ELECTRIC, WITH AN EDGE

A lot of consumers, companies, businesses and industries are starting to consider purchasing Cooper Pad-mounted Transformers for several reasons, such as because of their small size, versatility, durability, sustainability, effectiveness, and many more. But Here have a lot of questions, such as Pad-mounted Transformer Specifications, Inside a Pad-mounted Transformer, Pad-mounted Transformer Diagram.

In this article, DAELIM, an pad mounted transformer manufacturer that has been specializing in Cooper Pad-mounted Transformers for more than 20 years, will provide you with the Pad-mounted Transformer Specifications that will help you better understand this electrical device.

Looking for a high-quality and reliable cooper transformer manufacturer? Look no further than Daelim Belefic!

With over 15 years of experience, we are dedicated to providing our clients with the best products and services possible. Our commitment to excellence is reflected in everything we do, from our state-of-the-art facilities to our experienced team of experts.

At Daelim Belefic, we are always pushing the limits of what is possible, which is why we are constantly investing in research and development. Our R&D team has over 20 years of transformer design experience and is familiar with international transformer standards, including IEC, IEEE/ANSI, CSA, and more.

We take quality seriously and perform multiple tests on our products, such as the Type Test, FAT Test, and Inspection Test, to ensure they meet the highest standards of safety and reliability. We also strictly implement the ISO 9001 quality management system, so you can be confident in the quality of our products.

Our team is passionate about solving our customers’ problems quickly and efficiently. We strive to be a trusted and valued partner to our clients, and we are dedicated to meeting their needs and building long-term relationships.

Whether you need a custom transformer design or a standard transformer product, Daelim Belefic has got you covered. Contact us today to see how we can help you with your transformer needs!

But first, it is highly recommended that you understand what transformers are in general, to help you understand what Cooper Pad-mounted Transformers are.

For starters, transformers are primarily used for transforming electrical voltages, thus making it the reason why they are called “transformers”. Moreover, when it comes to transforming voltages, you can consider it as adjusting the voltages as well.

This is because transformers are normally used as tools or apparatuses to control voltages. For instance, DAELIM distribution transformers are capable of stepping up or increasing low voltages to higher levels for different purposes like for transmission.

On the other hand, distribution transformers also have the ability to step down or decrease high voltages to lower voltages. The best example for this is decreasing the transmission voltage levels to distribution voltage levels for consumer use. (i.e, houses, infrastructures, commercials, etc.).

So, what are Pad-mounted Transformers? Pad-mounted transformers are basically a type of transformer or an electrical device that sits on a pad made of concrete, (the material of the pad could also vary).

This type of transformer also has a different appearance compared to other types of transformers that you normally see in electrical plants or establishments. Furthermore, Cooper Pad-mounted Transformers have their unique functions, mechanisms, design, and diagram as well.

In this section, you will go through the Pad-mounted Transformer Specifications, which is essential to fully get to know what this type of transformer is capable, and if it fits your needs.

In terms of the structure of Cooper Pad-mounted Transformers, you would normally see them as an ordinary metal box that is enclosed in a metal fence or borders to prevent outside elements like pedestrians and animals from interfering with its operation.

