ELECTRIC, WITH AN EDGE

When it comes to public transformer placement, ground-mounted transformers and three-phase pad-mounted transformers are quite similar to pole-mounted transformers since these transformers are commonly seen on public, which is why learning the pad-mounted transformer diagram is a great way to understand how these transformers are safe in public

With the help of DAELIM, a company that has been manufacturing ground-mounted transformers for decades, you will be able to understand what this electric device is capable of, and if you should consider purchasing one for your project.

Choosing the right transformer manufacturer is also just as important as choosing the right type of transformer. High-quality transformers will go for as long as 40 years if manufactured professionally, and regularly maintained by the owner.

Pofessional Manufacturer of Pad Mounted Transformer Substation Transformer,HV Power Transformer Single Phase Transformer IEEE/ANSI,CSA,DOE,AS/NZS,IEC and etc。standards

Since this article will be focusing on two types of mounted transformers, which is the ground-mounted transformer and pole-mounted transformer, it is best to learn first why they are called mounted transformers.

Basically, transformers are usually seen on the ground, whether it is near a building, inside a power plant, or some remote area. The point is that transformers are basically seen standing in their place or on the ground.

Whereas mounted transformers are specifically mounted on to something while they are operating. They are leveraged to operate efficiently, this is why their sole purpose and design has a mounting utility on it.

Ground-mounted transformers are basically transformers that are placed on a concrete pad that is mounted to the ground. These are distribution transformers with a kV rating that is significantly lesser than typical distribution transformers.

This is because their build or construction is much smaller than normal transformers that can fit in more components that is a major contributor to the increase in kVA rating (kilovolt-ampere). Moreover, the material of the plate or pad that it is settled in can be made out of solid wood or concrete since these are non-conductive materials.

When it comes to the Ground-mounted transformer’s enclosure, they basically look like a small or big cabinet since there are ground-mounted transformers that can be as small as a storage box and some can be as big as a locker.

Regardless of the size, they are normally seen in a locked metal cabinet and the purpose of this is to keep people, animals, debris, and other outside elements from tampering with it while it is operating.

Small or big, ground-mounted transformers will always have a pad underneath them.This makes them easy to identify and distinguish among other transformers.

ground-mounted transformers have a unique working principle that allows primary cables to be connected with help of elbow connectors. This will be operated when it is energized, and with a use of a hot stick. Moreover, this enables users to repair and do maintenance much easier.

Ground-mounted transformers are also known to have underground connections, specifically underground utility lines that lead to service drops, which is an overhead electrical line that is running from a utility pole towards a consumer’s house or establishment.

The main function of this is to do what distribution transformers usually do, which is to decrease or “step down” the primary voltage on the utility distribution lines that is direct to a lower voltage. Specifically a lower secondary voltage for supplying consumer needs.

This is why ground-mounted transformers are able to supply electricity to numerous buildings, which is why it is not surprising to see a single ground-mounted transformer supplying a single household or large building.

This is why a lot of consumers, businesses, and companies prefer ground-mounted transformers since they are of the right size, easy to operate, and have the ability to provide sufficient electricity, which is good for almost any kind of project.

In terms of the area of where ground-mounted transformers should be placed, a lot of consumers tend to ask whether they can be placed indoors and underground, but you will get to know the answer to that in the frequently asked questions section.

Focusing on where you can commonly find ground-mounted transformers, as mentioned they can be seen almost anywhere in public. Some are even near pedestrian lanes, which does make you think if it is just safe to pass by or pass through.

Basically, it is not uncommon for ground-mounted transformers to be seen in residential areas. This is actually the reason why this type of transformer is also called “residential pad transformers” since it is normal for them to be seen in people’s front yards or front lawns.

The reason why they can be seen outdoors and near buildings is because unlike other types of transformers, ground-mounted transformers have their contact points that are live stored in a grounded metal box. The result of this makes the overall transformer safe to showcase or present in public areas, including houses that are close together in residential areas.

As you may have observed with other transformers, specifically ones that are not suitable for public locations, they are normally seen enclosed in a metal fence to protect pedestrians from coming in.

When it comes to ground-mounted transformers this is simply not necessary. However, you do normally see them with a safety lock to avoid pedestrians from tampering with it..

Single-phase ground-mounted transformers enable vertical feed to the primary and secondary bushings of the transformer. Single-phase ground-mounted transformers are the ones you normally see on industrial and residential applications. Because of this, there is a wide range of kVAs required and as well as a lot of cable involved.

Moreover, single-phase ground-mounted transformers accept single-phase alternating current (A.C) power. This involves the output for the single-phase A.C power that is usually between a higher or lower voltage level.

