ELECTRIC, WITH AN EDGE

Learn the fundamentals of Electric Pole Transformers, including What is pole mounted distribution transformer, pole mounted transformer specifications, pole mounted transformer drawing, pole mounted transformer sizes and custom options.

An electric pole transformer is an electric utility distribution transformer. It’s mounted on an electrical service pole made of wood or concrete. Usually, it is attached at the level of overhead cables.

The 16 kVA to 100kVA electric pole-mounted transformers range transforms 11,000 to 33,000 volts down to 400 lower volts.

DAELIM is one of the world’s leading professional transformers and electrical equipment manufacturers. For 15 years, DAELIM has been serving the electric industry with inexpensive and quality equipment. They have been following international standards like ANSI, IEEE, IEC, CSA, AS/NZ, etc.

Pofessional Manufacturer of Pad Mounted Transformer Substation Transformer,HV Power Transformer Single Phase Transformer IEEE/ANSI,CSA,DOE,AS/NZS,IEC and etc。standards

Transformers come in a variety of shapes and sizes with different functions and purposes. Ranging from very large transformers to very small transformers. When it comes to getting the job done, there is not much of a difference between the power transformers and small ones like the single-phase transformer.

Basically, this means that regardless of the size, transformers do the same thing but depending on your project or purpose of purchasing one, you need to first understand its properties in order to get the right type of transformer.

For starters, a transformer is an electrical device or machine that transforms the value of current and voltages; hence, getting the name “transformer”. There are many types of transformers out there, and you will learn several of them in this article.

A step-up transformer is a transformer that changes lower values to higher values. Step-up transformers are usually used for transmission systems.

Contrary to the step-up transformer, the step-down transformer does the opposite job, wherein it changes higher values to lower values, and they are commonly used in a distribution system.

So, what type of transformer is a pole electrical transformer? Is it a step-up or step-down?

pole electrical transformers are actually distribution transformers that are mounted on an electric service pole that could either be wood or concrete. Moreover, they are commonly leveled with the electric wires you see connected with the pole electrical transformer.

pole electrical transformers range from 16 kVA – 100 kVA and they have the capability to transform 11,000 volts – 33,000 volts down to 400 volts, which is very impressive for a transformer that has the size of a barrel.

Calculation Formula of Transformer Transformation Ratio

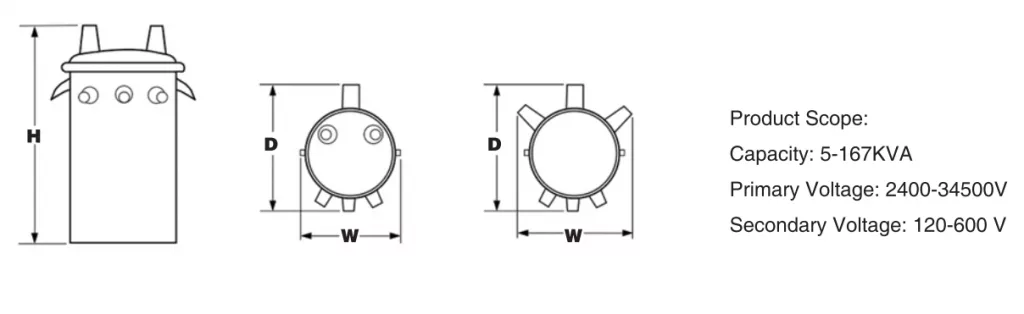

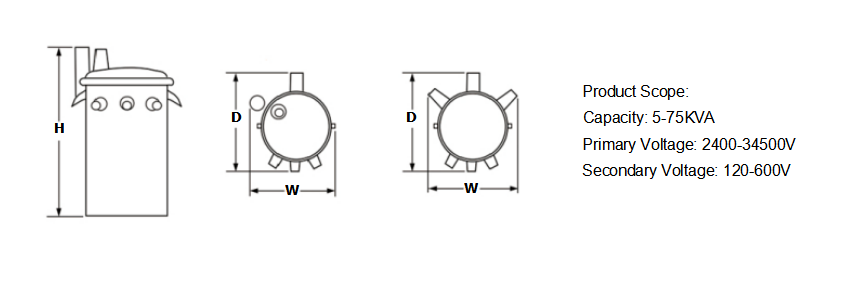

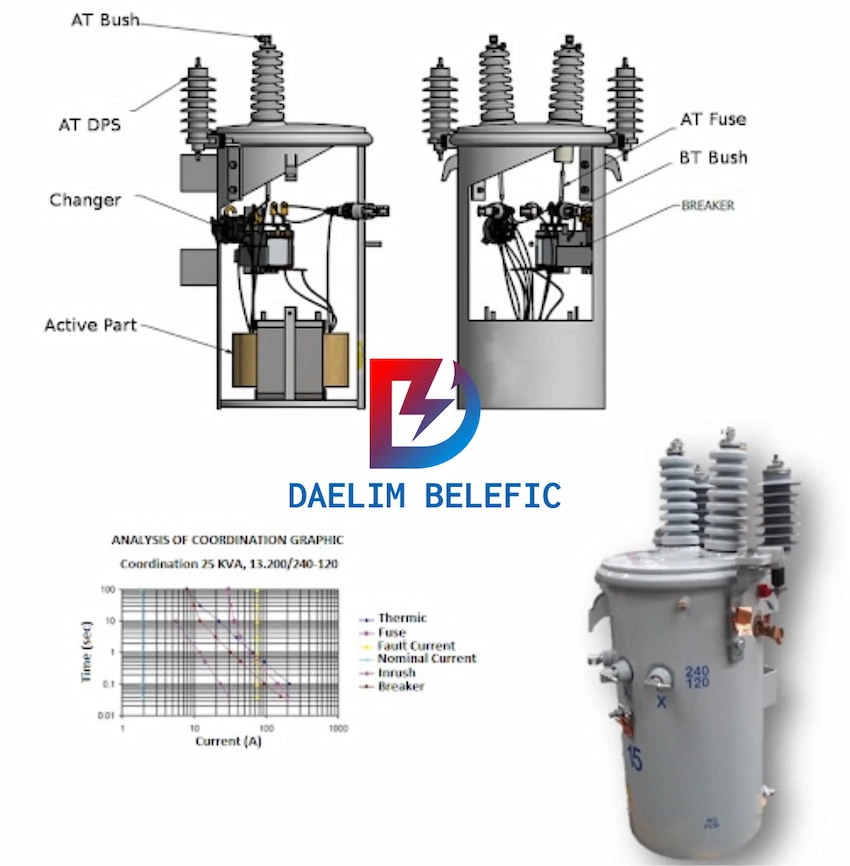

Daelim Belefic Single Phase Over head Transformer is designed and produced normally for stepping utility distribution voltages (ranging from 2400 to 34500 volts) down to lower utilization voltages. Although some are used for stepping down to commercial and industrial voltages such as 277, 240/480, 2400 and 4800, most are used for stepping down to the single-phase voltage of 120/240. These transformers are also used for small substations, miscellaneous applications and can serve to step up voltages.

The transformer type describes the basic protective devices which are included as an integral part of the transformer package. Table I defines each type as a function of the protective device(s) included. These protective devices and their functions are described later in this section.

| Table1 | ||||

| Type | CSP | CP | SP | S |

| Protective Devices | ||||

| High Voltage Surge Arrester | Yes | No | Yes | No |

| Low Voltage Circuit Breaker | Yes | Yes | No | No |

| High Voltage Protective Link | Yes | Yes | Yes | No |

Product model: SCZ10-50/10

No-load loss: 270W;

Load loss 120ºC: 990W;

No-load current: 1.9%;

Pole Mounted Transformer Sizes (L X W X H): 970×880×1015;

Installation size (mm): 500×820.