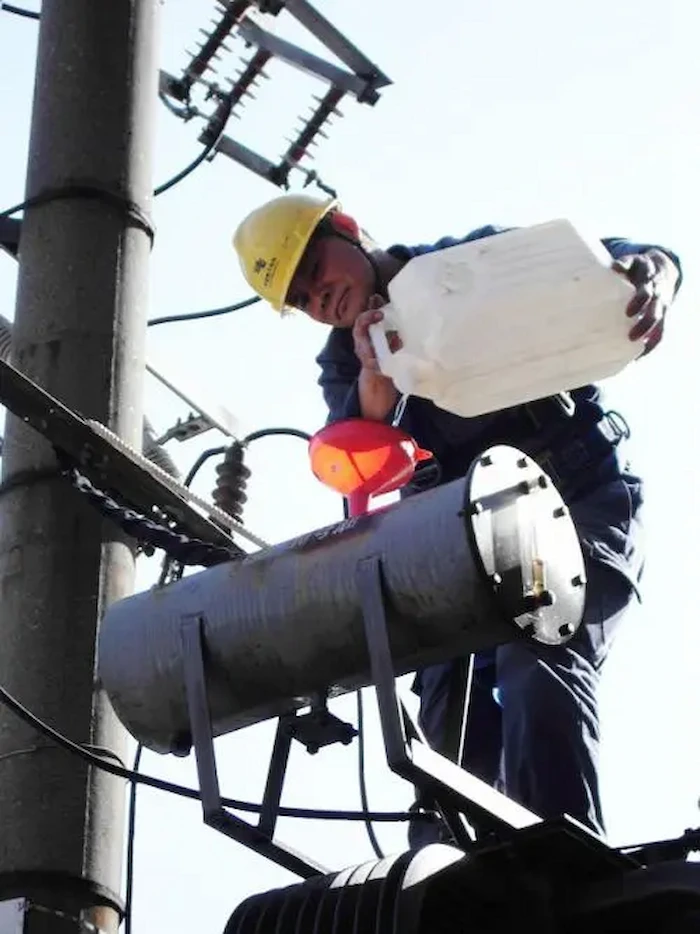

The Inside a Pad-mounted Transformer is also filled with oil on almost a regular basis since this is how these electrical devices work or operate at best. Moreover, its location to where it is supposed to be placed is for outdoors only.

Cooper Pad-mounted Transformers are also like other types of transformers that have their own core and coils as well. The core and coils of Cooper Pad-mounted Transformers are normally enclosed in a steel oil-filled tank, which you will get to know more as we go through its specifications deeper in the article.

The tank has a terminal for the transformer to be accessible in an adjacent lockable wiring cabinet setting. Furthermore, the wiring cabinet consists of two wiring compartments, which are the high and low voltage ones.

Before discussing the Pad-mounted Transformer Diagram, if you do not know what a diagram for transformers is, it is basically referred to this way. Normally, transformers have two coils that are electrically isolated, and they are operated on Faraday’s principle of the law of mutual induction.

This means that an Electromotive Force or E.M.F is induced to the secondary coil of the transformers, and this is caused by the magnetic flux that is created from the voltages and currents that are flowing or passing in the primary coil winding, and this is what the Pad-mounted Transformer Diagram follows.

In this part of the article, you will be provided with information regarding the numerous parts of the Cooper Pad-mounted Transformer. Moreover, this section still focuses on the Pad-mounted Transformer Specifications.

DAELIM professionally engineered their Cooper Pad-mounted Transformers to perform at optimum levels, which means that there are additional parts in the transformers that they manufactured that other Pad-mounted transformers do not have.

For instance, DAELIM’s Cooper Pad-mounted Transformers combines the function of a conventional distribution transformer with a Vacuum Fault Interrupter or V.F.I. The combination or the mix of these gives the Cooper Pad-mounted Transformer the ability to transform voltages.

Furthermore, the transformer overcurrent protection provides a cost-effective application and cost-effective package.

Pad-mounted V.F.I transformers are responsible for protecting the transformer, and this provides the proper coordination with the upstream protective devices as well. In the occurrence that a fault or overload happens, the V.F.I breaker will trigger, and the result of this will isolate the transformer.

Three-phase V.F.I breakers usually consist of an independent single-phase initiation. However, the three-phase of these will be mechanically gang-tripped.

Connection Mode of Working Winding of Three-phase Transformer

A single trip to the signal that is on any phase will cause the three phases to open. This feature is specifically designed to eliminate single-phasing that can happen to one of the phases in the three phases.

Furthermore, this feature enables the V.F.I breaker to be utilized as a load break switch in a three-phase setting. The characteristics of the V.F.I breaker is what makes the breaker unlock faster and easier,

The sealed visible break window and switch is an optional feature that can be installed to the transformer, and the main purpose of this is to provide visible break contact. Moreover, this promotes an enhanced safety mechanism, and transparency for the load break switch if it is in an open or closed position.

