How to Choose Pad Mounted Transformer?

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical

ELECTRIC, WITH AN EDGE

Daelim 220kv,110kv, and 69kv 66kv low-loss series Power Transformer and Distribution Transformer is our independently developed new generation of transformers on the basis of absorption of China and foreign advanced technology, which features low local discharge, low loss, high reliability, strong protection against abrupt short circuit.

When transformers were invented. It was imperfect, limited, and less capable of regulating electricity. But as time went on, transformers were modified and upgraded. In fact, you may not be aware that there are many types of transformers available in the market that come in a variety of different sizes, along with specific functions and designs.

There are different types of transformers available in the market that come in various sizes, but basically, they all have the same purpose, which is to regulate the electricity of buildings to prevent electrical disruptions.Despite the variety of different transformers, they all have the same purpose, which is to regulate electricity.

Which is very dangerous to those who have little to no knowledge about transformers.

But worry no longer! DAELIM, one of the most prestigious Power Transformer and Distribution Transformer manufacturers in China, provides you with everything you need to know about power and distribution transformers.

daelim is a transformer manufacturing plant with almost 20 years of experience in production and design. During these times, daelim has formed a team of experienced engineers, and we can design and produce transformers specifically for your needs, according to your requirements.

Daelim’s production site is in Jiangsu, China. Daelim can provide you with dry type transformers, mini substation transformers, pad mounted transformers, power transformers, etc, Daelim can provide you with dry-type transformers, mini substation transformers, pad mounted transformers, power transformers and other transformers of different styles and rated capacities.

Transformers are mediums for transferring energy from one circuit to another circuit by following the process of electromagnetic induction. In general, they are responsible for controlling or regulating voltage levels between circuits by either increasing (step-up) or decreasing (step-down) it down.

Transformers are considered to be very important. In fact, without transformers our electrical energies would not be regulated, controlled, and passed to our houses. You can think of transformers as the root of the tree, and power lines as its branches.

Power Transformers and Distribution Transformers are responsible for the basic components of both transmission and distribution of electricity in a power system. Without a transformer, the absence of it would pose a risk of electrical disruption or uncontrollable voltage that could cause explosion and fire.

One of the main functions of a transformer is to regulate the voltage, this is why it is necessary to have one in your building (depending on the size).

Transformers are responsible for regulating the electricity of buildings to prevent electrical disruptions and hazards. They keep the electrical currents flowing from house to house and power generator to power generator.

Compared to the past, there are now transformers that can be used to increase and decrease the voltage at the power generating station. This is to lessen the transmission losses during the process.

The increase in voltage is called step up while the decrease in voltage is called step down. With both purposes to supply power to the building.

In other forms of application that consist of different voltages, transformers are of great help because they can adjust the voltage to a compatible level for the appliance to work.

An example of this is that when a specific appliance requires a specific amount of voltage, and when the voltage is not at the right level, it will simply not operate. With the use of a transformer, adjusting the voltage can be easily done. Resulting in a fully functional appliance with the right amount of voltage.

They are also capable of converting quantities from a certain value to another, and are responsible for components of both transmission of electricity in a power system, including distribution as well.

Without the use of a transformer, there is a high chance that electrical disruptions or abnormal voltages will occur. Leading to hazards like fire and explosion.

Yes, transformers are considered to be very important. In fact, without transformers our electrical energies would not be regulated, controlled, and passed to our houses. You can think of transformers as the root of the tree, and power lines as its branches.

This is why it is essential to have a transformer in a neighbourhood, village, or urban areas.

There are other types of Transformers as well that serve their unique purposes. Should you require more information after this section, we can get you professional help here.

Core type transformers are usually used as energy transformation, transfer cores, and power grids.

It still serves its main function when it comes to electrical transformer applications, which is to step up transmission and step down transmission.

For its components, the core type transformer has two limbs, and the windings are contracted on two limbs of the core material.

Calculation Method of the Number of Turns of Power Transformer Core

Shell type transformers are commonly used for low voltage applications and in low voltage power circuits including electrical circuits.

For the components of the shell-type transformer, its core has three limbs and two windows. Both windings are contracted on the central limb specifically, one over the other.

The arrangements of these windings can also be done with one limb.

Power distribution transformers (not to be confused with Power Transformers) are mainly used for lower voltage distribution networks. Power, whatever source they come from, must be distributed from power plants to individual homes or establishments. This article will inform you of the basics of power distribution transformers.

Having been one of the leading brands when it comes to manufacturing power supplies and transformers for 15 years, DAELIM offers quality but inexpensive products. DAELIM follows international standards like ANSI, IEEE, IEC, CSA, AS/NZ, etc.

It cannot be denied that electricity serves a crucial role in the modern day-to-day lives of every human. Now, a power distribution transformer has a rating ranging from 200 MVA and below.

Mainly, distribution transformers are for circulation purposes. It steps down the voltage and level of a power transmission line to an allowable scale or rate. This rate or level is often called the end-user safety level – may it be for domestic or industrial use.

As previously mentioned, a distribution transformer’s main feature or function is its ability to step down the voltage at a certain point or up to the end-user safety level. It allows electricity to be used by consumers at lower and safer levels.

Unlike other transformers, distribution transformers can only handle voltages with ratings not exceeding 200 MVA (some go to a maximum of 240 MVA). It is considered a small to a medium-sized transformer.

A power transformer is similar to the distribution transformer but it has its own unique characteristics and capabilities. Starting with their applications, they are used for transforming power from a circuit to another circuit without changing its frequency.

Does it sound familiar to you? Because that is the basic definition of a transformer, which both power and distribution transformer can do. Since there are no moving parts in power transformers, they are considered as static devices.

This transformer operates on an AC supply, but a transformer does work on multiple principles including the principle of mutual induction.

Power transformers can also be used for regulating transmission networks that are in higher voltages (Increasing and Decreasing). They are usually generated at above 200 MVA ratings. For their components, they have a primary and secondary, and a set up of one input and one output.

In comparison to distribution transformers, they also have one primary but its secondary is tapped or divided. It can also have two or even more secondaries.

Performance-wise, it is analyzed by maximum efficiency because they operate full loads, and as mentioned, distribution transformers only run at low loads or sufficient loads (20%-60%) but definitely not full loads.

