ELECTRIC, WITH AN EDGE

The three phase padmounted transformer has the advantages of advanced structure, reliable performance, energy saving and consumption reduction, flexible use, strong adaptability, and economical advantages. Under the situation of urban power grid construction and transformation, the development and application of 3 phase pad mounted transformer has good prospects.

The three phase pad mounted transformer does not simply combine the transformer and the high and low voltage switchgear, but immerses the load switch and fuse on the high voltage side of the transformer with the core and windings of the transformer in the same oil tank. It is a new type of Comprehensive electrical equipment with substation and high and low voltage power distribution functions.

3 phase pad-mounted transformers are designed to sit on a pad, hence the name “Pad-mounted Transformer” refers to this fact.

The three-phase pad-mounted transformer has a completely enclosed design. Because of the configuration of the heat sink, three phase pad-mounted transformers have an excellent heat-dissipation capability. The 3 phase pad-mounted transformer has a rated power range of 75–2500KVA. There are a number of sites where the 3 phase pad-mounted transformer is commonly employed.

The 3 phase pad-mounted transformers are basically designed to sit on a pad, thus why it has the name “Pad-mounted Transformer”.

The 3 phase pad-mounted transformer is a transformer designed with a fully enclosed structure. The layout of the heat sink that can directly dissipate heat to the outside makes Three phase pad-mounted transformers have good heat dissipation. The rated power range of the 3 phase pad-mounted transformer is 75~2500KVA. The 3 phase pad-mounted transformer is widely used in parks, mines, stations and other places with high power demand.

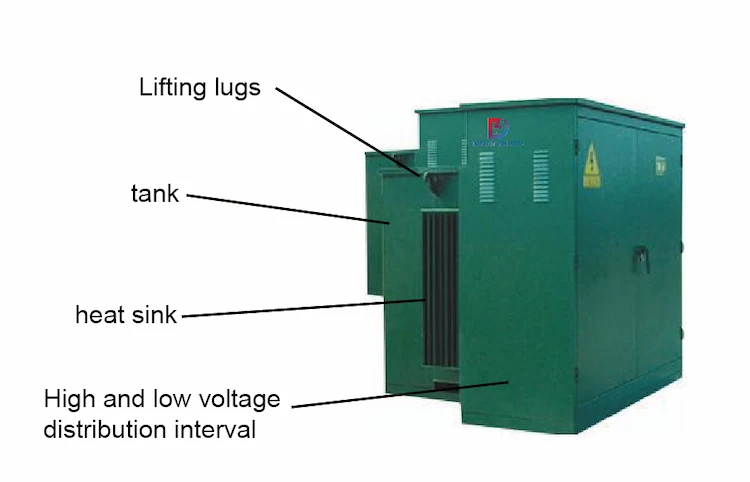

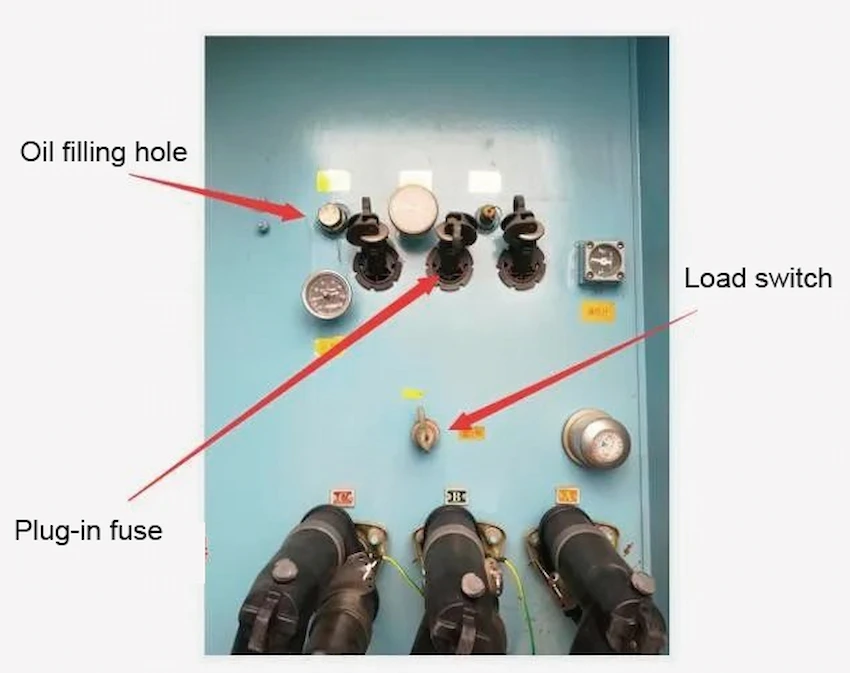

The structure and appearance of the three phase pad mounted transformer is shown in Figure 1. It is mainly divided into two parts: an oil-filled box and a radiator, and a high- and low-voltage power distribution interval.

The iron core and windings of the three phase pad mounted transformer, high voltage load switch, and protection fuse are all placed in the oil tank. The iron core of the pad mounted transformer can be different varieties such as cold rolled silicon steel sheet iron core or amorphous alloy coil iron core.

