How to Choose Pad Mounted Transformer?

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical

ELECTRIC, WITH AN EDGE

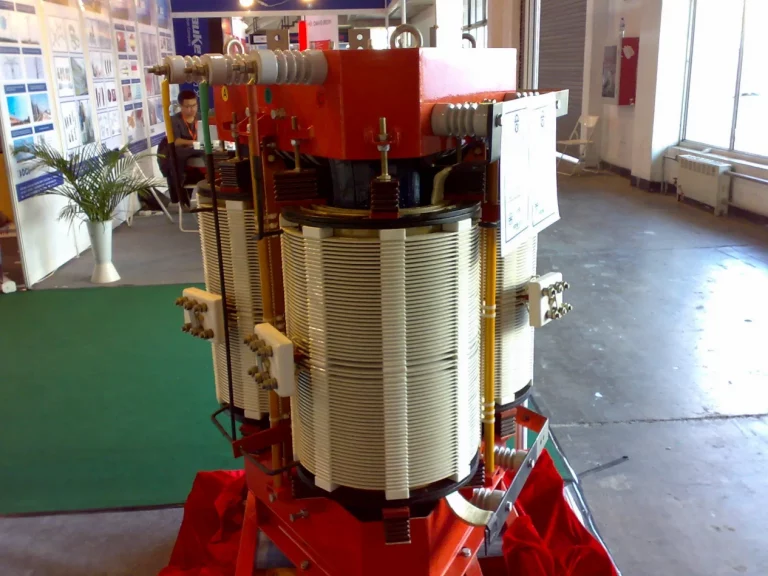

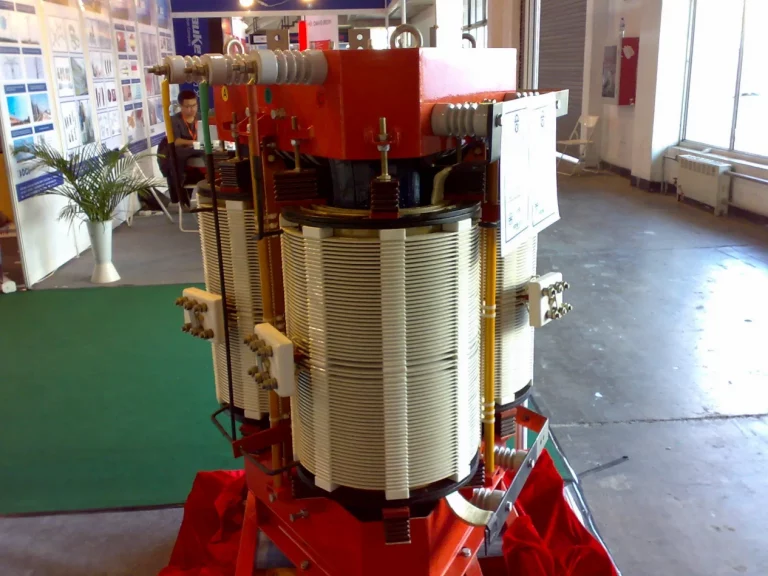

There are many types of Dry-type distribution transformers available today, and different types of Dry-type distribution transformers have obvious differences in terms of environmental protection, energy saving, noise and cost. The research on technical characteristics and performance of Dry-type distribution transformer should be increased, so as to select the Dry-type distribution transformer that best meets the actual needs and give full play to its functions and values.

In the 1970s, the amorphous alloy Dry-type distribution transformer was successfully developed, which is an energy-saving device, and compared with the silicon steel sheet Dry-type distribution transformer, the amorphous alloy Dry-type distribution transformer has the following advantages.

From the raw material manufacturing point of view, amorphous alloy heating only needs to be carried out once, while silicon steel sheet needs six times; amorphous alloy core annealing disposal temperature is 380℃, while silicon steel sheet is up to 800℃.

Amorphous alloy cores have higher magnetic induction strength and low loss, the actual no-load loss is less than 25% of silicon steel cores.

When there is harmonic voltage intrusion, silicon steel sheet core will form a lot of loss and noise, while amorphous alloy has good magnetic properties, the loss when bearing high frequency is about 10% of silicon steel sheet.

But amorphous alloy Dry-type distribution transformer also has some shortcomings.

First, the production cost input is more for the core made of non-metallic strip 0.02mm thick, the thickness is very small, but the density is not similar to that of silicon steel sheet, the surface area of the heart column is large, so the actual manufacturing to cast a larger number of wires.

Non-crystalline alloys show higher sensitivity to mechanical tension and stress, resulting in a significant increase in pressure and a corresponding increase in the amount of consumables.