During this process, energy is also transferred from one circuit to another through the law of electromagnetic induction.

When it comes to Three-phase pad-mounted transformers, the distinct difference between them compared to single-phase ground-mounted transformers is that they are used to change voltages with three phases.

Basically, three-phase pad-mounted transformers go through this process. This means that they are commonly used for power generation and as well as electrical distribution network applications.

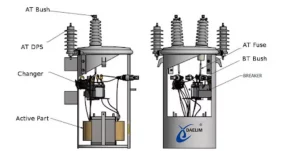

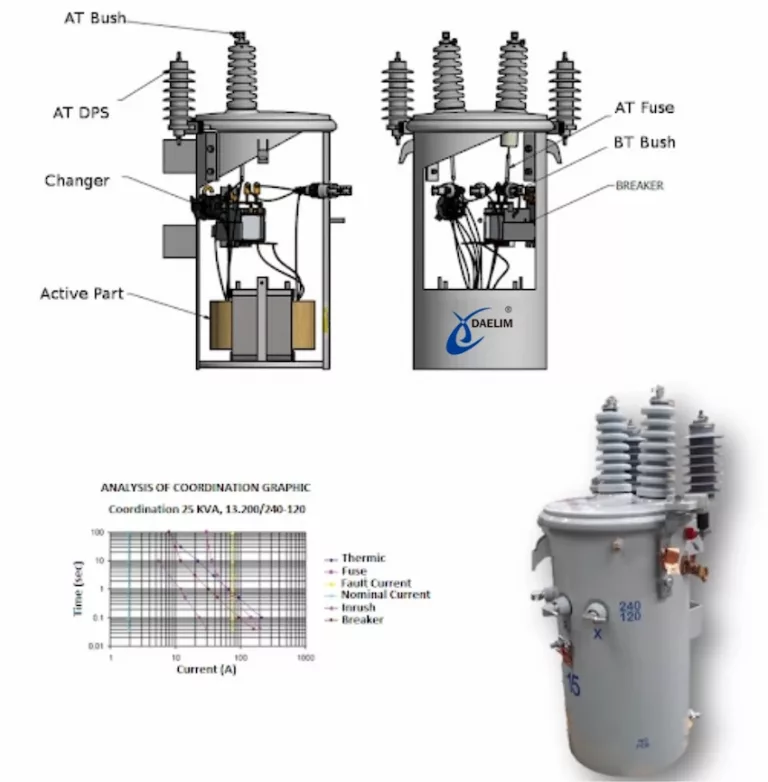

A pad-mounted transformer diagram refers to what the transformer itself does, and as well as how it works. As mentioned, ground-mounted transformers are operated with the help of underground electric power distribution lines at service drops, which is to step down the primary voltage to the lower secondary voltage to provide consumers electricity.

Those big green metal utility boxes in the streets of towns and residential areas are ground-mounted transformers that are operating to lower high voltage to standard consumer voltage.

Part worth noting of the pad-mounted transformer diagram is that these transformers are not in any way protected like the way overhead lines and substations are.

Basically, pole-mounted transformers are those barrel-shaped objects that you usually see at electricity poles or utility poles. Pole-mounted transformers are also part of the distribution transformer category but instead of being planted on the ground, these transformers are mounted on an electric service pole that is made out of concrete or wood.

In terms of their height in a utility pole, these are leveled with electric wires, which is the reason why you see a lot of wires connected to a single pole-mounted transformer.

The usual rate of Pole-mounted transformers range from 16 kilovolt amperes to 100 kilovolt amperes. It may not seem much but in terms of how much electricity they can transform, they have the ability to shrink 11,000 Volts – 33, 000 Volts to 400 Volts. They may be small, but there is no question about their ability to do that.

Another use case for pole-mounted transformers is converting distribution voltages to the 120/240 rate of the power system. This is the common rate that is used by consumers such as houses and other small to medium sized establishments.

For starters. pole-mounted transformers are considered as static devices that have no moving parts in them, but this does not mean that they are completely inside. Like most transformers, pole-mounted transformers have a magnetic core that is generated from laminations of silicon sheet steel. This is also known as “transformer steel”. The arrangement of this setup is stacked with the primary and secondary wire windings wrapped around them.

Each building or establishment may or may not have a transformer drum in their vicinity and it is mounted to a utility pole. However, this is not always the case for pole-mounted transformers since they can be located underground if buildings are too close to each other, like suburban neighbourhoods. Each house will have a transformer box underneath them.

