ELECTRIC, WITH AN EDGE

For starters, there are many electrical types of transformers in the open market. Such as numerous types of distribution transformers. Each type of transformer and its uses will be determined by the parts of the transformer itself which is why you should know all of these topics to make the right and best purchase decision.

In this article, DAELIM, a professional transformer manufacturer from China, will provide you with all the necessary information you need to fully understand these topics. To begin with, it is best to start from the basics or fundamentals, so that you won’t be confused as we go deeper into the article.

8+FAQ About the Power Transformer Manufacturers

-This article will talk about the most popular power transformer manufacturers like DAELIM around the globe today. Read on!

The 2021 Complete Guide to Live Front Pad-Mounted Transformer

-This article will help you understand what a live front pad-mounted transformer is, what it does for a system, and why. To know more, read on!

The 2021 Complete Guide to Transformer Producers

-Are you looking for companies that manufacture and distribute quality electric transformers? Find out here.

The 2021 Complete Guide to Dry-Type Power Transformer

-Dry-type power transformers are the most popular type of power transformer used today. Keep on reading to know more about Dry-Type Power Transformer!

An electrical transformer is basically a machine that transfers electricity from one circuit to another circuit with changing voltage without affecting the frequency.

Basically, they are designed to use alternating current supply or better known as A.C supply.

This means that the fluctuation in the supply voltage will have a huge impact on the fluctuation in the current. An increase in the current will result in increasing the voltage and vice-versa.

Moreover, transformers will improve the safety and efficiency of the power systems by raising and lowering voltage levels whenever there is a need to do so. Of course, transformers are not limited to these few functions since each type of transformer and their uses are capable of many applications.

Mostly, Electrical transformer types are commonly used in the distribution and regulation of power across long distances.

The primary winding is the part of the transformer that is connected to an electrical source, which is where the magnetic flux is being produced initially.

These coils are usually insulated from each other and the main flux is induced in the primary winding from where it will be passed to the magnetic core and connect itself to the transformer’s secondary winding through a path that is low reluctance.

The primary winding is the part of the transformer that is connected to an electrical source, which is where the magnetic flux is being produced initially.

These coils are usually insulated from each other and the main flux is induced in the primary winding from where it will be passed to the magnetic core and connect itself to the transformer’s secondary winding through a path that is low reluctance.

Moreover, the secondary winding’s task is to help complete the movement of the flux that will start at the primary side, and use the core that reaches the secondary winding.

Basically, the secondary winding is capable of picking up the momentum because both windings are wounded or connected to the same core.

Their magnetic fields also help create motion.

For Electrical transformer types, the magnetic core is formed or assembled by stacking the laminated steel sheets.

This will leave the minimum required air gap between them to ensure the continuity of the magnetic path.

The core is responsible for relaying the flux to the secondary winding to create a magnetic circuit that closes the flux, and this involves a low reluctance path that is placed within the core to maximize the flux linkage.

To begin with, an electrical transformer type works with the process of Faraday’s electromagnetic induction law which is the rate of change of flux linkage associated with the time that is directly proportional to the induced electromagnetic force in a coil or conductor.

An electrical transformer type physical basis will depend on the mutual induction between two circuits that are associated with a common magnetic flux. In a common setting, it is usually equipped with 2 windings, which are the primary and secondary winding.

These windings will share a magnetic core that is laminated, and mutual induction will take place between these circuits to aid in transferring electricity from one location to another.

However, this will depend on the amount of flux being linked between the primary and secondary windings, which means that there will be different rates for every change in flux linkage.

To make sure that the maximum flux linkage passes through and links efficiently to the secondary winding from the primary winding, there must be a low reluctance path that should be placed on the common to both windings. This will make it more efficient in terms of performance, and this will also form the core of the transformer.

Moreover, the application of the alternating voltage to the windings on the primary side should create an alternating flux in the core. The result of this will link both windings to induce the electromagnetic force in the primary and secondary sides.

The electromotive force in the secondary winding will case a current that is known as a “load current”, and if there is a load that is connected to the secondary section. This is how an electrical transformer delivers alternating current power from one primary circuit to the other secondary circuit.

This is done through the conversion of electrical energy from one value to another value through the conversion of electrical energy from one value to another value.

As mentioned, this will change the voltage level but it will not change the frequency in any way.

An electrical transformer type will not employ any moving parts to transfer energy.

This means that there will be no friction and windage losses as it operates. However, an electrical transformer type will get affected by negligible copper and iron losses.

Copper losses happen when there is a heat loss during the circulation of the currents around the copper windings, this will result in loss of electrical power. This will also be the greatest loss in the operation of an electrical transformer.

On the other hand, iron losses are caused by the delay of the magnetic molecules that are allocated in the core.

The delay happens due to its response to the alternating of the magnetic flux which leads to friction.

This friction will produce heat that causes a loss of power in the core. Furthermore, this can be drastically reduced if the core is constructed from special steel alloys.

The intensity of the power loss will determine the efficiency of an electrical transformer type, and this will be represented in terms of power loss between the primary and secondary windings. This will result in efficiency when it is being calculated in terms of the ratio of the power output at the secondary winding to the power input at the first winding.

It is highly recommended that the efficiency of an electrical transformer type should be around 94% to 97%

When it comes to the different types of transformers and their uses, there are various classifications that are rooted in different categories and this will depend on their construction, supply, parts of the transformer, and purpose.

