ELECTRIC, WITH AN EDGE

The primary purpose of a transformer is to “transform” electrical voltage to a usable rating. However, things can get confusing when you have to determine or specify what actual transformer is needed. And, this article by Daelim will be tackling one specific form of transformer, the Live Front-Three Phase Pad Mounted Transformer.

Live Front-Three Phase Pad Mounted Transformer is a loaded term. And to figure it out, we have to break down the terms that comprise it. Generally, it is a utility distribution transformer that is ground-mounted in a lockable metal cabinet on a concrete pad. Also, all live contact points are contained within a grounded metal enclosure.

DAELIM provides a full range of live front three-phase pad-mounted distribution transformers. These transformers are intended for use in commercial, residential, and industrial settings. If you’re not familiar with this transformer, then it’s important to learn what they do and how they work so you can decide if they might be right for you! Let’s get started!

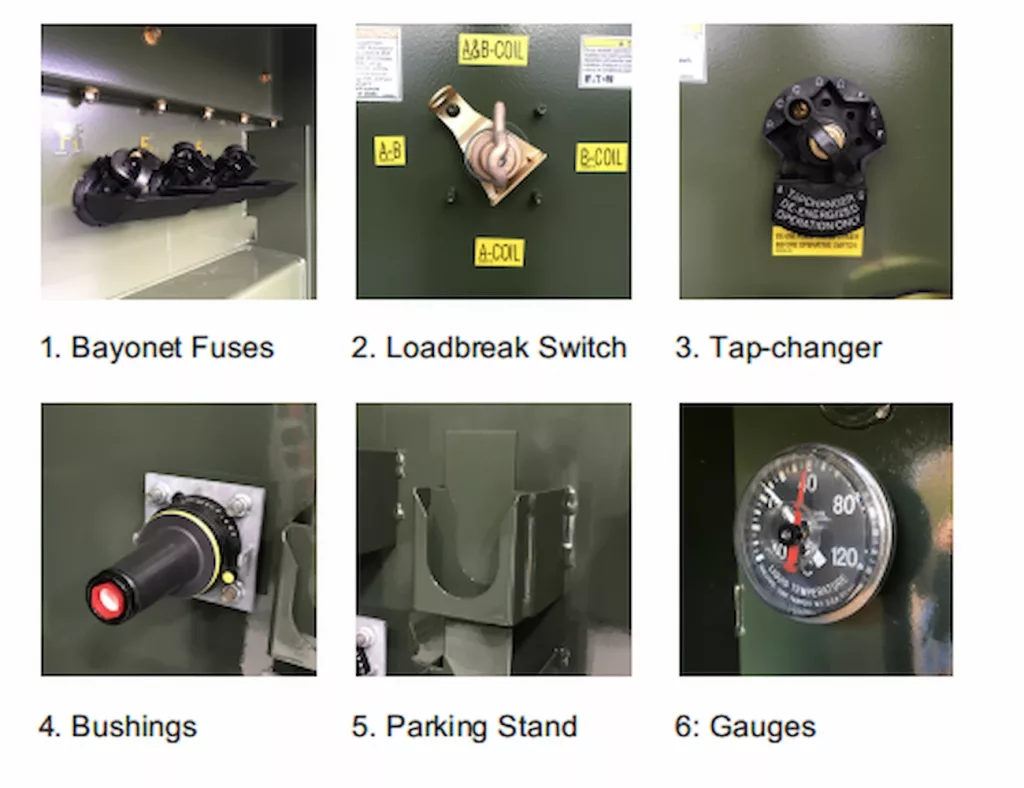

Different parts comprise a transformer. Among these are components called bushings. They are attached to the innermost core of an electric machine, and their purpose is to provide a bearing surface for the rotating parts. These bushings can be either live front or dead front types.

Live front bushing is a traditional type of bushing made of porcelain or epoxy. It refers to terminations that expose the cable and terminal. It has electricity running through it, and touching a live front bushing may result in electrocution.

At the top of the live front bushing is a spade where the actual termination with a crimp lug occurs. The bushings below the spade are made up of little ridges known as waffles that prevent a phenomenon known as creep.