Its rating is also greater than distribution transformers. Flux density is also higher than distribution transformers. Its primary windings are in a star connection, while the secondary windings are in delta connections.

Connection Mode of Working Winding of Three-phase Transformer

Power transformers are used to transmit electricity to any component of the electrical circuit between distribution circuits (primary) and the generator it is connected to. These transformers are usually utilized in distribution networks to adjust voltages.

In other words, power transformers convert electricity to both higher and lower voltage values for specific purposes. In power grids, it is considered as a major component to supply voltage to its connections.

Its destination is to supply voltages to the connections that are linked with the power transformer.

Power transformers are primarily used for increasing low AC voltages at high current but it can also be used to decrease high AC voltages at low current in electric power applications.

Power and Distribution transformers have an input side and an output side. This is how high-powered circuits enter the transformer, through its upper input, and exit on the output side with a rate of up to 1 kW.

Generators and batteries will be attached on a wire grid that is Heavi-Watt to give them a 20 kW capacity. This way, multiple transformers can be attached to supply consumers that are attached to a low wattage cable to cross tiles.

With that said, batteries on the output side of the transformers will be prevented since batteries have no limit to their output rates. A transformer is able to resist damage when the power draw goes beyond or above 1 kW. In the case that it overlaps, it will overload the circuit.

Another thing that power transformers are capable of is that they draw power from a circuit that is low wattage that is also attached to several power producers and output into a circuit that is of higher wattage,

In result, this would protect the lower circuit from overloading while it is continuously providing power to the main power circuit while taking advantage of the low wattage cable benefits.

The core of transformers direct to the path of the magnetic field between its primary and secondary coil to not waste energy. The moment that the magnetic field comes in contact with the secondary coil, it forces electrons to go along with it.

Which results in creating electric currents through electromotive force.

Just like other types of transformers, distribution transformers are categorized into different types based on application or requirement – they are as follows:

This type of transformer is explicitly used for networks where a three-phased type is not applicable. This type is mainly used for industrial lighting, commercial loads, and low power applications.

This type is mainly used to hold electrical energy from the primary source to a minor distribution circuit. It transmits the electrical current to a secondary distribution circuit while reducing the voltage based on consumer requirements. It is usually used for commercial and residential purposes.

It is a type of transformer that has a locked steel box that is mounted on a pad that is made of concrete. Pad-mounted transformers are usually found in open spaces. It is used in power distribution lines for reducing primary voltage to suit customer needs. This type of transformer can service homes and large buildings. It has a power rating ranging from 75 to 5000 kVA.

As the term suggests, this type of transformer is mounted on an electrical service pole. They are mainly used for changing high distribution voltages to lower level volt powers. It can be seen and is used in rural areas, having a rating ranging from 16 to 100 kVA. This type of transformer is compact so that it can be easily mounted on a single pole. It is also made to withstand harsh climates and weather.

Below are some of the main applications that a distribution transformer is typically used for:

– Changing high voltage electricity to a serviceable low amount of electricity for home and business use

– Step down the voltage that provides isolation between primary and secondary windings

– Distributes power to remote or rural areas from the primary power plants

– Distributes energy to industries have low voltage requirement not exceeding 440 volts

Let us start with distribution transformers. Distribution transformers are also known as service transformers because they provide the final voltage transformation in the electric power distribution system.

This can also be placed above ground level or underground. If they are mounted on a pole, the one we usually see on the streets, they are considered as pole transformers in which they are located above ground level to connect it with power lines.

Distribution transformers usually have a rating that is less than 200 kVA (Kilo Volt Ampere). But there are some standards (depending on what country you are in) that allows units up to 5000 kVA. Distribution transformers are constantly energized even without a load, which results in reducing iron losses.

Unlike power transformers, distribution transformers usually do not operate full loads, because they are specifically designed to have maximum efficiency at low loads. This is where voltage regulations take place, which should also be kept to a minimum. For small leakage reactance, this is natural since that is part of the distribution transformer’s design.

But with distribution transformers, It can be used to both increase and decrease the voltage at the station where it gets power from. This keeps the electricity regulated and prevents transmission losses.

Distribution transformers provide the final voltage transformation in the electric power distribution system, which requires it to step down the voltage in the distribution lines to the level that is used by consumers.

In other words, it performs the last voltage transformation in a distribution grid. Converting the voltage used in transmission lines that is compatible with common households and commercial uses.

Distribution transformers can be found at service drops in which you also see where the wires are connected if the transformers are above ground level. As aforementioned, distribution transformers can be placed underground which means that wires can also come from underground.

Distribution Transformers can be to supply electricity to isolated infrastructures such as a house that has no neighbors, farms, barns, etc. Another form of application is the power supply from the overhead wire of railways given with electricity (AC). For these types of applications, DAELIM suggests to use single phase distribution transformers.

Distribution transformers are capable of being connected to up to 50 houses. Several homes can even be connected to a single transformer. This is applicable to urban areas, but for rural areas, it may require one transformer per consumer. Voltage is a big factor in this when considering to use one transformer per consumer.

For large neighbourhoods and industrial complexes, it is not surprising they have multiple distribution transformers, this is because they consume a lot of electricity, which requires more regulation. The primary distribution lines from this are commonly located underground for security purposes. They are also more focused on using it for step-down or decreasing the value only.

You can also find distribution transformers at power collectors from wind farms, wherein they use it to step-up or increase the value of each wind turbine that is connected to a substation far away.

Distribution transformers have different sizes, usually heavy and it is recommended that you enhance a specific part of the module floor or platform deck at site of installation. DAELIM ensures security, which is why all transformers provided are placed on a flat level.

After installation, you may proceed on filling it up with transformer fluids. It is important to keep in mind that some of these transformer insulation fluids are toxic, which means you need to be extra careful when applying it in the transformer.

DAELIM will be responsible for checking the transformer after it is located and filled. Insulation tests will be taken as well, and after cabling there will be a follow up or second insulation test for all the windings and connections.

It all started back in the 1880s , but in terms of the property of induction, it was found in the 1830s, and this became the standard operating basis of a transformer. After years and years of development, transformers were modified, upgraded, and developed into different types. From large transformers, small and more efficient transformers were invented for total convenience.