The fuel tank body of the three phase pad mounted transformer is a fully sealed structure, and some manufacturers adopt a structure that is completely welded after assembly.

Strive to ensure that the three phase pad mounted transformer is maintenance-free and maintenance-free during the service life; some manufacturers use concealed high-strength bolts and oil-resistant nitrile rubber gaskets to seal the tank cover, which can withstand a pressure of 4.9 N/cm2.

The high and low voltage distribution intervals include high and low voltage outlet terminals, load switch control parts, no-load tap switch, plug-in fuse, pressure release valve, oil temperature gauge, oil level gauge, pressure gauge, oil injection hole, Instruments and components such as oil drain valve.

If a three-phase power monitor (anti-theft device) is installed, a variety of anti-theft functions can be added.

There are two schemes for the wiring of the high-voltage power distribution part of the three phase pad mounted transformer, namely, the box-type transformer and the ring-type box transformer for the terminal of the distribution network, as shown in Figure 2 (1) and (2) respectively.

The three-phase winding adopts the D, yn connection method, which has the advantages of high output voltage quality, low-voltage neutral point does not drift, and good lightning protection performance. The lightning current can circulate in the closed loop of the high-voltage winding, and the lightning current is in each iron core column. The total magnetic potential on it is almost equal to 0, which eliminates the overvoltage of the forward and inverse transformation in the case of lightning, so the lightning protection performance is good.

The iron core of the three phase pad mounted transformer is used to choose a three-phase five-column structure. The zero-sequence magnetic flux will pass through the two side columns instead of the box shell, so the box surface does not heat up.

If the amorphous alloy wound core is selected, it also has the advantages of small excitation current, low no-load loss, and small size. The oil tank can be filled with ordinary transformer oil or high ignition point oil.

There are three phases of a pad-mounted transformer in the oil tank, which includes the windings, iron cores, and fuses. The oil tank holds a significant volume of transformer oil. For the sake of their long-term viability, these sections will be protected from the elements by using these oils.

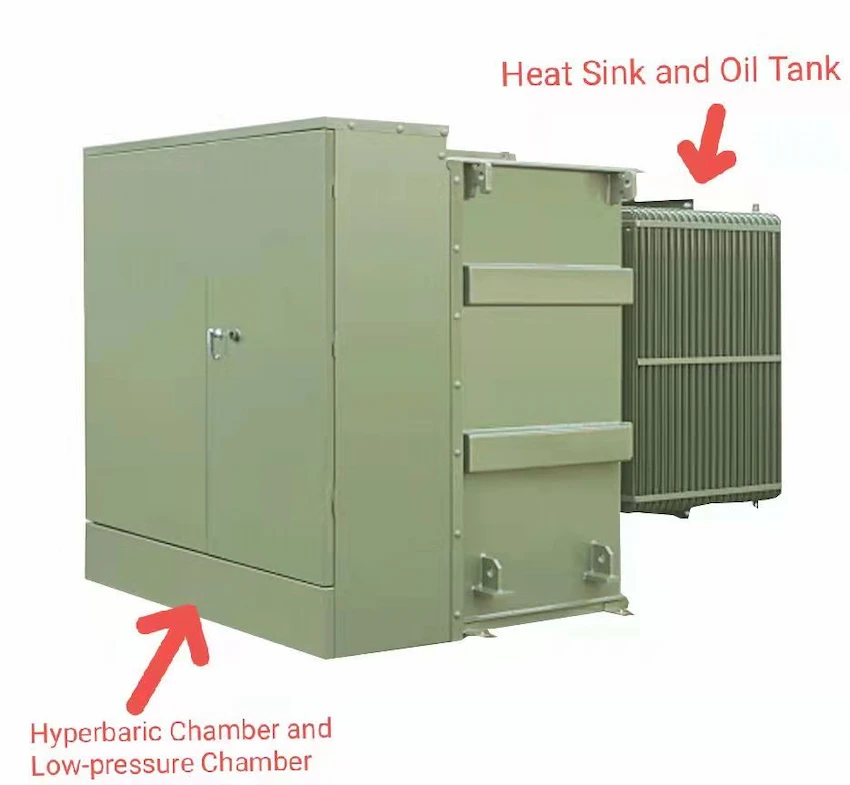

The front and rear distributed configuration is used for the three-phase pad-mounted transformer. The high- and low-pressure chambers are located in the front of the device. Heating and oil tank at the back.

For example, the high-pressure chamber has a 10 KV load switch, no-load tap switch, plug-in fuse, pressure release valve, oil temperature thermometer, oil level gauge, oil filling hole, and an oil drain valve, among other things.