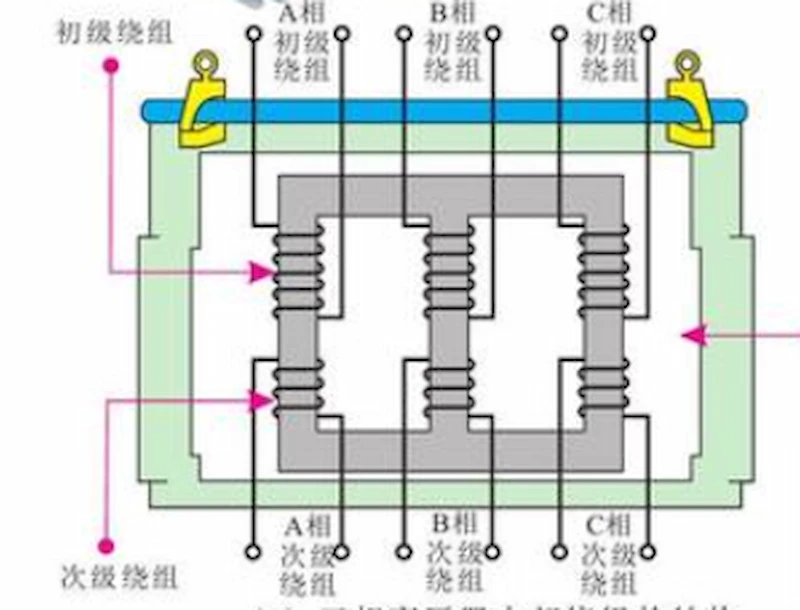

Calculation Method of the Number of Turns of Power Transformer Core

Creep is the movement of an arch across the surface area while accompanied by a small amount of water, dust, or oil. Waffles, with greater surface area, offer the required clearance to prevent creep. Also, there is a stud that links the bushing to the core and the coil inside.

On the other hand, a dead front bushing performs the same function as a live front bushing, but it is fully insulated. The cable and current-carrying elements are encased inside molded rubber components. Because there are no current-carrying parts exposed to the operator, safety is improved.

The advantage of a dead-front transformer is that you can open the cabinet with very little chance of arch-flash. Furthermore, a bushing well, a load break insert, and a load break elbow are its common components.

There are two popular configurations of transformer systems: single and three-phase transformers. Both have their respective advantages and disadvantages to consider. Also, they differ significantly in that the single-phase utilizes one conductor and one neutral wire to complete a circuit. In contrast, the three-phase supply requires three conductors and one neutral wire.

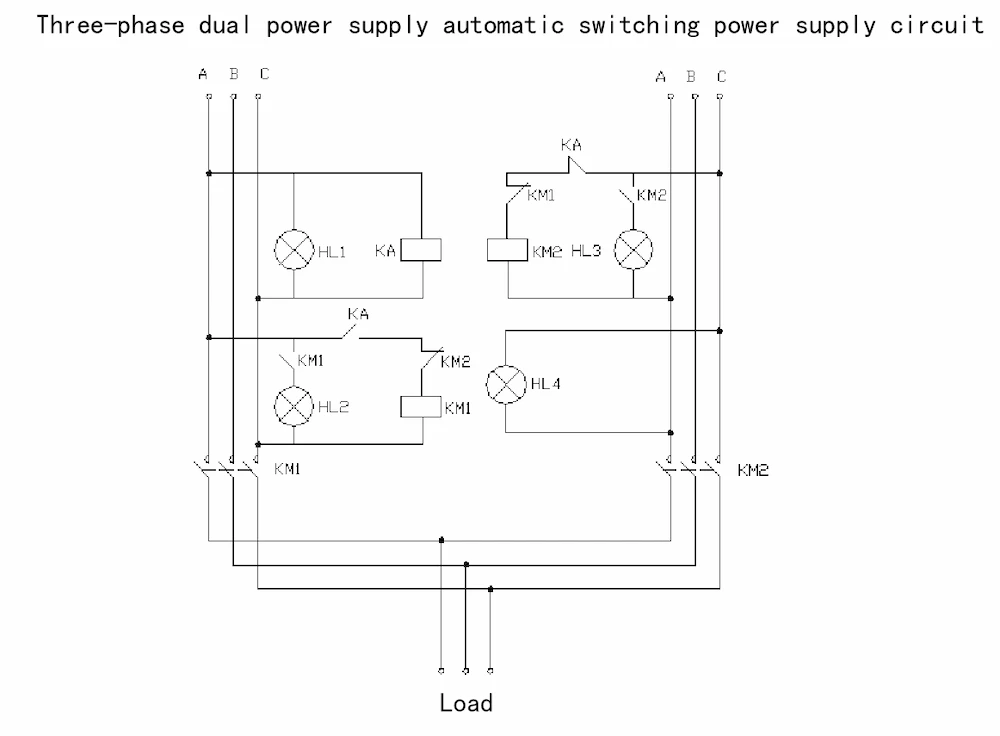

Transformer three-phase dual power supply automatic switching

The primary purpose of using either type is to change the voltage while keeping the current at a constant value. To better understand the difference between the two, you must learn the features and how these transformers work.