Moreover, the potential of transformers grew as kVA and mVA came into existence, A 400KV electrical power transformer was invented at a high level voltage electrical network back in the year 1950. For transformers that supported mVA, the 1100 mVA came into existence in the early years of 1970.

Power increased as years went on, and so did the modification of the various types of transformers.

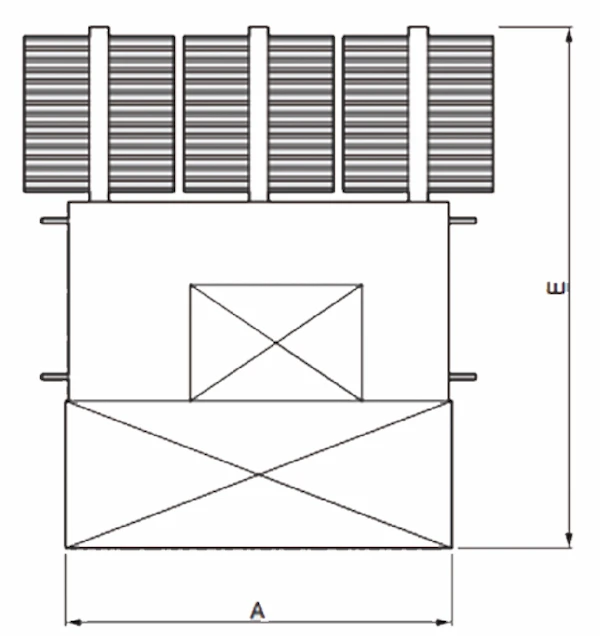

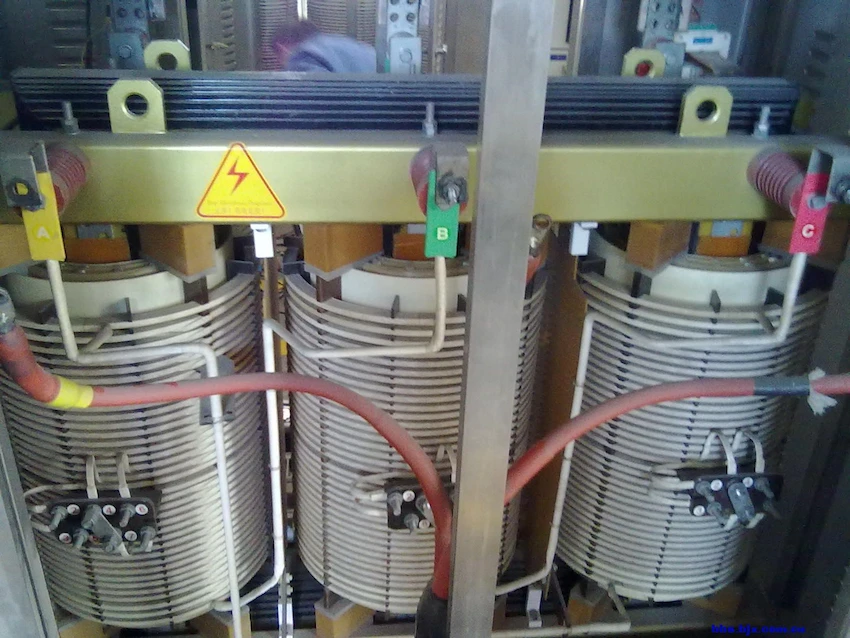

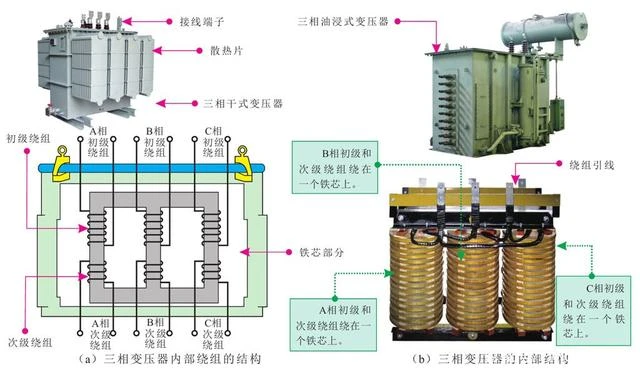

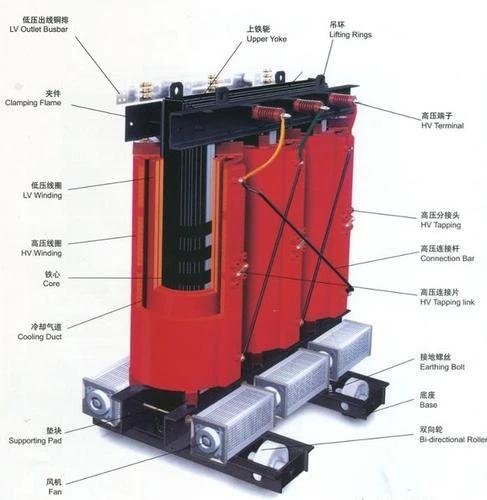

The power transformer’s design is composed of metal that is covered by stainless steel sheets. It is either fixed into a shell type or core type. In terms of its structures, they are contracted, this employs conductors to produce three one-phase transformers or one three-phase transformer.

Three one-phase transformers require each of its banks isolated from the extra parts, this provides the continuous service in case one bank malfunctions. On the other hand, a single three-phase transformer, whether the core or shell type, will not function.

This is why the three-phase transformer is cost-effective in terms of production, with lower carbon footprint and better operation with higher efficiency.

Its structure is molded in a fire retardant specific fluid inside a tank. The conservatory on top of the tanks enables the moving oil to cover it totally. The charger of the load’s responsibility is to drain the side of the tank for optimal voltage adjustment.

For its bushings, its bushings enable other parts of the tank to enter and exit the system without coming in contact or damaging the outer shell. Power transformers can be operated even beyond its low rating as long as it is within the right temperature. Specifically 65ºC.

These transformers do have special fans that help cool the transformer for operating below the specified temperature.

In today’s generation, electrical energy in low-voltage ratings has been considered too cost-effective. This low-voltage rating can be transferred to another receiving section, causing more line wastes.

But if the voltage rate is increased or improved, you can expect that the current of the power will be decreased, resulting in a reduction in ohmic or I2R wastes in the networks. This also enhances the voltage adjustment in the system, but because of this, it is required to step it up for effective electrical power applications because of the lower-rating power it is in.