Product model: SCZ10-80/10

No-load loss: 360W;

Load loss 120ºC:1370W;

No-load current:1.8%;

Pole Mounted Transformer Sizes (L X W X H): 1050×880×1040;

Installation size (mm): 550×820

Product model: SCZ10-100/10

No-load loss: 400W;

Load loss 120ºC:1570W;

No-load current:1.6%;

Pole Mounted Transformer Sizes (L X W X H): 1100×880×1160;

Installation size (mm): 550×820;

Product model: SCZ10-125/10

No-load loss: 470W;

Load loss 120ºC:1800W;

No-load current: 1.5%;

Pole Mounted Transformer Sizes (L X W X H): 1110×880×1190;

Installation size (mm): 550×820;

Product model: SCZ10-160/10

No-load loss: 540W;

Load loss 120ºC:2120W;

No-load current: 1.4%;

Pole Mounted Transformer Sizes (L X W X H): 1110×880×1190;

Installation size (mm): 660×890;

Product model: SCZB10-400/10

No-load loss: 970W;

Load loss 120ºC:3980W;

No-load current: 1.2%;

Pole Mounted Transformer Sizes (L X W X H): 1320×950×1530;

Installation size (mm): 660×950;

A transformer trades voltage for current in a circuit while not affecting the total electrical power. It takes high-voltage electricity with a slight current. It changes it into low-voltage electricity with a large current or vice versa. Transformers only work for Alternating Current (AC), such as you get from your wall plugs, not Direct Current (DC).

Transformers increase or decrease the voltage. Transformers use two coils of wire wrapped around a metal core. The first coil is for the incoming electricity. While the other is for outgoing electricity. Alternating Current in incoming coil sets up an alternating magnetic field in the core. This generates Alternating Current in the outgoing coil.

First, using a pole mounted distribution transformer, the electricity voltage from a power plant is “stepped up” to the right level for long-distance transmission. Because high-voltage current can arc, step-up transformers called ignition coils. They power spark plugs. Dynamos at power plants generate large currents but not too high voltage. This electricity steps up to high voltage for transmission over wires. As electricity travels more efficiently at high voltage.

After that, the voltage is stepped down. A “step-down” transformer changes the 440-volt electricity in power lines to 120-volt electricity you use in your house. Then, the current can be used at that level for devices like light bulbs. It is converted to DC using an AC/DC adapter for devices like laptop computers.

This article mainly describes two transformers, Single Phase Overhead Conventional Electric Pole Transformer and Single Phase Overhead Completely Self Protected (CSP) pole mounted distribution transformer. Including this two pole mounted transformer drawing and pole mounted transformer sizes.

| Rated Power (KVA) | High Voltage (V) | Low Voltage (V) | Loss(W) | Dimension(mm) | Weight(kg) | ||||

| No-load Loss(W) | On-load Loss(W) | W | D | H | Oil Weigh | Total Weight | |||

| 5 | 34500 19920 13800 7957 7957 13200 7620 12470 7200 or others | 120-240 240-480 347600 | 19 | 75 | 465 | 485 | 855 | 15 | 92 |

| 10 | 36 | 120 | 500 | 525 | 885 | 22 | 150 | ||

| 15 | 50 | 195 | 520 | 565 | 905 | 30 | 210 | ||

| 25 | 80 | 290 | 560 | 590 | 935 | 45 | 258 | ||

| 37.5 | 105 | 360 | 610 | 625 | 935 | 50 | 340 | ||

| 50 | 135 | 500 | 635 | 675 | 1035 | 62 | 395 | ||

| 75 | 190 | 650 | 745 | 840 | 1035 | 88 | 480 | ||

| 100 | 210 | 850 | 770 | 965 | 1135 | 94 | 530 | ||

| 167 | 350 | 1410 | 795 | 890 | 1335 | 138 | 680 | ||

Note: The above data is only subject to our standard design, special requirements can be customized.

| Rated Power (KVA) | High Voltage (V) | Low Voltage (V) | Loss(W) | Dimension(mm) | Weight(kg) | ||||

| No-load Loss(W) | On-load Loss(W) | W | D | H | Oil Weigh | Total Weight | |||

| 5 | 34500 19920 13800 7957 7957 13200 7620 12470 7200 or others | 120-240 240-480 347 600 | 35 | 75 | 400 | 530 | 960 | 30 | 115 |

| 10 | 50 | 120 | 430 | 530 | 980 | 45 | 150 | ||

| 15 | 65 | 195 | 480 | 580 | 1000 | 55 | 205 | ||

| 25 | 105 | 290 | 500 | 580 | 1030 | 66 | 345 | ||

| 37.5 | 140 | 360 | 560 | 640 | 1080 | 78 | 335 | ||

| 50 | 180 | 500 | 560 | 640 | 1130 | 85 | 370 | ||

| 75 | 250 | 650 | 780 | 800 | 1170 | 138 | 505 | ||

Note: The above data is only subject to our standard design, special requirements can be customized.

