ELECTRIC, WITH AN EDGE

Liquid-filled transformers are used in a wide range of commercial and industrial applications. This electrical transformer transmits electricity from one circuit by varying the voltage level but not the frequency. Transformers can be categorized into two types based on the cooling system utilized within the transformer: dry-type and liquid-filled transformers. The oil-type transformer was one of the first models of transformers, and since then, they continue to be widely used even in today’s time.

It enhances the safety and efficiency of power systems by adjusting voltage levels as needed.

DAELIM’s high-quality materials and cutting-edge technologies will provide you years of dependable service. When investing in your high-voltage infrastructure, it is critical to understand your transformer in achieving energy savings. Let’s look at how a liquid-filled transformer works in more detail below!

To begin with, it is best to go back to what transformers are in general to grasp every bit of information there is. This will make understanding it much easier.

So, what are transformers?

Back then, there were only a few models of transformers, but in today’s generation, there are many types of transformers developed that serve different functions, services, and mechanisms.

Along with that, transformers now come in different sizes and shapes. There are transformers available in the market that are as big as a car, and there are transformers out there as well that are as small as a barrel.

But regardless of their shape and size, all transformers have one element in common, and that is to regulate currents, voltages, or electricity in general.

Moreover, transformers can transfer electricity from circuit to circuit with adjusting voltage levels that do not disrupt the frequency. Transformers nowadays commonly function with the use of an AC supply.

The fluctuation in supply voltage will be affected by the fluctuation in the currency as well.

Increase in current is equal to increase in voltage, vice versa.

Transformers also improve the safety and efficiency of power systems through regulation of the voltage levels by stepping up (increasing) or stepping down (decreasing) the voltage levels when necessary.

When it comes to distribution of electricity to long distances, transformers are very capable in doing so.

In case you are confused by some of the terminologies mentioned, below are their definitions

In a situation where there is a change in flux linkage, electromotive forces (EMF) will then be induced. These EMFs will generate a time-varying magnetic field.

You probably heard of magnetic fields your whole life without knowing what its meaning is. Well, for transformers including oil-type transformers, a magnetic field is produced when primary voltages drive a current that is alternating through the primary coil.

This goes along with changes in the current as well.

The transformer’s coil will be the one to increase the strength of the magnetic field as it passes through the secondary coil.

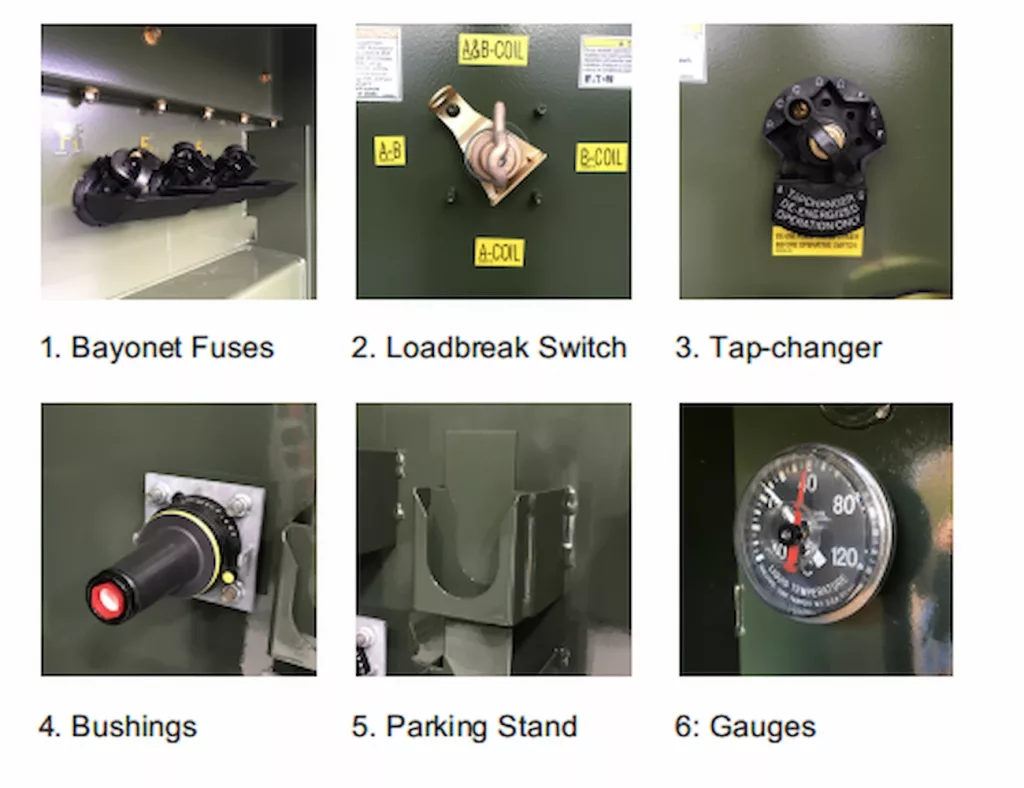

Transformers consists of several parts. Before we go through what oil-type transformers are, and what they form, It is best to know what are its individual parts to have a better understanding as we go further down in this article.

