ELECTRIC, WITH AN EDGE

Power pole transformers are a necessary component in power distribution systems to compensate for voltage drops. These drops may be due to transmission and distribution line losses. It is like an auto-transformer that is located at the end of a power line.

The power grid is the interconnected transmission and distribution lines that bring electricity to all homes, businesses, and other buildings. It consists of three parts, namely the bulk grid, sub-transmission grid, and distribution grid.

DAELIM is a leading global company that specializes in the manufacture of transformers and electric motors. In addition, Daelim has been producing transformers for over 50 years and is widely considered a pioneer in transformer technology.

Power pole transformer is widely used in complex terrain due to its excellent mobility and overload capacity.

But you may find that the existing specifications of the Power pole transformer cannot meet your requirements. It’s ok. You can tell Daelim that Daelim has a professional design team that can customize the Power Pole transformer for you according to your needs.

Download Resource

-Learn the fundamentals of Electric Pole Transformers, including What is pole mounted distribution transformer, pole mounted transformer specifications, pole mounted transformer drawing, pole mounted transformer sizes and custom options.

-FIND THE BEST PAD-MOUNTED TRANSFORMER GUIDE ON THE WEB ALL IN ONE PLACE. SEE OUR LIST OF 14+FAQ RIGHT HERE.

-Find out what a single phase pad-mounted transformer is and what you need to know about it. Keep on reading!

-A completely self-protected transformer (CSP) is designed to protect electrical equipment from damage caused by lightning, switching surges, and severe overloads.

Power pole transformers are step-down transformers that can reduce distribution level voltage to a more manageable utilization level.

In addition, they are beneficial in reducing the voltage of the electric current before distributing it to homes across cities.

These are typically mounted on poles, making them more accessible for maintenance, inspection, and repair.

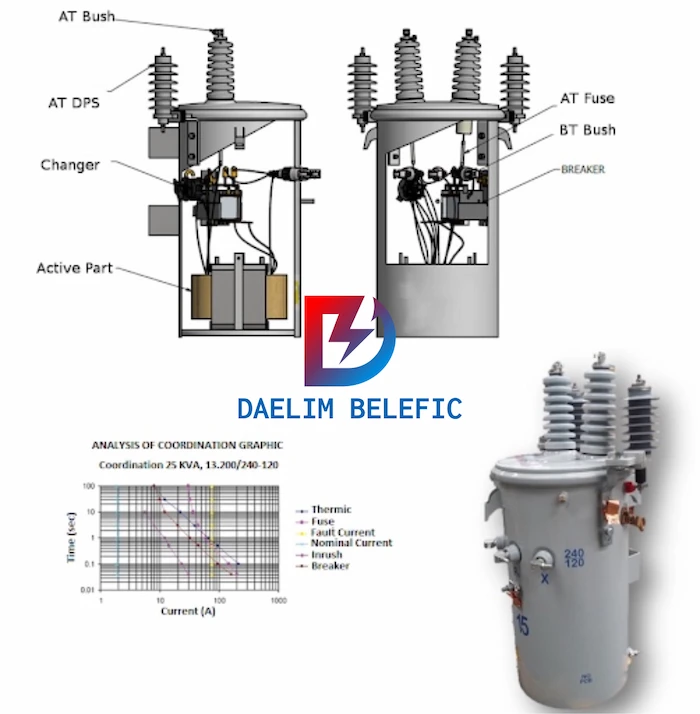

There are eight sizes of single-phase pole-mounted transformers.

The smallest is a 1.5 kVA transformer, and the largest is a 25 kVA transformer.

Older homes are generally able to use smaller transformers.

Meanwhile, larger transformers are used for newer homes and commercial buildings.

Three-phase pole-mounted transformers are typically rated in kilovolt amperes (kVA).

The kVA rating is determined by multiplying the input voltage (volts) by the transformer’s constant.

The power transformer has higher ratings, while the distribution transformer has lower ones.

Distribution transformers step down voltages to usable levels. Meanwhile, power transformers focus on distributing high voltages.

“Power-pole transformers” is an industry term that refers to a type of distribution transformer.