The non-crystalline alloy puts higher requirements on the processing process, so that the number of equivalent non-crystalline alloys on the market is above the cost of silicon steel sheet itself.

Secondly, non-crystalline alloys are highly sensitive to mechanical stress, especially under the condition that their own thickness is small, and it is easy to generate a lot of noise during the operation.

Non-crystalline alloy Dry-type distribution transformer is heavy in mass and occupies a large area, which is easy to cause noise aggravation, and can achieve good noise reduction effect through the configuration of noise elimination instrument.

Third, the non-crystalline alloy changes because of its own thickness is not enough, brittle on the large side, it is difficult to increase the capacity of the load-bearing core, so that the volume is small.

The epoxy resin itself is a chemically stable material, with the properties of dust and moisture resistance, and can be used normally in very harsh conditions, even with 100% humidity in the air, and can continue to operate without drying after shutdown.

Resin casting is mainly to pour epoxy resin in the mold and make it cured into a complete rigid body structure, the mechanical strength is at a high level, but the process is very complex, and the casting operation is not standardized to cause local cracking of epoxy resin after long-term use.

The chemical stability, electrical and mechanical properties of Nomex paper are high, and the risk of aging and cracking is low, and it can still maintain excellent performance for more than 10 years even at 220℃.

The insulation temperature rise margin between Class C and Class H materials is used to provide Dry-type distribution transformer equipment with a strong overload capability. Using vacuum pressure impregnation process, the performance of Dry-type distribution transformer is obviously enhanced to prevent moisture and mildew.

The three core columns of the planar core have unequal lengths, while the three core columns of the three-dimensional coil core form an equilateral triangle with the same magnetic path, so its three-phase no-load current also achieves absolute balance.

Generally, silicon steel strip is selected as the raw material for the manufacturing of three-dimensional coil cores, which is made through the traditional winding process, without gaps and balanced distribution of the magnetic circuit, thus avoiding the distortion phenomenon, significantly reducing the magnetic resistance and reducing the no-load current.

In the case of the same net cross-sectional area, the core diameter is also shortened, which means that the length of the wound coil is also reduced, reducing the amount of raw materials, reducing load losses, and reducing the weight of the core by 15% to 20%. In the core cross-sectional area, window height, heart column distance, etc. at the same time, and flat core Dry-type distribution transformer, compared to the three-dimensional coil core Dry-type distribution transformer iron yoke usage is reduced by about 25%.

Because the three-dimensional coil core uses a seamless continuous winding structure, the silicon steel strip is very tight, the amplitude is very small, the noise can be controlled below 45dB, the volume level is comparable to indoor air conditioning, basically will not make the residents in daily life discomfort.

First of all, as the above analysis shows, different types of Dry-type distribution transformer equipment have different performance and advantages and disadvantages, but the use method and operation process are more or less the same, before operation, we should check the Dry-type distribution transformer shell, parts, etc., to find and deal with Before operation, the Dry-type distribution transformer shell and parts should be inspected to detect and deal with problems such as local damage. Test the sensitivity and solidity of the operating mechanism to ensure that the electrical contact is good and reliable, and make sure that all the cable lines are tightened and closed.

Second, after checking each position of Dry-type distribution transformer equipment and determine its normal, carry out electrical handover test, the test results should meet the requirements of technical specifications, the electrical insulation degree of each substation should also match the requirements of the relevant regulations, and the frequency withstand voltage test should not see no breakdown, flashover and other abnormalities. After closing the high load switch, it should be put into no-load operation.

Furthermore, combined with the selected Dry-type distribution transformer model and specification, the stop button and other parts of the chain button are operated in strict accordance with the design process, and the operation of each part is checked and inspected to see if the current and voltage parameters comply with the relevant regulations. Finally, Dry-type distribution transformer should actively implement various safety measures during the use of the transformer.

First, assign a person to do routine monitoring and record, real and detailed record of the daily maximum load state of the power transmission, pay attention to the start-up and shutdown operation process, and carefully implement the relevant regulations.

Second, do a good job of routine maintenance work, regularly remove the dirt attached to the periphery of the Dry-type distribution transformer equipment, if the detection of corrosion or insulation resistance value reduction and other abnormal conditions, to investigate the causes and repair as soon as possible.

Third, regularly check the grounding and seal operation status, etc.

Fourth, for a long time shelved Dry-type distribution transformer equipment, must be used to protect moisture, rust and other protective methods, before re-commissioning to conduct electrical performance checks, testing after passing before use.

According to the established norms, the ambient temperature of 20℃ and the insulation heat resistance level of the transformer are selected as the basis for the normal expected life of the arithmetic transformer.

