ELECTRIC, WITH AN EDGE

Electric Utility Pole Transformer is critical components of the transmission and distribution energy infrastructure. Transformers reduce higher voltage energy carried by primary lines for usage. Besides, they convert high-voltage electricity power plants generate to lower-voltage electricity utilized in companies, offices, and residences.

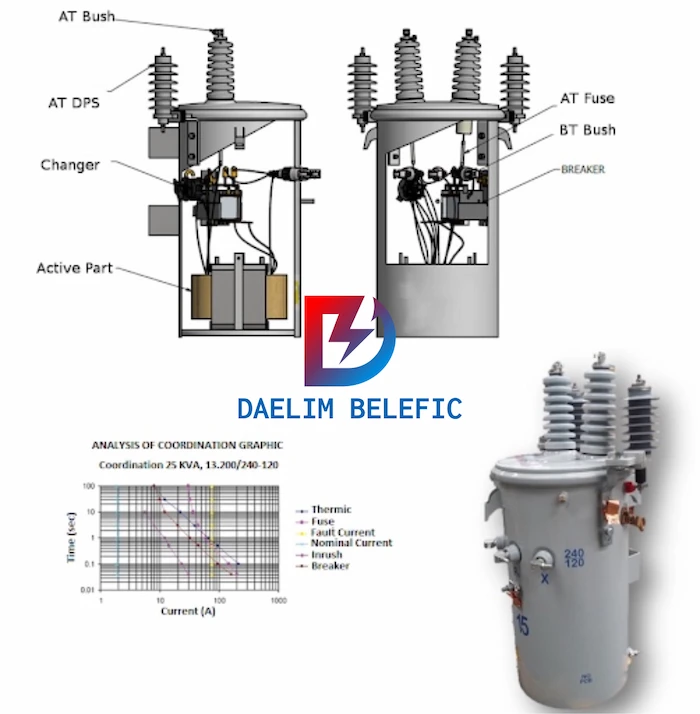

DAELIM provides the most up-to-date information on utility pole transformer features, protection, applications, ratings, and maintenance. All of which may be used immediately to make your utility as cost-effective and practical as possible. Let’s look at how it works in more detail!

Welcome to Daelim Belefic, a leading manufacturer of power pole transformers for over 15 years. At Daelim Belefic, we are committed to providing our customers with high-quality electrical equipment that meets and exceeds their expectations.

We understand that the reliability and safety of power distribution is critical to the success of your business. That’s why we invest in the latest technology, machinery, and facilities to produce transformers that are efficient, safe, environmentally friendly, and low in life cycle costs. Our expert team, including electrical engineers, CAD draftsmen, and skilled technicians, controls every process from product development to design, production, and manufacturing to ensure we achieve our goals.

At Daelim Belefic, we strictly implement the concept of “DAELIM EDGE+ ADVANTAGE.” This allows us to provide our customers with multiple standards, cutting-edge service, and speed, all while delivering customized solutions that meet their specific needs.

We also take pride in our investments in research and development, which enables us to develop innovative transformer product solutions that help clients reduce costs and create new values. We are familiar with international transformer standards, such as IEC, ANSI/IEEE, CSA, and more, and use them to develop products that meet the technical requirements of our clients.

Quality is at the core of our values, which is why we have strict quality control measures in place. We carry out three different quality tests, including type tests, FAT tests, and inspection tests, to ensure that our transformers meet the highest standards of reliability and safety. We also strictly implement the ISO 9001 quality management system to ensure we deliver the best products to our clients.

At Daelim Belefic, our dedicated customer service, product innovation, engineering excellence, and strong sense of social and environmental responsibility have made us a valued and trusted power solutions partner for the global electric industry. We take pride in our goal to become a leader in the transformer industry in China and around the world.

Choose Daelim Belefic for high-quality power pole transformers that meet your needs and exceed your expectations. Contact us today to learn more about our products and services.

An electric pole transformer is an electric utility distribution transformer. It’s mounted on an electrical service pole made of wood or concrete. Usually, it is attached at the level of overhead cables.