Below are more details of what is inside a Pad-mounted Transformer.

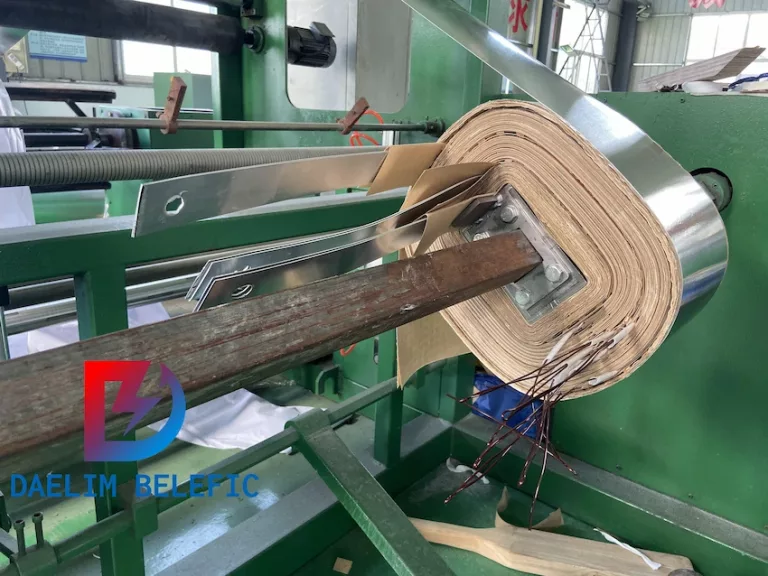

As mentioned, like any other type of transformer, this transformer has its own core. In fact, its core can be more complicated than the other types. The composition of the Cooper Pad-mounted Transformer’s coil is basically manufactured with the use of a high-quality cutting machine.

You can expect to see a three-legged mitered core construction in Cooper Pad-mounted Transformers. For the best performance, the cores are specifically stacked, and this is to eliminate that are in the corner joints.

Five-legged wound cores or shell-type triplex designs are also used in different types of transformers with a special design like the wye-wye connected transformers. Cores can be manufactured with a precision cut as well.

There are countless core steels that are available to enhance the core and reduces core loss efficiency as well.

In terms of the coils of the Cooper Pad-mounted Transformer, this type of transformer normally sports a rectangular-shaped coil along with wire-wound, sheet-wound secondaries, and high-voltage primaries.

This design is specifically engineered to minimize axial stress that is developed by short circuits, and it provides high-quality windings as well. This is developed by short circuits that provide for magnetic balancing among the tap connections.

The coils that are wound are using the highest quality winding machine that provides exacting tension control and conductor placements for the purpose of enhancing the strength of the short circuit, and this involves maximum efficiency too.

When it comes to mechanical strength, this is mainly provided by a diamond pattern that is commonly used throughout the coil. This may or may not have additional epoxy as well, the purpose of adding this is for heavy stress points.

The diamond pattern distribution of the epoxy will give a network of passages to its cooling medium or fluid to freely circulate. The coil assemblies are also heat-cured that is calculated to make sure that the performance against short-circuit occurrences.

In terms of the core and coil assemblies of the inside a Pad-mounted Transformer, these are normally braced with a heavy type of steel to prevent the coil that is rectangular from degrading or distorting when short-circuits occur.

The plates are also clamped in place and pressers are normally used for this, and this is welded or bolted to form an excellent core and coil assembly, which is a vital factor to the performance of the transformers.

The plates are primarily clamped in place with the help of presses and bolts that is used to form the solid core and coil assembly.

When it comes to the Cooper Pad-mounted Transformer’s tank, it is basically designed to withstand high-strength operations, but it is conveniently easy to handle. Moreover, the installation will not be an issue, and as well as maintenance since it has little to almost no maintenance at all.

Doing your part in maintaining your transformer’s tank will make it last for a very long time. Monitoring it every once in a while is a good practice that is highly recommended.

