How to Choose Pad Mounted Transformer?

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical

ELECTRIC, WITH AN EDGE

portable electrical substation belongs to the manufacturing technology field of special substations in the power system, and is an effective emergency power supply solution, mainly used for transforming class substations, improving safety operation level, guaranteeing uninterrupted power supply, and solving the problems of transforming substations with all kinds of electric transformation transition construction, large workload, high construction difficulty and long construction period.

The use of mobile substation will effectively reduce the substation transformation outage time, can be in the case of accidents, emergency repair and natural disasters, rapid replacement of conventional substations, play the role of emergency power supply.

Vehicle-mounted mobile substation belongs to the special substation in the power system, is a small substation with electrical secondary equipment organically integrated and installed on one to more semi-trailers, can replace a small substation for power supply, and has protection, monitoring, remote functions.

With the continuous development of social economy, the number of large load users is increasing, the load density is growing faster, and the users have higher and higher requirements for the continuity and reliability of power supply.

Vehicle-mounted mobile substation is a substation that installs the electrical primary equipment and electrical secondary system of traditional substations in a flatbed trailer or container, which is mobile and flexible with a small footprint, suitable for a variety of places and can solve a variety of sudden changes in power demand. In particular, mobile substations with conventional capacity of 10~40MVA, 35kV and 110kV can greatly improve the reliability of power supply, which is an effective solution to reduce the average power outage time of customers and is in line with the development trend of the new generation of intelligent substations.

Portable Electrical Substation has been developed for decades, and Portable Electrical Substation has a wide range of applications. In recent years, Portable Electrical Substation with primary rated voltage of 66~132kV and capacity of 20~50MVA has been put into operation, which has reached the capacity and voltage level of conventional substations in medium-sized urban power grids.

At present, the international Portable Electrical Substation with the highest voltage of 245kV and the largest capacity of 63MVA is manufactured by Siemens in Italy and applied in Ethiopia.

portable electrical substation is an effective emergency power supply equipment, generally consists of transformer trolley module, distribution vehicle module and other optional modules, consisting of HGIS high-voltage combined electrical apparatus, main transformer, medium voltage switch, integrated automation system, transport vehicle body and other functional units, etc., with high integration, reliable performance, small footprint, transport It is characterized by high integration, reliable performance, small footprint, convenient transportation and very good rapid arrangement.

The portable electrical substation is a major solution for emergency response planning.

With very good flexibility to ensure the emergency rescue and other work, temporary conventional substation in time and scale is not possible, in special times, mobile substation to assume a special emergency role, can quickly replace the conventional substation, play the role of emergency power supply.

Since all the equipment of portable electrical substation is tested for pre-assembly, pre-coupling and pre-generation, it can be put into operation within a few hours.

At present, the design and production capacity of 35kV mobile substations of 5MVA to 20MVA capacity and 110kV mobile substations of 20MVA and 31.5MVA capacity are very mature, widely used and experienced in operation, and can meet the needs of most of the power emergency power supply and planned load transfer.

The design and production capacity of 110kV mobile substations with 40MVA capacity are basically mature, and five of them have been put into operation in China.

However, the 50MVA/110kV mobile substation and higher voltage substations are more powerful, more adaptable, and more economically and socially beneficial.

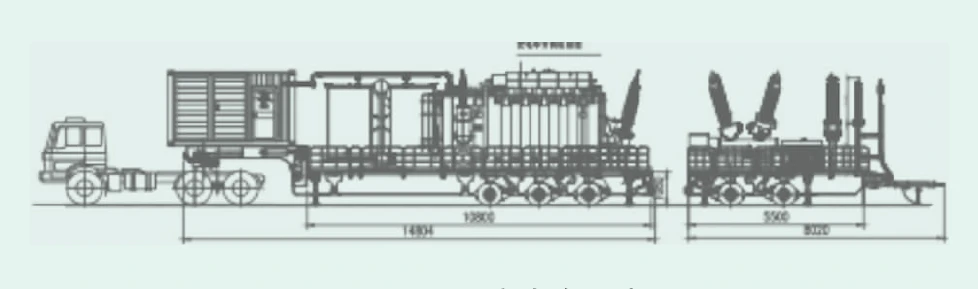

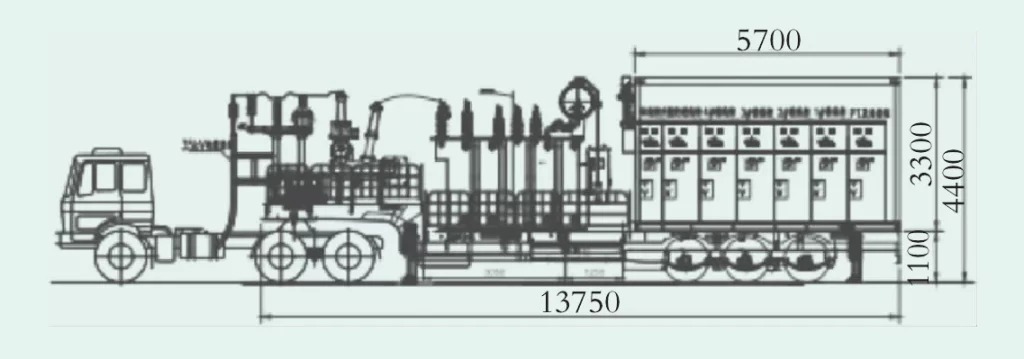

This paper designs a 50MVA capacity class 110kV truck-mounted mobile substation, which consists of main transformer truck, HGIS truck and medium voltage distribution truck, and adopts a two-truck, three-truck free combination scheme.