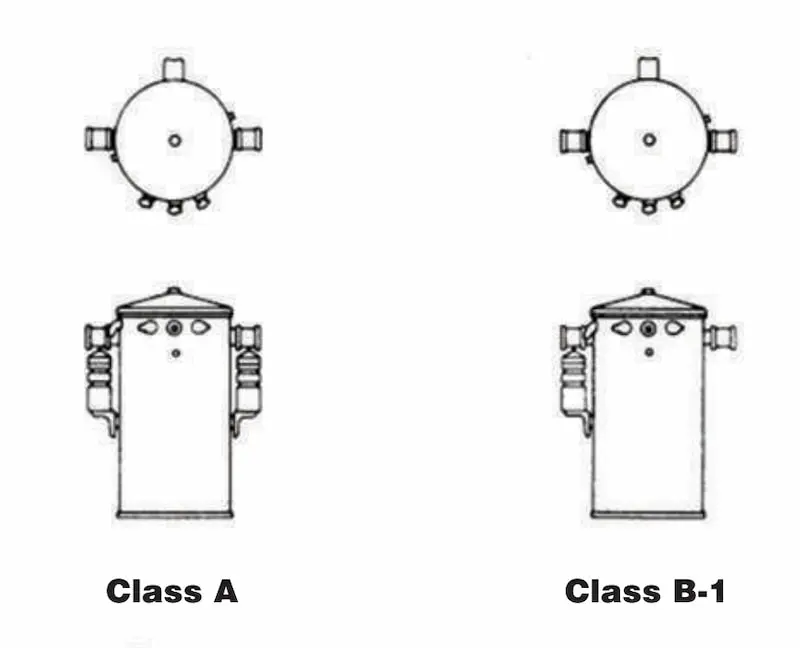

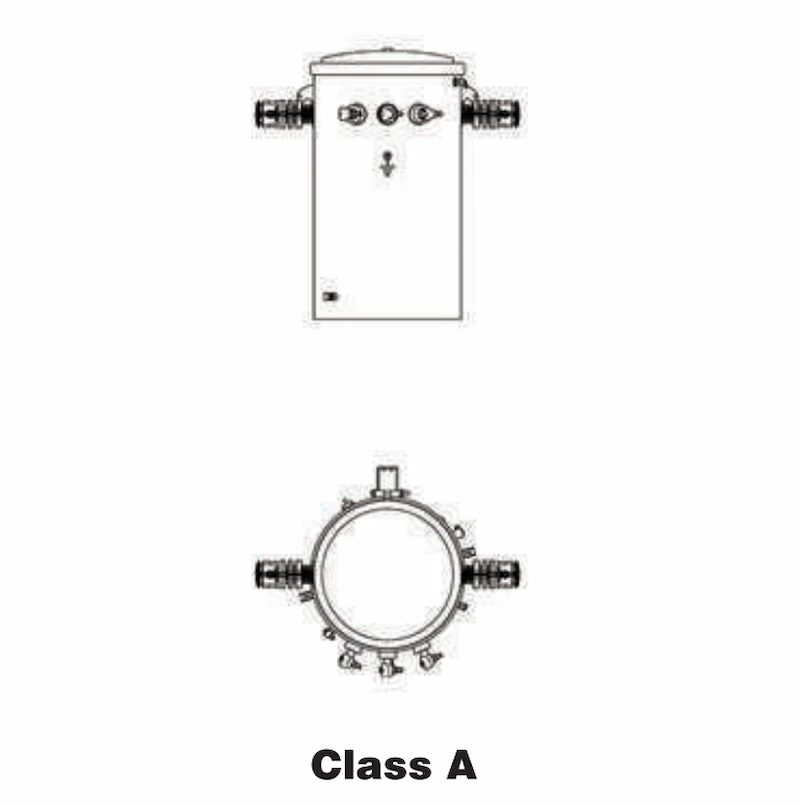

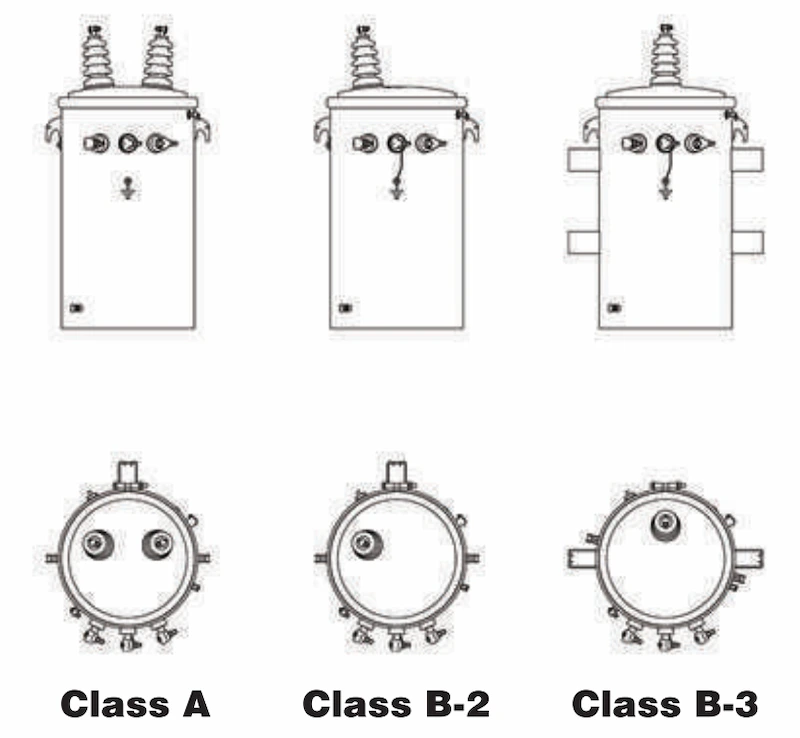

Class A: Two fully insulated high voltage bushings, two arresters, two protective links, and external breaker handle. Suitable for application on either wye or delta distribution systems. Single-position pole mounting in accordance with latest ANSI standards.

Class B-1: Two fully insulated high voltage bushings, one arrester, two protective links and external breaker handle. Normally applied on solidly grounded systems.

Class B-2: Not Available.

Class B-3: Not Available.

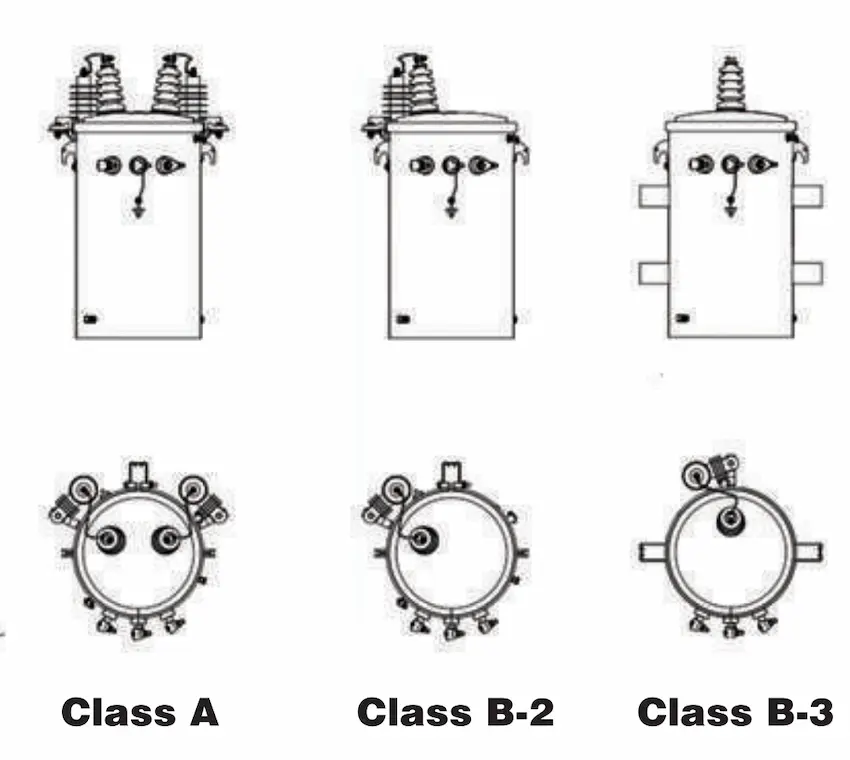

Class A: Two fully insulated high voltage bushings, two arresters, two protective links and external breaker handle suitable for application on either wye or delta distribution systems. Single-position pole mounting in accordance with latest ANSI standards.

Class B-1: Two fully insulated high voltage bushings, one arrester, two protective links and external breaker handle. Normally applied on solidly grounded systems.

Class B-2: One fully insulated high voltage bushing, one arrester, one protective link and external breaker handle suitable only for application on solidly grounded distribution systems.

Single-position pole mounting in accordance with latest ANSI standards.

Class B-3: Same as Class B-2 except with two-position mounting.

Class A: Two fully insulated high voltage bushings, suitable for application on either wye or delta distribution systems. Singleposition pole mounting in accordance with latest ANSI standards.

Class B-1: Not Available

Class B-2: Not Available

Class B-3: Not Available

Class A: Two fully insulated high voltage bushings, suitable for application on either wye or delta distribution systems. Single-position pole mounting in accordance with latest ANSI standards.

Class B-1: Not Available

Class B-2: One fully insulated high voltage bushing, suitable only for application on solidly grounded distribution systems. Single-position pole mounting in accordance with latest ANSI standards.

Class B-3: Same as Class B-2 except with two-position mounting.

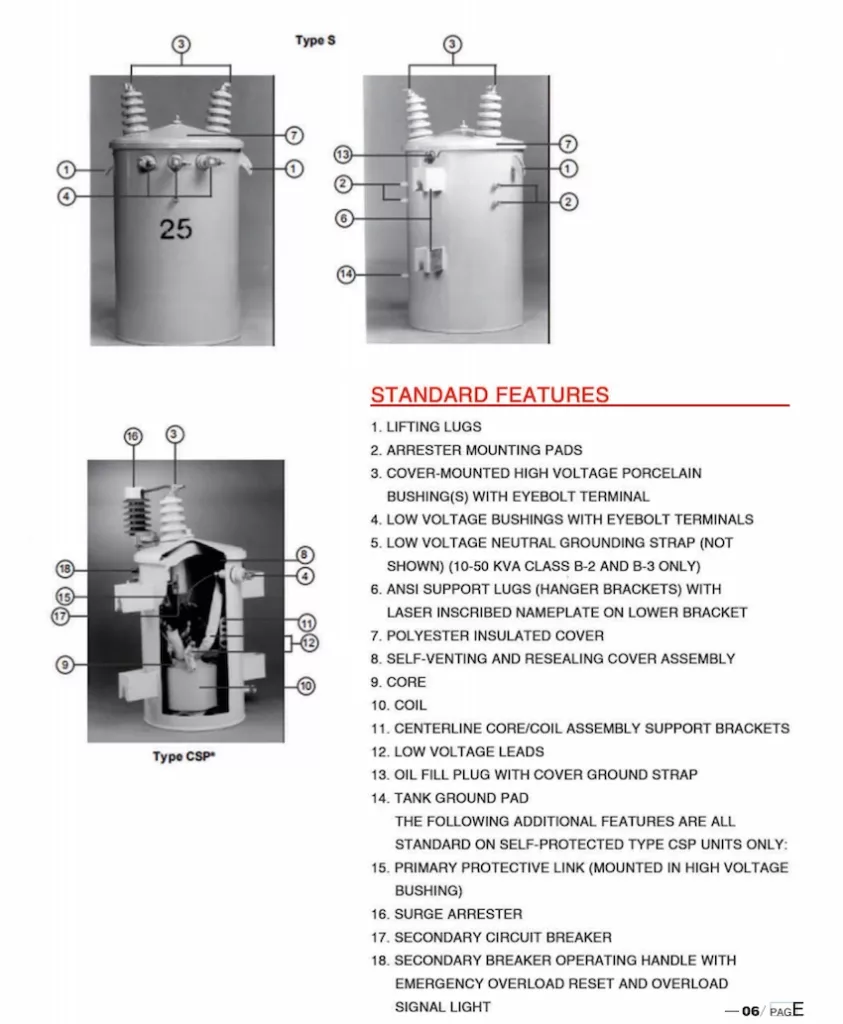

1.LIFTING LUGS

2.ARRESTER MOUNTING PADS

3.COVER-MOUNTED HIGH VOLTAGE PORCELAIN BUSHING(S) WITH EYEBOLT TERMINAL

4.LOW VOLTAGE BUSHINGS WITH EYEBOLT TERMINALS

5.LOW VOLTAGE NEUTRAL GROUNDING STRAP (NOT SHOWN) (10-50 KVA CLASS B-2 AND B-3 ONLY)

