 | 3270 | 3470 | 3730 | |

| 400 | 980 | 3750 | 3990 | 4280 | |

| 500 | 1160 | 4590 | 4880 | 5230 | |

| 630 | 1340 | 5530 | 5880 | 6290 | |

| 630 | 1300 | 5610 | 5960 | 6400 | 6 |

| 800 | 1520 | 6550 | 6960 | 7460 | |

| 1000 | 1770 | 7650 | 8130 | 8760 | |

| 1250 | 2090 | 9100 | 9690 | 10370 | |

| 1600 | 2450 | 11050 | 11730 | 12580 | |

| 2000 | 3050 | 13600 | 14450 | 15560 | |

| 2500 | 3600 | 16150 | 17170 | 18450 | |

| 1600 | 2450 | 12280 | 12960 | 13900 | 8 |

| 2000 | 3050 | 15020 | 15960 | 17110 | |

| 2500 | 3600 | 17760 | 18890 | 20290 | |

| Rated Capacity(kVA) | No-load loss (W) | Load loss/W | Short circuit resistance (%) | ||

| B(100℃)) | F(120℃)) | H(145℃)) | |||

| 30 | 170 | 670 | 710 | 760 | 4 |

| 50 | 240 | 940 | 1000 | 1070 | |

| 80 | 330 | 1290 | 1380 | 1480 | |

| 100 | 360 | 1480 | 1570 | 1690 | |

| 125 | 420 | 1740 | 1850 | 1980 | |

| 160 | 480 | 2000 | 2130 | 2280 | |

| 200 | 550 | 2370 | 2530 | 2710 | |

| 250 | 640 | 2590 | 2760 | 2960 | |

| 315 | 790 | 3270 | 3470 | 3730 | |

| 400 | 880 | 3750 | 3990 | 4280 | |

| 500 | 1040 | 4590 | 4880 | 5230 | |

| 630 | 1200 | 5530 | 5880 | 6290 | |

| 630 | 1170 | 5610 | 5960 | 6400 | 6 |

| 800 | 1360 | 6550 | 6960 | 7460 | |

| 1000 | 1590 | 7650 | 8130 | 8760 | |

| 1250 | 1880 | 9100 | 9690 | 10370 | |

| 1600 | 2200 | 11050 | 11730 | 12580 | |

| 2000 | 2740 | 13600 | 14450 | 15560 | |

| 2500 | 3240 | 16150 | 17170 | 18450 | |

| 1600 | 2200 | 12280 | 12960 | 13900 | 8 |

| 2000 | 2740 | 15020 | 15960 | 17110 | |

| 2500 | 3240 | 17760 | 18890 | 20290 | |

| Rated Capacity(kVA) | No-load loss (W) | Load loss/W | Short circuit resistance (%) | ||

| B(100℃)) | F(120℃)) | H(145℃)) | |||

| 30 | 70 | 670 | 710 | 760 | 4 |

| 50 | 90 | 940 | 1000 | 1070 | |

| 80 | 120 | 1290 | 1380 | 1480 | |

| 100 | 130 | 1480 | 1570 | 1690 | |

| 125 | 150 | 1740 | 1850 | 1980 | |

| 160 | 170 | 2000 | 2130 | 2280 | |

| 200 | 200 | 2370 | 2530 | 2710 | |

| 250 | 230 | 2590 | 2760 | 2960 | |

| 315 | 280 | 3270 | 3470 | 3730 | |

| 400 | 310 | 3750 | 3990 | 4280 | |

| 500 | 360 | 4590 | 4880 | 5230 | |

| 630 | 420 | 5530 | 5880 | 6290 | |

| 630 | 410 | 5610 | 5960 | 6400 | 6 |

| 800 | 480 | 6550 | 6960 | 7460 | |

| 1000 | 550 | 7650 | 8130 | 8760 | |

| 1250 | 650 | 9100 | 9690 | 10370 | |

| 1600 | 760 | 11050 | 11730 | 12580 | |

| 2000 | 1000 | 13600 | 14450 | 15560 | |

| 2500 | 1200 | 16150 | 17170 | 18450 | |

| 1600 | 760 | 12280 | 12960 | 13900 | 8 |

| 2000 | 1000 | 15020 | 15960 | 17110 | |

| 2500 | 1200 | 17760 | 18890 | 20290 | |

| Rated Capacity(kVA | No-Load loss/W | On Load loss/W | Short circuit resistance (%) |