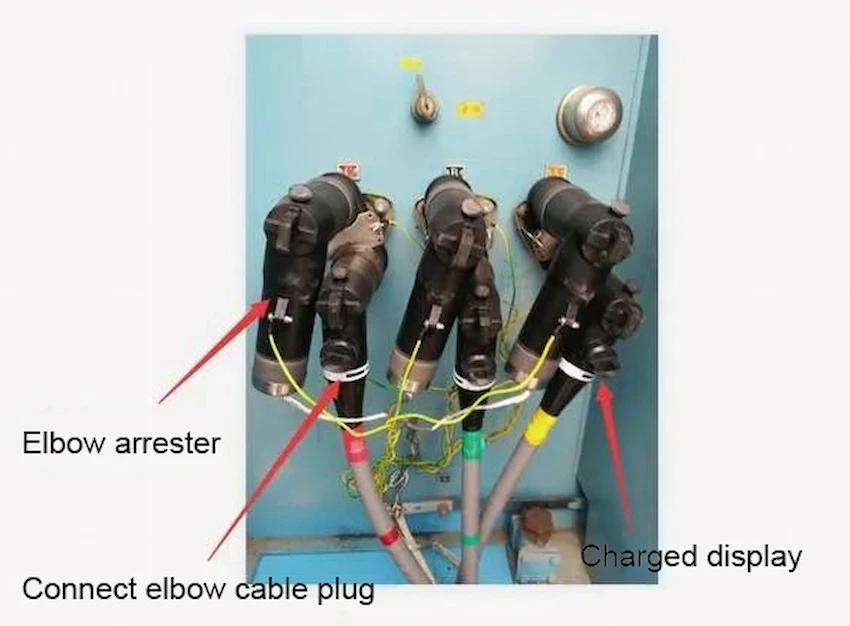

To protect the 3 phase pad mounted transformer’s high voltage terminals, high voltage bushings are installed (single-pass or double-pass). Connecting the elbow-type cable plug with the elbow-type fully insulated lightning arrester.

Fuse and current limiter are used to protect the 3 phase pad-mounted transformer from overheating. In the event of an overcurrent, the plug-in fuse is the one to blame. A three-phase pad-mounted transformer can be protected from overload and high oil temperature with this device.

For a wide range of fault currents, the backup current-limiting fuse is the one to blame. Short-circuit faults on the high-voltage side of the transformer might lead to this problem. Quickly disconnecting and protecting high-voltage cables are two of the benefits of using this type of transformer.

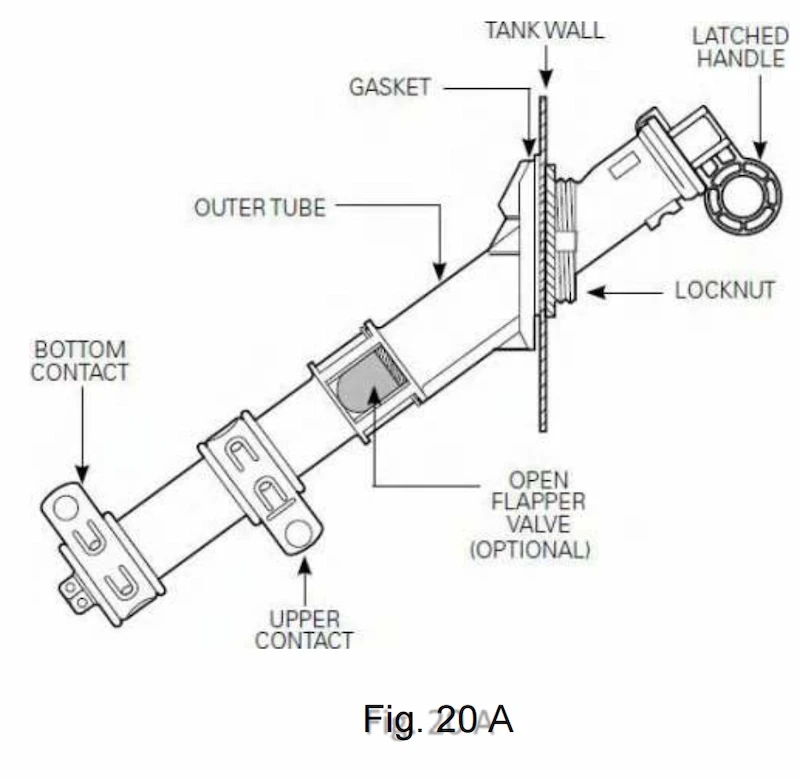

The oil-immersed load switch is a three-phase linkage switch with a spring operating mechanism. There are two types of two stations and four stations. The working status is shown in Figure 3.

The main technical parameters of the oil-immersed load switch are shown in Table 1.

Technical parameters of oil-immersed padmounted transformer STB load switch | |||

parameter name | Parameter value | ||

Rated current/A | 600 | 300 | 200 |

Rated voltage/kV | 15 | 25 | 35 |

Power frequency withstand voltage (kV/ min) | 35 | 40 | 50 |

Impulse withstand voltage/ kV | 95 | 125 | 150 |

Breaking current / A | 600 | 300 | 200 |

Short-time withstand current/ kA( 2 s) | 12 | 12 | 12 |

Rated short-circuit making current/ kA | 12 | 12 | 12 |

The three phase padmounted transformer adopts the principle of double-fuse series protection, which is quite unique in technology.

FU1 in Figure 20 A is a plug-in Bay-0-net fuse, its appearance is shown in Figure 4, inserted into the fuel tank when in use, rated operating current is 15, 25, 40, 50, 65 A and so on. Its function is to protect the secondary side of the transformer from short-circuit, overload and action when the oil temperature is too high, so it is also called a “double sensitive fuse” with dual sensitivity characteristics of current and temperature.