The mobile substation is mainly composed of five modules: main transformer module, 110kV composite combined appliance HGIS module, 10kV low-voltage side inlet switch room module, 10kV box-type switch station module and trailer module.

According to the structure form of line transformer group, the main equipment includes high voltage arrester, HGIS, power transformer, 10kV flexible cable, 10kV switchgear, AC/DC integrated power supply system, measurement, monitoring and protection system, and secondary cable. It is also equipped with 110kV high-voltage cables, 110kV overhead line brackets, grounding wires, lighting, air conditioning, fire-fighting facilities, and grounding rod mobile escalators.

Compared with other wiring forms, the line transformer group way less equipment, investment saving, easy operation, so the line transformer group wiring way.

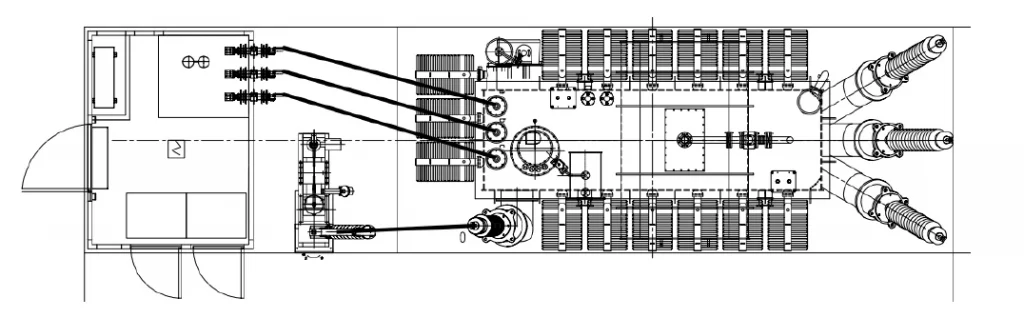

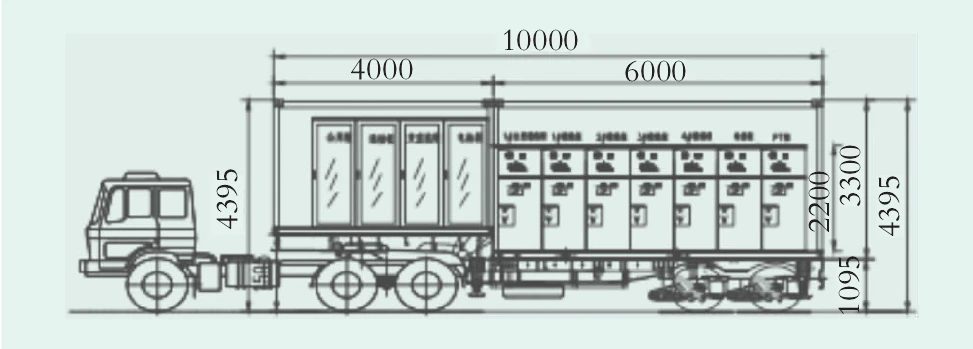

In order to facilitate the protection of the main transformer and minimize the connection cables between the trailers, the high voltage side, main transformer and low voltage side are combined in one trailer, i.e., the portable electrical substation. portable electrical substation mainly consists of the main transformer module and the 10kV low voltage side inlet switch room module, as shown in Figure 1. This is shown in Figure 1.

Due to the size and weight limitation of the mobile substation, the main transformer module adopts a two-winding three-phase on-load regulator power transformer with a voltage level of 110/10.5 kV and a capacity of 50 MVA. In order to minimize the box, reduce the length of the trailer and improve the economy, the 10 kV low-voltage side inlet switch room module adopts one inlet cabinet, one main transformer screen and one wall-mounted DC power supply system, which mainly consists of It mainly provides operation and control power for HGIS combined electrical appliances and low-voltage side circuit breakers, and also provides power for main transformer protection.

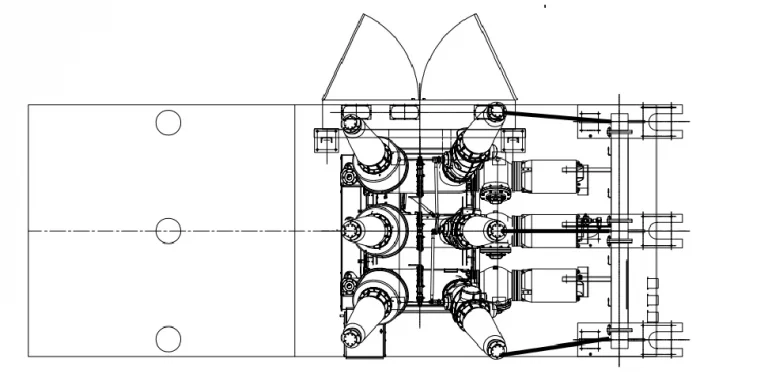

The HGIS vehicle is mainly composed of 110kV composite combined apparatus HGIS module and lightning arrester.

The composite combined appliance HGIS is an advanced combined SF6 high-voltage switchgear that combines the advantages of open and enclosed switchgear, integrating circuit breaker, isolation/earthing switch, current transformer, voltage transformer and sink control cabinet into one module, and the communication protocol follows IEC61850, which occupies less space, is easy to install and commission, and is maintenance-free.

When the mobile substation in substations and other places with lightning rod operation or storage, if the protection range of the lightning rod can cover the location of the mobile substation car, do not design a special lightning rod protection, in places without lightning rod, you can use the mobile tower lightning rod to achieve lightning protection.