For starters, single-phase, like single-phase ground-mounted transformers, need two wires. On the other hand three-phase, like three-phase pad-mounted transformers need three or four wires.

Single-phase ground-mounted transformers simultaneously change the supply voltage of an alternating current power by a system.

Furthermore, single-phase power is a two-wire A.C power circuit while three-phase is a three-wire A.C power circuit. In terms of the three-wire A.C power circuit, each phase is expected to be 120 electrical degrees apart

Basically, the design of ground-mounted transformers is what makes it a safe public transformer. This goes to show that ground-mounted transformers do not pose a threat to people who are standing near it or passing by.

But for the safety of the pedestrians, it is best to avoid contact with a ground-mounted transformer. Better yet, put a warning sign near since children might play around with it or worse, play on top of it.

The safe distance recommended is at least 3 letters from any ground-mounted transformer.

When it comes to transformers that can be placed indoors, people who have knowledge about transformers would usually think of dry-type transformers as a best example for indoor placement.

However, for ground-mounted transformers, this usually depends on the transformer if its rating meets the safety standard of the establishment. Since ground-mounted transformers make use of transformer oil or mineral oil, this means that they are highly flammable.

Public buildings have fire codes with them, so depending on the rating and fire code of the building, ground-mounted transformers may or may not be placed indoors.

Aside from the obvious and simple explanation that indoor transformers are specifically for indoors, while outdoor transformers are specifically for outdoors, there are standards to consider to declare if a transformer belongs to the indoor or outdoor transformer category.

For ground-mounted transformers, it is best to locate them outdoors. They are highly flammable so it’s best to keep them out of establishments. Nevertheless, it is not worth taking the time to worry about its condition outdoors since the design is very solid.

Implementing circuitry for ground mounted transformers calls for careful planning and implementation. Here’s an in-depth guide:

Installment Site Evaluation: Perform an extensive analysis of the place where the setup will occur. Analyze the soil’s stability, the proximity to nearby structures, and the convenience of gain access to for upkeep functions.

Prior to starting the installation, verify that all precaution are correctly established, consisting of sufficient grounding and insulation from energetic circuits, to ensure a protected and hazard-free atmosphere.

Securely link the high voltage lines by following nationwide and local electrical laws. Use appropriate insulation and protective equipment to make sure a protected link.

Arrange the reduced voltage output lines in an arrangement that ensures correct insulation and routing to stop electrical risks.

Basing Implementation: Establish a thorough grounding system, which is essential for security and effective procedure. This entails connecting the transformer to the earth making use of grounding rods or plates, making certain a low-resistance course to ground.

Setting Up Switchgear and Fuses: Position these elements strategically for operational effectiveness and simplicity of future maintenance.

workable Intelligence: Subterranean vs. Pillar-Installed Transformers

Choosing in between ground and pad-mounted transformers depends upon details site requirements and usage scenarios:

Compact and aesthetically appealing pad-mounted transformers are excellent for installation in metropolitan or residential areas where room is restricted. On the other hand, ground-mounted transformers are much better suited for industrial or rural areas where area is plentiful.

Access and Maintenance: Ground placed transformers are commonly less complicated to service as a result of their open design. This is useful in industrial setups where routine maintenance checks prevail. Pad-mounted transformers, with their enclosed and safe layout, are better in public areas however may call for even more initiative to access for upkeep.

Industrial Setting: In a commercial complex needing a high-capacity transformer, a ground installed device was selected for its easy availability and suitability for heavy loads. The installation procedure involved:

Customized circuitry designed for handling boosted power demands.

Stronger safety measures, such as reputable grounding and sturdy secure fencing surrounding the transformer, have actually been carried out to make certain a more secure environment.

An upkeep strategy that consists of routine checks and quick access to switchgear and fuses for operational performance.

Residential Area: A residential community required a transformer that was safe and inconspicuous. A pad-mounted transformer was chosen for its small size and visual housing. Secret steps in the installment included:

Strategic placement to lessen aesthetic impact while making certain safety.

Installation of safe locking devices and warning signs to stop unapproved access.

Collaboration with close-by utility service providers to connect to the grid and abide by regional area rules.

Implementing circuitry for ground mounted transformers calls for careful planning and implementation. Here’s an in-depth guide:

Installment Site Evaluation: Perform an extensive analysis of the place where the setup will occur. Analyze the soil’s stability, the proximity to nearby structures, and the convenience of gain access to for upkeep functions.

Prior to starting the installation, verify that all precaution are correctly established, consisting of sufficient grounding and insulation from energetic circuits, to ensure a protected and hazard-free atmosphere.