Basically, there are two types of transformer designs in the market, namely:

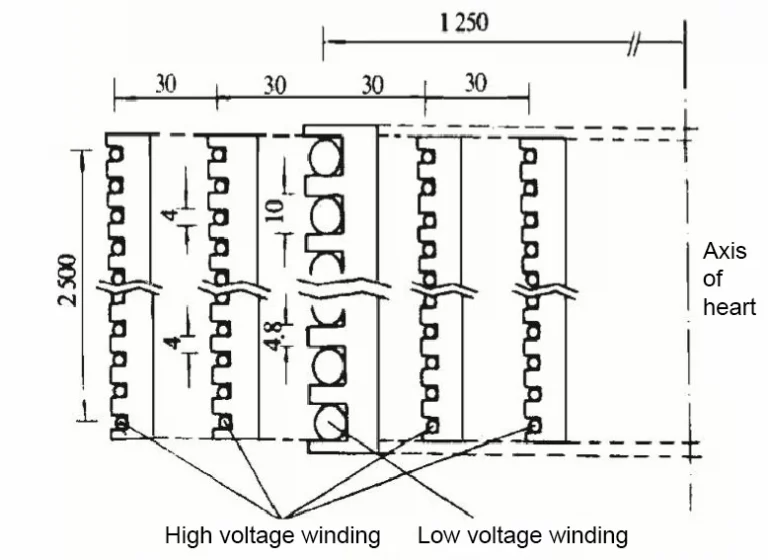

This type of transformer features two horizontal sections with two vertical limbs in a rectangular core with a magnetic circuit.

Moreover, the cylindrical coils (H.V and L.V) are placed on the central limb of the core type transformer.

On the other hand, the shell-type transformer consists of a double magnetic circuit and a central limb with two outer limbs.

Just like transformers that are based on design, there are two types of transformers that are based on supply as well, which are the single-phase transformer and three-phase transformer.

A single-phase transformer only has one set of windings.

Separated single-phase units can offer the same results as three-phase transformers perform.

However, they must be externally interconnected first to achieve this.

A triple-phase or three-phase transformer has three sets of primary and secondary windings that form a bank of three single-phase transformers.

Three-phase transformers are commonly used for the generation, transmission, and distribution purposes in the power industry.

On the basis of purpose, there are two types of transformers for this role as well.

For starters, a step-up transformer is determined by the number of turns of wire.

This means that if the secondary set has a greater number of turns than the primary side, this will mean that the voltage might correspond to that, which will form the base of a step-up transformer.

On the other hand, step-down transformers are primarily used for stepping down the level of voltage in a power transmission and distribution network. This means this is the exact opposite of what a step-up transformer does.

In terms of the function or application of the transformer, there are several variants for this category. Including but not limited to:

Power transformers are primarily used for transmitting electricity that has a high rating.

A distribution transformer consists of a lower rating because the main purpose of the many different types of distribution transformers is specifically for distributing electricity.

For instrument transformers, they are sub-categorized intro current and potential transformers.

For the cooling medium, there are three primary insulations that transformers use.

The oil-filled transformer is a type of transformer that is employed in small transformers of up to 3 M.V.A, and it is also described this way due to its design that gives it the ability to cool itself around surrounding air flow.

The dry-type transformer is basically a transformer that uses forced air or pressurized air as its cooling medium.

This means that this type of transformer makes use of blowers and fans that force the circulation of air to scatter within the transformer for its cooling or regulating the temperature.

This type of transformer makes use of a heat exchanger for facilitating the transfer of the heat from the oil to the cooling water.

Aside from the three main parts of the transformer, there are other components that play a significant role in the transformer’s performance as well. These parts can vary depending on what type of transformer you are getting. But there is a chance that your transformer might have these parts, including but not limited to:

Aside from the cooling medium of the transformer (which varies depending on the type of transformer), there are insulating materials as well like cardboard and paper that are used to isolate the primary and secondary windings from each other.

This also includes the transformer core as well.

Basically, these windings are made of copper due to their high conductivity and ductility. High conductivity will minimize the amount of copper needed to minimize losses.

Moreover, high ductility will result in easy being of the conductors into tight windings around the core which will minimize the copper and volume.

The explosion vent plays a critical role in the transformer’s performance because the boiling hot oil from the transformer is being expelled during internal faults through the explosion vent to avoid the explosion of the transformer.

This is generally placed above the level of the conservator tank. This part of the transformer will help you easily understand which different types of transformers and their uses are better for your use case.

With a lot of transformers available in the market, you should consider a transformer that has an explosion vent for safety purposes.

A breather is basically a cylindrical container that is filled with silica gel, and they are primarily used for keeping air from entering the tank moisture-free. This is because the insulating oil when reacting to the moisture can affect the insulation and cause internal faults.

This is why it is a must to keep the air free from moisture. Inside the breather, the air will be able to easily pass through the silica gel, which makes the moisture contents get absorbed by the silica gel crystals.

When you need to find more than just existing transformers, Daelim’s Transformer Service Center can help you design and produce distribution transformers that meet your unique needs.

We have our own factory and a professional team of engineers, which can design and modify application requirements that meet all your conditions.

Download Resource

ELECTRIC, WITH AN ENGE-- DAELIM BELEFIC