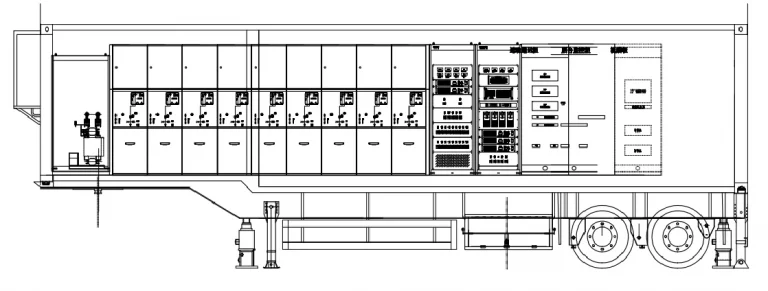

The medium-voltage distribution vehicle mainly consists of 10kV box-type switchgear station module, containing 10kV switchgear, small resistance grounding device and integrated automation system, etc., separated by partitions in the middle and separate compartments. The comprehensive automation compartment contains AC/DC screen, battery screen, public measurement and control screen, monitoring system screen and communication screen.

The external communication adopts wireless public network communication, and a set of station GPRS communication equipment is equipped with TCP/IP protocol for direct and convenient network access; the physical link data of GPRS is transmitted with encryption, and the monitoring center is directly connected to the GPRS network, which is essentially an intranet solution, and all data are isolated from the INTERNET, greatly enhancing the security of information.

The dispatching side is separately configured with dispatching monitoring computer, which is not networked with the power system dispatching and has no influence on the power dispatching network.

In addition to install air-conditioning equipment in the box, thus creating a very ideal working environment for the primary equipment and microcomputer integrated automation protection devices.

In order to protect the station equipment and personal safety, comprehensive consideration of the substation grounding network of the use of years, ground network materials, grounding resistance, geological conditions, humidity and temperature and other natural factors, to vertical grounding pole of the artificial grounding network, set grounding terminals on the car body of the mobile substation, in the substation when received substation reserved grounding terminal, such as in other power-using areas of operation shall be set in the substation car parking position vertical Grounding pole and horizontal grounding pole.

portable electrical substation and HGIS car in road conditions allow, the whole by a head traction transport, narrower roads, traffic can also be separately traction, portable electrical substation and HGIS car can be used independently, to achieve two cars three cars free combination mode.

Based on the special characteristics of vehicle-mounted mobile substation that needs to move frequently, involving road bumps during transportation, construction and installation and safe operation considerations, the equipment inside the box is fixed, and the substation is designed according to the basic seismic intensity of 7 degrees.

110kV composite combined electrical HGIS access to the power system, there are overhead line access and cable wiring 2 access methods, can adapt to a variety of cases of portable electrical substation access.

For the main transformer module, the incoming and outgoing lines on the high voltage side are connected to the composite combined appliance HGIS module using overhead conductors or factory prefabricated integral cable terminations.

On the low voltage side, the incoming and outgoing lines are connected to the medium voltage switch incoming and outgoing lines on the low voltage side using overhead conductors or factory prefabricated integral cable termination joints and cables.

Considering the rated current and cable wiring, the 10kV high-voltage switchgear is connected to the busbar bridge overhead, and the connection part is considered to have a certain adjustment capacity, i.e., Ω bend or soft connection, considering the force on the busbar during transportation. 10kV compartment switchgear is connected to the cable inlet and outlet, one inlet, six outlets, one PT cabinet and one transformer cabinet.

The incoming and outgoing lines of the entire portable electrical substation are connected by cables, and the cable compartment is connected to the cable trench with measures to prevent small animals from entering. The installation position of cable head and connection method are considered for easy dismantling and wiring during maintenance and test. The height of the lower end of the cable terminal from the bottom of the switchgear ≥ 500mm.

Trailer design to meet the following requirements: (1) to ensure the height of cable access, the trailer chassis from the ground should not be less than 1200mm.

(2) to ensure road transport, the trailer width should not be greater than 3500mm, traction ring diameter, traction point height should be matched with the tractor head, to ensure reliable towing.

(3) The trailer circuit system adopts the standard seven-hole socket, and the signals such as steering and braking of the trailer are realized by connecting the electric socket at the end of the head.

(4) in order to ensure sensitive braking, the trailer’s own air system uses a double-pipe air break braking with air storage tanks, and the connection with the tractor head using standard air self-sealing quick-change couplings.

(5) the trailer configuration of the towing hook point, socket, brake joints should be good moisture, rain and other protective measures when not in use.

(6) the trailer is easy to walk and turn freely when hauling, and consider anti-vibration and vibration reduction measures, so as not to damage the equipment due to transportation and affect normal work and operation.

(7) the trailer fixed with “H” bracket, screw legs, use and parking tires suspended; (8) with the operating platform, the usual operation of the trailer, the trailer will be used to support the “H” bracket, screw legs.

(8) with the operating platform, usually when not in use can be put away to reduce space, and configured with guardrails to ensure the safety of operators and maintenance personnel.

(9) Install online vibration, acceleration and positioning monitoring equipment to monitor the dynamic response to the vibration and acceleration characteristics of the transport road of the mobile substation, so as to realize the structural design control and dynamic monitoring of the on-board stability and safety of the mobile substation.

The number of medium and low voltage circuits is an important parameter in the demand of vehicle-mounted mobile substation, which determines the composition of the vehicle-mounted mobile substation to some extent. A separate medium voltage distribution truck is generally required for 10kV 5-turn and above lines.

The main transformer protection is considered in a purely conventional way. Separate configuration of differential protection, high back-up protection and testing device, low back-up protection and testing device, non-electricity and operation box, propriety measurement and control.