This is operated on a step-up device at the specialized sending section of the power network. However, large voltage power may not be distributed to its users directly, which requires it to be stepped down at a suitable rate, with the help of a step-down device on the receiving end.

This is why electrical transformers are important because they play a vital role in transmission cases.

Two winding transformers are usually applied when there is a high level voltage or low that is higher than 2. This is cost-effective to apply an transformer that is automatic where the level between high and low voltage is lower than two,

This is why it is important to keep in mind that three-phase transformers or only one unit of it is more efficient than three single-phase transformers in a three-phase network. However, one simple three-phase set can cause complications, which should be stopped immediately if this case happens.

With a closer inspection, the power transformer and distribution transformer has its similarities, differences, and uniqueness. Power transformers are commonly applied in a full load since it is designed to have high efficiency at a full load.

On the contrary, distribution transformers also have high efficiency applications if the load is half or filled up 70%. Meaning, it is not advised to operate distribution transformers at full loads.

Power transformers are known to lead large voltages during an adjustment, whether a step-up or step-down. Their windings have better insulation compared to distribution transformer windings. Since they employ high-levels of insulation, you can expect it to be enormous and heavy.

Also, it is worth mentioning that power transformers are typically not connected to houses directly. This results in small load fluctuations every now and then. For distribution transformers, they experience heavy loads.

Power transformers are basically used in transmission networks at high voltages for increasing and decreasing applications. Moreover, power transformers can operate at full loads while distribution transformers are only efficient at much lower rates compared to the capability of power transformers.

The power transformers and distribution transformers are loaded daily, so the iron and copper wastes occur often. The flex density for power transformers is also greater than of the distribution types.

Power Transformers

Power transformers are generally used for heavy load transmissions. It carries a load with a rating more excellent than 33 kVA with a 100% efficiency rating. In terms of size, it is more significant than a distribution transformer.

It constantly operates on rated full loads because load fluctuations are less likely to happen. It is used in generating stations and transmission substations with high insulation levels. Lastly, iron and copper losses are happening continuously throughout the day for power transformers.

Distribution Transformers

Distribution transformers distribute electrical energy at a low voltage not exceeding 33 kVA for industrial purposes and not exceeding 220v for domestic purposes. It is small and has a low-efficiency rate of 50-70%.

It is operated at a load less than whole as the variation in the loads is very high. Its iron loss occurs continuously throughout the day, while the copper losses depend on the load cycle.

There is no one-size-fits-all when it comes to transformers. The type of transformer, whether a power or distribution transformer, will depend on where you will use them. Budget is also one of the things you have to consider.

If you are a home or business owner, it may be best for you to utilize a single-phase transformer, for they can only handle a small amount of electrical energy or power. If you have more significant business or commercial needs, you may want to consider using three-phase transformers or even pad-mounted transformers. They are designed to handle more loads to cater to more extensive services.

On the other hand, if you are a contractor building up neighborhoods or are powering up more significant buildings, pad-mounted distribution transformers might be the best for you. It handles more oversized electrical loads and is built to withstand different environmental factors like harsh climates.

These are the common applications for distribution transformers:

It is very common for chemical industries to use distribution transformers as their choice of transformers, because its design is built to be environmentally-friendly and less flammable compared to oil type transformers.

As you know, chemical industries are exposed to dangerous elements and fire hazards, which is why the best choice for them are distribution transformers.

Forests are highly risky because they are prone to fire, which can easily spread out at a very fast rate. For industries that are near forests or high-risk fire areas, they use distribution transformers in order to prevent fire.

Distribution transformers are commonly used substations as well as this is more suited for the area because of its safer mechanical components.

Since there are a lot of buildings in residential complexes, the risk of using oil type transformers is just too high to be applied in residential complexes. A fire could easily start and could spread easily.

The same goes with villages, as this can also be dangerous for the people living in close distances.

Large buildings are known to always choose distribution areas because they prefer an environmentally-friendly transformer around.

When it comes to apartments, distribution transformers do an excellent job at regulating the circuits in apartments, and it is simply more reliable than oil type transformers

Let us first define what Eddy Currents is. Eddy Currents are loops of electric currents created when a conductor is placed on varying magnetic fields. They are induced whenever there is an interaction between a magnetic field and a conductor. In transformers, eddy currents cause power loss in the core.

Eddy current loss, therefore, is the power losses in conductors and ferromagnetic cores. It is also the electrical energy lost or wasted in the form of heat produced by eddy currents.

Faraday’s Law causes eddy current losses. It is “Any change in the environment of a coil of wire will cause a voltage to be induced in the coil, regardless of how the magnetic change is produced.”

What is the no load losses of transformer?What is the short-circuit loss of the transformer?

At this point, you are now aware that there are many types of transformers out there, but since we have only discussed power and distribution transformers, let us look into the other types of transformers.

Current transformers are used for measuring and protection. Specifically, when the current in the circuit is too high to apply, the current transformer is utilized to convert high currents into the specific value that the circuit requires.

The primary winding of a current transformer is linked in series to its main supply, and the measuring instrument’s function is to support it. The current ratio and phase relation enables the meter to cooperate with its secondary side.

The ratio has a great significance and phase relation because this enables the meter to keep up with the secondary side.

The primary current in current transformers is the vector sum of excitation current.

Instrument transformers or also known as isolation transformers, is an electric device that is used to convert current and voltage levels. The common use of instrument transformers is to secure or safely isolate secondary windings when the primary is at a high voltage level and high current supply which relays to the secondary side of the transformer to not get damaged.

There are two types of instrument transformers

Potential transformers are next in this list.

Potential transformers are also known as voltage transformers, but we will refer to it as is. The primary winding of potential transformers are connected across high voltage lines, wherein its voltage is measured, and the measuring instruments and meters are linked to the secondary side.

In terms of its primary winding. It is grounded as a safety point. For example, the voltage ratio is 500:120 (primary to secondary), this means that the output of its voltage will be 120 Volts when 500 Volts is applied to the primary.

Electricity or power has been an essential part of the everyday lives of every human being. From lighting your homes to charging your gadgets, electricity is being used. But electricity cannot be used in its purest form. Energy is passed down from the power plants or power source through power distribution transformers, which convert them to a manageable or serviceable form.