A single-phase transformer uses two coils, one main and one secondary, to perform voltage translation. It comprises two highly inductive coils wound on an iron or steel core to generate the necessary voltage using these two windings. The winding linked to the alternating current (AC) supply is the first winding, while the other is the secondary winding.

It features four terminals, two on the input and two on the output, with no delta or star connections. In most situations, a single-phase transformer does not require a cooling system. A system’s single-phase power adjusts the supply voltage of an alternating current (AC) power simultaneously. Because it is what most houses use, single-phase electricity is more commonly referred to as “residential voltage.”

A single-phase power distribution system employs phase and neutral wires. The phase wire carries the current load, whereas the neutral wire serves as a return channel for the current. It generates only a low voltage which commonly begins at 230V. Its frequency is also close to 50Hz.

Single-phase motors require extra circuits to work since a single-phase supply connecting to an AC motor doesn’t generate a rotating magnetic field. Also, the power output of a single-phase supply is not constant, meaning its voltage supply rises and falls.

Furthermore, power lines are an input source in a single-phase power system because they convert high voltage to low voltage, similar to a step-down transformer. Thus, it is best suited for household applications.

Single-phase transformers are used in applications where a low voltage circuit needs to be powered from a higher voltage network. Single Phase Transformers take this one step further and allow more individual systems, each operating at their voltage, to be distributed across a common line. It greatly increases efficiency and reduces costs associated with the distribution of electricity to numerous systems.

In addition, here are the other benefits of using a single-phase transformer:

Single-phase transformers are used to increase the voltage of alternating current motors, and they have some advantages. However, they have their disadvantages too, which includes:

What is the Difference Between 1 Phase 2 Phase and 3 Phase Power?

A three-phase transformer is made by winding three single-phase transformers on one core. It contains six coils, three each for the primary and the secondary sides, separated from the opposite by an angular difference of 120 degrees.

It also features star and delta connectors and twelve terminals with various connections to them. Depending on the power rating of the transformer, three-phase transformers need a powerful cooling system.

These transformers can transport the appropriate amount of voltage across great distances with only a small conductor, assisting in the smooth operation of industrial equipment. Three-phase transformers are well-known for their effectiveness in meeting the demands of heavy-duty applications, making them ideal for heavy industrial applications.

Three-phase transformers are utilized in various phases of a power transmission system to step up or step down high voltages. It transforms input power to the necessary voltage level while maintaining proper phasing and polarity.

Three-phase power works differently in that electricity is created by rotating three coils within the generator through a magnetic field. The three primary coils are linked to give the appropriate polarity and are arranged in a pattern known as Delta.

The three secondary windings are likewise linked at the plant, but they will be arranged as Delta or Wye depending on the voltage needs. The windings are 120 degrees apart and produce electricity as they revolve through the magnetic field. The produced electricity is then distributed across three distinct lines, which is called three-phase power.

Three-phase transformers are particularly useful for large motors and other equipment; thus, for industrial uses, three-phase transformers are far more efficient. Aside from that, there are other advantageous features of transformers that operate from a three-phase source:

Three-Phase Transformers are used in most electrical power systems due to their reasonability and efficiency compared with single-phase transformers. However, this type of transformer still has its disadvantages.

A pad-mounted transformer is a ground-based electric power distribution transformer housed in a lockable steel cabinet. It is installed on a pad (often concrete or polymer concrete). All electrified connection points are safely covered in a grounded metal casing, allowing it to be put in locations where a fenced enclosure is impossible.

Pad-mount transformers are used at service drops on underground power distribution lines to reduce the primary voltage to the lower secondary voltage provided to utility consumers. A single transformer may service a huge structure or several dwellings. Also, it comes in single-phase and three-phase configurations.

Pad-mounted transformers are transformers with superior technical features. They offer many benefits such as:

Pad-mounted transformers may not appear dangerous, yet they may transport the same amount of voltage as overhead power lines. The most obvious disadvantage is that the transformer’s pads are sometimes thin and insufficient to provide adequate mechanical support.

Also, pad-mount transformers are oil-filled devices that should be installed outside only. Though this equipment is usually carefully stored in green metal boxes, preventive measures must still be taken. Like, children should not be allowed to play on or around pad-mounted transformers. Also, replace the lock of the box when it is tampered with or broken.