The model of the FU2 fuse shown in Figure 2 is ELSP type, with a rated fusing current of 50, 80, 125, 160 A, etc., which is a current-limiting type, used to protect the internal fault of the three phase pad mounted transformer, and is a backup protection element, which is not easy at ordinary times Action, no need to replace on site, can be installed in the transformer tank and directly connected to the winding of the three phase pad mounted transformer.

It is used to connect the incoming cable with the high-voltage terminal, and the live part is sealed in the insulator to form a fully insulated structure. The surface of the terminal is not charged, which can ensure personal safety. The elbow cable plug can be plugged and unplugged when the transformer is fully loaded, so the elbow cable plug can also be used as a load switch.

Sometimes there are some wall hangings welded on the box shell, which are used to fix the bearing-type insulating sleeve joints. When the elbow cable plug is unplugged when the power is on, it can be plugged into the support-type insulating sleeve connector immediately.

It can be installed at the elbow cable plug of the three phase pad mounted transformer to save installation space. ZnO arresters with silicone rubber protective covers should be used to prevent the explosion of the porcelain shell arrester and the fragments from flying out after the explosion, causing the expansion of the accident.

The development momentum of three phase padmounted transformer is very strong, and it has been widely used in urban network construction and transformation. It is widely used in high-rise buildings, industrial parks, residential quarters, integrated power distribution points of urban power supply networks, tourist attractions, commercial centers, etc.

The product structure design is reasonable and compact, and the volume is small, which is only 1/3 of the European-style box change with the same capacity.

The fully-sealed structure shell is grounded without electricity, and there is no need to set up additional barriers, which can ensure personal safety.

The wiring method is flexible, and it can be used for both ring network power supply and the terminal of the distribution network.

New types of high and low voltage power distribution equipment are selected, such as oil-immersed load switches; plug-in fuses with dual-sensitivity characteristics; elbow cable plugs that can replace disconnect switches and can be operated with load; fully shielded and fully insulated silicon Zinc oxide lightning arrester with rubber shell, etc.

The transformer adopts D, yn wiring scheme and three-phase five-post iron core structure, high voltage quality, neutral point does not drift, cabinet does not generate heat, low noise, and good lightning protection performance.

The overload capacity is strong, and it is allowed to run for 2 h at 2In and 7 h at 1.6In without affecting the life.

The power saving effect is good. The loss of the cold-rolled silicon steel sheet iron core transformer is slightly lower than that of the S9 series products. If the amorphous alloy iron core transformer is selected, the no-load loss can be reduced to 20%.

Derivative products with anti-theft function can be produced. After the anti-theft device is installed, it can record: the power stolen time by disconnecting the voltage circuit of the electric energy meter and the stolen power when the current circuit of the electric energy meter is connected incorrectly. ;

In addition to the light signal display, it can also send out a radio signal. The FM radio can receive the signal within a distance of 100 m, and the thief can be found; it can also prevent the user from replacing the large-scale current transformer and using the thief without authorization. Meter stealing electricity.

The three phase pad mounted transformer can choose high ignition point insulating oil, such as R-TEMP oil produced in the United States, which has an ignition point as high as 312 ℃, which is good for fire prevention.

It is highly adaptable to the operating environment and can be used in stormy and highly polluted areas to prevent flashover accidents caused by condensation inside the cabinet.

To better understand transformers and how they work,look at some of the most commonly used types. When looking for power transformers, there are a number of critical requirements to keep in mind. Power transformer characteristics include the maximum power, maximum secondary current, maximum voltage, and o/p type. Specifications for a power transformer are primarily focused on

In terms of the 3 phase pad-mounted transformer specifications, just like normal transformers, they are capable of doing what typical transformers do such as stepping down voltage levels.

Like the single-phase pad-mounted transformer, 3 phase pad-mounted transformers also have windings inside of them. Like most transformers, 3 phase pad-mounted transformer sizes come in different dimensions as well. There are small ones and large ones available in the market.

The main purpose why pad-mounted transformer manufacturers made different variations in terms of the 3 phase pad-mounted transformer sizes is because to make the 3 phase pad-mounted transformer placeable indoors, or in small spaces outdoors.

However, in terms of the size, you can expect that it is far from the large sizes of big transformers. It is almost the same size as a home cabinet, which is convenient for installment.

An important note when it comes to 3 phase pad-mounted transformer sizes is the voltage rating. The smaller it is, the less kilovolt ampere rating there will be. On the other hand, the bigger it is, then the higher the kilovolt ampere rating.

The 3 phase pad-mounted transformer is divided into two types: Liquid-Filled Loop Feed Pad-Mounted Transformer and Liquid-Filled Radial Feed Pad-Mounted Transformer.

How To Choose A Distribution Power Transformer?

The following is the specific data.