The type of transformer used, either power or distribution, will mostly depend on the consumer use or loads needed for industrial, commercial, or residential purposes. Whatever the purpose may be, DAELIM can help you decide which is best for you to use. Contact DAELIM now and know which transformer suits your needs best.

A static device is a device or machine that has no moving parts in it, which means it is low maintenance since there are little to almost no components in it. These transformers are designed that way in order to mitigate flammable components.

Yes, distribution transformers are used for distribution networks that require low voltages as a compensation to end the user connectivity, and they are commonly rated less than 200 MVA. Power transformers are used transmissions that are heavily loaded at a high voltage.

Specifically greater than 33 kV with supreme efficiency.

The most commonly used sizes of transformers are usually from 15 to 500 kVA ratings. Anything higher than that is used primarily for bigger-scale industries.

Electricity regulation is essential because this keeps electricity stable, without stabilization, there is a high probability that electricity will convert into a stray voltage, which can cause serious injuries and even death.

Furthermore, this can potentially lead to fire and even explosion.

Different types are depending on use and load capacity. The following are the most common types of transformers: step up, step down, power, distribution, instrument, potential, comprising current, single-phase, 3-phase, auto, etc.

Yes, if they are not properly operated, which is why we highly recommend you to contact DAELIM if there is something that you do not quite understand. DAELIM would be glad to assist.

For a small-sized transformer, a simple touch of hand could be done. However, this is not entirely safe. So it is best to use thermometers in whatever size transformer you have. It is essential to monitor the heat to avoid transformer failures and accidents.

There are many reasons why a transformer could fail. The most common ones include lightning strikes, overloading, corrosion, power surges, and moisture. Transformer failure is usually manifested by a loud exploding sound that may emit fireballs and smoke.

Preventive measures for tripping of three-side switch of 110kV main transformer

Depending on what your purpose is, both power and distribution transformers are top of its tier. If you are looking for a transformer that is capable of operating at full loads, then power transformers are what you should get, but if you are looking for a transformer that is low maintenance and capable of exceptionally operating at average loads, then distribution transformers will do.

There are similarities and characteristics both the power transformer and distribution transformer share, which can be very complicated when making a purchase decision, but rest assured both transformers are at the top of its tier.

Should you have any further questions and concerns, you can contact DAELIM, and the team will accommodate you right away. Rest assured, these transformers are excellent in regulating electricity.

In short, distribution transformer want to really achieve orderly and smooth operation, operation and maintenance staff need to bring their role into full play, pay attention to the problems that arise in the operation process, develop a perfect method to solve the problem properly.

In addition, it is also necessary to increase the strength of the overhaul and maintenance, the first time to find the problem, and properly solve, reduce and reduce the possibility and probability of accidents, to ensure that the distribution network in the process of operation can be more stable.

It is also necessary to apply scientific methods to improve the comprehensive quality and working ability of operation and maintenance staff, and to conduct training for them in a regular and periodic way, and to combine theory and practice in the training process, so as to deepen the staff’s understanding and memory of the training content, only in this way can the distribution transformer daily operation and maintenance work towards a more Only in this way can the daily operation and maintenance of the distribution transformer develop and move forward in a more standardized direction to ensure the normal and stable operation of the distribution transformer and finally achieve a stable power supply.

Distribution transformer is a very critical and important power supply facility in the process of distribution network operation. When the operation and maintenance staff is involved in the daily maintenance process of distribution transformer, they need to clarify the key points to help the distribution transformer play its role and finally achieve stable operation.

Therefore, this paper mainly analyzes the key points of operation and maintenance in the operation of distribution transformer, hoping to provide reference and help for relevant staff.

The distribution transformer is a static electrical equipment, which plays a major role in the distribution system.

In essence, the distribution transformer is closely related to people’s daily life and social and economic development. Only by effectively doing the operation and maintenance work in the process of distribution operation and properly solving the existing problems can we ensure the normal use of electricity by customers and further improve the overall quality of power supply services.

Based on this, this paper mainly discusses the key points of operation and maintenance in the operation of distribution transformer.

The oil-immersed distribution transformer is widely used with its own strong advantages and characteristics, and the main models include S9, S11 or S13.

The actual structure of each type of distribution transformer is not very different from each other, but mainly consists of 3 phase transformer box, transformer oil, iron core, decomposition switch and other major parts.

The 3 phase transformer case is mainly the overall shell of the distribution transformer, which protects the parts included inside the 3 phase transformer. The inside of the case is filled with 3 phase transformer oil, which makes the windings and the core inside the 3 phase transformer The case is filled with 3 phase transformer oil, which insulates the windings and cores inside the 3 phase transformer from the case.

Another very obvious function of the transformer oil is to dissipate heat, so that when the temperature of the distribution transformer is too high, the temperature can be reduced to within the specified range in the first place, providing security and support for safe operation.

When the distribution transformer is in operation, there are some hidden problems that are difficult to find during the regular inspection of the S11 distribution transformer by professional staff, such as abnormal temperature.

If the temperature of the distribution transformer is higher than the original operating temperature under constant load and heat dissipation conditions or quiet temperature, and if the temperature shows an increasing trend, it can be judged to have a temperature anomaly.

In order to detect the abnormal temperature of the distribution transformer in the first place, it is necessary to use an infrared imager.

After the 3 phase transformer is put into use, there is a high possibility of oil seepage or oil leakage, if after careful inspection by professional staff, it is found that oil seepage and oil leakage are within a certain range, the 3 phase transformer can still maintain normal work, but such a situation should not be ignored by the staff, operation and maintenance The staff should observe the distribution transformer, if they find that the oil leakage is high or the 3 phase transformer continues to leak oil, then the staff should cut off the power quickly and let the 3 phase transformer stop working, and then send the problematic 3 phase transformer to the overhaul department, where the overhaul staff will check and solve the problem at the first time.

In addition, if the oil level of the 3 phase transformer is too low during operation, coupled with the complete exposure of the leads and disintegration switch in the air, then its insulation will continue to decline, increasing the possibility and probability of breakdown discharge problems.

A large part of the oil seepage problem in daily operation is caused by broken enclosures and poorly secured on-load tap-changers.

When the distribution transformer is in operation, when the power is turned on, the magnetic field changes and the current and other factors will have a certain effect on it, the internal system and the winding column will make a humming sound, but if it is overloaded, the sound is very heavy.