The 16 kVA to 100kVA electric pole-mounted transformers range transforms 11,000 to 33,000 volts down to 400 lower volts.

Electric pole transformers are the standard breadbox transformers. They are used for converting distribution voltage to 120/240-volt power. Homes and low-volume commercial installations commonly use it.

Standard appliances are not designed to handle high current levels, a transformer can scale down high voltage levels to a much lower value. In addition, it provides a convenient way to measure and monitor electrical current safely.

Utility pole transformers are also known as pole-mounted step-down transformers. They are often located at the level of overhead wires. What’s more, utility pole transformers are used to convert distribution voltage to the 120/240 V electricity residences, and business installations utilize. It has reasonable voltage control and runs 24 hours a day with a maximum efficiency of 50% at full load.

DAELIM is one of the world’s leading professional transformers and electrical equipment manufacturers. For 15 years, DAELIM has been serving the electric industry with inexpensive and quality equipment. They have been following international standards like ANSI, IEEE, IEC, CSA, AS/NZ, etc.

The brand was built around a concept called DAELIM EDGE+ADVANTAGE. An idea aims to deliver multiple standards, cutting-edge service/ speed, and expert-level customization skills.

Utility pole transformers are also known as electric transformers mounted on a pole. These transformers change the phase of electrical voltage, generally stepping down the voltage ratio from higher to lower. This is achieved by using the principle of magnetic induction to transform voltage and current levels between coils.

Utility pole transformers are commonly used to reduce distribution-level voltages, such as 12000V to 120/240V, to supply residential loads close to the transformer. It is achieved when primary wires run from a substation to the top of the pole carry 12,000 volts of power. After passing through the transformer, the lower voltage electricity is taken via the secondary wire.

A transformer trades voltage for current in a circuit while not affecting the total electrical power. It takes high-voltage electricity with a slight current. It changes it into low-voltage electricity with a large current or vice versa. Transformers only work for Alternating Current (AC), such as you get from your wall plugs, not Direct Current (DC).

Transformers increase or decrease the voltage. Transformers use two coils of wire wrapped around a metal core. The first coil is for the incoming electricity. While the other is for outgoing electricity. Alternating Current in incoming coil sets up an alternating magnetic field in the core. This generates Alternating Current in the outgoing coil.

First, using a transformer, the electricity voltage from a power plant is “stepped up” to the right level for long-distance transmission. Because high-voltage current can arc, step-up transformers called ignition coils. They power spark plugs. Dynamos at power plants generate large currents but not too high voltage. This electricity steps up to high voltage for transmission over wires. As electricity travels more efficiently at high voltage.

After that, the voltage is stepped down. A “step-down” transformer changes the 440-volt electricity in power lines to 120-volt electricity you use in your house. Then, the current can be used at that level for devices like light bulbs. It is converted to DC using an AC/DC adapter for devices like laptop computers.

All transformers share some standard features regardless of their type:

On the other hand, an electric pole transformer has a low voltage bushing insulator available in fiberglass reinforced polyester material or porcelain (both eyebolt and spade terminals). Low-voltage neutral grounding strap (furnished on 10 – 50 kVA single HV bushing units)

The cover has 15 kV dielectric insulation and increased resistance to corrosion. In addition, the body is sloped 15°, preventing water from collecting and reducing corrosion and leaking.

Utility pole transformers are small and light. They are simple to install on single-pole structures and larger units on two-pole structures approximately 5 meters above the ground. Likewise, it keeps the transformers inaccessible, reducing the risk of animal and human damage as well as vandalism. Below are other features of a utility pole transformer.

Utility pole transformers are exposed to harsh weather conditions, and durability has been included in the specification. The tanks are designed to prevent the accumulation of water and corrosive compounds. Corrosion-resistant coatings are applied, and tanks in coastal regions are zinc sprayed. Tanks in highly corrosive environments are composed of stainless or 3CR12 steel.