6.ANSI SUPPORT LUGS (HANGER BRACKETS) WITH LASER INSCRIBED NAMEPLATE ON LOWER BRACKET

7.POLYESTER INSULATED COVER

8.SELF-VENTING AND RESEALING COVER ASSEMBLY

9.CORE

10.COIL

11.CENTERLINE CORE/COIL ASSEMBLY SUPPORT BRACKETS

12.LOW VOLTAGE LEADS

13.OIL FILL PLUG WITH COVER GROUND STRAP

14.TANK GROUND PAD THE FOLLOWING ADDITIONAL FEATURES ARE ALL STANDARD ON SELF-PROTECTED TYPE CSP UNITS ONLY:

15.PRIMARY PROTECTIVE LINK (MOUNTED IN HIGH VOLTAGE BUSHING)

16.SURGE ARRESTER

17.SECONDARY CIRCUIT BREAKER

18.SECONDARY BREAKER OPERATING HANDLE WITH EMERGENCY OVERLOAD RESET AND OVERLOAD SIGNAL LIGHT

Daelim Belefic pole mounted distribution transformer is designed and produced normally for stepping utility distribution voltages (ranging from 2400 to 34500 volts) down to lower utilization voltages. Although some are used for stepping down to commercial and industrial voltages such as 277, 240/480, 2400 and 4800, most are used for stepping down to the single-phase voltage of 120/240.

The pole mounted distribution transformers are also used for small substations, miscellaneous applications and can serve to step up voltages.

Surge arresters are mounted on the outside of the transformer tank. Their function is to intercept and divert to ground various overvoltage transients (such as lightning surges) which originate on the distribution system.

Grounding requirements for lightning protection in Pad-mounted substations

Improper coordination with primary protective devices separate from the transformer could prevent the link from operating properly both for load current characteristics and for fault current characteristics.

Transformer Types SP, CP and CSP have protective links (expulsion type fuses) in them. These are mounted either in the bottom of the high voltage bushing or in a terminal block between the high voltage coil and the high voltage bushing. These protective links must be under oil for proper operation. Upon request DAELIM provides curves giving characteristics of these protective links so their characteristics can be coordinated with protective devices on the primary side of the transformer.

Protective links are oil-immersed high voltage expulsion fuses designed to isolate the transformer from the primary distribution system in the event of a transformer fault inside the tank on the load side of the link. The purpose of this link is to prevent a line lockout when a transformer fails; not to provide overload or fault current protection for the transformer.

What are the main neutral grounding methods of power systems?

High voltage current-limiting fuses are designed to limit the flow of current (and energy) to a low impedance fault. When properly applied, they prevent almost all violent failure of transformers. Like protective links, their purpose is to isolate the transformer from the distribution system in the event of an internal transformer fault. Current-limited fuses usually are applied when the system available fault current exceeds the interrupting capability of the protective link. Because partial range type current-limiting fuses are normally applied on overhead distribution transformers, a series protective link is applied with each current-limiting fuse.

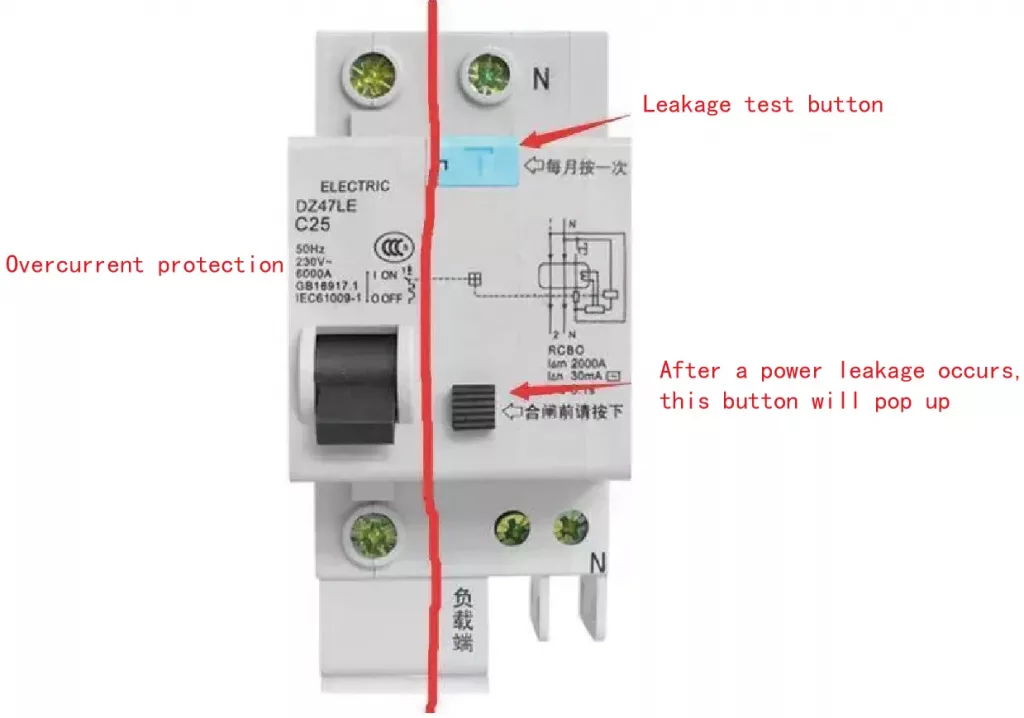

Type CSP and CP pole mounted distribution transformer have circuit breakers mounted under oil and connected between the coils’ low voltage winding leads and the low voltage bushings. These are to protect the transformer from severe overloads and short circuits external to the transformers. The low voltage breaker is not intended to protect secondary (low-voltage) circuits and connected apparatus (meters, meter sockets, connectors, service entrance equipment, etc.) from thermal and magnetic effects due to short circuits and overloads. The breaker is calibrated to trip when its bimental reaches a pre-determined temperature. Some breaker sizes have an additional feature that is a magnetic trip element so that breaker can respond quicker to higher fault current.

The breaker is primarily a protective device designed for only occasional switching operations; as such it is not intended for frequent (weekly or daily) switching duty.

The bimetallic element of the breaker is connected in series with the secondary windings of the transformer and responds thermally to the flow of transformer load current through it and to the oil temperature.

The circuit breaker is always used in conjunction with a protective link.

The circuit breaker coordinates with the protective link so it opens first on overloads and faults on the load side of the circuit breaker.

Should it be necessary for a short time emergency situation, the breaker’s calibration can be changed to allow additional overload capacity. The emergency trip setting of the breaker should be used only when absolutely necessary and for as short a duration as possible because extended use of the setting will result in higher winding temperatures before the breaker can trip. These higher winding temperatures cause a reduction in transformer life. When the emergency control setting is made it increases the load at which the signal light will come on and the breaker will trip by about 20%.

The breaker is recalibrated to the emergency position by removing the meter seal and rotating the emergency control handle upward, in a clockwise direction away from the breaker operating handle as shown in Figure 8. After the emergency condition, the emergency control handle should be returned to its normal position. It is recommended that a new seal be applied to the handle when it is returned to the normal position to avoid inadvertent operation of the emergency control.

Type CSP and CP pole mounted distribution transformer can be supplied with an overload signal light. When the signal light comes on it gives a warning that the transformer has experienced a heavy overload. The signal light remains lighted until reset by means of the breaker operating handle. It can be reset by operating the breaker handle to the maximum upward position and then back down to the closed position.

If the breaker handle is operated to the reset position and then to the close position and the signal light remains on, the temperature of the transformer oil is still too hot to allow the signal light to turn off.

If the signal light bulb is burned out, it can be replaced from outside the transformer by unscrewing the signal light lens and then the bulb.

The Protecto-Combo device consists of a flip open type of fuseholder and a surge arrester. The fuse link is normally supplied by the user. The Protecto-Combo device requires field assembly. This protective device is used only on transformers 50 kVA and below, Class B-2 or B-3 type units with one cover mounted high voltage bushing. This optional device is not shown on the nameplate.