Oil-type transformers have different cores, depending on the manufacturer, but most cores are made up of iron and they are laminated with a thin sheet. This is to prevent eddy currents from forming, which is great for reducing energy losses.

Transformers have different kinds of cores, the iron core of transformers is commonly laminated with a thin sheet, which keeps eddy currents from forming. This is great for reducing energy losses as well.

Transformers usually have two windings, which are called the primary winding and the secondary winding. Each of which have different functions and purposes.

For instance, the primary winding’s function is to draw power from its source. On the other hand, the secondary winding is the coil that delivers the energy in the converted voltage towards the load.

Transformers contain insulation materials as well. The majority of transformers usually have paper press-boards and transformer boards that are formed from cellulose. Cellulose insulation that is combined with mineral oil is usually utilized as cooling mediums for transformers.

Obviously, oil-type transformer have oil in them. This serves as their cooling system. However, not all transformers use oil as their cooling medium. Some transformers use air or forced air as their cooling medium.

This will be thoroughly discussed as we go further.

Tap charger is a function that enables variable turn ratios to be pickled in specific steps, this is done by connecting a number of access points.

For transformers that use oil like oil-type transformer, they have oil conservators within them and this provides space to increase the amount of oil inside the transformer when the time comes that its temperature increases.

Oil conservators are also known as reservoirs for the transformer’s oil.

Transformers have breathers with them that help prevent atmospheric moisture from coming in the transformers. This reduces the maintenance costs.

Cooling tubes are components that also help with regulating the temperature of the transformer. This includes external radiator tubes that can come from air cooling that is installed on the walls of the transformer’s tank.

The fans will then absorb the air below and lead it to the top part of the tubes, which results in cooling the oil.

For oil-type transformers, fans are not necessary if they are not operating on full loads.

Cooling tubes include external radiator tubes that can be from air cooling installed on the walls of the transformer tank. The fans will absorb the air underneath and force it to go on the top part of the tubes which cools the oil.

If the transformer is not fully loaded, the cooling systems can be operated with or without fans.

Buccholz relay is a safety device that is utilized for oil-type transformers to protect the transformer from faults that are most likely to happen inside the transformer. These faults could range from insulation failures, impulse breakdowns, and many more.

The function of explosion vents is to prevent the release of excessive pressure that is formed inside the transformer.

Now that you know the different parts of transformers, understanding oil-type transformers will be much easier! But if up until now you are still confused, and you have some questions, you can easily contact DAELIM’s team of professionals for immediate answers.

So, what is the oil-type transformer?

This type of transformer is basically transformers that use oil as their cooling medium. Oil-type transformers are known to be efficient even at high loads due to their effective cooling medium that helps them regulate hot temperatures.

The examples below are distribution transformers that make use of oil as their cooling system.

10 KV distribution transformers are electrical devices that play a vital role in the distribution network and power supply for industrial and mining endeavors. This is because of their compact size that is far different compared to other distribution transformers.

Speaking of compactability, along with its build is a simple but modern design. In addition, you do not have to worry about noise since 10 KV distribution transformers produce low noise but this does not mean it is operating at average.

10 KV distribution transformers have a sealed and conservator type, which gives you the upper hand.

These are the common applications for 10 KV three phase distribution transformers:

Based on KV alone, the 20 KV three phase distribution transformer is slightly more versatile, powerful, and efficient compared to the 10 KV variant.

The 20 KV three phase distribution transformer has more power supply capabilities, and it is more efficient at controlling voltage qualities. Moreover, 20 KV transformers can debase electric energy that is already lost in the system.

This is great since it helps conserve energy which lessens the construction fee.

35 KV three phase distribution transformers tops the two transformers above since they have the highest KV of them all. This transformer complies with the standard of ANSI C57.12.00, IEC60076, GB1097, and GBT6451.

Furthermore, the no-load loss and on-load loss are lower. They are premium, safe to be operated, and widely used around the world.

So, you can expect that the 35 KV three phase distribution is reliable and so are the other two oil-type transformers in this list.

Oil-type transformers are transformers that make use of oil to insulate the transformers to prevent it from going to high temperature levels or overheating. Oil-type transformers are designed to be durable and resistant to high temperatures.