Width: 1350 mm

Depth:900 mm

Height:1430 mm

Oil Weight: 100kg

Total Weight: 540kg

Width: 1390 mm

Depth:910 mm

Height:1430 mm

Oil Weight: 120kg

Total Weight: 645kg

Width: 1420 mm

Depth:920 mm

Height:1430 mm

Oil Weight: 138kg

Total Weight: 729kg

Width: 1510 mm

Depth:980 mm

Height:1530 mm

Oil Weight: 201kg

Total Weight: 989kg

Width: 1510 mm

Depth:980 mm

Height:1530 mm

Oil Weight: 201kg

Total Weight: 989kg

Width: 1660 mm

Depth:1080 mm

Height:1680 mm

Oil Weight: 260kg

Total Weight: 1415kg

Width: 1810 mm

Depth:1160 mm

Height:1790 mm

Oil Weight: 325kg

Total Weight: 1905kg

Width: 2030 mm

Depth:1300 mm

Height:2030 mm

Oil Weight: 535kg

Total Weight: 2755kg

Width: 1651 mm

Depth:1549 mm

Height:1854 mm

Oil Weight: 650kg

Total Weight: 3235kg

Width: 2210 mm

Depth:1470 mm

Height:2150 mm

Oil Weight: 748kg

Total Weight: 5835kg

Width: 2380mm

Depth:1600 mm

Height:2220 mm

Oil Weight: 950 kg

Total Weight: 6430 kg

Width: 2480mm

Depth:1650 mm

Height:2330 mm

Oil Weight: 1020 kg

Total Weight: 8865 kg

The 3 phase pad-mounted transformer places the windings, iron cores, fuses, and high-voltage load switches in the oil tank. A large amount of transformer oil is stored in the oil tank. These oils will isolate these parts from contact with air, ensuring that they can work stably.

The 3 phase pad-mounted transformer adopts a front and rear distributed layout. The front part is the high-pressure chamber and the low-pressure chamber. The rear part of the heat sink and oil tank.

The high-pressure chamber includes a 10 KV load switch, no-load tap switch, plug-in fuse, pressure release valve, oil temperature gauge, oil level gauge, oil filling hole, oil drain valve, etc.

The high-voltage terminals of the 3 phase pad-mounted transformer are equipped with high-voltage bushings (single-pass or double-pass). It plays the role of connecting the elbow-type cable plug and the elbow-type fully insulated lightning arrester.

The 3 phase pad-mounted transformer adopts a plug-in fuse and backup current-limiting fuse for two-stage series protection. The plug-in fuse is responsible for a small range of overcurrent breaking. It can protect the 3-phase pad-mounted transformer in case of overload and high oil temperature.

The backup current-limiting fuse is responsible for a wide range of fault current breaking. If it occurs in the case of a short-circuit fault on the high-voltage side of the transformer. It can provide 3 phase pad-mounted transformer services to quickly cut off faulty transformers and protect high-voltage lines.

The plug-in fuse is easy to replace.

The backup current-limiting fuse needs to be drained before replacing the transformer oil.

Load switches are divided into two positions and four positions.

Two positions are used for terminal type;

Four positions are used for ring network type or dual power supply.

A grounding grid surrounds the three-phase pad-mounted transformer. As a result of this, all buildings within a radius of the grounding grid are grounded.

It is imperative that the grounding device’s buried depth and weld requirements are in accordance with the design standards.

It is only possible to conduct a grounding resistance test in good weather when the ground humidity meets the requirements. It is necessary to add additional grounding electrodes and grounding busses in order to meet the grounding resistance requirements if a device is present that does not meet these specifications.

There should be a strong and attractive connection between the equipment and the grounding device.

Assemble and pre-install the 3-phase pad-mounted transformer’s base and cable protection steel pipes.

Maintenance procedures for pad-mounted transformers

Whether the foundation is tight, whether the holes are blocked, and whether there is moisture in the cabinet.

Whether the grounding device is complete and well connected. Whether the grounding resistance meets the requirements.

Is there any change in the outdoor environment? Whether it affects the safety of traffic and pedestrians.

Check the load of each feeder. Whether the three-phase load is balanced or overloaded, whether the switching position of the switch, the meter indication is correct, and whether the control device is working normally.

The inside of the dust removal box of the 3-phase pad-mounted transformers is dusted every other year. The cabinet surface and airbox surface of the high-pressure room, the low-pressure room can be wiped with a damp cloth. 3 -phase pad-mounted transformers use air blowing or vacuum cleaner to remove dust.

Daily maintenance and overhaul of the fan. Check the operation of the fan. If it is not running, use the temperature and humidity controller to adjust the temperature below the existing temperature and start the fan to check.

Maintenance and repair of the high-voltage switch and low-voltage switch electric operating mechanism.

8. Auxiliary routine test: Routine test of temperature and humidity controller; routine test of smoke alarm device; tightening and inspection of terminal block: tightening and inspection of standard parts.

9. Terminal block maintenance. Due to thermal expansion and contraction, the terminal block may become loose. For annual maintenance, all terminals in the terminal room should be re-tightened.

Note: Before re-tightening, please make sure that both the primary AC circuit and the secondary control circuit are powered off to avoid electric shock!

The foundation, holes, and moisture in the cabinet should all be checked for leaks.

No matter how properly linked and complete the grounding device is Whether or whether the grounding resistance is sufficient.