Tap changers are connected into the high voltage coil. The pole mounted distribution transformer output voltage can be increased or decreased by changing the tap changer setting.

The internal tap changer is operated by removing the pole mounted distribution transformer handhole cover, or transformer cover, and turning the tap changer handle to the position desired on the tap position indicator. The tap changer numbers on the position indicator are the same as ones on the transformer nameplate.

To change taps with the externally operated tap changer, loosen the locking screw in the handle, turn the handle to the tap position needed and tighten the locking screw.

Dual voltage switches permit the use of pole mounted distribution transformers on different primary voltage systems. They are externally operated with a handle on the outside of the tank. Voltage ratings are given at the switch handle and on the transformer nameplate.

The switch handle is held in place by a locking screw. Back out the locking screw until it is clear from the locking hole, then rotate the handle. The locking screw should then be put into the locking hole for the new position and tightened.

A unique feature of the pole mounted distribution transformer cover is its ability to flex and relieve pressure which can build up from some internal faults. Except in cases of extreme dynamic pressure build up, the cover automatically reseals itself. Whenever the cover needs to be removed, any internal static pressure is relieved automatically as the cover bolt is loosened. When the bolt is being loosened, the cover can vent but the bolt is still held by a nut in the cover beam.

The cover bolt should be tightened to 350 in. lbs. (27 ft. lbs.)+ 10% to insure that the cover vents properly. If there is a handhole cover on the transformer cover, the handhole cover bolt should be tightened to 150 in. lbs. (13 ft. lbs.) + 10%.

All pole mounted distribution transformers are tested in strict accordance with the latest revision of applicable ANSI™, IEEE™, NEMA, and RUS with test reports available by serial number of the transformer

Routine tests are:

•Leak test

•Polarity and phase relation

•Resistance

•No-load losses and excitation current

•Load losses and impedance

•Applied voltage

•Induced voltage

•Full wave impulse

•Ratio test

There are two common Electric Pole Transformers: Single Phase Overhead Conventional Transformer and Single Phase Overhead Completely Self Protected (CSP) Transformer.

5 kva Single-phase transformer

Width: 465 mm

Depth:485 mm

Height:855 mm

Oil Weight: 15 kg

Total Weight: 92 kg

10 kva Single-phase transformer

Width: 500 mm

Depth:525 mm

Height:885 mm

Oil Weight: 22 kg

Total Weight: 150 kg

15 kva Single-phase transformer

Width: 520 mm

Depth:565 mm

Height:905 mm

Oil Weight: 30 kg

Total Weight: 210 kg

25 kva Single-phase transformer

Width: 560 mm

Depth:590 mm

Height:935 mm

Oil Weight: 45 kg

Total Weight: 258 kg

37.5 kva Single-phase transformer

Width: 610 mm

Depth:625 mm

Height:935 mm

Oil Weight: 50 kg

Total Weight: 340 kg

50 kva Single-phase transformer

Width: 635 mm

Depth:675 mm

Height:1035 mm

Oil Weight: 62 kg

Total Weight: 395 kg

75 kva Single-phase transformer

Width: 745 mm

Depth:840 mm

Height:1035 mm

Oil Weight: 88 kg

Total Weight: 480 kg

100 kva Single-phase transformer

Width: 770 mm

Depth:965 mm

Height:1135 mm

Oil Weight: 94 kg

Total Weight: 530 kg

167 kva Single-phase transformer

Width: 795 mm

Depth:890 mm

Height:1335 mm

Oil Weight: 138 kg

Total Weight: 680 kg

5 kva Single Phase CSP Transformer

Width: 400 mm

Depth:530 mm

Height:960 mm

Oil Weight: 30 kg

Total Weight: 115 kg

10 kva Single Phase CSP Transformer

Width: 430 mm

Depth:530 mm

Height:980 mm

Oil Weight: 45 kg

Total Weight: 150 kg

15 kva Single Phase CSP Transformer

Width: 480 mm

Depth:580 mm

Height:1000 mm

Oil Weight: 55 kg

Total Weight: 205 kg

25 kva Single Phase CSP Transformer

Width: 500 mm

Depth:580 mm

Height:1030 mm

Oil Weight: 66 kg

Total Weight: 345 kg

37.5 kva Single-phase transformer

Width: 560 mm

Depth:640 mm

Height:1080 mm

Oil Weight: 78 kg

Total Weight: 335 kg

50 kva Single-phase transformer

Width: 560 mm

Depth:640 mm

Height:1130 mm

Oil Weight: 85 kg

Total Weight: 370 kg

75 kva Single-phase transformer

Width: 780 mm

Depth:800 mm

Height:1170 mm

Oil Weight: 138 kg

Total Weight: 505 kg

All transformers share some standard features regardless of their type:

On the other hand, an electric pole transformer has a low voltage bushing insulator available in fiberglass reinforced polyester material or porcelain (both eyebolt and spade terminals). Low-voltage neutral grounding strap (furnished on 10 – 50 kVA single HV bushing units)

The cover has 15 kV dielectric insulation and increased resistance to corrosion. In addition, the body is sloped 15°, preventing water from collecting and reducing corrosion and leaking.

pole electrical transformers are used for converting distribution voltage to the 120/240 power system that are used by houses and also low-volume installations. As aforementioned, these transformers have a kVA range of 16 – 100 kVA and easily convert 11,000 – 33,000 V to 400 V.

Electricity is an integral part of many people’s daily lives. As a result, pole mounted distribution transformers have evolved to play an essential role in generating and distributing electrical power. Besides, pole mounted distribution transformers regulate electricity by modifying current to run from one electric circuit to another.

All transformers have one primary function: increasing or decreasing alternating current within the electrical system. By regulating the current flow, the transformer allows for increased energy efficiency, which governs and ultimately lowers electricity bills.

Pole mounted distribution transformers are also helpful in stopping the flow of electricity and interrupting an electric current. Transformers are commonly present in circuit breakers. They use a switch to automatically interrupt the flow of electricity and prevent damage due to high voltage.

The functioning of generators fuels battery charging mechanics. Transformers control the voltage that enters the battery during the charging process to prevent any internal battery component damages. It is essential because an unregulated voltage can result in high surges during the charging of batteries.

Steel manufacturing plants rely on high voltage pole mounted distribution transformers to provide a range of voltages for the manufacturing process. For example, high currents are required for melting and welding of steel, and lower currents are required during the cooling process. It provides this range of voltages for regulating currents within the system.

In chemical engineering and manufacturing, electrolysis gets fuelled by the functioning of transformers. Metals such as copper, zinc, and aluminum are typically used for electroplating.

Transformers provide a regulated electrical current to drive the chemical reaction from the beginning stages until completion. The current can therefore be regulated as the reaction proceeds.

The Electric Pole Transformer is small and light. It can be mounted on a pole, which is convenient for installation. Electric Pole Transformer has a small footprint and is economical.

It can reach the load center to the greatest extent, shorten the power supply radius of the low-voltage network, and reduce losses.

According to the installation requirements of distribution transformers, the typical configuration of sElectric Pole Transformer installation is summarized: Electric Pole Transformer, low-voltage switch, reactive power compensation device, distribution load monitoring system and other equipment.

Installation method: Single-pole suspension can be used for Electric Pole Transformer installation, and the poles can be 12 m heavy-duty cement poles or 15 m cement poles.

Selection of installation location: The installation location of Electric Pole Transformer is less restricted by geographical factors and more restricted by load characteristics.

When the power supply radius of the three-phase distribution transformer is too large, resulting in a low end power supply voltage, which affects the normal power consumption of users.

Install an Electric Pole Transformer at the end of the power supply. Then cut the low-voltage network, and shorten the low-voltage power supply radius, which can solve the problem of low voltage for users.

When the load of the three-phase distribution transformer is too heavy. According to the characteristics of the load, select the appropriate branch line to install the single-phase distribution transformer, cut and transfer the load, which can solve the problem of capacity increase;

Install Electric Pole Transformer to supply power to residents at locations. It can shorten the low-voltage power supply radius and reduce losses;

Installing single-phase distribution transformers for power supply in locations with low load density, wide distribution. It can save investment and solve the problem of power supply points.

