ELECTRIC, WITH AN EDGE

Transformers are responsible for ensuring that we use all our appliances and other items that need electricity at a safety level. One type of Transformer is the 33 kV transformer.

Let’s talk about what it is, how it works, and why 33kV transformers are important for your electricity needs.

DAELIM is the world’s top professional Transformer and electrical equipment manufacturer.

This company has been a reliable and trusted brand for more than 15 years. Following international standards like ANSI, IEEE, IEC, CSA, AS/NZ, etc.,

DAELIM upholds these standards with inexpensive and premium products.

The 2021 Complete Guide to 3 Phase Step Up Transformer

-A lot of consumers tend to confuse 1 phase transformers with 3 phase step-up transformers from 220v to 480v step-up transformers.

The 2021 Complete Guide to Transformer Producers

-Are you looking for companies that manufacture and distribute quality electric transformers? Find out here.

8+FAQ About the Power Transformer Manufacturers

-This article will talk about the most popular power transformer manufacturers like DAELIM around the globe today. Read on!

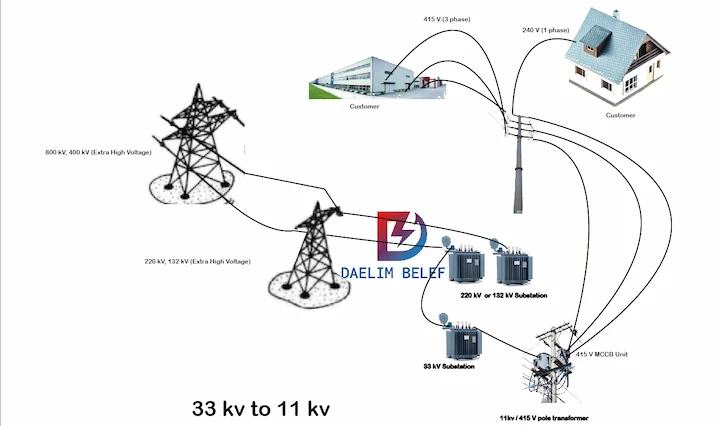

A 33 kV transformer is a high voltage substation that distributes voltage levels in residential areas through 11kV feeders.

This type of Transformer has a very high voltage to prevent transmission loss when power is transferred over long distances.

33kV transformers lower down the voltage to 11kV to be safely used in homes and businesses.

The 33kV diagram above shows how power is converted from a 33kV station to 11kV supplies appliances at home and in business areas.

Different transformer specifications are designed to match different transformer needs.

When looking for a 33kV transformer, you should always check the most suitable 33kv/415v transformer specification that will match the needs of your different appliances.

The essential specifications of a 33 kV transformer are the core structure, the phase design, and the cooling design.

The core structure of a 33 kv transformer is the same as every other transformer, but there are some differences.

We use a lamination process to enhance the performance of the windings and allow more power to be transferred from the primary winding to each secondary winding.

The core is found at the center of the transformer.

These are the two most basic designs of the core structure are the core type and shell type.

For a core-type transformer, the coils of primary and secondary windings are wound around the core ring; they are commonly cylindrical types.

Generally, the coils can be circular, oval, or rectangular.

A small-sized core-type transformer uses a rectangular core with cylindrical coils that are either rectangular or circular.

On the other hand, large-sized core-type transformers use cylindrical, circular coils to be wound perfectly to fit over the cruciform-shaped core.

Circular cylindrical coils are commonly preferred with core-type transformers because of their superior mechanical strength.

Shell-type transformers, the coils of primary and secondary windings pass inside a steel magnetic circuit or core, which forms a protective shell around both windings.

The coils are commonly wound in pancakes, where each multilayer disk is insulated using paper.

With shell-type transformers, they can have a simple rectangular or a distributed form.

The phase design of transformers can either be single-phase or three-phase.

The major difference between the two is how each completes one circuit.

Let us compare and contrast the two types of phase designs.

Single-phase transformers use one conductor and one neutral wire to complete one circuit.

They refer to transformers that use only one pair of primary and secondary coils to produce the voltage needed.

A single-phase transformer consists of 2 inductive coils that are wound on either an iron or steel core.

The winding or coil attached to the AC supply is the first or primary winding, while the other is the secondary winding.

33kV Transformers with a single-phase design is commonly used in residential areas to convert high voltage into low voltage.

Generally, single-phase transformers do not need cooling systems. Some of the benefits of single-phase transformers include:

Three-phase transformers compose of six coils, three each on the primary and secondary sides. All of the three coils are separated from each other by 1200 degrees of angular difference.

They are made by winding three units of single-phase transformers on a single core. 33kV three-phase transformers need three conductors and one neutral wire to complete one circuit.

For 33kV three-phase transformers to efficiently achieve the desired voltage, they are placed in a dielectric oil-crammed enclosure. They are mostly used for heavy-duty and industrial applications. Some of the benefits of transformers with a three-phase design include:

The cooling design is an important aspect of a transformer because it ensures that it is kept at the ideal temperature for proper function.

Generally, the cooling design of a transformer can be oil-cooled or dry type.

A dry-type 33kV transformer utilizes air as the cooling medium.

Air is made using vacuum pressure impregnation in polyester, silicone varnish, or VPI epoxy and cast resin to survive harsh environmental conditions.

For a dry-type transformer, the maximum voltage to perform well is limited to 33kV.

Oil-cooled 33kV transformers have coils immersed in mineral oil to maintain the temperature of the Transformer for maximum function.

The oil used dissipates through the radiators attached to the tank of the Transformer.

Cooling is enhanced by the installation of fans on the radiators to bring the Transformer’s temperature down.

Oil-cooled transformers can reach voltage capacity as high as 1000kV.

11kV transformers are more commonly used in residential areas.

They feed the local transformers, which are responsible for distributing power to buildings in the same area.

33 kV transformers, on the other hand, are involved in converting higher voltages.

They are mainly used to distribute power in between substations.

To identify the kV rating of a transmission line, one of the most important factors to note is the number of disc insulators.

One disc insulator is equivalent to 11kV. This means that when a transmission line has one disc insulator, the kV rating for that transmission line is 11kV.

If three-disc insulators per phase are connected in one transmission line, the kV rating for that transmission line is 33kV.

Pin insulators can also help determine the kV rating of a transmission line. 33 kV transformers commonly use large-sized pin insulators.

kV or Kilovolt is the unit of measurement of voltage in high power transmission lines.

The main difference between kV and kVA is that kVA or Kilo Volt Ampere is the unit of apparent power rated by a transformer.

All transformers are always rated in KVA.

33 kV transformers can efficiently convert and distribute electrical power over long distances in industrial applications.

They are the transformers of choice when looking for high voltage transformers that generate less voltage transmission loss between substations.

Daelim guarantees safe, durable, and high-quality transformers for all your transformer needs.

These transformers are worth your money and will certainly last for years to come.

If you find that the existing distribution transformer types or power cannot meet your requirements. You can choose to tell Daelim. Daelim has a team that has always had a wealth of design transformers, and can give you a specific design plan in the shortest time.

Daelim’s distribution transformers comply with IEEE, ANSI, CSA, IEC certification, and are used in North America (such as Canada, the United States, Mexico), South America (such as Ecuador, Chile), Europe (such as Spain, Lithuania) and some Asian countries. Daelim even has a professional installation team that can provide you with installation services.

ELECTRIC, WITH AN ENGE-- DAELIM BELEFIC

After filling in the contact information, you can download the PDF.