The above equipment need to form a separate screen cabinet, considering that the main transformer is placed in the high-voltage car body and the cables are mostly concentrated in the high-voltage car, this screen cabinet is placed in the high-voltage car body. 10kV adopts the integrated protection and measurement device, which is installed in the switch cabinet of the medium-voltage car body.

The manufacture of portable electrical substation should be based on the specific regional environment, roads and transport distances as design conditions to meet the special conditions and technical parameters to ensure that all equipment of portable electrical substation is in good condition and can be put into the grid for a short period of time ” requirements. portable electrical substation seismic design equipment should have several conditions.

(1) each main equipment support frame design solid.

(2) transformer selection and arrangement to try to reduce the height in order to reduce the weight of the vehicle.

(3) For high-voltage switchgear to reduce its installation height and center of gravity position, change the slenderness ratio.

(4)when the road condition is bad and strong vibration is received, the metal structure and reinforcement point of electrical equipment installation should not be deformed and damaged.

Distribution device and transformer in the corresponding in the same line and located in the trailer axis, electrical safety distance should be in line with the provisions of the following table.

The distance between equipment on portable electrical substation should ensure that various transport processes do not collide, to ensure that the equipment disassembly and installation spacing and a simple inspection channel, the distance should meet.

(1) high-voltage side arrester and cable terminal center distance: ≥ 600mm.

(2) HGIS equipment and lightning protection casing between the net distance: ≥ 600mm.

(3) transformer and HGIS equipment net distance: ≥ 1000mm.

(4) transformer and medium-voltage power distribution installation net distance: ≥ 1000mm.

The minimum width of the channel of the distribution panel: The minimum width of the channel in front of and behind the distribution panel arranged in rows shall comply with the following regulations.

To ensure the safe operation of the vehicle-mounted mobile substation, the safety protection requirements are as follows.

(1) A fixed fence of not less than 1.7m high around the vehicle-mounted mobile substation for engineering purposes.

(2)When the height of the bare charged body above the channel of the medium voltage switch control room of the vehicle-mounted mobile substation is lower than 2.3m, it should be shielded.

When operating a truck-mounted mobile substation, the following points should be noted.

(1) transformer fire prevention, substation flatbed truck should be set up on the inflow of oil facilities and oil blocking facilities.

(2) All types of medium-voltage systems should be taken to eliminate measures.

(3) Line side voltage transformers and simultaneous devices should be installed to prevent non-simultaneous parallel or non-simultaneous ring operation.

(4) in order to avoid the threat to the personal safety of staff, can increase the temporary grounding measures to reduce the grounding resistance.

The voltage level of the vehicle-mounted mobile substation is usually 35~110kV, while the distribution vehicle is 10kV.

All the high and low voltage electrical equipment of the truck-mounted substation is installed on a flatbed truck, so there are specific requirements for the equipment: the vibration resistance is high, and the high voltage side generally uses HGIS with better vibration resistance, and GIS is not recommended.

This is due to the large size of the GIS, the equipment must be fixed to the car body at multiple points, and the internal busbar of the equipment is a hard connection structure, so the car in the exercise process, due to the inconsistent vibration amplitude of the body, may cause the deformation of the switchgear and conductor stretching or extrusion, causing safety hazards to the product.

The HGIS has fewer support points with the body, so when the body vibrates, the equipment as a whole vibrates at the same frequency and synchronously, effectively overcoming the potential deformation and damage of the equipment and conductors.

For medium voltage switchgear, HGIS or fixed medium voltage cabinets with anti-vibration function are used.

Vehicle transformer capacity is usually 10MVA, 16MVA, 20MVA, 31.5MVA, if used near residential areas, should consider using low-noise transformers, for transport vehicles or roads and other conditions must reduce the weight of the transformer, you can use the cooling method of oil circulation. In order to improve operational reliability, when selecting transformers, try to use fully insulated transformers. When there is a large capacity demand, 2 transformers can be used in parallel, at this time to meet the load of 60%.

(1) 110kV portable electrical substation and 10kV distribution vehicle are 2 separate vehicles, as shown in Figure 1 and Figure 2. The 110kV portable electrical substation needs the 10kV distribution vehicle to be used, and the connection between the 110kV portable electrical substation and the 10kV distribution vehicle is realized by configuring the navigation plug adapter cabinet and the 10kV flexible cable.

(2) High voltage transformer module: 1 set of HGIS transformer, 1 set of electromagnetic voltage transformer, 1 set of zinc oxide surge arrester.

(3) Main transformer module: 1 set of 110kV three-phase double-winding self-cooling on-load regulating transformer with capacity ≤ 40MVA and voltage ratio of 110/10.5.

(4) 10kV box-type power distribution module.

①10kV switchgear: XGN fixed cabinet/C-GIS inflatable cabinet can be used, the switchgear contains 1 incoming cabinet, 4-8 outgoing cabinets, 1 TV cabinet, 1 station transformer cabinet.

②Electrical secondary equipment: main transformer protection measurement and control cabinet, remote communication cabinet, GPS backstage monitoring and five prevention system metering system, AC-DC integrated power supply cabinet, common cabinet aerial plug-in transfer cabinet, etc., to achieve unattended.

(3) Cabin: prefabricated cabin with protection grade IP54, equipped with air conditioner, fan, lighting, smoke sensor, etc., and independent chambers for primary and secondary equipment respectively, isolated by explosion-proof wall.

(5) It is suitable for the area under 2000 meters above sea level, and the 110kV inlet line is overhead wire or cable.

(1)35kV substation and 10kV distribution device share one vehicle, as shown in Figure 3. The substation and distribution device can operate independently and have the complete substation function.