Now that we have defined different terms included in this loaded term, we understand what this transformer is. Live Front-Three Phase Pad Mounted Transformer is designed to distribute three-phase power in industrial and commercial applications. The transformers are packaged in a weatherproof, pad-mounted, light-weight enclosure for easy installation.

Three-phase pad-mounted transformers are commonly used to service three-phase commercial and industrial loads from underground distribution networks.

A live front pad mounted transformer is a type of transformer that is commonly used in the electrical power distribution system. It is called a live front transformer because the high voltage components are installed in a compartment that is accessible while the transformer is energized or “live”. The transformer is usually mounted on a concrete pad and is designed to be placed in outdoor locations, such as on the side of a building or on a utility pole.

The purpose of a live front pad mounted transformer is to convert high voltage electricity from the utility company into low voltage electricity that can be used by homes and businesses. This type of transformer is designed to be efficient, reliable, and safe for use in residential and commercial applications.

Live front pad mounted transformers are available in different sizes and configurations to suit different power requirements. They can be designed for single-phase or three-phase power distribution, and can be rated for different voltage levels depending on the needs of the application.

In the next section, we will discuss the key factors to consider when choosing the best live front pad mounted transformer for your business.

A live front pad mounted transformer is a type of transformer that is mounted on a pad and has a front that is accessible for maintenance and operation. It is designed to be energized and operate continuously, making it an essential component in power distribution systems.

Live front pad mounted transformers offer several advantages over other types of transformers, including:

Increased Safety: Live front pad mounted transformers are designed with a live front, which means the energized parts are exposed and easily accessible. This allows for quick and easy maintenance, reducing the time that workers need to be exposed to hazardous electrical conditions.

Compact Design: Live front pad mounted transformers are designed to be compact and easy to install. This makes them ideal for use in urban areas where space is at a premium.

Cost-Effective: Live front pad mounted transformers are cost-effective, with a lower initial purchase cost and reduced installation costs. They also have a longer lifespan, which means they require less maintenance and have lower ongoing costs.

High Efficiency: Live front pad mounted transformers are highly efficient, with minimal energy loss during transmission. This reduces energy costs and makes them an environmentally friendly option.

Improved Reliability: Live front pad mounted transformers are designed to be highly reliable, with low failure rates and minimal downtime. This ensures a consistent and uninterrupted power supply.

Overall, live front pad mounted transformers offer a range of benefits that make them an excellent choice for a wide range of applications.

Live front pad mounted transformers offer several advantages, including easy installation, low maintenance requirements, and high efficiency. They are also versatile and can be used in a wide range of applications, from residential to commercial and industrial.

A live front three-phase-pad mounted transformer generates electricity by rotating three coils through a magnetic field. The three main coils are organized in a Delta pattern, while the secondary windings will be arranged as Delta or Wye, depending on the voltage requirements.

This type of transformer increases or decreases power supplied to a building system, such as the main level lighting and electrical load center. Also, its cable at terminals is exposed in the bushing. This transformer is supported on a concrete pad that is cast at the site.

The main advantages of this type are that they provide a small footprint, require very little space, and can be placed close to loading equipment and power system utilities. They also offer high reliability and the ability to withstand flooding, earthquakes, hurricanes, and other natural disasters.

The transformer load’s electrical size is measured in kVA. This rating specifies the corresponding power output supplied by the loads connected to the transformer on the secondary side of the equipment during a particular period.

For live front – three phase pad transformers, it is available in standard ratings or 45, 75, 112.5, 150, 225, 300, 500, 750, 1000, 1500, 2000, and 2500 kVA.

Live Front-Three Phase Pad Mounted Transformers are installed and used in various ways as part of a residential, commercial and industrial building’s electrical system. Among these application kinds are:

A pad-mounted transformer consists of core and coils housed in a steel oil-filled tank, with transformer terminals accessible through an adjacent lockable wire cabinet. There are high and low voltage wire compartments inside the wiring cabinet, and the underground high and low voltage wires enter the terminal chambers immediately

Carriage bolt-nut assemblies fasten the tank’s top. Also, the wiring cabinet has two end side walls with doors that open sideways to reveal the high and low-voltage wire compartments.

These transformers also feature their protective fusing. They consist of a low-energy Bay-O-Net fuse situated in the high voltage compartment and a backup high energy current limiting fuse connected in series. Both fuses are submerged in oil. The Bay-O-Net fuse is a replaceable field device that protects against secondary faults and transformer overload.