There are many parts inside the 3 phase transformer, and if there are various problems such as poor connection of many parts, the 3 phase transformer will have abnormal sound during operation.

If the noise is high and accompanied by an explosion, this is most likely due to internal problems, such as insulation breakdown or short circuit.

First of all, in the process of choosing the installation site of the distribution transformer, the staff must combine the real situation to ensure that the selection of the installation site is scientific and reasonable.

Because the installation not only needs to meet the voltage requirements proposed by the user, but also needs to prevent the problem of lightning strikes, remember not to install in the wilderness, mainly because the actual location of the installation and the residents living far away, it is very easy to be some unscrupulous people on the spot, and theft behavior. At the same time, the remote location will also give the staff of the later maintenance and management work to bring greater impact.

Second, the regular method of line inspection, to avoid collision problems with branches and wires in the field and produce low-voltage short circuit, the overall distribution transformer situation has a serious impact.

At the same time, do not add low-voltage meter on top of the distribution transformer, because the meter glass will be affected in the operation stage of the distribution transformer, if it is not replaced at the first time, it is very likely that in bad weather, there will be a meter burning problem, which will have an impact on the The distribution transformer will be affected by the weather.

Finally, the impact of natural factors on the distribution transformer.

First of all, in the process of choosing the installation site of distribution transformer, the staff must combine the real situation to ensure that the selection of the installation site is scientific and reasonable.

Because the installation not only needs to meet the voltage requirements proposed by the user, but also needs to prevent the problem of lightning strikes, remember not to install in the wilderness, mainly because the actual location of the installation and the residents living far away, it is very easy to be some unscrupulous people on the spot, and theft behavior.

At the same time, the remote location will also give the staff of the later maintenance and management work to bring greater impact.

Second, the regular method of line inspection, to avoid collision problems with branches and wires in the field and produce low-voltage short circuit, the overall distribution transformer situation has a serious impact.

At the same time, do not add low-voltage meter on top of the distribution transformer, because the meter glass will be affected in the operation stage of the distribution transformer, if it is not replaced at the first time, it is very likely that in bad weather, there will be a meter burning problem, which will have an impact on the The distribution transformer will be affected by the weather.

Finally, the impact of natural factors on the distribution transformer should not be ignored and should not be underestimated, and the insulation cover should be placed at the high and low voltage end of the distribution transformer. In the area frequented by animals or a relatively small space, adding high and low voltage insulation cover can effectively prevent things from falling on the distribution transformer terminal block, resulting in the occurrence of low-voltage multiplex problems.

In addition, the distribution transformer tap changer adjustment is not in place will certainly increase the possibility of short circuit problems, and even lead to burned situation, so do not allow unauthorized changes to the tap changer.

First of all, the professional staff will carefully observe the electric 3 phase transformer, and then enter into the process of testing the oil temperature, and then increase the number of inspections in the actual situation, in those cases where the weather is very bad and the load changes a lot.

In particular, the temperature of the top oil in the operation of the distribution transformer should be strictly controlled to below 95℃, not to make its temperature rise above 55℃, and the temperature of the top oil should not often exceed 45℃, because such a situation will cause the deterioration of the oil to accelerate.

Secondly, increase the strength of electricity load detection.

Especially in the peak period of electricity consumption, it is necessary to increase the measurement of the load of each distribution transformer, combined with the actual situation, increase the number of measurements, the first time to adjust the three-phase current imbalance of the distribution transformer, to prevent the neutral line current is too large and burn the lead problem, to protect more Professional equipment, for the stable operation of the distribution transformer to help.

Finally, the distribution transformer is very prone to problems, and there is a high risk of dust on the high and low voltage pipe sets, so professional staff is needed to wipe and clean them in time to prevent short-circuiting of the pipes in bad or humid weather, which may lead to fusing of the high voltage fuse and affect the normal operation of the 3 phase transformer. The normal operation of the 3 phase transformer is affected.

In addition, whether each lead of distribution transformer insulation resistance is firm is also an important element in the inspection process, and the staff needs to pay more attention to the low-voltage outlet connection, focusing their attention on whether the temperature is abnormal, whether the contact is good and other aspects.

The staff involved in the operation and maintenance of the distribution transformer needs to monitor and control it with rich working experience and solid professional knowledge, therefore, it is very crucial and important to improve the comprehensive education and working ability of the operation and maintenance staff.

Only in this way can the problems in the operation of the distribution transformer be found in time, and then through regular maintenance, adjustment of taps and other effective methods, help The distribution transformer is in good operating condition.

At the same time, the power supply department also needs to bring its role into full play, popularize the most professional knowledge and principles of distribution transformer for operation and maintenance staff, emphasize the importance of safety risk control, and help staff master more methods and techniques of distribution transformer management.

Distribution transformer failure can have a serious impact on the safe and stable operation of the power grid. In this paper, three consecutive cases of 3-phase distribution transformer failures of the same manufacturer with similar manufacturing dates in a power supply bureau are analyzed by DC resistance and insulation resistance tests of windings and disassembled by lifting the core. The purpose is to provide a reference for the analysis of the distribution transformer batch failure.

During the period from September 2020 to July 2021, the 3-phase distribution transformers of the same manufacturer with similar manufacturing dates in a power supply bureau had successive failures (named as No. 1, No. 2 and No. 3 in order of the sequence of the failures). The basic information of the 3-phase distribution transformer is shown in Table 1.

On September 4, 2020, the power supply bureau received a report from the customer about the fault of the 3-phase distribution transformer. After the emergency repair personnel arrived at the scene, they carried out DC resistance testing on the faulty 3-phase distribution transformer, and the DC resistance data of the high-voltage winding could not be measured, and the conditions for continued operation were no longer available. The repairers checked the load situation of the 3-phase distribution transformer for a period of time before the fault, and the load rate was low and there was no heavy overload.

Table 1 Basic information on faulty three-phase distribution transformers

no | Failure time | 3-Phase distribution transformer Model | Date of manufacture |

1 | 2020-09-04 | SH15-M-125/10 | 2012-04 |

2 | 2020-10-18 | SH15-M-80/10 2 | 2012-03 |

3 | 2021-07-07 | 7 SH15-M-125/10 | 2012-03 |

On October 18, 2020, the power supply bureau found that the transformer’s low-voltage b-phase terminal was skewed after inspection, and then organized personnel to carry out repair, during which it was found that the 3-phase distribution transformer’s high-voltage DC resistance test data exceeded the requirements of the regulations and could not be operated normally. The transformer had no heavy overload.