Is there a noticeable shift in the atmosphere outside of the building? Whether or not it has an impact on pedestrians and vehicles.

Each feeder’s capacity should be checked. Whether or not the three-phase load is balanced or overloaded, whether or not the switch is switched in the correct position, whether or not the meter indication is correct, and whether or not the control device is regularly working.. etc.

Every two years, the 3-phase pad-mounted transformers’ dust removal boxes are cleaned. A moist towel can be used to clean the cabinet and airbox surfaces of the high-pressure and low-pressure rooms. A vacuum cleaner or air blower is used to clear dust from three-phase pad-mounted transformers.

The fan is serviced and repaired on a daily basis. Check the fan’s operation. Use a temperature and humidity controller to lower it below the current temperature and turn on the fan to see if it’s working.

Electric operating mechanism maintenance and repair for high- and low-voltage switches.

In addition to routine testing of the temperature and humidity controller; the smoke alarm; the terminal block; and the standard parts, there are a number of auxiliary tests.

Repairs to terminal blocks. The terminal block may come loose as a result of thermal expansion and contraction. Terminal room terminals should be re-tightened for annual maintenance.

Please disconnect both the primary AC circuit and the secondary control circuit before re-tightening to prevent electric shock.

A three-phase transformer door has a windproof mechanism built into it. It’s a safety device to keep it open at all times. When shutting the cabinet door, lift up the windproof mechanism’s root. Close the door firmly to avoid damaging the mechanism or the door itself. The usual operation of the three-phase pad-mounted transformer will be disrupted by this issue.

Before putting the load switch operating handle back on the handle bracket within the outer door, perform a local manual operation of high-voltage load switch

Before powering on the high-voltage ring main unit, the standby circuit should be secured or a matching insulating cap should be used to block the cable seat to prevent an accident.

Insulating caps are not substitutes for dust caps on three phase pad-mounted transformers!

During operation, short-circuit plugs are not permitted to be placed into the test hole. The voltage sensor will be ruined if it isn’t replaced.

Only when the low-voltage isolating switch is unlocked can it be used.

To begin with, electrical transformers are generally machines or electrical devices that have the ability to transfer electricity from circuit to circuit that involves no change in terms of frequency.

These electrical devices have numerous variants pertaining to appearance, size, shape, functions, types, etc. In fact, even 3 phase pad-mounted transformer sizes come in variants as well. Imagine the totality of all the different sizes of all types, there are simply countless sizes available in the market.

This is because as time goes on, more and more transformers are developed that are made to serve a unique function while still having the main purpose, which is to increase or “step-up” and decrease or “step down” voltage levels.

Most transformers operate on Alternating Current supply or better known as “A.C” in electrical terms. When it comes to using A.C as a supply, the fluctuation in terms of the supply voltage is affected by the movement of the current. In short, you can consider it as a reciprocal response. Whenever there is an increase in the current, the same goes for the voltage as well.

Furthermore, transformers back then weren’t only limited to controlling or transferring voltages and currents. They were also designed to enhance its safety it, and as well as its efficiency when it comes to power systems.

This is done by increasing and decreasing voltages whenever there is a need to do so. Moreover, transformers of all types are commonly used in residential applications. For industrial applications, there are many projects it serves as well. Transformers are essential for the distribution of power that is passing through long distances, as well as regulation.

Like most transformers, the 3 phase pad-mounted transformer generally works the same as normal transformers. Even single-phase pad-mounted transformers but you will get to know more about single-phase pad-mounted transformers as we go deeper in the article.

For now, understanding how transformers operate is the main focus. To put things in a simple definition, most transformers follow Faraday’s electromagnetic induction law.

The basic definition of this law is that induced Electromagnetic Force (E.M.F) in a coil or conductor is proportional to the rate of change in flux linkage.

To make these elements easier to understand, most transformers including single-phase pad-mounted transformers and 3 -phase pad-mounted transformers, normally rely on mutual induction when it comes to physical basis.

They normally consist of two windings, which are the primary winding and the secondary winding. Both windings actually share a magnetic core, which is laminated for security purposes. The mutual induction will normally trigger when circuits are operating to import electricity from point A to B.

The amount of linked flux has an impact on the different rates of the change in flux linkage. This is associated with the primary and secondary windings.

The setting of ensuring the flux linkage (maximum) has a lot to do with the reluctance of path in both windings. Basically, the maximum flux that is going through the secondary winding and linking it to the primary is the result of this.

In return, this results in optimum efficiency in working performance, and the core formation of the transformer.

When it comes to the application of alternating voltages to the windings, the primary winding will be responsible for creating an alternating flux in the core. You can expect the linkage between both windings. Afterwards, both windings are able to induce an Electromagnetic Force in the primary and secondary sides.

Electromagnetic Force in the secondary winding generates a current that is commonly known as a “load current”, this only occurs if there is a load that is associated with the secondary section.

Normally, that is how transformers distribute alternating current power from a primary circuit to the secondary circuit by converting the electrical energy from one value to a different value. Again, without disturbing the frequency.