Securely link the high voltage lines by following nationwide and local electrical laws. Use appropriate insulation and protective equipment to make sure a protected link.

Arrange the reduced voltage output lines in an arrangement that ensures correct insulation and routing to stop electrical risks.

Basing Implementation: Establish a thorough grounding system, which is essential for security and effective procedure. This entails connecting the transformer to the earth making use of grounding rods or plates, making certain a low-resistance course to ground.

Setting Up Switchgear and Fuses: Position these elements strategically for operational effectiveness and simplicity of future maintenance.

workable Intelligence: Subterranean vs. Pillar-Installed Transformers

Choosing in between ground and pad-mounted transformers depends upon details site requirements and usage scenarios:

Compact and aesthetically appealing pad-mounted transformers are excellent for installation in metropolitan or residential areas where room is restricted. On the other hand, ground-mounted transformers are much better suited for industrial or rural areas where area is plentiful.

Access and Maintenance: Ground placed transformers are commonly less complicated to service as a result of their open design. This is useful in industrial setups where routine maintenance checks prevail. Pad-mounted transformers, with their enclosed and safe layout, are better in public areas however may call for even more initiative to access for upkeep.

Industrial Setting: In a commercial complex needing a high-capacity transformer, a ground installed device was selected for its easy availability and suitability for heavy loads. The installation procedure involved:

Customized circuitry designed for handling boosted power demands.

Stronger safety measures, such as reputable grounding and sturdy secure fencing surrounding the transformer, have actually been carried out to make certain a more secure environment.

An upkeep strategy that consists of routine checks and quick access to switchgear and fuses for operational performance.

Residential Area: A residential community required a transformer that was safe and inconspicuous. A pad-mounted transformer was chosen for its small size and visual housing. Secret steps in the installment included:

Strategic placement to lessen aesthetic impact while making certain safety.

Installation of safe locking devices and warning signs to stop unapproved access.

Collaboration with close-by utility service providers to connect to the grid and abide by regional area rules.

Ground Mounted Transformers in the U.S: A Market Analysis and Practical Guide

The U.S. Market for Ground Mounted Transformers

The United States ground mounted transformer market is identified by a diverse and ever-changing landscape, with applications extending across different industries, consisting of household, business, and commercial. Leading consider this market include:

Need for Energy-Efficient Models: With enhancing focus on power effectiveness, there’s a growing need for transformers that supply greater performance ratings and reduced losses.

Technical Advancements: Innovations in transformer layout and products are resulting in more small, long lasting, and environmentally friendly designs.

Adherence to strenuous requirements, consisting of those established by the Environmental Protection Agency (EPA) and neighborhood electric codes, is an important aspect for suppliers and customers to address in their operations.

In the United States, a number of manufacturers have gotten acknowledgment for their remarkable high quality and stability. These consist of:

Daelim has earned an online reputation for producing top-notch ground installed transformers that surpass expectations. Their dedication to high quality is reflected in the sturdiness and effectiveness of their items, which abide by both U.S. and international requirements.

Other Notable Manufacturers: Include companies like ABB, Siemens, and General Electric. These suppliers use a variety of transformers suitable for various applications, from little residential devices to big industrial transformers.

When purchasing a ground mounted transformer in the U.S., consider the following:

Calculate the required transformer ability by assessing the power needs of the end-use application. This consists of examining the total load and factoring in prospective future development requirements.

Regional Regulations: Ensure the transformer complies with regional and nationwide policies, including security and environmental requirements.

Manufacturer Reputation and Support: Choose producers with a strong credibility for top quality and reliability, and who supply excellent consumer support and warranty terms. Daelim, as an example, is an option several consider for their dedication to top quality and client service.

California industrial facility showcases sensible application

Initial Assessment: The task involved examining the website’s power demands, thinking about aspects like peak lots, future growth, and neighborhood electrical codes.

The Daelim ground mounted transformer was selected based on its efficiency, adherence to California’s rigorous ecological legislations, and the maker’s solid credibility, adhering to an analysis of numerous versions.

Installation and Compliance: The installment followed a detailed strategy, making certain compliance with state and federal guidelines. It consisted of coordination with neighborhood utility companies, establishing ideal safety measures, and establishing an upkeep schedule for long-term operational effectiveness.

Figuring out the proper transformer for a specific application involves taking into consideration the transformer’s ability, which is gauged in kilovolt-amperes (kVA). Below is a useful means to approach this:

Identifying the Load Requirements: Start by arranging the general electrical worry of the room or facility. This involves accumulating the power demands of all equipment and systems that will certainly be linked to the transformer.