(2) High-voltage combined appliance module: 1 set of HGIS combined appliance, 1 set of electromagnetic voltage transformer, 1 set of zinc oxide arrester.

(3) Main transformer module: 1 set of 35kV three-phase double-winding self-cooling on-load regulator transformer with capacity ≤10MVA and voltage ratio 35/10.5.

(4) 10kV distribution device and secondary equipment module: XGN fixed cabinet/C-GIS inflatable cabinet is used for 10kV, 1 inlet cabinet, 4 outlet cabinets, 1 TV cabinet, 1 station transformer cabinet; secondary configuration includes: main transformer protection and control cabinet, monitoring and remote control cabinet, AC/DC integrated power cabinet, metering meters, etc., which can be unattended.

(5) It is suitable for the area below 2000 meters above sea level, and the 35kV incoming line is overhead wire or cable.

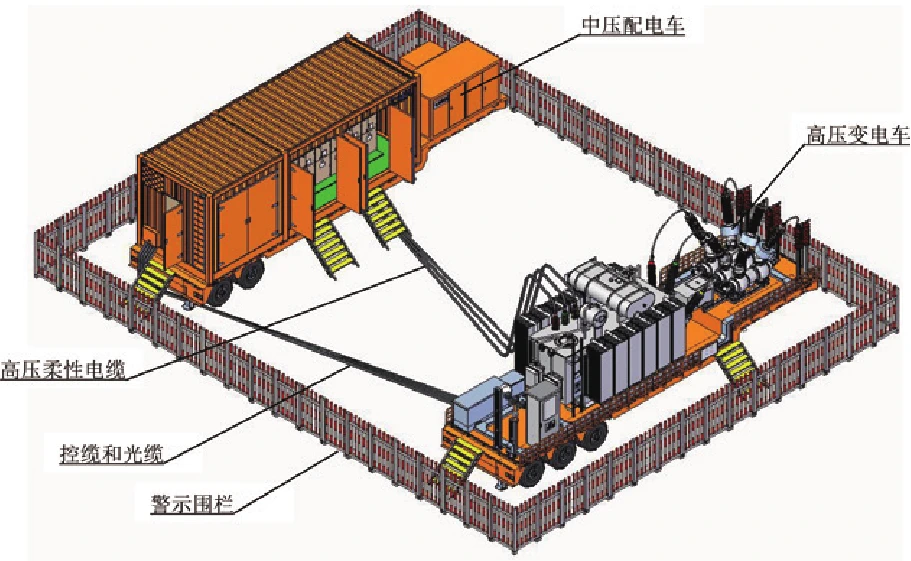

Portable electrical substation generally consists of three parts: high voltage transformer trolley, medium voltage distribution trolley, and cable connection. The high-voltage substation consists of high-voltage switchgear module, power transformer module, auxiliary system module and transportation module, the first three of which are uniformly installed on the trailer.

The medium-voltage distribution vehicle consists of medium-voltage switchgear module, intelligent integrated control module, auxiliary system module, and transportation module, of which the first three are uniformly installed in the prefabricated cabin, which is then fixed to the trailer.

The cable connection part is composed of cable winch, high-voltage flexible cable and control cable. At the time of commissioning, the cable connection section establishes the connection between the high and medium voltage power systems through the terminal boxes installed on the high voltage transformer truck and medium voltage distribution truck respectively.

Each module is prefabricated, assembled and commissioned in the factory, and is already a fully functional substation when it leaves the factory.

The advantages of portable electrical substation are reflected in the ability to quickly commission and restore power supply in emergency situations such as natural disasters and sudden failures, so the selection should be combined with the voltage level, transformer capacity, number of feeders and other factors of the existing substation.

In cold areas, 66kV dual coil oil transformer should be preferred, with a capacity of 20MVA, and the number of feeders should be 4~6 intervals.

The form of transport load is low flat semi-trailer body to adapt to a variety of site conditions and transport environment. The protection and control system should be connected by optical fiber or cable. The AC power supply mode adopts one main and one backup, and the backup power supply is external diesel generator or consider distributed PV micro-grid system.

High-voltage transformer tram part

The high-voltage transformer tram consists of high-voltage switchgear module, power transformer module, auxiliary system module and transportation module, the first three of which are uniformly installed on the trailer.

The high-voltage switchgear module of 66kV has a single equipment configuration, usually HGIS equipment, whose small size and flexible application characteristics are given full play in the portable electrical substation.

In order to realize the monitoring of incoming voltage and current, external current and voltage transformers are generally installed in the incoming and outgoing bushings. As the 66kV high-voltage switchgear uses HGIS, which is filled with SF6 gas and is a pressure vessel, it needs to be transported at reduced pressure during transportation, so it should be equipped with SF6 gas recovery device.

After the winding and capacity of the transformer are determined, special attention should be paid to the neutral insulation of the transformer. Generally, the neutral point of the transformer in conventional stations is semi-insulated and relies on the neutral point of the medium voltage equipment in the substation to complete the grounding.

When a portable electrical substation is connected to the grid, its neutral grounding method should be in line with the overall grid dispatching principle, and generally does not design its neutral point as fully insulated, so it needs an external neutral set of devices.

According to the characteristics of the mobile substation, the core and winding force structure should be enhanced to strengthen its seismic strength, in order to avoid the relative displacement of the transformer and the box, the mechanical strength of the insulation layer between the bottom of the transformer and the tank chassis should be strengthened, and the strength of the transformer fasteners should be enhanced.

Transformer body should be equipped with three-dimensional impact recorder, transformer transport process impact is not greater than 3g when the transformer body should not have any loose, displacement and damage.