However, there are cases that the oil capacity is not enough to cool the transformer for long periods, which is why some consumers add cooling tubes like fans, external radiators, and others to make oil circulate through the process of convection.

Oil-type transformer that have oil conservators can be added with a gas detector relay for the safety of monitoring it. This will alarm you if there is an increase of gas inside the transformers, this happens when it is overheating.

This also triggers circuit breakers to activate or cut off power from the transformer. For those transformers who do not have a detector relay, there is usually another relay built-in in the transformer which serves the same function but alarms in a different way.

Like most transformers, oil-type transformer work with the same principle as other transformers but instead of air, this type of transformer uses oil as its cooling medium, which is known to be very effective.

The liquid-filled transformers are also known as liquid-cooled transformers. Since the liquid, typically oil, contained within the transformer cools it. These transformers are durable and may be installed indoors or outdoors in severe environments. It requires low maintenance and has a service expectancy of up to 35 years.

A liquid-filled transformer is primary function converts electrical energy from distribution level voltage to use level voltage. Greater ratings are available for liquid-filled transformers. Mineral insulating oil is standard liquid-filled transformer oil. Silicon oils, esters, and other materials, though more expensive, can also be utilized.

Although liquid-type power transformers have been available for almost a century, new technological improvements have enhanced their usefulness. The windings and core of a liquid-filled transformer are entirely submerged in the liquid. It serves as a cooling medium as well as an insulator to limit stray currents.

The liquid-filled transformer, also known as oil-type transformers, have a long lifespan, with an average lifespan of 25 years. Most probably, it may have a service life of 35 years and several more advantages. This technology is low-cost, flexible, and simple to maintain.

Liquid-filled substation transformers are used in a wide range of commercial and industrial applications. When a larger capacity is required, liquid-filled transformers are used since they are notably more efficient in this application. They are also used both indoors and outdoors and serve a variety of functions.

Three-phase liquid-filled transformers are utilized in applications such as mining, automotive, and assembly line machines. They are frequently situated in outdoor locations due to their extra cooling and insulating qualities. Oil-type transformers are designed to endure extreme temperatures and severe loads while retaining structural, electrical, and mechanical integrity.

What’s more, liquid-filled or oil-filled transformers are also frequently coupled with other arriving or departing equipment to lower utility voltage. The cooling properties of liquid-filled transformers are generally smaller when compared to a dry-type transformer of the same rating.

Transformers are devices that allow electricity to be used efficiently by items that can only handle low voltage electricity. Currently, two types of transformers are in use, dry-type and oil-type transformers. Besides, they both serve the same goal, yet there are some significant distinctions between them. Take a brief look at the differences between a dry-type and a liquid-filled transformer.

Dry-type power transformers have typically been utilized in low and medium-voltage construction applications. Surges and short circuits are not a problem for some cast-coil items present in dry-type systems. Moreover, dry systems avoid the environmental hazards associated with leaks and spills since it only uses air. Thus, they are suggested for indoor power distribution due to their enhanced safety.

The cooling medium for dry-type transformers is typically air. So they are also known as air-cooled transformers. Natural air cooling and forced air cooling are the two cooling modes of dry-type power transformers. In addition, the transformer may run continuously for extended periods of natural air cooling and maintain its rated capacity under typical conditions.

An air-cooled transformer is bigger than liquid-filled with the same capacity and voltage, making it unsuitable for restricted space sites. It has a maximum rating of 3 MVA. Dry transformers with greater capacity must utilize air-blast systems to cool the core and windings. Because of these constraints, many experts propose 2.5 MVA as the transition point for dry and wet goods.

Liquid-filled are often more efficient than dry-types and have a longer life lifespan. The cooling qualities of liquid-filled transformers are lower than those of a dry-type transformer of the same rating. The liquid is a more efficient cooling medium than air for significantly reducing hot spots in coils. Also, liquid-filled devices have a greater overload capacity.

When used for outdoor applications, liquid-filled and oil converters are often the least costly option. While dry-type transformers offer numerous advantages such as safety, their voltage rating and compactness are restricted. Liquid-filled transformers can withstand significantly higher electrical loads and have higher voltage ratings.

Liquid-filled transformers have transformer oils or dielectric fluid that have high flashpoints and a shared environmental effect. High-voltage customers can simply recycle or remanufacture liquid-filled transformers. In addition, because of the decreased working noise, liquid-filled transformers are appropriate for indoor usage. These transformers outlast dry-type goods.

Flammable and ecologically hazardous dielectric fluids were a significant disadvantage to liquid-filled transformers. A transformer that leaks mineral oil has the potential to ignite a fire. As safer alternatives to typical liquids, you can utilize non-flammable and biodegradable liquids.