Pad-mounted transformers commonly do not pose risks. However, it still converts high-voltage energy to the lower voltage required for underground cables for power houses’ lights and appliances. They function similarly to the transformers found on electricity poles linked to overhead power lines. Thus, you must be extremely careful around them.

A box that has been pushed sideways by machinery, or has been tampered with and lacks a lock, can pose a severe hazard to anyone, especially youngsters, who frequently use them as a platform. Children should not be near these boxes since they are potentially hazardous and should not be played with.

Keeping bushes, buildings, or structures away from the pad-mounted transformer is critical. Also, make sure that plant roots do not develop to interfere with wires and underground cables. Lastly, always double-check that the box is securely locked because poorly secured pad-mounted transformers can be a major threat.

Yes, because the term “live” refers to the fact that the transformer’s bushing terminal cable is truly exposed. When you come in contact with these transformers, especially to the bushing, you might get electrocuted. Remember that this kind of bushing is not insulated.

Yes, it is cheaper to run three-phase systems. First, because it isn’t carrying much current, you can minimize the size of your neutral conductor. In fact, three-phase systems can have three times the power of single-phase systems while utilizing half the amount of copper as a conductor. Given the cost of these materials, this would represent significant savings in the long term.

Three-phase systems provide more control over how much power is supplied to your equipment, which may allow you to utilize less equipment in some instances. It reduces your equipment and power use, which lowers your electricity cost.

Though three-phase system transformers may have a higher initial cost, you will save in the long term. More efficient power means greater production and, eventually, more money.

Though many factors determine the life expectancy of a transformer, it is expected to have a service life ranging from 30 to 50 years.

A transformer situated near a building, in general, requires 4ft clearance from the vertical surfaces of the structure, assuming no windows from grade to 18ft. The sides of the transformer must be 3 feet free of all objects, and the transformer must be 10 feet horizontally from any doors, windows, or fire hydrants.

Transformers must typically be positioned adjacent to buildings such that the front doors face away from the building and there are no balconies or overhangs above. Line trucks must be able to access the transformer for future repair or replacement.

Live front pad mounted transformers come in different types, each designed for specific applications. Here are the common types of live front pad mounted transformers:

Three-Phase Live Front Pad Mounted Transformers: These transformers are commonly used in commercial and industrial settings. They come in different sizes and are designed to handle high power loads.

Single Phase Live Front Pad Mounted Transformers: These transformers are designed for smaller loads and are commonly used in residential areas. They are relatively smaller and less powerful compared to three-phase transformers.

Compact Live Front Pad Mounted Transformers: These transformers are designed for applications that require a smaller footprint. They are ideal for areas with limited space and are commonly used in urban areas.

Low Profile Live Front Pad Mounted Transformers: These transformers are designed to be installed in areas where overhead lines are not allowed. They have a low profile design that makes them ideal for use in residential areas.

Dead Front Transformers: These transformers have a front cover that can be removed to allow access to the connections. They are commonly used in underground applications and areas with limited space.

When choosing a live front pad mounted transformer, it is important to consider the specific application requirements to ensure that the right type of transformer is selected.

Live front pad mounted transformers are critical components in electrical systems, and selecting the right one for your business requires careful consideration. Here are some factors to consider when choosing the best live front pad mounted transformer for your business:

Capacity: The first factor to consider when selecting a live front pad mounted transformer is its capacity. You need to choose a transformer with the right capacity to handle the electrical load of your business. Consider the maximum power demand of your facility and select a transformer that can handle that load.

Voltage: Another critical factor to consider is voltage. Transformers come in different voltage ratings, and you need to select one that is compatible with your electrical system. Make sure to choose a transformer with a voltage rating that matches the voltage of your electrical system.

Efficiency: The efficiency of a transformer is another essential factor to consider. A more efficient transformer will result in lower energy costs and less energy waste. Look for transformers with higher efficiency ratings, which will save you money on energy costs in the long run.

Reliability: The reliability of a transformer is crucial for the smooth operation of your business. Look for transformers that are built with high-quality materials and have a proven track record of reliability.

Environmental factors: The environment where the transformer will be installed is also important to consider. The transformer needs to be able to withstand the environmental conditions of your location, such as temperature, humidity, and elevation.

Safety features: Safety should always be a top priority when selecting a transformer. Look for transformers that have safety features such as overload protection, short circuit protection, and fire-resistant construction.

Manufacturer: Finally, it is essential to choose a reliable manufacturer when selecting a live front pad mounted transformer. Look for manufacturers with a reputation for quality and reliability, and who offer good customer support and warranties.