In order to meet the requirements of mobile transformer transportation oil storage cabinet need special design, in order to meet the calculated oil storage volume at the same time try to reduce the height of the oil storage cabinet structure, it is appropriate to take flat design, while enhancing the oil storage cabinet and the transformer body fixed, enhance its stability when transport. Ensure that under various working conditions (ramming 5g) oil storage cabinet does not occur damage.

At the same time, the oil level indicator, temperature controller and other monitoring instruments are placed at the bottom of the transformer, so that the inspection during operation. Auxiliary system module. The auxiliary system of the high-voltage transformer consists of a front-side “arrester-insulator” access terminal combination, which can be connected to both overhead conductors and high-voltage cables.

It also includes the lift lighting at the rear of the vehicle, the lift video monitoring system, and the double ring grounding network around the entire vehicle. The working, protective and equipotential grounding of all electrical components should be connected to the double-ring grounding network, and the control, signal and power cables should be routed through the ring channel box, with all external interfacing ports leading to the mistake-proof air socket in the terminal box.

The running time of portable electrical substation is much longer than the loading and parking time of general vehicles, so electric or hydraulic legs should be installed at the beginning, end and middle of the trailer to carry the weight of the whole high-voltage substation to avoid the occurrence of burst tires and other hazards, so as not to cause equipment damage.

The electric or hydraulic legs should be equipped with mechanical locking or mechanical auxiliary legs to avoid the phenomenon of soft legs when working under load. At the same time, a leveling device should be installed around the loading platform of the vehicle to ensure that the vehicle and equipment level does not tilt before commissioning.

The medium-voltage distribution vehicle is composed of medium-voltage switch module, intelligent integrated control module, auxiliary system module and transportation module, of which the first three are uniformly installed in the prefabricated cabin, which is then fixed to the trailer. Medium-voltage switchgear module.

The medium-voltage 10kV switchgear module generally adopts metal-clad fixed indoor switchgear with seismic performance, and if there is insufficient space due to too many feeder circuits, the C-GIS indoor switchgear can be chosen instead.

At the same time, the main busbar of the convergence should be connected flexibly, such as multi-layer copper foil rolling, to avoid the vibration of transportation that causes mutual influence between switchgear.

Intelligent integrated control module. portable electrical substation’s intelligent integrated control device and conventional substations are basically the same, when the mobile substation access to the grid, in order to adapt to the integration of regulation and control requirements need to upload the “four remote” signal.

Transformer high-voltage side and high-voltage switch should collect current and voltage values and switch signals to receive control commands through the intelligent terminal integration device of the combined unit, and connect with transformer protection, measurement and control devices through optical fiber, and medium-voltage switchgear protection and measurement and control devices should be installed locally.

Power supply system should fully consider the mode of operation, portable electrical substation in addition to self-sufficiency, should also consider the distribution of power for the use of other equipment, the general choice of capacity of 65Ah battery. If the financial situation allows, distributed photovoltaic can also be set on the top of the prefabricated cabin to form a micro-grid system.

Take 40GP prefabricated cabin as an example, generally 6k W distributed photovoltaic micro-grid system can be arranged, which is sufficient to meet the power consumption of the vehicle-mounted mobile substation itself. Auxiliary system module. The auxiliary system of the medium voltage distribution vehicle includes the video monitoring system, fire alarm system and HVAC lighting system inside the prefabricated cabin.

All electrical components in the prefabricated module are connected to the external interface through the cable channel at the bottom of the prefabricated module to the anti-misplug aviation socket in the terminal box. A double-ring grounding network is provided at the bottom of the prefabricated cabin for working grounding, protective grounding and equipotential grounding of electrical equipment. The ring ground grid extends outward at the four corners of the prefabricated module and is connected to the trailer grounding point.

The running time of portable electrical substation is much longer than the loading and parking time of general vehicles, so electric or hydraulic legs need to be installed at the beginning, end and middle of the trailer to carry the weight of the whole high-voltage transformer, so as to avoid the occurrence of burst tires and other hazards, which may cause damage to the equipment. The electric or hydraulic legs should be equipped with mechanical support.

The electric or hydraulic outriggers should be equipped with mechanical locking or mechanical auxiliary outriggers to avoid the phenomenon of soft legs when working under load. At the same time, a leveling device should be installed around the loading platform of the vehicle to ensure that the vehicle and equipment are not tilted before commissioning.

Cable connection module consists of cable reel, high-voltage flexible cable and control cable. Both ends of the high-voltage flexible cable are equipped with heavy-duty connectors or standard terminal blocks, and both ends of the secondary control cable are equipped with anti-misplug aviation plugs, and the cable is stored on the cable capstan when it is out of operation.

Drive the tractor truck to tow the high-voltage transformer car and medium-voltage distribution car to the destination, park the two cars reasonably according to the site conditions, and then drive away the tractor truck, support the legs of the two cars, and modulate the level of the vehicle platform according to the level meter.

The outlet end of high voltage inlet switch HGIS is connected to the transformer high voltage side bushing using aluminum stranded wire or flexible wire, the transformer low voltage side bushing is connected to the inlet switch on the medium voltage distribution vehicle using flexible cable, and the feeder end on the medium voltage distribution vehicle is connected to the 10kV lead-in cable to connect the control cable and signal fiber optic cable between the terminal boxes of the two vehicles.

Then prevent the warning fence at a distance of not less than 1 meter from the outside of the two vehicles.

Single-mother segmented mobile substation access: The 66kV inlet side of the high-voltage transformer is connected to the 66kV bus in the original substation, and the 10kV outlet side of the main transformer is connected to the distribution truck.