The power supply radius of a Electric Pole Transformer is only 10-15 m. Compared with a three-phase distribution transformer, the power supply radius is greatly shortened, and the low-voltage line loss is significantly reduced. 7.61% decreased to 2.72%, and the monthly electricity saving was 1810 kWh.

As the radius of the low-voltage power supply is greatly shortened, the line voltage loss is small, and the qualified rate of household voltage is significantly improved.

As the radius of the low-voltage power supply is greatly shortened, the line voltage loss is small, and the qualified rate of household voltage is significantly improved.

Single-phase distribution transformers are used for power supply.

The High-voltage lines can be erected as two lines.The low-voltage lines can be erected as two or three lines.

When three-phase distribution transformers are used for power supply, high-voltage lines must be erected as three lines, and low-voltage lines as four lines.

From the perspective of engineering cost, the engineering cost of using Electric Pole Transformers to supply high and low voltage lines can be saved by 1/5.

From the perspective of the construction cost of the station area.

The cost of building a pad-mounted transformer is 3 times that of an Electric pole transformer.

Yes, they can be dangerous and highly flammable. pole electrical transformers could also fall down, which might hit someone that is just near the pole. When it comes to its voltage, the power lines or wires between the areas could cut off and start to spark in an abnormal way, getting hit by live wires can potentially burn our insides and cause other life-threatening injuries.

Power lines are strung between utility poles in urban areas. It goes from 4 to 25 kilovolts or less. At this voltage, touching a power line can already cause severe injuries. At times, the wound left by electricity exiting the body can cause such severe damage.

This electric shock this large can stop your heart. What’s more, tree branches that come in contact with a power line energize the tree and the ground around it. So it creates a very hazardous situation.

That’s why it’s essential to choose a brand of transformer that significantly focuses on quality. It will guarantee that you are safe from any hazardous instance.

At DAELIM, you are guaranteed to get quality transformers that are hazard-free. Being in danger while using an electric pole transformer is the last thing that will cross your mind.

First, a pole mounted distribution transformer should be installed with the front (doors) facing away from the building, with no balconies or overhangs above. Second, the transformer must also be accessible to line trucks (The size and weight of a cement truck) for maintenance or replacement.

Generally, a transformer near a building requires 4ft clearance from the vertical building surfaces, assuming no windows from grade to 18ft. In addition, the sides of the transformer must be clear of all objects for 3ft, including landscaping. More so, transformers must be 10ft horizontal from doors, windows, or fire hydrants.

The transformer’s front (door side) shall have a 10 ft. clearance. This ensures line crews safely perform maintenance or repairs on the. This clearance requirement includes landscaping. When it comes to landscaping during emergency repairs, the utility can remove the landscaping or leave and await notice when offending vegetation has been removed.

The utility will not attempt to work on the transformer during routine maintenance until the landscaping has been removed.

Suppose you put a secondary coil of wire next to the first and send a fluctuating electric current into the first coil. In that case, you’ll create an electric current in the second wire. The electric current in the first coil is usually called the primary current. At the same time, the current in the second wire is the secondary current.

Note: This trick works only if the electric current fluctuates somehow. In other words, you have to use a constantly reversing electricity called alternating current (AC) with a transformer.

pole electrical transformers contain a magnetic core that is produced from laminations of silicon sheet steel or otherwise known as transformer steel, that are stacked together. There are also primary and secondary wire windings wrapped around them.v

Each house has a pole mounted distribution transformer drum that is mounted to a wooden or concrete pole. For houses that are near each other or suburban neighbourhoods, the distribution wires are located underground with transformer boxes underneath every house.

What these transformers do is reduce 7,200 V to 240 V, this is sufficient for running a normal household with electrical services.

Below are the different types of pole mounted distribution transformers you usually hear from other companies who are considering buying premium pole mounted distribution transformers for their inventory stocks. You will have a better understanding about the different types of transformers after reading this section.

Core type pole mounted distribution transformers are commonly used in applications such as for transferring cores, energy and power grids. So, it still has the main function of what transformers do which is the ability to increase and decrease values.

When it comes to their mechanical properties, the core type pole mounted distribution transformer has two limbs with windings contracted to the core material.

Shell type pole mounted distribution transformers may not be popular but it does not mean that they are not worth considering. They are used for low voltage applications including low voltage power circuits that involve electrical circuits.

Its mechanical components are composed of its core, three limbs, and two windows. For its windings, they are contracted on the center or central limb, in a “one over the other” position. Nonetheless, the arrangement of these windings can be progressed with one limb.

The spiral core transformer is considered to be the modern one since it has the latest development in its core construction.

The core is formed in a continuous strip or ribbon form that is somewhat similar to a circular cylinder, hence, getting the “spiral core” for its name. These shape allows its core flux to escort the grain of the iron

Calculation Method of the Number of Turns of Power Transformer Core

Yes, pole electrical transformers help regulate and distribute the right amount of voltage to each house smoothly. Without pole electrical transformers. Moreover, this keeps the electricity flowing consistently to provide homes electricity without getting it cut off.

Yes, they do contain oil, distribution transformers like single-phase transformers and pole electrical transformers contain oil for electrical insulation and cooling to the windings inside the transformer.

There is a specialized oil that is specifically made for pole mounted distribution transformers, thus, claiming its name “transformer oil” that is also referred to as insulating oil. These are used for oil-type transformers, fluorescent lamps, high-voltage switches, and circuit breakers.

When there is a disturbance or interruption that causes the pole electrical transformer to receive too much electricity, the energy and electricity passing through it gets uncontrolled which results in an explosion and possibly followed by fire.

Normally, the range of connection between how many houses connected to a single pole electrical transformer varies but it can be connected to up to 50 houses. But for industrial and commercial applications that require high loads of electricity, it can be as low as only 4 to 5 large infrastructures.

The amount of copper in a pole electrical transformer contains about 15% to 20% along with steel materials and core laminations including the insulating oil inside the pole electrical transformer.

In this section, you will learn the advantages and drawbacks of pole electrical transformers. This section helps you give a final verdict on your purchase decision. So, once again, do look into the details that are provided,

If there are any concerns you would like to be assessed, DAELIM is ready to answer them. But before that let us look into its advantages.

Here are the main advantages of using pole electrical transformers.

When it comes to control of energy transmission, there is without a doubt that pole electrical transformers do a decent job. It is simply well-designed and is the only compact transformer that can do energy and electricity transmissions on a pole.

This is the reason why pole electrical transformers can have a lot of wired connections. It has no problems in distributing electricity to all connected houses because of its effective mechanical components that are behind the smooth voltage transmission from house to house.

By now you could definitely tell that pole electrical transformers do well. In fact, the place you are living in might even be powered with a pole electrical transformer! A lot of companies tend to use two or three of these because large consumption is enough for 4 to 5 huge buildings already.

Compared to its other big competitors, pole electrical transformers are fairly priced in the middle. It is compact, low maintenance, and highly efficient. What more could you ask for? It is at the top of the league compared to its alternatives.

As mentioned, it requires little to almost no maintenance at all! Have you noticed that electricians rarely visit pole electrical transformers? This is because it has no moving parts inside, and its material is so solid that it can withstand changing temperatures, typhoons, and heavy beating.

There are no moving parts whatsoever in pole electrical transformers which is why it is considered as a solid state device. This means that you have less to worry about, especially random explosions, fire, or electricity cut offs.

Below are the disadvantages or drawbacks of pole electrical transformers.

Since it has little maintenance and no moving parts inside, you cannot expect that it will stay in pristine condition forever, which means you will have to replace it every 3-4 years or so. Some pole electrical pole mounted distribution transformers even require yearly replacement.

But with high-quality ones, you do not have to worry about constantly replacing your pole electrical transformers. DAELIM has several pole electrical transformers you can choose from.

Since it is mounted to a pole, without checking it every once in a while, pole electrical transformers might get loose and fall off, which is why it is very important that it is installed properly by experts who are responsible for strongly clamping it to where it is mounted.

DAELIM offers low cost installations for you to not go through that hassle. Rest assured, your pole electrical transformer will never budge with DAELIM’s low cost installation.

As mentioned before in a previous section, some pole electrical transformers require oil as an insulation. Oil can be quite costly, and you do have to fuel it up every once and a while as well. If this is something you do not want to apply, do reconsider or contact DAELIM for your concerns.