Basically, Pad-mounted transformers, from the name itself, are a transformer that is mounted on a pad. But is it large like the DAELIM Distribution Transformers and DAELIM Power Transformers? The simple answer to that question is – No.

In fact, when it comes to appearance, it looks nothing like it, but they do have a similar function such as stepping up or stepping down voltage levels when needed.

Pad-mounted transformer manufacturers specifically designed this type of transformer to be accessible, cost-effective, and not space-consuming unlike other types of transformers.

When it comes to its maintenance, for a transformer that is not as big as the others, it is expected that it has less maintenance, but this definitely does not mean you should not regularly monitor it.

This brings me to my next point, which is longevity. The same with other transformers, Pad-mounted transformer manufacturers ensured consumers that the longevity of pad-mounted transformers are just as long as the other types of transformers.

This goes the same for both single-phase pad-mounted transformers and 3 phase pad-mounted transformers.

Now that you know the basics of what a transformer in general is, now is the best time to know what Single-phase pad-mounted transformers are before getting familiar with 3 phase pad-mounted transformers.

The sections are divided this way for you to have a better and simplified understanding of the two pad-mounted transformers.

The sections are divided this way for you to have a better and simplified understanding of the two pad-mounted transformers.

The DAELIM Single-phase Pad-mounted Transformer is engineered to improve the performance of standard Single-phase Pad-mounted Transformers. When it comes to performance, the kilovolt ampere rating, lightweight, safety, durability, and compact dimensions of this electrical device are winning factors.

This can be placed indoors and outdoors with no distribution room whatsoever, this can also be placed in the streets with no problems. The green belt ensures the safety of the public in case there is a malfunction or misoperation, which rarely or never happens when properly operated.

The DAELIM Single-phase Pad-mounted Transformer is one of the most commonly used pad-mounted transformers in residential areas, industrial areas, businesses, hospitals, and many more worldwide!

It has a low profile that sports a compartment-type for easy access and it is very suitable for mounting outdoors without any additional protective enclosure. This means that it is cost-effective as well, and it passes the standards of the I.E.C 60076, A.N.S.I / I.E.E.E. C57.12.00, C57.12.20, C57.12.38, C57.12.90 and etc.

Supply Ability: 200 Set/Sets per Month Single-phase Pad-mounted Transformers.

Packaging Details: This can be sealed in a wooden case or depending on what the customer’s request is.

(Europian type pad-mounted 50 kVA / 100 kVA/ 12/4 kV oil-filled power distribution transformers that pass the I.E.C standards for power transformers.).

The requirements of sealing the electrical device are strictly following international standards for optimum security.

Shipping: The shipping will go through either land or water transportation. DAELIM has shipped its electrical devices all over the world without any complaint from its international customers.

DAELIM has a logistic network worldwide for the best transportation option for the customers.

The biggest difference between the two is that pad-mounted transformer manufacturers specifically designed this type of transformer to be mounted on the ground while settling in a pad. On the other hand, Overhead transformers or pole transformers are mounted on a utility pole.

Moreover, most of the components of the overhead transformer are exposed, wherein 3 phase pad-mounted transformers, the unit itself is sealed when its lid is closed.

For starters, the outside of a Pad-mounted transformer is secured with a ring lock to unauthorized operations. Most 3 phase pad-mounted transformers have a special socket that allows operators to access the transformer.

If a 3 phase pad-mounted transformer is live, then you will most likely see wires that are connected to it since it is serving a meter or other purposes.

The way it works is that the primary voltage enters a cable that is capable of withstanding 14,400 Volts. It enters an H1-A bushing and it goes through the transformer, then through the windings. Afterwards, it goes through the side of the Z bars.

From the Z bars, it goes through the connection points that leave the cable to go through the meter or to where it is designated. For houses, this serves around 220 Volts – 240 Volts.

There are two sorts of pad-mounted transformers: the loop feed and the radial feed versions.

Normal transformer criteria relate to these 3 stage pad-mounted transformers too, thus they may do the exact same features as standard transformers such scaling down voltage levels.

3 stage pad-mounted transformers share the same windings as single-phase transformers. These transformers can be found in different sizes, comparable to other transformers, with a variety of alternatives readily available in the market.

To deal with the demands of numerous installations, manufacturers of 3-phase pad-mounted transformers have established a series of dimensions that can fit in both interior and portable outdoor rooms.

In regards to its size, you can anticipate it being much smaller sized contrasted to the huge transformers. It is roughly the size of a common kitchen cabinet, which makes it easy to establish.

When selecting a pad-mounted transformer, it’s essential to think about the voltage rating, as it directly influences the size of the tool. A reduced kilovolt ampere rating suggests an extra portable transformer, while a greater score calls for a bigger tool.

2 preferred types of 3 stage pad-mounted transformers are the fluid filled loop feed transformer and the liquid filled radial feed transformer.

The overload capability of a three-phase pad-mounted transformer is significant. For a period of two hours, it permits overwhelming twice. The 3 Phase Pad-mounted Transformer can even be overwhelmed 1.6 times for seven hours without affecting its service life.

The joint plug adapter is frequently utilized with three-phase pad-mounted transformers to comfortably link high-voltage incoming cable televisions. It functions as an emergency power switch that can be easily connected in and unplugged while the power gets on.