On July 7, 2021, the user reported that the 3-phase distribution transformer was out of phase, and the repairer arrived at the site, carried out voltage detection and found that the transformer’s low-voltage side c-phase voltage was zero, and applied to the dispatcher at 1805 to pull the fuse for inspection and processing. In June 2021, the average load was 11.94% and the maximum load was 32.26%, so the load ratio was low and there was no heavy overload.

From Table 1, it can be seen that the three cases of 3-phase distribution transformer failures are all made by the same manufacturer on the same date, and the failure time of No. 1 and No. 2 3-phase distribution transformers is only about 1 month apart. According to the actual fault condition, the three 3-phase distribution transformers did not have heavy overload before the fault, and the fault phenomenon was the same.

(1) DC resistance test of winding

According to the requirements of the regulations, the deviation between phases is not more than 4% and the deviation between lines is not more than 2% for the capacity below 1600kVA.

Table 2 Winding DC resistance test data – low-voltage winding (No. 1 3-phase distribution transformer)

Test Location | ao/Ω | bo/Ω | Co/Ω | Imbalance rate/% |

Low voltage winding | 6.905 | 7.108 | 6.998 | 2.897 |

2)Insulation resistance test

The insulation resistance test data of 3-phase distribution transformer No. 1 is shown in Table 3. From Table 3, it can be seen that the insulation resistance value of the 3-phase distribution transformer is high and the insulation condition is good.

Table 3 Insulation resistance test data (No. 1 3-phase distribution transformer)

Test position | Insulation resistance R60s/GΩ |

High voltage winding to ground | 12.8 |

Low-voltage winding to ground | 4.28 |

1)Winding DC resistance test

The DC resistance test data of No.2 3-phase distribution transformer winding are shown in Table 4 and Table 5. From the data in Table 4 and Table 5, it can be seen that the low-voltage winding of this 3-phase distribution transformer meets the requirements of the regulation, but the DC resistance data of BC and AC cannot be measured when the high-voltage winding is in block I, and the DC resistance unbalance rate in the remaining block exceeds the requirements of the regulation.

Table 4 DC resistance test data of winding – high voltage winding (No.2 3-phase distribution transformer)

Test Location | AB/Ω | BC/Ω | CA/Ω | Gear position | Imbalance rate/% |

High Voltage Winding | 24.90 | Not measurable | Not measurable | I | – |

24.2 | 54.53 | 26.10 | II | 86.540 | |

23.62 | 52.78 | 34.35 | III | 78.989 |

Table 5 Winding DC resistance test data – low voltage winding (No. 2 3-phase distribution transformer)

Test Location | ao/Ω | bo/Ω | Co/Ω | Imbalance rate/% |

Low voltage winding | 12.51 | 12.24 | 12.32 | 2.185 |

2)Insulation resistance test

The insulation resistance test data of No. 2 3-phase distribution transformer is shown in Table 6. From Table 6, it can be seen that the insulation resistance value of this 3-phase distribution transformer is high and its insulation condition is good.

Table 6 Insulation resistance test data (No. 2 3-phase distribution transformer)

Test position | Insulation resistance R60s/GΩ |

High voltage winding to ground | 0.818 |

Low-voltage winding to ground | 1.830 |

1)Winding DC resistance test

The DC resistance test data of No. 3 3-phase distribution transformer winding are shown in Table 7 and Table 8. The data in Table 7 and Table 8 show that the low-voltage winding of the 3-phase distribution transformer meets the requirements, but the DC resistance unbalance rate of the high-voltage winding exceeds the requirements of the regulations at all stops.

Table 7 DC resistance test data of winding – high voltage winding (No. 3 3-phase distribution transformer)

Test Location | AB/Ω | BC/Ω | CA/Ω | Gear position | Imbalance rate/% |

High Voltage Winding | 15.57 | 15.74 | 31.31 | I | 75.407 |

15.13 | 16.20 | 30.64 | II | 75.085 | |

14.70 | 15.16 | 29.88 | III | 76.230 |

Table 8 Winding DC resistance test data – low voltage winding (No. 3 3-phase distribution transformer)

Test Location | ao/Ω | bo/Ω | Co/Ω | Imbalance rate/% |

Low voltage winding | 7.071 | 7.054 | 7.0176 | 0.758 |

2)Insulation resistance test

The insulation resistance test data of 3-phase distribution transformer No. 3 is shown in Table 9. From Table 9, it can be seen that the insulation resistance value of this 3-phase distribution transformer is high and its insulation condition is good.

Table 9 Insulation resistance test data (No. 3 3-phase distribution transformer)

Test position | Insulation resistance R60s/GΩ |

High voltage winding to ground | 14.19 |

Low-voltage winding to ground | 11.01 |

From the insulation resistance and DC resistance test data, we can see that the three cases of faulty 3-phase distribution transformer are highly similar in terms of fault characteristics.

From the DC resistance data, the DC resistance of the low-voltage winding of the three cases of faulty 3-phase distribution transformer meets the requirements of the regulations, but the high-voltage winding has a serious three-phase DC resistance imbalance and the resistance value cannot be tested, and it is not related to the operating position, indicating that the factors leading to the DC resistance imbalance of the winding are not related to the tap changer fault.

The three cases of fault 3-phase distribution transformer DC resistance test are used the same type of digital DC resistance tester, check the technical parameters of the test equipment, the range of the maximum value of 500kΩ, that is, the DC resistance data can not be properly displayed in the case of the actual electrical connection of the DC resistance value should be greater than 500kΩ. And DC resistance value is large, it indicates that the electrical circuit of 3-phase distribution transformer has poor contact phenomenon or even more serious broken strands and broken circuit.

To further determine the location of the fault and clarify the cause of the fault, the faulty distribution transformer was lifted and disassembled for inspection.

The inspection shows that the distribution transformer has good appearance, normal oil level, intact high and low pressure porcelain sleeve, no signs of oil leakage, and no jamming when turning the tap changer.