As you know, there are a lot of power lines or wires connected to a single pole electrical transformer especially in urban areas. The range could go from 4 to 5 kilovolts. Even at this low voltage, a contact with a power line can seriously cause injuries to those who come in contact with it.

This is the reason why live wires can cause injuries that require amputations, and even death. Electricity that is that large of an amount is capable of stopping your heart from working. Touching a tree branch that is in contact with the wire can still reach you.

So, whenever there are live wires down connected to a pole mounted distribution transformer, stay as far away from it.

The pole, wood, or concrete that it is mounted to is usually applied with preservatives that contain harmful chemicals that are dangerous to animals, and humans. These preservatives can cause cancer, complications to our systems, and even birth defects.

So, if ever you are in a case wherein your 2nd floor is near to a transformer, keep the windows closed or wear a mask. These preservatives will eventually fade away after a month or so. Depending on how strong it is.

When the insulation that is surrounding old power lines underground degrade, the wires become exposed to the ground or soil, in which stray electrical currents can travel through soil.

YES, electricity can travel through soil. Especially, metal objects on the surface including sheets of metals, utility poles, fire hydrants, etc. Coming in contact with flowing electricity in the ground with your bare feet can cause an electric shock that causes severe injuries.

There have been lots of reports of people and animals dying from stray voltages.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Transformers are essential in our daily lives; they ensure that our houses and appliances are electrically powered at a voltage level that’s safe for everyone. They are usually located in different locations.

For instance, a transformer on power pole.

Power line transformers are commonly step-up transformers that produce very high voltage levels needed to transmit electricity.

Let’s talk more about what power line transformers are, how transformers on power poles are installed, and how they can help supply the needed electricity.

DAELIM is one of the world’s top professional and electrical transformer manufacturers.

For more than 15 years, DAELIM has been committed to providing its customers with inexpensive, high-quality products.

These reliable transformers and electrical pieces of equipment follow international standards such as ANSI, IEEE, IEC, CSA, AS/NZ, etc.

A transformer on power pole is a distribution transformer mounted on a utility pole, otherwise known as a pole-mounted transformer.

These are mounted on power poles made of concrete or wood.

You can frequently see them oriented horizontally to overhead cables.

They are mainly used to convert distribution voltage to the power source needed in homes to supply appliances, commonly at around 120/240 voltage.

Generally, you can find several pole-mounted transformers in rural areas.

Because they are small, transformers on power poles can be easily installed in single-pole and two-pole structures.

They are commonly installed five meters above the ground, making them inaccessible to humans and most animals.

Unlike transformers installed on the ground, where they have to be enclosed in a protected covering to prevent humans from injury, a transformer on power pole is installed high above the ground.

Because of this, humans and land animals cannot touch and mess up these transformers.

Another advantage of pole-mounted transformers is their size and design.

Because they are compact and small, these power transformers don’t need much space.

The advantage of using a transformer on a power pole is it lessens the potential dangers. Here’s an illustration.

If you place a transformer on the ground, people who aren’t knowledgeable might see it, then acquire it.

However, it won’t be the case since it’s placed high above the ground.

People will recognize that it’s dangerous and won’t bother climbing up.

Another advantage is that it’s closed-packed and won’t take too much ground space.

If you’re getting groundwork on a small lot, it is ideal to use a pole-mounted transformer.

A disadvantage of pole-mounted transformers is the difficulty in maintenance because of their location.

You might have to contact an electrical company to fix the transformer when needed.

Pole-mounted transformers may also need to be replaced more often than ground-installed transformers because they are in constant heavy contact with different elements like the wind and rain.

There are notable advantages of using a transformer on a pole. However, there’s also a downside.

These types of transformers are very difficult to maintain. If there’s damage, you’ll have to ask power companies specializing in these repair types.

Aside from that, another disadvantage is transformers on poles need to be repaired or replaced from time to time.

Since these are placed above the ground, they’re more susceptible to harmful elements and events.

A transformer on a pole can either be single-phase or three-phase.

Choosing which to use and install depends on your voltage needs and area.

Transformers are important as they function to generate current and power into your homes.

They can increase voltages while traveling long distances before they reach your house.

Now, there are two types of transformers on a pole.

Single-phase pole-mounted transformers are designed with single pairs of coils, one primary and secondary, to produce the voltage desired for electricity supply. These are installed in residential areas where they serve as step-down transformers to lower the voltage to a level suited in homes.

A single-phase pole-mounted transformer commonly does not need a cooling system and consists of four terminals with no star or delta connections.

The benefits of installing single-phase pole-mounted transformers are the following:

A single-coil pair, consisting of primary and secondary, will produce an ideal voltage known as a single-phase transformer.

Its coils are highly inductive and are wound up on a steel or iron core.

This type of transformer is composed of four terminals.

Two of which are output, and the other two are for input.

Additionally, there are no delta nor star connections available.

These single-phase transformers are ideal for residential and office needs because they can handle high-powered voltage into low ones.

Not only that, but they’re relatively less expensive and have low power output.

By the same token, if you use these transformers, you have to pair them with a cooling system.

A 3 phase pole mounted transformer consists of winding three single-phase transformers on a single core. It contains six coils, three on the primary and secondary sides. These coils are separated by a 1200 degree angular difference.

The 3 phase pole mounted transformer is more commonly installed for heavy industrial applications because they deliver heavy-duty voltage requirements. They can also transmit the desired voltage level even across long distances.

The benefits of three-phase pole-mounted transformers include the following:

The 3 phase pole mounted transformer winding three single-phase transformers into one core.

The three transformers are composed of six coils, three for the primary and three for the secondary.

This type of transformer is known to provide power for heavy-duty needs. Since these have small conductors, the electricity flow is smooth.

That’s why three-phase is the best one to use if you’re into industrial equipment.

In distribution transformers, the 3P contributes significantly and has a high KVA.

If the coils are properly placed and connected to the incoming voltage, they can perform well.

The pole mounted transformer installation process requires a professional electrician.

You cannot install the transformer on your own to prevent any risk of injury.

The step-by-step guide below is a summary of how pole-mounted transformers are installed.

Before installing and lifting the transformer, ensure that the transformer can be safely lifted.

Also, ensure that your personnel wear a pair of minimum Class O rubber gloves during handling energized and disconnected secondary conductors.

This type of transformer can withstand a lot and can last up to 50 years at most.

However, it can heat up and be destroyed. The price range will depend on what it’s designed to handle.

The pole mounted transformer price can range from $3,000 to $7,000; this depends on the amount of electricity they can handle and convert.

If you’re looking to buy a pole transformer, you must get a transformer that can handle a high voltage level.

Transformers on power lines manipulate and convert high voltage levels flowing through power grids.

They decrease the voltage level traveling through power grids to a safe level desired by end-users in commercial and residential areas. In other words, they serve as step-down transformers.

The homeowner owns the power line from the power pole to a house.

When something happens or when the power line between the pole to a homeowner’s house is damaged, the homeowner is responsible for its maintenance.

There are almost 30 line companies that sell electricity, depending on your location and national grid company.

The line company owns the power lines until it reaches and connects to your property boundary.

You, as the homeowner, have ownership if the power lines are located between the power pole and your house.

Meaning, you’ll have to maintain and call a repair company should there be any problems.

Bitcoin mining is a process of entering new bitcoins into circulation.

Through this, a network can confirm new transactions critical in developing and maintaining blockchain ledgers.

The first component you need to enable a bitcoin mining power system is a utility company’s transformer.

Transformers are responsible for converting medium voltage from one substation to a level that can supply the power for mining.

Crypto mines commonly use transformers deployed in 1000kvA, 2000kvA, and 5000kvA increments.

Bitcoins are digital currency and offer fewer transaction and payment fees than normal currency.

Not to mention, bitcoins also use cryptocurrency, a technique used to secure its details.

To keep this digital crypto power on the market, there’s the process called bitcoin mining. How does it work?

Bitcoin mining is carried out using an advanced computer and mathematical computation.

The fastest machine to generate results will have the most bitcoins. Then, the process will repeat in a cycle once more.

Since you’ll need power for mining, the equipment you’ll use is a transformer.

When indulging in crypto mining, you’ll need a transformer to convert medium voltage into a mining power supply.

The best voltage increments are 1000kVA, 2000kVA, or 5000kVA.

Not to mention the configurations needed are 208V 3 Phase Delta, 240V/415V 3 Phase Wye, and 277V/480V 3 Phase Wye.

