ELECTRIC, WITH AN EDGE

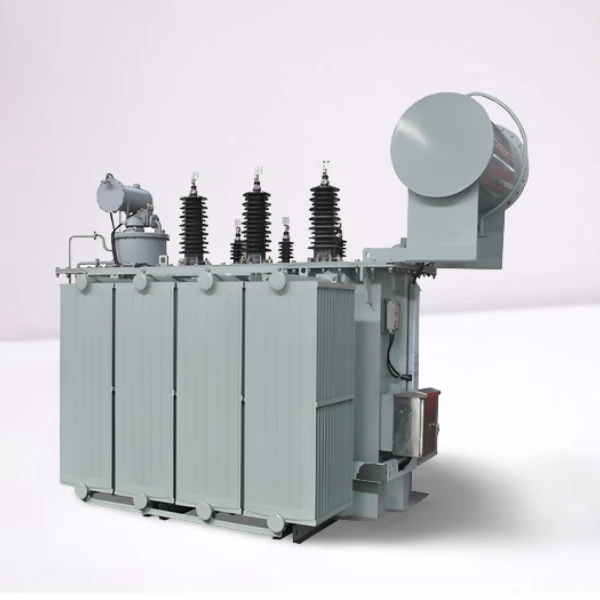

The 15 MVa Transformer is a new high-performance modular transformer easily integrated into your local power grid. It is the only transformer that doesn’t require transformers within it, meaning less internal space and fewer cables. The MVa is also highly customizable to optimize efficiency for any load type. Daelim offers quality but inexpensive MVa Transformers for your needs.

Daelim is an electrical company specializing in designing, engineering, and manufacturing top-tier electrical products and solutions. Serving clients for more than 15 years, the company delivers top-tier products in the electrical industry.

15 MVa transformers are designed to carry much higher loads than ordinary transformers and operate at high outputs, lower temperatures. MVa transformers also carry increased static and dynamic ratings, as well as a longer life expectancy.

A 15 MVa Transformer can operate at a voltage input of 1500 V. It’s most commonly used in applications that require high power and low current (not designed for residential use). You can easily find this type of transformer in arc welding machines, industrial plants, and electric robots.

Additionally, a 15 MVa transformer transfers electrical power from source to destination. The transformer has a primary and secondary winding, and you can use it for AC or DC power. This device is often found in the power distribution system of electric utility systems such as substations.

Daelim MVa transformers have specifications that are high-performance, highly efficient, and safe. They also meet ANSI, IEEE, CSA, and IEC standardization requirements. If you’re looking for a top-notch and safe 15 MVa transformer, Daelim has all the features you need!

A 15 MVA transformer is a high-capacity electrical transformer that can convert power from one voltage level to another in power systems. It is used in power generation, transmission, and distribution systems, as well as in industrial and commercial applications.

Three-phase transformers are the most common type of transformer in use today. They can deliver up to 15 MVa (megavolt amperes) of power, which is important because they have many applications.

Also, these transformers create a magnetic field that generates an electrical current from the power supply. The transformer can adjust the voltage and current by using one or all of these phases.

Additionally, the three-phase transformer is a device that uses three different voltages. It consists of three identical coils, each with a separate voltage. Then, it rotates them at the same speed against one another. The transformer’s output current varies according to the number of turns in each coil.

It is used to step up or down the voltage to transform any single voltage source into three separate phases. Then, these are connected using a common bus bar.

Thus, for a transformer to work, it must be in a three-phase configuration. The primary coil is in the middle, and the secondary coils are on either side of it. The design of three-phase transformers is more efficient than single-phase designs. This is because there are fewer resistances in this type of transformer.

Oil-cooling is the most efficient method for power transformers to maintain their rated load. This type of cooling also can reduce operating costs by up to 40% with no additional investment.

When designing systems that require higher transformer ratings, oil-cooling is the most cost-effective way to go.

Larger transformers can be worth it because of their efficiency and high reliability. The extra money spent on oil-cooled transformers can help your company save money in the long run.

Additionally, Oil-cooling is one of the most important features of a transformer. The oil-cooled transformer can deliver up to 25% higher energy than a three-phase transformer with the same rating. This allows for increased efficiency, reduced size, and reduced cost.

Lastly, oil-cooled transformers are more resistant to power surges and reduced susceptibility to mechanical damage.

A Complete Guide to Oil Immersed filled Distribution Transformer

Although sometimes the oil oxidation products in transformer oils may affect the transformer. Oil oxidations are highly harmful acids that can attack insulation and other materials, causing overheating and degrading insulation. This will ultimately result in increased operating costs due to increased maintenance.

15 MVa transformers are available in designs that are either two-winding or three-winding. They are usually either single-phase or three-phase power transformers.

Single-phase, two-winding transformers are used for low-power applications. However, three winding transformers are used for medium and high power applications.