When the distribution vehicle is connected, a certain interval in the feeder circuit of the medium-voltage distribution vehicle is selected and set up as a bus contact switch to form a segmented operation with the original 10kV bus; Separate (independent) operation type mobile transformer access: the power is drawn from the 66kV bus to the 66kV inlet side of the high-voltage transformer tram.

The distribution vehicle is connected and runs independently of the original 10kV system in the substation with load, which does not affect the original system wiring and protection methods.

The truck-mounted mobile substation is equipped with a complete AC/DC system or PV micro-grid system and a comprehensive self-protection system, with protection measurement and control realized locally. Optional fiber optic communication equipment and PMS management system are available.

The vehicle-mounted mobile substation has two fast and reasonable grounding schemes designed in advance due to the irregular use location and the fast requirements for its commissioning, and different schemes are adopted to realize fast grounding according to the different operating environments of the vehicle-mounted mobile substation. According to the substation equipment grounding process standards.

The horizontal grounding body of 66kV substation generally adopts 50×5mm galvanized flat iron, and the grounding resistance of grounding network is generally not more than 0.5 ohm.

The high-voltage transformer truck is equipped with two kinds of ring grounding copper rows for working and protection grounding and equipotential grounding, and electrical equipment such as transformer is connected to the ring grounding copper row nearby; medium-voltage distribution truck is equipped with working and protection grounding and equipotential grounding points at all four corners of the truck, and these four grounding points are connected to the grounding points of electrical equipment inside the prefabricated cabin through the grounding circuit at the bottom of the prefabricated cabin.

The vehicle-mounted mobile substation is located within the conventional substation.

When the vehicle-mounted mobile substation is located inside the conventional substation, the vehicle-mounted mobile substation can be connected to the grounding network with the help of the existing grounding network of the conventional station; 2~4 points are selected on the ring grounding network around the high-voltage transformer tram body, and the multi-stranded soft copper wire is connected to the existing grounding network nearby.

Select 2 or all 4 points diagonally at the grounding points of the four corners of the medium-voltage distribution vehicle body and connect them to the existing grounding network using multi-stranded soft copper wire. The vehicle-mounted mobile substation is located outside the conventional substation.

When the vehicle-mounted mobile substation is located outside the conventional substation or far from the conventional substation, because there is no existing grounding network available at the site, galvanized steel pipe or galvanized flat iron should be used to make grounding electrode, and the grounding electrode should be directly nailed into the ground through the grounding electrode, and the nailing depth should not be less than 0.8m when there are no special geological requirements, and it is appropriate to choose one grounding electrode on each side of the two vehicles.

In the medium-voltage distribution vehicle body four corners of the grounding point selected near the two points of the high-voltage change tram, the use of multi-stranded soft copper wire near the high-voltage change tram body around the ring grounding network, so that the two vehicles themselves ground network to form a ring circuit, and then selected two points near the grounding pole using multi-stranded soft copper wire and grounding pole connected.

The portable electrical substation is more integrated and flexible than conventional substations, which are fixed, while the portable electrical substation is mounted on a low-profile semi-trailer and can be moved to the destination using a standard tractor as long as the road traffic permits and the power point is suitable. It can be moved to the destination, connected to the high-voltage incoming power and medium-voltage feeder cables, and put into operation after a short period of commissioning.

Compared with conventional substations, the portable electrical substation has a compact arrangement of primary and secondary electrical equipment, and each functional unit module is connected with a quick coupler, and since it is pre-assembled and pre-generated before leaving the factory, the actual workload on site is minimal, almost only the cable connection of electrical equipment. It also covers a small area, with a projection area of less than 100m2 for two vehicles.

The 110kV vehicle-mounted mobile substation adopts various measures to achieve light load and weight reduction as well as size control, such as reducing the body, reducing oil weight, improving copper-iron ratio, appropriately relaxing losses, increasing temperature rise, improving cooling and insulation media.

The winding design winding choose higher electric density (about 5.0A/mm2) to reduce the weight, than the conventional transformer weight reduction of about 3.6t. cooling method using forced oil circulation air cooling, transformer oil weight can be controlled at about 8.6t, than the conventional transformer weight reduction of about 7.7t.

Insulation medium heat-resistant design by preliminary calculations, the transformer temperature rise than conventional transformers about 10 ℃, the proposed use of E-grade insulation materials, allowing the operation of the top layer of oil temperature up to 105 ℃. The core design adopts high permeability silicon steel, appropriately increase the magnetic density (1.757T), reduce the core size, and reduce the weight about 3.5t than the conventional transformer.

Structure weight reduction design adopts high strength steel plate, optimizes oil tank design (flat oil pillow or rectangular oil pillow), and reduces the amount of steel plate used for oil tank, clamped parts and other structural parts, which reduces weight by about 9t compared with conventional transformers.

Optimized lead design for outlet line and structure size, the bushing adopts dry capacitor type bushing, leading from the bottom of the transformer, eliminating the elevated seat and elevated seat CT.

V-type on-load tap-changer is used to reduce the size of the transformer and reduce the weight of the switch and the amount of oil used. The weight reduction is about 1t compared to conventional transformer.

The mobile substation is generally designed with a complete 110kV terminal substation as the design goal.

In order to meet the demand of power supply capacity, if two sets of 110kV/20MVA vehicle-mounted mobile substations are configured, not only will they occupy more locations than one set of 110kV/40MVA vehicle-mounted mobile substations, but also the equipment will be repeatedly configured and the total investment will be more than one set of 110kV/40MVA vehicle-mounted mobile substations.