In terms of its process of creation, they are specifically welded with precision cuts, oiled steel, pickling, etc.

These are sealed to protect the insulating fluid as well, and this includes other internal components. Transformer tanks are also pressure-tested, which means they can withstand 7 PSIG without having any problems or complications against distortion and rupture.

Tank finish refers to the multi-stage finishing process, and like the core and coil assemblies, this also exceeds the requirements of the I.E.E.E std C57. 12.28 2014 standards. This eight-stage and pre-treatment procedure ensures optimum coating and adhesion that makes it resistant to corrosion.

When it comes to the tank’s surfaces non-metallic iron phosphate coating is essential. The paint method is composed of two distinct layers of pain. The E-coat or first epoxy primer is responsible for providing a barrier that is against moisture, salt, and corrosives.

Two-component urethanes final coat seals and ultraviolet are the final touches to this process.

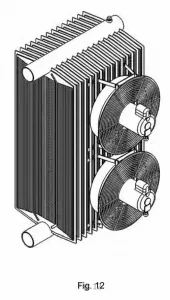

Vacuum processing is primarily used to fill up transformers with their insulating liquid or cooling medium, and vacuum processing also has a major role in energizing the secondary windings.

The coils that are heated and driven out of moistures ensure optimum penetration of the mineral oil to the coil insulation system.

DAELIM’s Cooper Pad-mounted Transformers utilize mineral oil or commonly known as transformer oil for their cooling medium, which is an effective cooling medium compared to pressurized air that is used on dry-type transformers.

However, it is worth noting that mineral oil or transformer oil does have its pros and cons. For instance, DAELIM Dry-type Transformers have less maintenance since they are static devices that do not need an oil change, whereas DAELIM Oil-filled Transformers require regular maintenance due to their oil usage.

But regardless of their cooling medium, it will have to go down on which you prefer.

Three functions and performance requirements of transformer oil

Load break switches are another electrical device that is primarily utilized to open an electrical circuit by isolating the source from the consumer. This can be manual or motorized, and trip functions can be used as well. These devices ensure on-load markings, safety disconnections, and breaking.

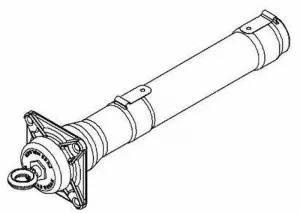

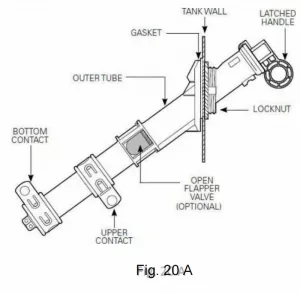

Cooper Pad-mounted Transformers have a bushing that is also considered as an insulating structure that facilitates the passage of energized conductors passes through the tank that is the ground of the transformer.

When it comes to capacitance-graded bushings, they are specifically designed for higher voltage ratings that are applicable to high voltage windings from transformers.

In terms of low-voltage bushings, in general, they are the complete opposite of high-voltage bushings, and they are designed for surface-mounted distribution transformers, these terminate the transformer’s internal low voltage as well.

This leads to the wall of the tank for the purpose of applying a standard threaded connection to the external low voltage cable circuit.

If you are not familiar with what a Sill is, transformers normally have enclosures like Cooper Pad-mounted Transformers, which consists of a hood and a sill that is attached to the transformer’s tank.

It is basically attached to the front of the tank that is near the base. Moreover, it has a gate that is either designed to open sideways, up or down for an expanded position.

Cooper transformers, also known as copper transformers, are electrical transformers that use copper windings as the primary conductor material. They are used to transfer electrical energy between circuits, and are an essential component of most electrical distribution systems. Copper is a highly conductive material, which makes it an ideal choice for transformer windings. Copper transformers are available in a range of sizes and configurations, and can be designed to meet the specific needs of a wide variety of applications.