Also, the two-winding design features one winding on the bottom and a second winding on top. This design is used in many different transformers, including step-up, step-down, and three-phase designs.

The three-winding design has separate windings for the primary and secondary voltages.

A transformer core is a magnetic device used to step up or step down high voltages following the Transformers, Inc. They are made of copper, iron, nickel, or aluminum. Transformers are essential in most electrical engineering applications, including the distribution of power. The output voltage is determined by its input voltage and the number of turns on its coils.

Amorphous steel is a transformer core made up of an amorphous alloy, which means it has no crystalline structure. This type of core is used in transformers that are designed to remain stable at high temperatures.

The amorphous steel can be magnetized or demagnetized depending on the needs of the application. Furthermore, the Amorphous Steel core creates a transformer for greater efficiency and power output.

Carbonyl Iron type of transformer cores is specially designed to reduce the risk of fire and electric shock. These types of transformers contain a very high percentage of iron material, which is denser than copper. They’re also more resistant to corrosion and will carry heavy currents for a longer time.

Ferrite Ceramics are the most commonly used type of core in transformers. They tend to be less expensive than other cores, but they are more fragile and require more maintenance over time.

Moreover, ferrite ceramic has high permeability and is excellent for use in transformers. The ferrite core also helps decrease the transition losses of the transformer due to the low relative permeability.

This type of core will help improve efficiency and decrease energy consumption. Additionally, it helps protect against wear and tear on materials.

They help prevent overheating and protect against damage caused by overvoltage, under-voltage, and general industrial accidents. Lamination provides insulation between parts of the core.

The lamination enhances the performance of the transformer by keeping its insulating properties intact. Laminating also reduces the loss of electricity that occurs when there are orientation changes.

The silicon steel core is a type of non-ferrous metal that can withstand high currents and voltages. It allows the rotating magnetic field to flow through the material. Plus, it’s non-conductive and doesn’t allow current to leak away from the transformer.

This one can carry large amounts of electricity. As the primary circuit, it runs on an alternating current (AC). The iron core takes all the power from the alternating current. Then, it transforms into a direct current (DC) with a magnetic field surrounding it.

The solid iron core can produce up to 95% less hum. Effective to keep the noise level down, which enables you to avoid hearing the protectors. Additionally, the efficiency is increased, and it helps in reducing the emission of electromagnetic radiation.

MVa is the amount of electrical energy that you can deliver through a conductor. The unit of measure is MVa. KVa is the transmission voltage at which an alternating current flows.

MVa to kVa conversion is a straightforward calculation using the formula: Kva = 2.5 * Mva. So, if you have a motor with an MVa of 15, multiply it by 2.5. The result is a Kva of 37.5.

A 15 MVa transformer will cost about $2,400.00. This price is while you can get a 10 MVa Transformer for approximately $1,200.00. You’ll need to decide which one would be the best choice for you.

The price range of a 15 MVa Transformer varies widely depending on the brand, manufacturer, and model. A 15 MVa Transformer might cost between $8,000 and $14,000. However, you can find one for as low as $1,500 or as high as $30,000.

The applications for a 15 MVa transformer are quite varied. However, the main ones are in electronics, electrical engineering, transport, and industry. You can use them to produce or modify electric motor power by converting mechanical power into electrical energy.

They are also used in power distribution systems. Because of their high voltage capability, transformers are widely used in robotics and large industries.

MVa is a term used to describe the maximum voltage and power capacity of transformers. MVA is used as the basis for the design of transformers. It is an important factor in determining how it can feed much power into a transformer before being damaged.

No. MVa stands for Maximum Voltage Amps. MVa is the apparent power because it’s based on real voltage and amps. MW is the real power, which is not usually measured. MVAR is a reactive power, which is always negative.

The specifications of a 15 MVA transformer may vary depending on the design and application requirements. At Daelim Belefic, we manufacture 15 MVA transformers in accordance with international standards such as IEC and ANSI/IEEE, and can provide customization options. The transformers are typically designed for 3-phase systems, with voltage levels ranging from 66 to 161 kV.

A 15 MVA transformer is a large power transformer that can handle a maximum power output of 15 million volt-amperes. The specifications of a 15 MVA transformer can vary based on the manufacturer, but some general specifications include:

Rated Voltage: The rated voltage of a 15 MVA transformer is typically between 66 kV to 220 kV, with a nominal voltage of 138 kV being common.

Impedance: The impedance of a 15 MVA transformer is usually between 6% to 8%, depending on the specific model and design.

Cooling Method: A 15 MVA transformer can be designed with either a forced-air or liquid cooling system, which affects the size, weight, and efficiency of the transformer.

Phase: A 15 MVA transformer can be single-phase or three-phase, depending on the application and voltage requirements.