A transformer on power pole is important because it ensures that our homes are supplied with the electrical power that our appliances and other electrical equipment need.

They are safer than ground-installed transformers because humans cannot access them; thus, reducing exposure and injury risks.

The pole-mounted transformers are advantageous to use in areas with small ground space.

Since they’re installed up, you don’t have to worry about accidents or people mistakenly manipulating these transformers.

Similarly, these are used more often in residential and commercial houses.

Single-phase pole-mounted is used in houses, while the three-phase counterpart is used to power up industrial pieces of machinery.

Depending on the use, pole-mounted transformers will vary in price, starting from $3,000-$7,000.

The best equipment to use in bitcoin mining is transformers. At Daelim, you’ll find the right machine for your electricity needs.

When you purchase from Daelim, you can be assured that you can get the best possible transformer.

At Daelim, we know that you value your transformer products, and we want to help you get the best products at an affordable price.

The most stereotypical type of power distribution is a transformer on power pole. These are sketched out to improve its operation.

Its components are specifically made to help resist any dangerous conditions.

Not to mention, its steel tank has coils and core assembled with a top-caliber oil to facilitate cooling.

The main function of a pole-mounted transformer is to facilitate the final voltage transformation as it reaches the grid for transformation.

It has to provide the right voltage for home and establishment. How? It will downgrade the voltage to 240 volts.

With DAELIM, most customers are well-pleased with the company’s products and services.

Daelim is dedicated to providing quality-standard machinery, should you need transformers and electrical apparatuses.

A pole-mounted transformer commonly seen in breadbox transformers converts voltage ranges from 120-140 volts.

It’s used to power houses and commercial establishments. Additionally, it’s also used in wide rural areas.

Power-mounted pole transformers are attached to wood or cement concrete and are leveled overhead poles.

The transformer on power pole powers up to 100kVa and transforms from 11,000-33,000 volts.

These pole-mounted transformers are designed to be small. Why?

It is to avoid any accidents and destruction that may potentially occur. The installation can also be set up with a length of up to 5 meters.

Below is the guide for pole mounted transformer installation.

The first thing you have to do is to put the most weight on the bolt’s top, the process to tighten it fully using a wrench.

Then, check if it’s fully secured. You can proceed to detach the sling from the transformer.

Next, paste the H1 from the bottom to the cut-out.

Proceed to attach a primary riser to the head of the cut-out.

Ensure that it’s hanging down and no conductor with energy and movement riser is handled.

Thirdly, you have to dangle the fused cut-out door into the slots at the bottom cut-out.

After which, don’t forget to paste the ground, neutral and secondary connections.

The fourth step is to remove all cover-ups.

These need to be eliminated, so check on and remove using a proper technique.

Using a grip-stick, attach the primary riser to the primary distribution conductor.

Lastly, using a switch stick, close the cut-out door.

Check to see if the voltage is suitable for the new transformer.

The transformers are made to a level of voltage that passes through any point and into a grid.

In terms of distribution, it manipulates the voltage to fit the right amount for houses and establishments.

There are various reasons why transformer lines fail. It can be corrosion, overheating, and lighting strikes.

Transformers can bear these circumstances because they carry oil minerals to avoid exhaustion.

A power transformer changes the electricity voltage from higher to lower levels as needed by different systems.

This piece of equipment is so important in homes and businesses because it makes using electrical devices safer than if you didn’t have it.

The voltage that comes through the electrical system can be extremely dangerous.

Without this transformer, it would be extremely dangerous to use any electrical devices in your home or business.

Single-stage transformers are commonly used to provide electricity for personal lights, containers, cooling, and heating.

The essential winding and auxiliary twisting can be created in two equal portions, giving these a lot more flexibility.

Three-stage transformers have six windings: fundamental and discretionary.

The windings are related by the maker as either delta or wye.

As of late communicated, the fundamental windings and discretionary windings may each be related in a delta or wye course of action.

Delta and Wye are the two three-stage power association systems.

The Greek letters Delta and Wye refer to the arrangement of wires on transformers.

In a delta association, the three conductors are connected from beginning to end in a triangle or delta configuration.

For wye, each conductor transmits from the center, implying that they are all connected at the same normal position.

One of the most important things to understand is the power transformer’s role in the overall power distribution process.

Generally, it helps to step down voltage levels to be safe and usable for homes and businesses.

Without this crucial piece of equipment, the voltage coming from the utility company would be too high for most applications.

A power pole is a wooden pole typically used to support overhead electrical wires.

It is used in electricity distribution and transmission to route electric current from transmission lines or between utility poles.

The cross-section of a power pole can vary greatly depending on its use and where it was manufactured.

Poles are made out of wood, concrete, or steel. Concrete poles are filled with sand and gravel for added strength.

One reason why there is a power transformer on pole is electrical safety.

The voltage levels distributed by utility companies can be too high for residential and commercial use.

So, a transformer needs to step down those levels as much as possible.

Another reason for these power transformers on a pole is the amount of space available in neighborhoods.

Utility companies need to find a way to distribute power safely and efficiently, and putting power transformers on a pole is one way to do that.

Different regions may also have different voltage requirements based on their history and needs, so a power transformer on pole helps step up or down voltage levels safely and effectively.

There are several key components in a power transformer on pole.

The primary coil is the part of a transformer on a pole that steps down voltage into usable levels.

The secondary coil is where power is distributed to homes and businesses in your area.

There is also a transformer core, which helps to stabilize the voltage levels and protect against surges.

Finally, there is the housing or enclosure for all of these components.

There are several common pole mounted transformer sizes.

The size of a transformer depends on how much energy it has to handle and its voltage rating.

So, the more power needs to be handled or the higher the voltage rating, the larger it will be.

Smaller transformers can often handle between 100-300 volts, while larger ones can handle 600-3600 volts.

Bitcoin mining is a process that helps to secure the Bitcoin network and generate more Bitcoins.

To do this, miners need to solve complex mathematical problems. One of the ways that miners can increase their chances of solving these problems is by increasing their mining power supply with powerful power transformers.

This will allow miners to draw more energy from the grid to increase their crypto farm power, which gives them a competitive edge in the mining process.

In addition, power transformers help enhance the Bitcoin mining power system and other hardware that miners use in their quest for more Bitcoins.

Also, power transformers step down the electrical power voltage; bitcoin miners can use less powerful rigs for their Bitcoin mining power system, which saves them money on electricity costs.

A pole-mounted transformer generally contains two coils of copper wire, called the primary and secondary.

The primary coil is responsible for stepping up the voltage of electrical power.

In contrast, the secondary coil is responsible for stepping it down to a level that your home or business can use.

There are also typically three windings in each coil, which helps handle more power.

A pole-mounted substation is a structure that contains electrical equipment and is used to provide electricity for your home or business.

The output of a pole-mounted Substation is the same as in an underground or substation.

It can be single-phase, two-three phase, and three-phase with neutral terminals.

The primary voltage may vary from 66 kV to 500 kV. And the secondary voltage is around 11 kV to 33kV.

Its maximum output current can be up to 50-100 Amps depending on the capacity of the transformer.

A pole-mounted distribution transformer is fitted with three main poles.

These are Neutral and safe earth (ground) connections, a Line terminal for connecting to the line voltage of the supply.

Distribution transformers are associated with delta-star.

This plan requires 3 conductors on the high voltage side and two on the low voltage side.

The start point of the secondary winding is connected to neutral and grounded metal parts such as a water pipe or conduit.

Also, there are two 120 degrees apart high voltage to low voltage phase conductors.

The first is the ‘A’ wire, while the other is called ‘B.’

These transformers play an important role in the overall distribution process, and they can be found in neighborhoods all across the country. In addition, power transformers are essential for Bitcoin mining operations, and they help to power computers and other hardware used in this process.

Finally, it’s important to understand the basics of a power transformer on pole, including the different components that make up this equipment.

If choosing a suitable transformer seems like a daunting task for you, contact DAELIM for assistance before you make your next purchase.

Electrical transformers make it possible for large quantities of electrical loads.

It is because they carry on a primary source to a smaller output device.

For a single electric barrel that is capable of passing energy of up to 50 houses, it is very efficient in its job and with little maintenance, it sustains itself very well.

Should you have further questions and concerns, you may contact DAELIM’s team of professionals who are ready to accommodate.

After filling in the contact information, you can download the PDF.