Utility pole transformers are electrified 24 hours a day: thus, minimizing iron losses is critical in their design. They are intended to function at optimum efficiency at lesser loads since they are rarely used at full load. Voltage regulation in these transformers should be maintained to a minimum to enhance efficiency. As a result, they’re made to have a low leakage reactance.

Utility pole transformers with primary and secondary windings might be made of copper, aluminum, or a combination of the two materials. Resin-impregnated paper is used to insulate the windings. To add to it, the whole assembly is baked to cure the resin before being submerged in a powder-coated steel tank filled with inert and non-conductive transformer oil.

Besides cooling and insulating the windings, the transformer oil also protects them from moisture that floats on the oil’s surface. So during manufacturing, the tank is temporarily emptied to eliminate any leftover moisture that may induce arcing, and the top is sealed against the elements using a gasket.

The primary and secondary wire windings are wrapped around the magnetic core, formed of laminations of sheet silicon steel stacked and either bonded with resin or steel straps. This core design is intended to decrease core losses or the dissipation of magnetic energy as heat in the core, which is a significant source of power loss in utility grids.

Eddy currents and hysteresis loss in the steel both contribute to core losses. Silicon steel has a low hysteresis loss. What’s more, the laminated structure, on the other hand, prevents eddy currents from passing into the core and dissipating power in the steel resistance.

Surge arresters and safety fuse connections are frequently included with utility pole transformers. An internal fuse and surge arrester are included in a self-protected transformer. Now, these components are installed independently outside the tank in conventional transformers.

Utility pole transformers are an essential part of the chain of facilities that deliver electricity to residences and commercial buildings. Transformers boosts the voltage of electricity from a power plant before transmitting it across long-distance transmission lines. Other transformers lower the voltage to a level that home appliances can utilize, first in substations and subsequently in communities.

Its lone application and function are to supply safe electricity for the everyday use of appliances and devices. Then, the final voltage transformation in the electric power distribution system is provided by a utility pole transformer, which steps down the voltage used in the distribution lines to the level utilized by the customer.

Electricity is an integral part of many people’s daily lives. As a result, transformers have evolved to play an essential role in generating and distributing electrical power. Besides, transformers regulate electricity by modifying current to run from one electric circuit to another.

All transformers have one primary function: increasing or decreasing alternating current within the electrical system. By regulating the current flow, the transformer allows for increased energy efficiency, which governs and ultimately lowers electricity bills.

Transformers are also helpful in stopping the flow of electricity and interrupting an electric current. Transformers are commonly present in circuit breakers. They use a switch to automatically interrupt the flow of electricity and prevent damage due to high voltage.

The functioning of generators fuels battery charging mechanics. Transformers control the voltage that enters the battery during the charging process to prevent any internal battery component damages. It is essential because an unregulated voltage can result in high surges during the charging of batteries.

Steel manufacturing plants rely on high voltage transformers to provide a range of voltages for the manufacturing process. For example, high currents are required for melting and welding of steel, and lower currents are required during the cooling process. It provides this range of voltages for regulating currents within the system.

In chemical engineering and manufacturing, electrolysis gets fuelled by the functioning of transformers. Metals such as copper, zinc, and aluminum are typically used for electroplating.

Transformers provide a regulated electrical current to drive the chemical reaction from the beginning stages until completion. The current can therefore be regulated as the reaction proceeds.

Utility pole transformers typically have capacities of less than 200 kVA. The voltage ratings are 11kV, 6.6kV, 3.3kV, 440v, and 230 volts, respectively. But, specific national standards allow for distribution transformers with up to 5000 kVA.

The price of a utility pole transformer is based on the average cost of one assembly. Accessories such as the pole, cross-arm, capacitor, insulator, lightning arrester, meter, and other accessories are not included in the price. So depending on how much electricity they’re designed to handle, they cost anywhere from $3,000 to $7,000 each.

Power lines are strung between utility poles in urban areas. It goes from 4 to 25 kilovolts or less. At this voltage, touching a power line can already cause severe injuries. At times, the wound left by electricity exiting the body can cause such severe damage.