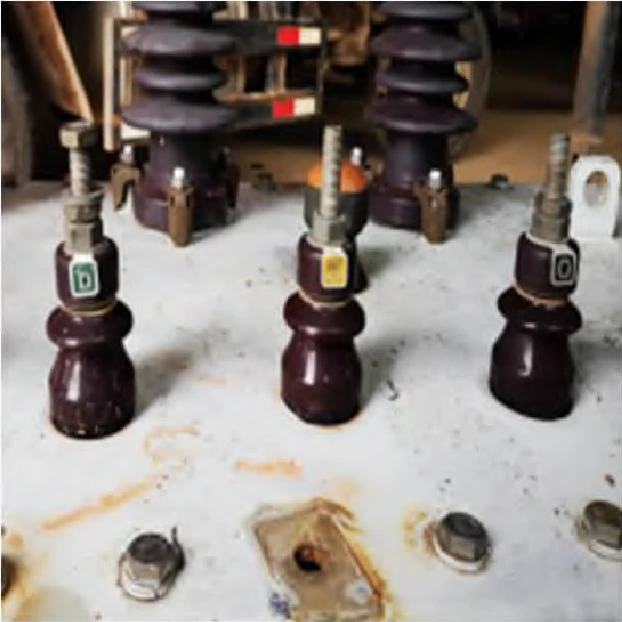

Figure 1 Distribution power transformer No. 1 appearance inspection

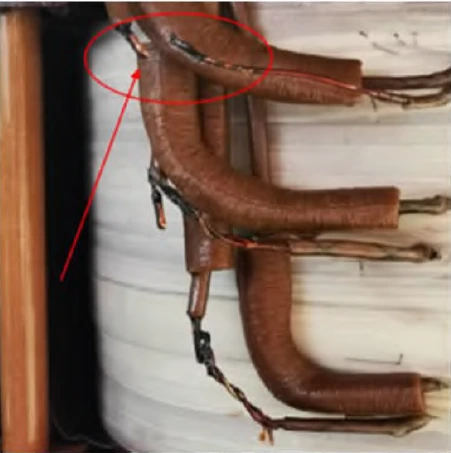

As shown in Fig. 2, the distribution power transformer A, B and C phases have obvious broken points in the high voltage leads, and the broken points are located at the tap winding lead wires, with obvious desoldering and dummy welding. There are obvious traces of carbonization on the surface of the enameled wire fracture point.

The overall inspection of the No.2 distribution power transformer is shown in Fig.3. The results show that the winding as a whole is in good condition, no deformation of the bulge, the high-voltage bushing is intact and not broken, and the oil level meter is red, indicating that the internal oil level of the distribution power transformer is insufficient.

The results show that the distribution power transformer A and B phase high voltage leads have obvious break points, and the break points are located at the tap winding lead wires.

The inspection shows that the overall appearance of the transformer is good, the oil tank body is not deformed, the high and low voltage bushings are intact and not damaged, the oil level meter color code is difficult to identify and cannot accurately determine the internal oil level, and the on-load tap-changer rotation is not stuck.

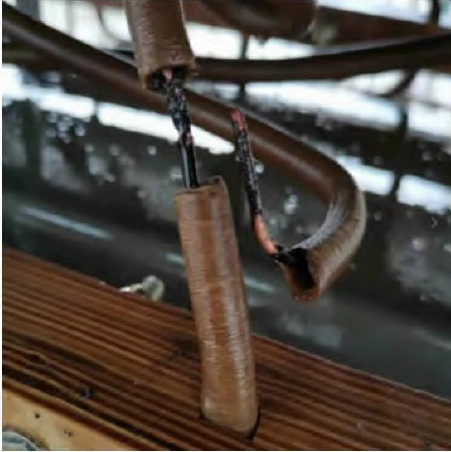

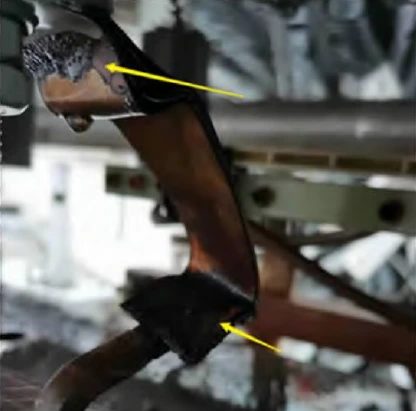

No. 3 distribution power transformer lifting core inspection, as shown in Figure 6, the results show that lifting the core inspection, the tank sealing rubber ring gasket intact, no oil seepage, but the rubber ring gasket around the dirty serious, the overall situation of the winding good, no obvious deformation of the bulge, but the high voltage lead C phase there are false welding, broken strands and winding outer insulation tie with obvious After strict inspection of the winding welding, the high-voltage winding A and B phase winding have such condition in the same position, and there are 6 broken strands in total and the enameled wire surface insulation layer has traces of overheating and ablation. The soft connection surface of the low-voltage winding has obvious traces of carbonization and ablation due to overheating (Figure 7a~Figure 7c), and all three phases of the winding have such a situation, and the ablative carbide has been granular and spread on the insulating paper surface of the low-voltage winding (Figure 7d).

From the distribution power transformer lifting core and disassembly inspection, it can be seen that the three cases of faulty distribution power transformer have a high degree of consistency in fault location and fault characterization, mainly in that the fault location is all in the distribution power The fault is characterized by poor welding quality of the winding weld points, resulting in false welding or excessive contact resistance, which can lead to local overheating and winding breakage under long-term operating conditions, especially for distribution power transformer No. 3. This phenomenon is also consistent with the actual test situation, especially the DC resistance test. Therefore, considering that the three cases of failure of the distribution power transformer were produced by the same manufacturer on a similar date (one month difference in manufacturing time), with the same model number and highly consistent fault characterization and fault site, this failure should be a batch product quality problem.

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical

The primary function of the pad mounted transformer is to serve as a critical distribution

A pad mounted transformer operates through electromagnetic induction, serving as a crucial distribution component that

When you need to find more than just existing transformers, Daelim’s Transformer Service Center can help you design and produce distribution transformers that meet your unique needs.

We have our own factory and a professional team of engineers, which can design and modify application requirements that meet all your conditions.

Download Resource

After filling in the contact information, you can download the PDF.