Scalability: Think ahead and plan for prospective growth or increased needs. Choosing a transformer with a marginally higher ability than your current requirements enables adaptability and adaptability in the future.

Determine with a Cushion: Incorporate a security margin right into your estimations to avoid overburdening the transformer and running the risk of malfunction or decreased durability.

The number of households that a transformer can provide is a frequently asked question, and the reaction depends on the transformer’s ability and the normal quantity of power eaten by a family.

A 50 kVA transformer can usually supply electrical power to around 10 to 15 average-sized households, depending upon their typical power use.

A transformer with a capacity of 100 kVA can supply power to around 20-30 properties.

A transformer was required to provide power for 25 houses in a new country housing project.

Remedy:

A 100 kVA ground mounted transformer was picked, offering enough capacity with a margin for potential future expansion.

The setup strategy included examining the site layout, making sure optimum placement for ease of access and safety and security, and preparing for below ground cabling per home.

Adherence to neighborhood electric regulations and partnership with the energy company were important components of the project’s success.

Seek advice from specialists: Interact with electrical engineers or reach out to transformer manufacturers such as Daelim for tailored suggestions.

Examine Local Rules: Make certain that the transformer version and arrangement satisfy the requirements established by neighborhood construction guidelines and electric standards.

Consider environmental considerations: When handling specific environmental situations, go with transformers that are constructed to endure those problems.

Making Sure Safe Operations and Adherence to Regulations for Ground-Based Transformers in the United States.

Recognizing and adhering to policies and standards in the United States.

In the United States, the installment and operation of ground installed transformers are governed by a set of rigid policies and requirements to guarantee safety and performance. Secret guidelines include:

The National Electric Code (NEC) provides guidelines on mounting transformers, needs for grounding, and precaution.

Occupational Safety and Health Administration (OSHA): Sets criteria for risk-free working conditions around electric equipment, consisting of transformers.

Environmental Protection Agency (EPA): Regulations worrying ecological effects, particularly for transformers having oils or chemicals.

To efficiently fulfill these policies, think about the complying with steps:

Conformity with NEC: Ensure all facets of the transformer’s installation follow the NEC. This includes correct grounding, risk-free distances from frameworks, and adequate safety actions.

Maintain employee safety by sticking to OSHA requirements for installment and maintenance to stop electric threats.

When handling transformers that might include unsafe products, it is essential to follow the Environmental Protection Agency’s (EPA) guidelines for handling and disposal to reduce injury to the atmosphere.

Situation: A commercial center in Ohio needed to update its transformer to a greater ability model.

Solution:

Option of Transformer: A 150 kVA ground mounted transformer was chosen for its capacity and effectiveness.

Electrical Safety: The setup technique represented NEC guidelines, including suitable spacing, reliable grounding techniques, and safety obstacles to guarantee the transformer’s secure procedure.

Adherence to OSHA standards was made sure throughout the setup process, with a concentrate on electric precaution such as appropriate signage, provision of security tools for employees, and preserving a risk-free distance from live elements.

The style of the transformer consisted of procedures to comply with EPA standards for consisting of and preventing spills because of the existence of oil.

Talk To Local Authorities: Before setup, speak with neighborhood structure assessors or electrical authorities to guarantee compliance with all relevant codes and laws.

Normal Inspections and Maintenance: Establish a routine for assessments and maintenance, sticking to the supplier’s standards and safety requirements.

Maintain Up-to-Date with Regulatory Changes: Compliance needs staying present with the most recent developments in guidelines and requirements. Ensure to regularly check for updates to ensure your company stays certified.

For various other states, the contact details for neighborhood electric departments can be located through the complying with actions:

State Government Website: Visit the official state government internet site. A lot of states have a specialized section for utilities or power departments.

State Regulatory Authority: Check with the state’s Public Utility Commission or a comparable governing body. These organizations typically have territory over matters related to power and various other energies.

Neighborhood Utility Companies: Contact neighborhood energy business. They can offer information or direct you to the proper state department in charge of electric policies.

State Electrical Licensing Boards: Some states have electrical licensing boards which can give support on laws and compliance.

Make use of cyber directory sites or official federal government web sites that offer accessibility to state division get in touch with details.

There is no doubt here that ground-mounted transformers are excellent transformers. But if your project requires higher voltage levels, then it is best to choose pure distribution transformers or power transformers.

But if your project only requires electricity that can provide one to multiple buildings, then ground-mounted transformers are definitely for you. They are small, easy to operate, and safe to place outdoors.

Should you have any questions or concerns, please do not hesitate to contact DAELIM’s team of professionals for professional help.