By considering these factors, you can choose the best live front pad mounted transformer for your business, ensuring efficient and reliable power supply.

Live front pad mounted transformers are designed to provide reliable power distribution in various settings, including residential, commercial, and industrial applications. To ensure the optimal performance of your transformer, it is important to consider its specifications when choosing the right one for your needs.

KVA Rating: The KVA rating, or kilovolt-ampere rating, is a measure of the transformer’s capacity to handle loads. This rating is essential in determining the appropriate transformer size for your application.

Voltage Rating: The voltage rating refers to the maximum voltage at which the transformer can operate. This specification is critical to ensure that the transformer can handle the voltage requirements of your application.

Phase: Live front pad mounted transformers can be single-phase or three-phase. The number of phases needed depends on the electrical load requirements of your application.

Frequency: The frequency rating of a transformer specifies the operating frequency range in hertz. This is an important specification to consider, especially when working with sensitive equipment.

Insulation: The insulation system of the transformer determines the maximum temperature it can withstand before breakdown or damage. The most common insulation materials used in transformers include oil, dry-type, and silicone.

Enclosure Type: The enclosure type of the transformer is important to consider, depending on the application’s environment. NEMA enclosures are commonly used for outdoor applications, while indoor transformers can be housed in cabinets or vaults.

Cooling Method: The cooling method of the transformer can be either natural or forced. Forced-air cooling is recommended for high-temperature applications, while natural cooling is sufficient for lower-temperature environments.

Efficiency: Transformer efficiency refers to the percentage of input power that is converted to usable output power. The higher the efficiency rating, the more energy-efficient the transformer is.

By considering these specifications when choosing a live front pad mounted transformer, you can ensure that you get a reliable and efficient solution for your power distribution needs.

When it comes to purchasing a live front pad mounted transformer, choosing the right manufacturer is essential. Here are some top manufacturers to consider:

ABB: ABB is a leading supplier of power and automation technologies that offers a variety of live front pad mounted transformers. Their transformers are designed to meet customer-specific requirements and are built to withstand harsh environments.

Eaton: Eaton offers a range of live front pad mounted transformers designed for residential, commercial, and industrial applications. Their transformers are engineered for high performance, reliability, and energy efficiency.

GE: GE is a well-known manufacturer of electrical equipment, including live front pad mounted transformers. Their transformers are designed for high voltage applications and are built to last.

Schneider Electric: Schneider Electric offers a range of live front pad mounted transformers designed for both indoor and outdoor use. Their transformers are built to withstand extreme weather conditions and are designed for easy installation and maintenance.

Siemens: Siemens is a global manufacturer of electrical equipment and offers a variety of live front pad mounted transformers. Their transformers are designed to meet the needs of different industries and are built to last.

When selecting a manufacturer, consider factors such as product quality, reliability, cost, and customer service. It’s also important to choose a manufacturer that offers after-sales support and maintenance services to ensure that your transformer is properly maintained and functioning at optimal levels.

Some top live front pad mounted transformer manufacturers include ABB, Eaton, Schneider Electric, Siemens, and General Electric.

There are several types of live front pad mounted transformers, including single-phase, three-phase, and underground. Single-phase transformers are used in residential applications, while three-phase transformers are used in commercial and industrial applications. Underground transformers are used in areas where space is limited.

To choose the best live front pad mounted transformer for your business, consider factors such as the required voltage, current, and power rating, as well as the size and weight of the transformer. You should also consider the manufacturer’s reputation, warranty, and customer support.

The specifications of a live front pad mounted transformer include the voltage rating, current rating, power rating, and physical dimensions. These specifications will vary depending on the specific transformer and its application.

Live front three-phase pad-mounted transformers give you three-phase electricity without having to fork out thousands on installing a sub-station at extra cost. It is designed for high efficiency and safety when converting electric power from one voltage level to another.

DAELIM’s live front phase-pad mounted transformers are an ideal solution for any distribution system, all of which are built with enhanced safety and reliability margins. In line with the current industry requirements, all DAELIM transformers are designed and manufactured following IEEE standards. Contact us today for the availability of kVA sizes, features, and designs that best meet your needs!

When you need to find more than just existing transformers, Daelim’s Transformer Service Center can help you design and produce distribution transformers that meet your unique needs.

We have our own factory and a professional team of engineers, which can design and modify application requirements that meet all your conditions.

Download Resource

After filling in the contact information, you can download the PDF.