Based on the above requirements, this paper designs a complete set of 110kV/40MVA unattended intelligent vehicle-mounted mobile substation, including 110kV high-voltage switchgear combination appliances, 110kV/40MVA main transformers, 10kV distribution devices, intelligent protection and monitoring systems, and vehicle-mounted platforms to meet substation assembly and road requirements.

The research forms key technologies and methods such as compact arrangement technology and weight reduction method for 110kV/40MVA mobile transformer and outlet bushing, compact arrangement technology for 110kV mobile high-voltage switchgear combination appliances, vehicle-mounted compact arrangement technology for high-voltage distribution devices and convenient connection technology for 10kV feeders, intelligent protection and monitoring, etc., to realize complete equipment configuration of 110kV/40MVA substation, mobile mobility of vehicle-mounted platform, and technology integration of intelligent substation.

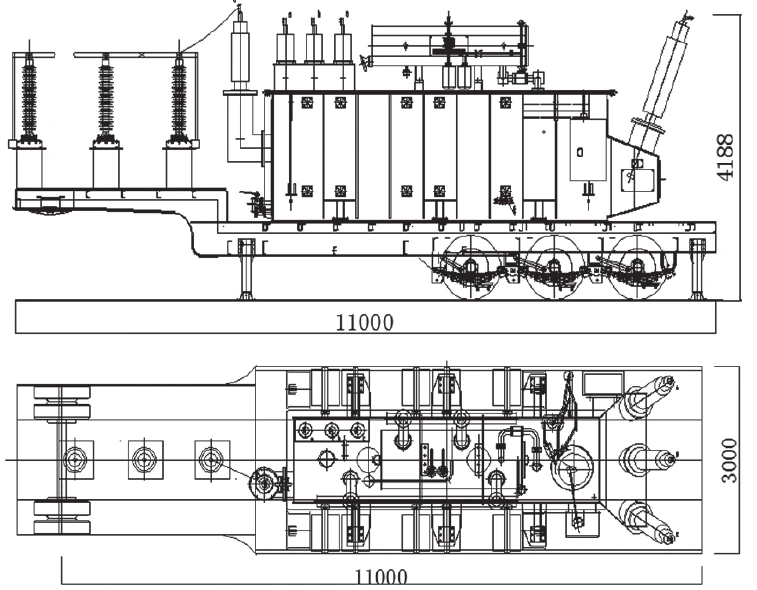

The current conventional 110kV/40MVA transformer generally weighs about 60t, with a length close to 7m, width close to 5m and height over 5m, which does not meet the requirements of road transport gross vehicle weight ≤ 55t, while the size also does not meet the requirements of transport height ≤ 4m and width ≤ 3m.

At present, the minimum weight of the tractor that can pull the vehicle transformer is generally 6.5t, then the total weight of the transformer and semi-trailer ≤ 48.5t, in order to meet the total weight ≤ 55t requirements.

Therefore, based on the total weight and size to meet the road transport requirements, the transformer needs to be a separate vehicle, while the need to combine the transformer and semi-trailer research compact weight reduction technology, mobile transformer truck to take a series of weight reduction measures, including the use of forced oil circulation air-cooled mode oil-immersed power transformers, high electric density, E-class insulation materials, five column type high permeability silicon steel core, high-strength steel plate, optimize the design of the oil tank, reduce The weight of 110kV/40MVA transformer is reduced from the conventional 60t to about 40.5t.

The SF6 gas insulated metal semi-enclosed multi-functional combined electrical apparatus (HGIS combined electrical apparatus) and semi-enclosed compact combined electrical apparatus (PASS switch) are used to integrate circuit breakers, disconnecting switches, grounding switches, voltage transformers, current transformers and other functional components together, taking into account the advantages of GIS and the advantages of external connection of high voltage buses in AIS, effectively utilizing space and simplifying the substation Layout.

The high voltage switchgear weighs about 6t, the high and low voltage distribution and intelligent monitoring and protection container weighs about 15t, and the common 13m long and 3m wide transport semi-trailer weighs about 11t, so the total weight of the vehicle and cargo can meet no more than 55t.

Considering the transport size limitation of the configuration equipment, the high-voltage switchgear combination appliance is a separate vehicle, and the medium-voltage switchgear and secondary system are integrated into one vehicle.

Therefore, the project proposes to adopt a three-car technical solution: the 110kV vehicle-mounted mobile substation consists of three cars combined as follows.

(1) No. 1 car (GIS car): 110kV incoming switchgear interval equipment (GIS combined electrical appliances)

(2) No. 2 car (main transformer car): main transformer and belonging equipment (40MVA, SFPZ-40000/110, YNd11, 110±8×1.25%/10.5k V, on-load regulation)

(3) No. 3 car (medium voltage car): 10kV bus and belonging equipment (provide five outgoing lines) three cars are electrically connected to form 110k V line change group, 10k V single bus wiring.

The vehicle-mounted mobile substation is an important part of the “emergency plan for power system emergencies”. Because of its excellent flexibility and rapidity, it can quickly replace a conventional substation to restore power supply in emergency situations such as natural disasters, emergency rescue and rescue, and sudden equipment accidents.

Mobile substation can be put into operation during the high load season to overcome the shortage of power supply capacity in the region, and can also be put into operation as a temporary substation in areas with high growth in power demand or beyond advance power construction planning, thus relieving the tension of power supply.

Download Resource

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical

The primary function of the pad mounted transformer is to serve as a critical distribution

A pad mounted transformer operates through electromagnetic induction, serving as a crucial distribution component that

After filling in the contact information, you can download the PDF.