These installed poles eliminate the need for new poles and reduce the number of transformers needed on each line.

The term power here refers to the fact that this transformer is part of the power grid.

The transformer produces electrical power by converting alternating current from the grid into direct current used by customers.

A power transformer converts electric energy from one voltage to another.

It typically consists of two coils of wire wound around an iron core and connected by an electromagnetic field.

When an alternating current (AC) flows through the primary coil, the magnetic field induces a voltage in the secondary coil.

In that way, electrical energy is transformed from one voltage to another.

The working principle of a transformer is to transfer electrical power from one voltage to another. A transformer transfers power by means of electromagnetic induction.

It has two coils of wire, called the primary and secondary coils, which are separated by an air gap.

The primary coil carries electrical power to the transformer while the secondary coil carries it away. This can be demonstrated using Faraday’s law.

Power pole transformer explosions have been a source of concern for many people. In this article, the causes of power pole transformer explosions are also discussed.

Transformers are very robust pieces of equipment. Overloading usually takes years to destroy a transformer.

When the load increases, the windings heat up and then cool down again when it is decreased.

It will burst when the load is extremely high for a short period, but this does not generally happen.

Causes of overload are evident when too much power is drawn from a pole transformer.

This may be due to the demand for power being greater than the capacity of the transformer.

A power company upgrades the transformers when needed.

Power pole transformer explosions can be prevented by monitoring power usage and installing surge protection devices.

Moreover, replacing old poles with built-in lightning protection devices can be beneficial.

Damages caused by natural wear and tear on the power poles are the leading cause of transformer explosions and outages.

For determining the causes of failure, the transformers’ age is critical information for narrowing down the list of possible issues. If the transformer in question is old (15 to 20 years), damages can be due to natural wear and tear.

This type of wear and tear can be caused by wind, hail, and other natural elements. These forces can weaken the power pole’s foundation, which can result in a transformer outage.

Lightning strikes are the leading cause of power pole transformer explosions.

The sudden rise in electricity causes the power pole transformer to heat up rapidly, which causes the wiring to spark.

These sparks can cause an explosion if there is not enough airflow to cool it down.

When a nearby object is struck by lightning, it becomes an easier pathway for electricity to travel.

This can result in a power pole transformer becoming damaged and even exploding.

Moisture builds upon the power poles and is used as a conductor for electricity.

Water conducts electricity from the power line to the transformer, creating high voltage traveling through the wires, causing a spark.

This spark ignites any residual moisture on the pole, causing an explosion.

The two common methods to measure the moisture content are dew point analysis and water-in-oil analysis.

Once you have determined moisture contaminants, there are ways to remove them from the transformer insulation.

These methods are hot oil flush and hot oil spray.

Single-phase distribution transformers are a device that converts main power from electric utilities into voltages and current levels needed.

This transformer consists of a primary coil and a secondary coil, both wound on an insulated core.

The secondary coil is wound on the same core as the primary coil.

This core is called a laminated iron core.

When transformers are subjected to voltages and currents that exceed their design specifications, they will experience decreases in life expectancy.

Insulation systems will break down, resulting in excess heat buildup and insulation failure.

To prevent transformer overload, you need to ensure that the transformer is the correct size for the application.

You can also check if the fuse or circuit breaker protects it.

When three-phase transformers are not used, transformer banks are made by attaching two or three transformers to the same circuits.

In addition, they are used to reduce the capacity that is needed.

They can produce a better average voltage along with the secondary and have greater flexibility with load growth.

Technology continues to evolve together with the needs of electric power distribution.

Pole power transformers are an integral part of the electric infrastructure.

They are needed to convert high-voltage transmission lines into lower voltage for distribution to the pole-mounted transformers.

Without these transformers, power distribution would be impossible.

Daelim is one of the most trustworthy companies in the world.

Daelim has a wide range of power distribution solutions for any project. It doesn’t matter if you’re a large company or a small business.

Daelim can provide you with the power distribution solutions that are right for you.

ELECTRIC, WITH AN ENGE-- DAELIM BELEFIC