Non-flammable liquid-filled transformers are made up of silicone, perchloroethylene, high-temperature hydrocarbons, and oil-perchloroethylene. All of these fluids are fire-resistant and non-hazardous to the environment. These are made from animal fats and vegetable oils, which are less damaging to the environment than oils.

Biodegradable fluids are filled with the previously stated less-flammable dielectric fluids. The benefits of employing these fluid transformers include greater fire and flashpoints. It reduces flammability problems and high environmental absorption because they are from a toxin-free resource.

Regardless of whatever distribution transformer you choose, you must maintain rigorous maintenance. A yearly inspection program to ensure that the transformers function safely and to their maximum capacity.

Polychlorinated biphenyls are an artificial chemical produced initially over a century ago. These were discovered to have favorable properties, leading to their widespread usage. PCBs were once used as transformer oil due to their high dielectric strength and lack of flammability. Yet, PCB causes harm to humans. Chronic PCB exposure may result in toxicity as hepatotoxicity and neurotoxicity.

On the other hand, silicone transformer liquid is both chemically and thermally inert. Through extensive testing, the safety of silicone liquid has been confirmed. Silicone is an exceptionally safe material for transformers due to its low heat release rates. Furthermore, it is among the least hazardous commercial compounds. Because of its ecological compatibility, silicone is a safe environmental alternative.

The oil used in transformers is called transformer oil, but its name is specifically mineral oil.

The transformers above use oil because of its compatibility. Mineral oil is considered far more effective than other types of oil because of its better electrical and cooling properties.

Mineral oil can be expensive, but regardless, it ensures the best way to cool transformers. There are alternatives available but are less effective, and some are even more expensive.

In this section, you will get to learn the major differences of the two popular types of transformers.

Dry-type transformers use air or forced air as their cooling medium, which means that they cost less and are environmentally friendly. However, they are known to be less efficient compared to mineral oil.

In terms of maintenance, the dry-type transformer has lower maintenance compared to the oil-type transformer. Oil-type transformer’s cooling medium alone requires regular maintenance.

When it comes to noise, dry-type transformers produce more noise than oil-type transformers due to the air that moves makes the parts inside move and rattle, which creates clanking metal noises.

Dry-type transformers are less efficient due to their size and limited voltage ratings, which makes them prone to overheating if overloaded. Forced air is less effective when it comes to cooling at high overloads.

Which results in high electrical losses, and more expensive maintenance for the power supply.

When it comes to price and budgeting, dry-type transformers are more expensive, because you do not need to purchase mineral oil, it can be used in public, and it’s not flammable.

Oil -type transformers are the superior choice for overload capabilities, because their insulation helps them operate in high temperatures, which dry-type transformers struggle with.

Although mineral oil is typically successful as transformer oil, it has certain drawbacks. It has a comparatively low flash point compared to some alternatives, making it combustible. Because of the transformer oil’s flammability, it is frequently prohibited from being used inside buildings or structures. A poorly shielded liquid-filled transformer might potentially explode.

As people become more concerned about fire safety in and around buildings, they may have issues with liquid-filled transformers. Because liquid-type units employ a liquid cooling medium that might catch fire, fire protection is particularly critical. Containment troughs and other safety measures were necessary for oil-filled transformers.

Fire rules frequently mandate that transformers installed within buildings use a less-flammable liquid or that they be dry-type transformers with no fluids at all. Indoor installations were deemed dangerous for possible fire dangers and dielectric fluid exposure. But, numerous mineral oil substitutes are now accessible.

Synthetic esters and Pentaerythritol tetra fatty acid naturally are composed and developed as a popular mineral oil substitute. They are used explicitly in high-fire-risk applications. Even if you have it indoors, due to their high fire point exceeding 300 °C, they are also easily decomposable. Silicone or fluorocarbon-based oils, which are less flammable, are also utilized. Although, they’re more costly and less biodegradable than esters.

Oil-type transformers have its pros and cons, and depending on what your project is or how you plan to use it, make sure to heed to its disadvantages to make sure you get the most out of the transformer’s performance.

Liquid-filled transformers use insulating oil, which is an oil that remains stable at high temperatures. That’s why this type of transformer is highly recommended for large-scale projects. But, many variables must be considered while deciding on the type of transformer to be chosen. You must consider the voltage rating and capacity, location of the transformer, and footprint.

We provide a comprehensive selection of liquid-filled transformers using mineral oil or synthetic fluid to meet your needs at DAELIM. For your extensive distribution transformers, we intend to provide the efficiency required in industrial and commercial applications.

Are you unsure which transformer is best for you? Contact us, and we’ll provide you with a liquid-filled transformer that will meet your power needs while saving you money.

ELECTRIC, WITH AN ENGE-- DAELIM BELEFIC