There are two fuses shielding the triple phase pad-mounted transformer. Short-circuit protection on the secondary side of the 3 Phase Pad-mounted Transformer is given by the plug-in fuse (BAY-o-net), which is a twin delicate fuse (temperature level, present). The high-voltage side of the 3 Phase Pad-mounted Transformer is safeguarded by the ELSP, a backup current-limiting defense fuse.

Fr3 grease or mineral oil can be utilized in the 3 Phase Pad-mounted Transformer. It can be chosen based on the circumstances.

A totally confined building and construction is used for the three-phase pad-mounted transformer. The oil tank is utilized to keep components such as wires, iron cores, fuses, and high-voltage lots switches.

The three-phase pad-mounted transformer does likewise to various other transformers in the majority of respects. Most transformers, including single-phase pad-mounted transformers and three-phase pad-mounted transformers, rely on mutual induction as its physical basis, that makes it easy to comprehend.

The two major types of windings are the key and secondary windings, both with laminated magnetic cores for defense. Throughout the procedure of a circuit transferring electrical power from one indicate one more, shared induction is expected to occur.

There are variable rates of change link change relying on the quantity of connected flux that exists in the system. This links the key and additional windings.

Change linkage (maximum) has a substantial influence on the course hesitation in both windings. It is due to this that the secondary winding and the main winding are connected by the biggest amount of flux that they might be.

Consequently, the core of the transformer is developed and working at its optimum performance.

It is the primary winding that is in charge of developing an alternating flux in the core when alternating voltages are applied to it. Both windings are anticipated to be connected. As a result, the key and second windings are able to produce an Electromagnetic Force.

When a load is attached to the second winding, electro-magnetic force creates a present referred to as a “lots existing.”

Converters often transform electrical energy from one degree to an additional to facilitate the transmission of alternating present power from key to secondary circuits. This process is done repetitively without disrupting the consistency.

To make sure accuracy in rankings, transformers are assigned in KVA, instead of kilovolt-ampere (kVA). This is since transformer designers are unaware of the specific lots that will be attached to their item. For instance, home heating resistors could be powered by the transformer, which would provide 1250 Kwatts in this circumstance. Nevertheless, electric motors present a responsive power element, where the present lags behind the voltage.

The parameters include a key side voltage of 4160v with 5 faucets, a second side voltage of 480v, various coolant choices, and a 325-gallon tank capability.

Watts are normally volts divided by amps, nevertheless the motor load includes a sensation referred to as the power aspect. Power factor is the sum of voltage (V) and current (I). According to the amount of lots on the motor, induction electric motors usually have a power element between 0.3 and 0.9. The 0.8 PF figure is all we’re mosting likely to opt for below.

Expect the transformer is completely inhabited by motors running at near complete ability.

The current overall power is KVA X 0.8 pf, which amounts to 1.2 million watts. Although the transformer creates 1250KVA of power, making use of watts to examine its top quality is misleading. KVA is a much more trustworthy sign of transformer quality.

Generally, 3 phase pad-mounted transformers are outstanding electric tools that are at the top of their tier when it involves offering their functions. It easily exceeds single-phase pad-mounted transformers, however this does not indicate that single-phase pad-mounted transformers are not worth thinking about.

Both Pad-mounted Transformers were crafted by their suppliers with unique intents, and the option in between them hinges on the details requirements of your job or application. Carefully consider your demands to figure out which transformer ideal matches your functions.

DAELIM’s well-informed team is readily available to offer timely and effective support if you have any questions or issues regarding picking the ideal pad-mounted transformer for your demands. Don’t think twice to reach out for professional guidance and tailored recommendations.

hese transformers are crucial in electric circulation as a result of their advantageous high qualities, which make them suitable for numerous usages.

Pad-mounted transformers with 3 phases are essential elements in electrical circulation systems. They have several valuable top qualities that make them best for a selection of applications.

The 3-phase Pad-Mounted Transformers’ beneficial top qualities make them perfect for numerous applications, making them vital parts in electric circulation.

The electrical circulation system relies on 3-phase Pad-Mounted Transformers, which have a number of useful qualities that make them best for a large range of uses.

In electric distribution, 3-phase Pad-Mounted Transformers are vital due to their special top qualities, that make them excellent for many different applications.

Benefits

Constant power supply is ensured for integrity. Security is guaranteed by meeting UL criteria and demands for pad-mounted transformer clearance. Tailored options are provided for certain needs via customization.

When looking at 3 phase Pad-Mounted Transformers versus ABB pad mounted transformers, they typically fulfill the very same standards, but the 3 phase transformers are frequently offered at even more competitive rates (refer to the catalog for pad mounted transformers).

| Model | Price |

|---|---|

| Standard Model | $10,000 |

| Custom Model | $15,000 |

When you need to find more than just existing transformers, Daelim’s Transformer Service Center can help you design and produce distribution transformers that meet your unique needs.

We have our own factory and a professional team of engineers, which can design and modify application requirements that meet all your conditions.

Download Resource

After filling in the contact information, you can download the PDF.