Frequency: The frequency of a 15 MVA transformer is typically 50 Hz or 60 Hz, depending on the country and power grid it is designed for.

It’s important to note that the specifications of a 15 MVA transformer can vary based on the specific application and requirements of the user. As such, it’s important to consult with a reputable transformer manufacturer like Daelim Belefic to ensure that you are selecting the right transformer for your needs. They can provide you with a detailed list of specifications and customize the transformer to your specific requirements, such as voltage ratios, insulation levels, or protective devices.

If you are looking for a high-quality 15 MVA transformer, be sure to consider the technical specifications and quality standards. In addition, the dimensions and weight of the transformer should also be considered as they can impact the installation and transportation of the equipment. Finally, price is an important factor to consider, but it should not be the only factor. A low price may indicate a lower quality or substandard components, which can lead to maintenance or safety issues in the future.

The cost of a 15 MVA transformer can vary depending on a number of factors such as the manufacturer, construction materials, insulation type, and delivery location.

Generally, the cost of a 15 MVA transformer can range from tens of thousands of dollars to hundreds of thousands of dollars. The high cost of these transformers is due to the complexity of their construction, the high-quality materials used, and the extensive testing required to ensure their performance and reliability.

Additionally, the cost of a 15 MVA transformer can also be influenced by the supplier’s reputation and experience in the industry. Some suppliers may charge higher prices for their products due to their experience, reputation, and the quality of their products.

It’s important to note that the cost of the transformer is just one factor to consider when selecting a supplier. Other important factors to consider include the supplier’s experience, reputation, customer service, technical support, and product warranty. When evaluating potential suppliers, it’s important to take all of these factors into account to ensure that you’re getting the best value for your investment.

The dimensions of a 15 MVA transformer can vary depending on the manufacturer and the specific design of the transformer. However, in general, the dimensions of a 15 MVA transformer can be estimated based on its weight and voltage class.

For a 15 MVA transformer, the weight can typically range from 50,000 to 90,000 pounds or more, depending on the type of cooling system used and the specific design of the transformer. The dimensions of the transformer can also vary based on the type of cooling system used, with liquid-immersed transformers typically being larger than dry-type transformers.

In general, the dimensions of a 15 MVA transformer can range from 12 to 20 feet in length, 10 to 14 feet in width, and 10 to 16 feet in height, although these dimensions can vary based on the specific design and cooling system used. It is important to consider the available space and transportation requirements when selecting a 15 MVA transformer, as well as any local regulations that may impact its installation.

It is recommended to consult with a reputable transformer manufacturer or supplier for more specific information on the dimensions and other specifications of a 15 MVA transformer, as well as pricing and delivery options.

The weight of a 15 MVA transformer can vary depending on its specifications, materials used, and the level of customization required. Typically, a 15 MVA transformer can weigh from 50 to 100 tons.

The materials used to manufacture a 15 MVA transformer vary depending on the design and application requirements. Generally, the transformer windings are made of high-quality copper or aluminum wire, which is coated with insulation to prevent short circuits. The transformer core is made of high-grade silicon steel laminations, which have low core loss and high magnetic permeability. The insulation materials used in transformers must be able to withstand high voltages, temperatures, and stress. Different types of insulation materials are used in different parts of the transformer, such as epoxy resins, polyester films, and mica sheets.

In addition to the primary materials, Daelim Belefic also ensures that other components such as bushings, tap changers, cooling systems, and monitoring devices are made of high-quality materials to ensure the durability and reliability of the transformer. The company uses only qualified standard materials which meet the standards of world-renowned suppliers through international procurement as well.

Moreover, Daelim Belefic also adheres to strict quality control standards to ensure that only the best materials are used in the manufacturing process. By using high-quality materials, Daelim Belefic’s transformers are able to perform efficiently and reliably for a long time.

Daelim Belefic offers a comprehensive range of services for 15 MVA transformers, including design, engineering, manufacturing, testing, installation, and maintenance. We also provide technical support and customization options to meet our customers’ specific requirements.

3 MVA Transformer, Everything You Should Know

The 15 MVa Transformer is a powerful, efficient machine that provides up to 48,000 volts of power. It uses only half the power of other transformer machines. Also, it has a wide range of applications for our homes and businesses. Its unusual features make it worth the investment.

This Daelim product will change the way you produce, deliver, and consume energy. It’s perfect for your new business or any other applications that need great energy yet are efficiently used. If you need MVa transformers, Daelim may have just what you’re looking for.

Although there are many different styles of transformers on the market, you may find that there is no one that suits you. At this time, you can contact Daelim.

Daelim is a manufacturer specializing in the design and production of 15 MVA power transformers. Daelim has more than 15 years of experience in transformer design. Engineers can design and produce 15 MVA power transformers that meet your requirements according to your needs.

Download Resource

ELECTRIC, WITH AN ENGE-- DAELIM BELEFIC