Oil-filled Cooper transformers, as the name suggests, are transformers that use oil as the insulating and cooling medium. The oil-filled transformers consist of a core, a coil, and an insulating oil. The oil is used to insulate the windings and prevent electrical arcing, which can cause damage to the transformer. It also helps to transfer the heat generated in the core and windings to the transformer tank, which is then dissipated through cooling fins or radiators.

The oil used in oil-filled Cooper transformers is typically mineral oil, which is a good insulator and has excellent dielectric properties. Mineral oil is also cost-effective, readily available, and easy to work with. However, some transformers may use other types of oils such as silicone or vegetable oil, depending on the specific requirements of the application.

Oil-filled transformers are generally used in high-voltage applications, such as power transmission and distribution, where they help to step up or step down the voltage for efficient power transfer. They are also commonly used in industrial applications such as steel mills and chemical plants, as well as commercial applications such as hospitals and data centers.

One of the advantages of oil-filled Cooper transformers is their durability and reliability. They can operate for decades with minimal maintenance and can withstand extreme temperatures, weather conditions, and other environmental factors. However, they require periodic oil sampling and testing to ensure the oil is still providing adequate insulation and cooling.

Overall, oil-filled Cooper transformers are a tried-and-tested technology that continues to be widely used in various industries due to their efficiency, reliability, and longevity.

Eaton Cooper Transformers are a type of electrical transformer manufactured by Eaton Corporation. These transformers are used to transfer electrical energy between two or more circuits through the use of electromagnetic induction. Eaton Cooper Transformers are known for their high-quality design and reliability, making them a popular choice for a wide range of industrial, commercial, and residential applications.

Eaton Cooper Transformers come in a variety of sizes and configurations, including single-phase and three-phase models. They are designed to meet a wide range of voltage and power requirements, making them suitable for use in a wide range of applications. Eaton Cooper Transformers are also available in a range of core and coil materials, including aluminum and copper, and are designed to provide high levels of efficiency and low levels of energy loss.

One of the key features of Eaton Cooper Transformers is their advanced construction and design. These transformers are built to withstand harsh operating conditions and are designed to deliver long-lasting, reliable performance. They are also built to meet the highest industry standards for safety and reliability, ensuring that they provide safe and efficient power transfer for years to come.

Overall, Eaton Cooper Transformers are a high-quality, reliable choice for a wide range of applications. Whether you need a transformer for industrial, commercial, or residential use, Eaton Cooper Transformers offer the advanced design, construction, and performance you need to get the job done.

Pad-mounted Cooper transformers are transformers that are designed to be installed and mounted on a concrete pad, typically outdoors, in a compact enclosure. These transformers are ideal for use in urban areas, as they can be easily installed in locations where space is limited, and they are less obtrusive than traditional pole-mounted transformers.

The pad-mounted design provides several benefits. The transformer is sealed and insulated, which ensures safe operation, even in wet or dusty environments. It is also equipped with a safety barrier and interlock switch to prevent unauthorized access. Pad-mounted transformers are designed to be energy-efficient and have minimal losses during operation.

Cooper pad-mounted transformers are available in a range of sizes and configurations to meet specific power requirements. They can be used for a variety of applications, including residential and commercial power distribution, lighting, and industrial power supply.

Cooper pad-mounted transformers are also easy to maintain. They require little maintenance beyond periodic inspection and testing, which can be performed without the need for expensive equipment. This makes them a cost-effective solution for long-term power supply needs.

Overall, pad-mounted Cooper transformers are a reliable, energy-efficient, and cost-effective solution for power distribution needs in urban areas, where space is limited, and safety is a top priority.

There are several top pad-mounted transformer manufacturers in the world that provide high-quality and reliable products for various industries. Here are some of the top manufacturers in the market:

ABB: ABB is a leading global technology company that offers a wide range of power and automation technologies. Their pad-mounted transformers are designed for high reliability and efficiency, and are suitable for various applications such as residential, commercial and industrial use.