This electric shock this large can stop your heart. What’s more, tree branches that come in contact with a power line energize the tree and the ground around it. So it creates a very hazardous situation.

That’s why it’s essential to choose a brand of transformer that significantly focuses on quality. It will guarantee that you are safe from any hazardous instance.

At DAELIM, you are guaranteed to get quality transformers that are hazard-free. Being in danger while using an electric pole transformer is the last thing that will cross your mind.

Electricity is important, but it is also dangerous. Utility poles are indistinguishable from our surroundings. If they’re close to your house, likely, you won’t see them. Hence, you need to keep a safe distance from a utility pole if one is nearby. But what exactly are the risks they pose to you and your family?

Transformers converts high voltage to low voltage. Thus, various sorts of cables and connections will be connected and carried by a utility pole. More so, high-voltage primary lines that carry up to 500 kilovolts travel to substations and rest at the top of the utility poles. For safety, a utility pole is usually 35 feet tall and can be anywhere from 20 to 100 feet tall, depending on the circumstances.

Most utility poles are made from wood, and they are vulnerable to environmental conditions and insect damage. Due to these damages, they might lean and break off, forcing the transformer to fall to the ground. Thus, it is essential to observe utility poles and report them once you notice an excessive leaning.

When the utility poles fall, electricity wires will fall with them. The voltage on these power lines is usually between 4 and 25 kilovolts, enough to inflict severe injury or even death. Also, tree branches that come into contact with electrical wires can energize the tree and the ground, making the entire region dangerous. It is important to keep your distance from fallen utility poles to avoid electric shock.

Electrical currents can flow through the soil and metal on surfaces when the wires are linked to the ground. It includes lamps, fire hydrants, and utility hole covers, among other things. Touching the said surfaces can get you electrocuted.

To ensure that utility poles last as long as possible, they are coated with chemicals before being placed. These chemicals have an impact on both humans and animals.

If you give a transformer the amount of electricity it was meant to handle, it will survive approximately 50 years. If too much electricity is sent through the transformer for an extended time, it may overheat or catch fire. It is because the wire can generate heat and a spark if it becomes overcharged. This massive overpressure might eventually force the transformer to burst or explode.

First, a transformer should be installed with the front (doors) facing away from the building, with no balconies or overhangs above. Second, the transformer must also be accessible to line trucks (The size and weight of a cement truck) for maintenance or replacement.

Generally, a transformer near a building requires 4ft clearance from the vertical building surfaces, assuming no windows from grade to 18ft. In addition, the sides of the transformer must be clear of all objects for 3ft, including landscaping. More so, transformers must be 10ft horizontal from doors, windows, or fire hydrants.

The transformer’s front (door side) shall have a 10 ft. clearance. This ensures line crews safely perform maintenance or repairs on the. This clearance requirement includes landscaping. When it comes to landscaping during emergency repairs, the utility can remove the landscaping or leave and await notice when offending vegetation has been removed.

The utility will not attempt to work on the transformer during routine maintenance until the landscaping has been removed.

Suppose you put a secondary coil of wire next to the first and send a fluctuating electric current into the first coil. In that case, you’ll create an electric current in the second wire. The electric current in the first coil is usually called the primary current. At the same time, the current in the second wire is the secondary current.

Note: This trick works only if the electric current fluctuates somehow. In other words, you have to use a constantly reversing electricity called alternating current (AC) with a transformer.

Utility pole transformers are part of our electric grid system. It is an electrical device that changes the voltage flowing through a power grid at any point. The transformer reduces the voltage passing via power lines to be more suited for home and commercial use.

Remember, it’s worth noting that these transformers allow you to live in peace without fear of what’s happening inside the electrical lines that run right above our heads every day. Utility pole transformers are tiny engineering marvels that play a large part in the electrical system.

At DAELIM, we will assist you in powering your home and business using safe utility pole transformers. Do you have any more questions concerning the utility pole transformers in your area? Give us a call today!

