How to Choose Pad Mounted Transformer?

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical

ELECTRIC, WITH AN EDGE

This comprehensive guide is your go-to resource for understanding distribution transformers, vital components in the power transmission and distribution network. We delve into the working principle, different types like the pole mounted and 3-phase distribution transformer, their ratings, diagrams, key manufacturers, and the essential parts making up these complex devices. As we explore these various facets of distribution transformers, you’ll gain a deep appreciation for their critical role in stepping down high voltage power to usable levels in commercial and residential applications.

If you have been looking for a transformer, chances are, you might have heard of distribution transformers, which is one of the most widely used transformers in the world for many reasons such as easy installation of distribution transformer, and their useful distribution transformer working principle that is supported by the distribution transformer parts.

However, with so many distribution transformers available in the market, it is hard to find which one is suitable for you. For that specific reason, DAELIM, one of the top distribution transformer manufacturers in the world, will help you make the right purchase decision by assisting you with what you need to know about this electrical device.

For starters, it is vital to know what are distribution transformers first before going through their mechanism, functions, parts, installation, and many more.

High Voltage Distribution Transformer

-A lot of electrical companies use high voltage Distribution transformer to effectively operate at applications that are at high voltage levels.

A Complete Guide to Single Phase Distribution Transformer

-Consumers use electricity for different industries. Transformers work to make this happen as single-phase distribution transformers.

Calculation Formula of Transformer Transformation Ratio

-The calculation formula of transformer transformation ratio, the voltage at both ends of the loaded primary winding must be the rated value.

Basically, a distribution transformer is also known as a common kind of isolation transformer, and its main function is to alter the high voltage of the transformer from normal voltages like 240/120 volts to use in electric power distribution/s.

When it comes to the distribution system, there are several types of transformers out there. Including but not limited to single-phase transformers, three-phase transformers, pad-mounted transformers, pole-mounted transformers, and many more.

In general, these types of transformers are usually available in various sizes with different levels of efficiencies, and there is a difference in their insulating oil as well. The selection of these transformers relies on the equipment and also your budget.

Basically, there are four kinds of distribution transformer connections out there. These are the star-star connection, delta-delta connection, star-delta connection, delta-star connection, and ZigZag or delta Zigzag.

In terms of the design of the transformer, the distribution transformer is closely manufactured the same way small-size transformers are done.