Siemens: Siemens is a German multinational conglomerate that offers a range of electrical equipment, including transformers. Their pad-mounted transformers are designed to be compact and energy efficient, and are suitable for use in public areas such as parks, schools, and hospitals.

Schneider Electric: Schneider Electric is a French multinational corporation that specializes in energy management and automation solutions. Their pad-mounted transformers are designed to provide reliable and efficient power distribution, and are ideal for use in urban areas where space is limited.

Cooper Power Systems: Cooper Power Systems is an American company that designs and manufactures electrical equipment, including pad-mounted transformers. Their transformers are designed to be compact and efficient, and are suitable for use in residential and commercial applications.

Daelim Belefic: Daelim Belefic is a China-based company that specializes in the design, engineering, and production of high-quality electrical equipment. Their pad-mounted transformers are designed to be energy efficient, reliable, and safe, and are suitable for use in various industries.

Overall, these manufacturers offer high-quality and reliable pad-mounted transformers that are suitable for various applications. Customers should consider factors such as energy efficiency, reliability, safety, and cost when choosing the best manufacturer for their needs.

Cooper transformers, whether oil-filled or dry-type, offer several benefits for various applications. Here are some of the benefits of using Cooper Transformers:

Energy efficiency: Cooper transformers are designed to reduce energy loss during the power transmission process, resulting in significant energy savings and lower operating costs.

Durability: These transformers are designed and manufactured to withstand harsh environments, high temperatures, and extreme weather conditions, ensuring a long service life.

Reliability: Cooper transformers are reliable and provide consistent performance over time, with minimal maintenance required.

Safety: Cooper transformers have several safety features, such as pressure-relief devices, to ensure safe operation.

Environmentally friendly: Dry-type Cooper transformers are free from oil, which means they are environmentally friendly and do not pose any environmental hazard.

Flexibility: Cooper transformers are available in various sizes and types to suit different applications, ensuring flexibility in design and installation.

Cost-effective: Cooper transformers are cost-effective, providing value for money and reducing operating costs.

Overall, Cooper transformers offer a reliable, durable, and energy-efficient solution for power transmission, making them an excellent choice for various applications.

Daelim Belefic is a reputable manufacturer of high-quality cooper transformers with over 15 years of experience in the industry. They have a team of expert professionals with a wealth of knowledge and experience in designing, engineering, and producing high-quality electrical equipment.

Choosing Daelim Belefic for cooper transformers comes with numerous benefits, such as their commitment to providing quality products that meet global standards. They have invested in research and development to provide efficient and professional transformer product solutions to help clients reduce costs and create new values.

Daelim Belefic’s transformers are made of qualified standard materials that meet the standards of world-renowned suppliers through international procurement. They also use the latest technology, machines, and other modern facilities to produce transformers that are efficient, safe, environmentally friendly, and have low life cycle costs.

Daelim Belefic’s quality management system is strictly implemented, and they conduct three different tests to ensure the best quality for their customers. They have a Type Test, which confirms that new product types meet global standards before production. The FAT test is a standard production test that ensures the quality of products, and the Inspection test is an SGS, CSA special inspection service.

Daelim Belefic’s dedicated customer service, product innovation, engineering excellence, and strong social and environmental responsibility sense make them a valued and trusted power solutions partner for the global electric industry. They aim to become a leader in the transformer industry in China.

Overall, choosing Daelim Belefic for cooper transformers ensures that customers receive high-quality products that meet global standards, are cost-effective, and come with exceptional customer service and support.

If you are looking for a convenient transformer that is sustainable, durable, versatile, and easy to use, then the Cooper Pad-mounted Transformer is definitely for you. This type of transformer may be small, but rest assured, it can operate and last for decades if properly taken care of.

Should you have any questions or concerns, do not hesitate to contact DAELIM’s team of professionals to assess them.

When you need to find more than just existing transformers, Daelim’s Transformer Service Center can help you design and produce distribution transformers that meet your unique needs.

We have our own factory and a professional team of engineers, which can design and modify application requirements that meet all your conditions.

Download Resource