| 50 | 270 | 990 | 4 |

| 100 | 400 | 1570 | |

| 160 | 540 | 2120 | |

| 200 | 620 | 2520 | |

| 250 | 720 | 2750 | |

| 315 | 880 | 3460 | |

| 400 | 970 | 3980 | |

| 500 | 1160 | 4880 | |

| 630 | 1340 | 5870 | |

| 800 | 1520 | 6950 | |

| 1000 | 1760 | 8120 | 6 |

| 1250 | 2090 | 9690 | |

| 1600 | 2450 | 11730 | |

| 2000 | 3320 | 14450 | |

| 2500 | 4000 | 17170 |

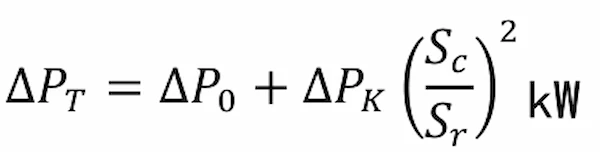

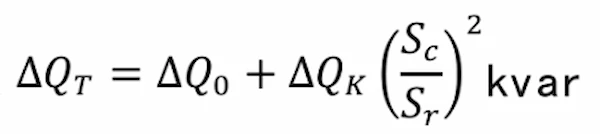

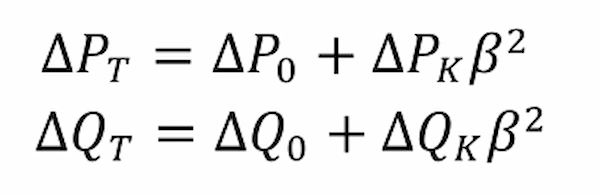

The power loss of a dry-type transformer is composed of active and reactive power.

The active power loss of a dry-type transformer consists of the following two parts:

One part is the active power iron loss produced by the main magnetic flux in the dry-type transformer core. The iron loss has nothing to do with the load of the dry-type transformer. When the power supply voltage and frequency are unchanged, its value is unchanged;

The other part is the copper loss generated in the primary and secondary windings when the dry-type transformer passes the load current, which can be approximated as the loss ΔPK measured in the dry-type transformer short-circuit experiment. Copper loss is related to the size of the load, and it is proportional to the square of the current.

The reactive power loss of dry-type transformers also consists of two parts:

Part of the reactive power is used to generate the main magnetic flux, that is, the excitation current or the no-load current I0, which has nothing to do with the size of the load;

The other part of the reactive power is consumed by the reactance of the primary and secondary coils, which is proportional to the square of the load current under the rated load.

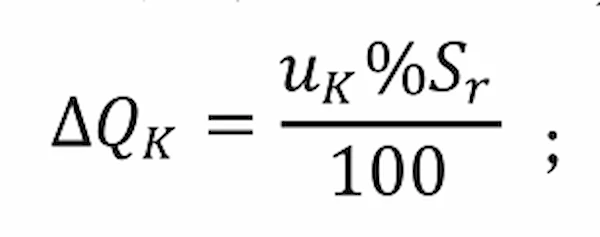

uK% — The percentage of the transformer impedance voltage to the rated voltage. In the above power loss calculation formula, S c/ S r is the load factor β during operation of the transformer, and the relationship between the active and reactive power losses of the transformer and the load factor of the transformer can be expressed as:

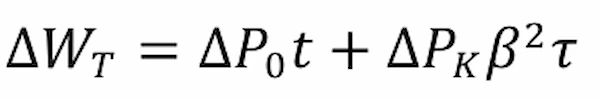

Transformers in civil buildings are generally equipped with on-site reactive power compensation, so that the power factor of the transformer reaches the limit required by the power supply part, and the reactive power loss of the transformer is no longer considered from the perspective of operating costs. The annual active power loss ΔWT of the transformer is:

t is the number of operating hours of the transformer throughout the year. When the transformer is put into operation throughout the year, τ is the number of hours of maximum load annual loss.