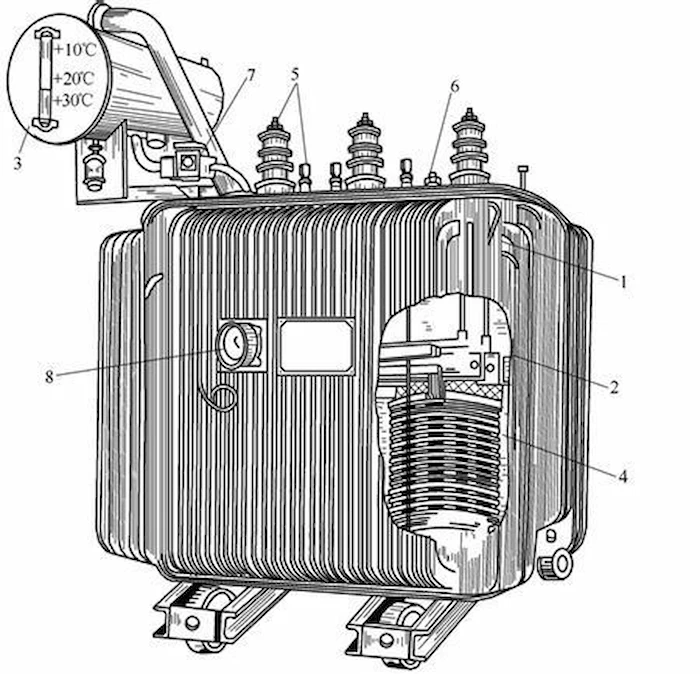

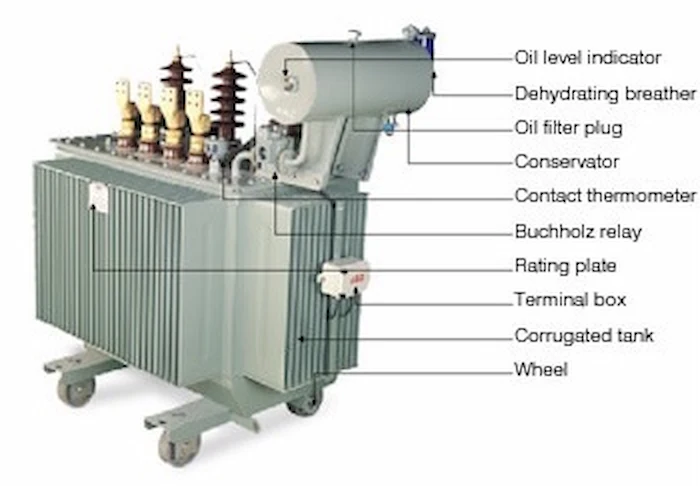

This means that the main distribution transformer parts mainly include an oil tank, oil indicator, breather unit, Buchholz relay, conservator, temperature detector, thermal relay, bushings, pressure relief device, and several more.

This leads us to the functions of these distribution transformer parts.

Just like other types of transformers, distribution transformers consist of several components such as:

The oil tank’s primary function is to soak the windings by it inside.

Moreover, it is also used in oil-filled transformers.

There are even some types of high-voltage capacitors, lamp ballasts, fluorescent, and high-voltage switches and circuits breakers that’s purpose is to insulate, suppress corona arcing and discharging.

Lastly, it can also serve as a coolant.

A transformer’s conservator is formed above the oil tank, specifically outside the transformer’s frame.

Moreover, it is also connected to the main tank with the help of a metallic tube.

The oil inside the tank can be easily enlarged and contacted if there is a need to.

It is accessible throughout the loading to adjust the temperatures whether to increase or decrease.

The Buchholz relay is primarily used when a conservator tank is being used since it will indicate errors like loss of oil as it goes low.

This also involves the improper flow of oil between the tank and the transformer itself.

In other words, in electric power distribution and transmission, a Buchholz relay is considered a safety device that can be mounted on some oil-filled power transformers and as well as reactors that are equipped with an external overhead oil reservoir or also known as a conservator.

For the generic designation of this type of device, it is known as a detector relay.

A breather unit involves a silica gel that is responsible for absorbing moisture in the oil.

Moreover, it changes its color from blue to pink if it is not capable of absorbing the moisture in the oil.

In simpler terms, a transformer’s breather helps prevent atmospheric moisture from occurring.

Furthermore, this reduces maintenance costs.

For conservator-style transformers, this movement of the oil level will cause what is known as a transformer breathing cycle.

This happens as air is brought into the tank and expelled again later.

The oil indicator is basically what indicates the level of the oil within the conservatory unit.

In other words, if air bubbles remained in the transformer, then it is expected that gas will be generated due to an internal failure or if there is a leakage at the transformer tank.

As the name suggests, the temperature detector of a transformer is responsible for monitoring the temperature of the oil.

This means that if the temperature of the oil were to increase to a certain level, the transformer will be automatically disconnected from the service.

The function of the pressure relief device is to decrease the pressure within the transformer to avoid an explosion or fire from occurring inside the transformer.

The P.R.D is also used to avoid high oil pressure builds inside the transformer during faulty conditions.

It is fitted on top of the main tank.

Basically, the P.R.D enables the rapid release of excessive pressure that is generated in the event that there is a serious fault.

On the other hand, the thermal relay is used as an indicator for the temperature of the winding.

The thermal relay is also considered a protective device for the transformer since it protects it from overloads.

This type of protection generates the temperature of the transformer’s windings.

Moreover, the simulation is also based on the measure of the current and on the thermal time constant of the transformer.

In simple terms, a radiator of a transformer enables faster cooling rates.

This means that it plays a vital role in regulating the temperature of the transformer or increasing the loading capacity.

This is the basic function of a radiator of both power transformers and distribution transformers.

In short, the radiator is used to increase the transformer’s cooling efficiency.

The main purpose of the bushing for transformers is for connecting the internal windings of the transformer with the help or assistance of an exterior electrical network.

A transformer bushing is also an insulating structure that facilitates the passage of an energized, conductor that is also carrying a current through the grounded tank of the transformer.

The two principal types of bushing constructions are solid or bulk type and capacitance-graded, and they are also sometimes called condenser type.

As mentioned, isolation transformers like distribution transformers are used to transfer electrical power from a source of alternating current power to some equipment or device while isolating the powered device in front of the power source for safety reasons.

According to the way it is being used or its application, these transformers are categorized into several kinds such as single-phase transformer, three-phase transformer, pad-mounted transformer, pole-mounted transformer, and underground transformer just to name a few.