A power pole transformer is an electrical device that is used to convert high-voltage electricity into lower voltage levels that can be safely used by homes and businesses. It is mounted on a pole and is an essential part of the electrical distribution system.

A power pole transformer is an electrical transformer that is mounted on a power pole or utility pole, typically at the top or near the top of the pole. It is used to convert high voltage electricity from power lines to a lower voltage that can be used by homes and businesses. The transformer is usually connected to the power lines via high voltage cables and to the customer’s service line via a low voltage cable. Power pole transformers come in different sizes and voltage ratings depending on the needs of the customer and the electrical load that they need to support. They are commonly used in urban and suburban areas, but can also be found in rural areas with overhead power lines.

There are different types of power pole transformers available, depending on the specific needs and requirements of the distribution system. Some of the most common types of power pole transformers include:

Single-phase pole-mounted transformers: These are used for low voltage distribution and have a rating of less than 25kVA.

Three-phase pole-mounted transformers: These transformers are used for medium voltage distribution and are generally rated between 25kVA and 500kVA.

Pad-mounted transformers: These are larger transformers that are mounted on a concrete pad instead of a pole. They are commonly used for underground distribution and can be either single-phase or three-phase.

Substation transformers: These are the largest transformers and are used to step down high voltage power to lower voltage levels for distribution to homes and businesses.

The type of transformer used depends on the specific requirements of the electrical distribution system. It is important to select the appropriate transformer type, size and capacity to ensure reliable and safe power distribution.

Power pole transformers are generally not considered dangerous when they are functioning properly and are well-maintained. However, there are potential hazards associated with power pole transformers, particularly if they are damaged or mishandled.

For example, if a power pole transformer is damaged by a storm or other external factor, it can potentially leak oil, which can pose an environmental hazard if it is not contained and cleaned up properly. In addition, electrical fires or explosions can occur if a power pole transformer is not installed, operated, or maintained correctly.

It’s important to note that power pole transformers are designed and manufactured to meet strict safety standards and are tested extensively before being put into use. However, it is essential that they are properly installed and maintained to ensure safe operation.

If you suspect that a power pole transformer is damaged or malfunctioning, it’s important to contact a qualified professional immediately to assess the situation and take appropriate action.

The amount of copper in a power pole transformer can vary depending on the transformer’s design and specifications. Copper is one of the primary materials used in the construction of power transformers due to its high conductivity and ability to efficiently transmit electricity.

Typically, the amount of copper in a power pole transformer ranges from several hundred to several thousand pounds. The exact amount of copper used can depend on the transformer’s voltage rating, power capacity, and the specific requirements of the application.

In general, larger transformers used in high voltage power transmission systems contain more copper than smaller transformers used for local distribution systems. The amount of copper used in a transformer also affects the cost of the transformer, with larger transformers containing more copper and therefore being more expensive.

It’s worth noting that while copper is a valuable material, the value of the copper used in a power pole transformer is generally small in comparison to the overall cost of the transformer. The primary cost of a transformer is in the design, engineering, and construction of the transformer itself, rather than the materials used.

The price of a power pole transformer can vary widely depending on its size, capacity, and other specifications. Generally, smaller transformers with lower capacities can cost a few hundred dollars, while larger transformers with higher capacities can cost tens of thousands of dollars.

Factors that can affect the price of a power pole transformer include the type of insulation used, the quality of the core materials, the complexity of the wiring and connections, and the level of customization required. In addition, the cost of labor and manufacturing can vary depending on the location of the manufacturer and the availability of raw materials and skilled workers.

It’s important to note that while cost is an important consideration when purchasing a power pole transformer, it should not be the only factor. It’s crucial to choose a high-quality transformer that is designed to meet your specific needs and is manufactured to the highest standards of quality and safety. Choosing a reliable and reputable manufacturer like Daelim Belefic can help ensure that you get a transformer that meets your needs and is built to last.

ELECTRIC, WITH AN ENGE-- DAELIM BELEFIC

After filling in the contact information, you can download the PDF.