As Dry-type distribution transformer operating ambient temperature may be higher or lower than 20 ℃, the load may be above or below the rated load, so the transformer overload operation is easy to lose part of the life, can be effectively compensated by light load or low temperature environment operation.

Dry-type distribution transformer can be properly overload operation, but to ensure that it has a strong ventilation capacity, that is, no matter what fluctuations in cooling air temperature, generally required to consume about 3m3 / min of ventilation per kilowatt, the outlet and inlet air temperature difference is controlled within 15K, special circumstances can be added through the installation of exhaust air In special cases, the above difference can be maintained by adding an exhaust device.

Previous experiments have confirmed that the natural air cooling and heat dissipation capacity of Dry-type distribution transformer below 200kVA can meet the actual use requirements, for Dry-type distribution transformer ≥250kVA, because the temperature rise operation margin will not be very high, so it is best for its Additional forced cooling device and temperature control meter, the above method can make Dry-type distribution transformer equipment output capacity of about 40%.

For large high-rise buildings, the daily power consumption may reach several megavolt-amperes, and it is not recommended to operate a single Dry-type distribution transformer when designing the power supply system, because the self-weight of a large Dry-type distribution transformer can reach more than 10t, which makes it difficult to move.

If several Dry-type distribution transformers with small capacity are used, it is relatively reasonable to combine the installation capacity of power equipment on the floor, for example, one unit on 2~3 floors, which has the following advantages.

First, it is easy to move the equipment.

Second, the transformer or line sudden failure when the scope of impact is smaller.

Third, the ability to reverse the load of each other when overhauling lines or equipment, lifting the way to enhance the reliability of the power supply process.

Fourth, the low-voltage power supply radius is significantly reduced, line loss correspondingly decreased.

Dry-type distribution transformer operation is strictly prohibited to touch the insulating surface of the high-voltage coil with hands, to ensure operational safety, not only need to choose Dry-type distribution transformer with a protective shell, but also in its realistic operation to install a shield and safety warning signs to prevent extraneous personnel The Dry-type distribution transformer should not only be used with a protective casing, but also be equipped with a shield and safety warning signs to prevent the entry of unrelated personnel.

From the perspective of green and environmental protection, the current Dry-type distribution transformer mostly uses silicon steel sheet with relatively low cost investment, which has a relatively short service life and poor overall performance. In the future, Dry-type distribution transformer will develop in the direction of energy saving and low noise, high reliability, multi-function and intelligence.

In recent years, Dry-type distribution transformer equipment has made a great breakthrough in terms of consumption and noise, along with various types of low consumables, computer simulation, winding structure science and technology related research work, the future Dry-type distribution transformer will further improve the level of energy saving, operation The process of amplitude is smaller and the noise is lower.

The government should also pay attention to the development and application of Dry-type distribution transformer technology, and make certain tilt in policy, so that the design and development of environmentally friendly Dry-type distribution transformer has more power.

Dry-type distribution transformer is used in many fields, and the related projects are promoted with higher requirements for Dry-type distribution transformer operational reliability. In the following years, the casting process, magnetic field theory and quality assurance technology system should be used as support to continuously enhance the reliability of Dry-type distribution transformer in the process of use, so as to better meet the operational needs of modern projects.

In the process of urbanization construction, the electrical load shows a trend of increasing, and enterprises also put forward more and higher requirements in terms of electrical load. 35 kV large-capacity Dry-type distribution transformer has achieved popular application in major industries, and mega 35 kV mega-capacity Dry-type distribution transformer has been successfully developed. In the future, if there is a demand for engineering projects, super-capacity Dry-type distribution transformers will also be manufactured.

The Dry-type distribution transformer equipment with single function will be gradually eliminated and abandoned by the society. The future Dry-type distribution transformer will march towards multi-function and intelligence, not only with forced air cooling, protective shell and other functions, but also with power metering function.

In particular, the introduction of intelligent terminals will enable the Dry-type distribution transformer to have new functions such as data transmission and processing, state control and presentation to ensure that it is in the best working condition and create more ideal benefits.

Since entering the new century, the development level of transformer technology has shown a trend of year-on-year improvement, and the process of manufacturing has become increasingly perfect and mature.

Take the initiative to master the core technology of modern Dry-type distribution transformer, increase the application of new materials, and with the assistance of new processes, continuously improve the performance of Dry-type distribution transformer to provide support for reliable and effective operation of the power system for the benefit of human society.

Download Resource

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical

The primary function of the pad mounted transformer is to serve as a critical distribution

A pad mounted transformer operates through electromagnetic induction, serving as a crucial distribution component that

After filling in the contact information, you can download the PDF.