For 10 type, 11 type and amorphous alloy dry-type transformers with different capacities, the annual electricity saved when operating in the same environment is shown in Table 5.

The load loss of Type 10, Type 11 and amorphous alloy dry-type transformers is the same, and the difference in total cost of ownership is only related to the initial purchase cost and no-load loss cost.

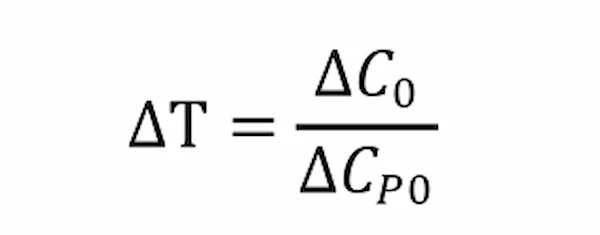

The payback period of the investment price difference of using different types of transformers is:

Since the price ratio of amorphous strips and high-quality cold-rolled silicon steel sheets is about 2.5:1, and because the working magnetic density is slightly lower and the amount of wires is large, the current domestic price of amorphous distribution transformers is about 1.3 ~ of that of silicon steel plates. 1.4 times.

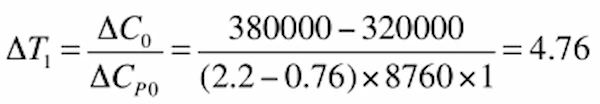

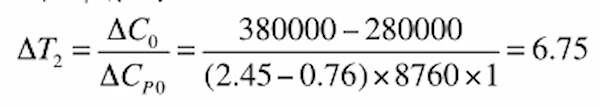

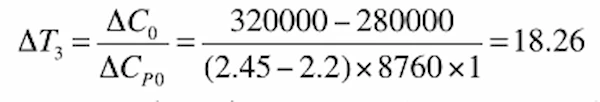

Take 10/ 0.4kV, D yn11 connection group, 1 600kV A dry-type transformer with impedance voltage of 6% as an example.

At this stage, the initial purchase cost of amorphous alloy dry-type transformers is about 380,000 yuan, the initial purchase cost of SC B11 dry-type transformers is about 320,000 yuan, and the initial purchase cost of SC B10 dry-type transformers is about 280,000 yuan.

The electricity price adopts the general commercial electricity price of 1 yuan/kWh as the calculation condition, and the payback period of the investment difference of the amorphous alloy dry-type transformer compared with the SC B11 dry-type transformer is:

The payback period of the investment difference of the amorphous alloy dry-type transformer compared with the SC B10 dry-type transformer is

The payback period of the investment difference of the amorphous alloy dry-type transformer compared with the SC B10 dry-type transformer is

As a policy regulation for weighing investment and energy-saving benefits, the general calculation of investment recovery period should not exceed 5 years, and the longest period should not exceed 7 years.

The use of more energy-efficient amorphous alloy dry-type transformers or SC B10 and SC B11 dry-type transformers can recover the investment within 5 to 7 years.

However, considering that the normal life of dry-type transformers is generally 25 to 30 years, from a long-term perspective, the use of more energy-saving amorphous alloy dry-type transformers can obtain huge economic benefits.

Compared with the SC B10 dry-type transformer, the energy-saving and economic efficiency of the SC B11 dry-type transformer is not significantly improved.

The above calculation is a static investment payback period, without considering the time value of an investment in money.

If you find that the existing distribution transformer types or power cannot meet your requirements. You can choose to tell Daelim. Daelim has a team that has always had a wealth of design transformers, and can give you a specific design plan in the shortest time.

Daelim’s distribution transformers comply with IEEE, ANSI, CSA, IEC certification, and are used in North America (such as Canada, the United States, Mexico), South America (such as Ecuador, Chile), Europe (such as Spain, Lithuania) and some Asian countries. Daelim even has a professional installation team that can provide you with installation services.

After filling in the contact information, you can download the PDF.