Single-phase distribution transformers are specifically designed for networks wherever a three-phase supply is not available or required.

In a normal situation, these are specially used for repairing overhead distribution loads in residential.

These are also applicable in industrial lighting, light commercial loads, and as well as power applications.

When it comes to three-phase distribution transformers, this kind of transformer is commonly used for holding electrical energy from the main distribution circuit to a minor distribution circuit. Moreover, this type of transformer transmits currents to a secondary distribution circuit that also reduces the voltage of the primary distribution circuit.

These transformers also reduce the voltage supply for the primary circuit based on the consumer requirement. It is expected that the voltage always changes and it is dissimilar for the users of commercial, residential, and also in the light industry.

These transformers work on different levels of voltage and frequency that is based on the standards of existing countries. These transformers are also widely available in both single-phase and three-phase ones.

Single-phase transformers are commonly found in residential applications. On the other hand, three-phase distribution transformers are used with pad underground primary circuits.

Aside from single-phase and three-phase pad-mounted distribution transformers, this type includes a locked steel cupboard that is arranged on a concrete pad.

This type of transformer is also installed in places where they do not have space for a fenced enclosure.

Moreover, this transformer is also used with an electric power distribution line at an overhead electrical line for reducing the primary voltage to supply for the customers.

A single transformer of this type can without a doubt serve many homes and even a large building.

The usual power rating of this transformer usually ranges from 75 kVA to 5000 kVA, and this also includes fixed switches and fuses.

Aside from pad-mounted transformers, there is also a pole-mounted transformer, which is the most common transformer that can be seen in the public since it is safe for displaying outdoors but above-ground only.

This type of distribution transformer can be seen mounted on an electrical service pole at the height of overhead cables.

These are used for changing high distribution voltages to low, usually around 120/240-volt power.

These types of transformers are also used in a wide rural area that usually ranges from 16 kVA to 100kVA.

They can be seen available in small sizes and are easy to fit on single-pole structures.

These transformers are very reliable in harsh climates since they have a strong build that is specifically designed to withstand various climates.

The tanks of the transformer can be shaped and protected from corrosion-resistant materials.

The design is also to avoid the accumulation of water.

For coastal areas, the tanks can still be protected from zinc spray.

On the other hand, high corrosive regions will require stainless steel tanks for maximum protection.

Pole-mounted distribution transformers have several applications, such as their ability to change voltages from high to low (for consumer use).

But its main or primary function is for stepping down the voltage to provide isolation between the two windings (primary and secondary).

Moreover, this type of transformer also has the ability to distribute power even in the most remote areas which are generated from power plants.

In general, this distribution transformer has the ability to distribute electricity to industries with less voltage that are under 33kV and 440 volts to 220 volts for domestic purposes.

When it comes to the distribution transformer working principle or the process of how they work, a distribution transformer is also known as a service transformer that is known for providing the final voltage transformation in the electric power distribution system, stepping down the voltage that is being used in distribution lines to the level being used by the customer.

When it comes to the installation of distribution transformers they are fairly easy to install.

However, it is highly recommended that you let the professionals do the work.

For professional help, advice, and assistance, contact DAELIM’s team for immediate accommodation.

This is to fully inspect and secure the transformer to see if it is ready to operate or not.

Moreover, the installation costs are only low since distribution transformers are much easier to install compared to other types of transformers.

Whether you have a small or big project for your purpose of needing a distribution transformer, there is without a doubt that this type of transformer is perfect for you since it has the ability to supply electricity to multiple houses, and does not have a problem of supplying electricity to a single building.

If you have any questions or concerns you would want to raise, do not hesitate to contact DAELIM’s team of professionals for immediate assistance.

DAELIM aims to help you make the best purchase decision and establish a successful project for you.

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical

The primary function of the pad mounted transformer is to serve as a critical distribution

A pad mounted transformer operates through electromagnetic induction, serving as a crucial distribution component that

If you find that the existing distribution transformer types or power cannot meet your requirements. You can choose to tell Daelim. Daelim has a team that has always had a wealth of design transformers, and can give you a specific design plan in the shortest time.

Daelim’s distribution transformers comply with IEEE, ANSI, CSA, IEC certification, and are used in North America (such as Canada, the United States, Mexico), South America (such as Ecuador, Chile), Europe (such as Spain, Lithuania) and some Asian countries. Daelim even has a professional installation team that can provide you with installation services.

After filling in the contact information, you can download the PDF.