ELECTRIC, WITH AN EDGE

The Three-phase transformers are widely used to generate, transmit and distribute electrical power to industrial and commercial businesses, but are they practical?

When it comes to generating and transmitting electrical power to your business establishment, transformers can furnish sufficient energy to run your business efficiently. Nonetheless, there are many different types of three phase transformer that you can choose from nowadays. Thus, it is best to pick the most suitable transformer based on your needs.

If you are a business owner that owns a manufacturing business or other industrial or commercial establishments, the 3 phase transformer is for you! This transformer is more practical when it comes to supplying large loads and large power distribution.

Although most of the utilization pieces of equipment are connected by single-phase transformers, these are not ideal for large power distribution in the viewpoint of practicality. So, if you are looking for a high-quality transformer for your business, it is best to look for it through trusted transformer manufacturers like Daelim.

DAELIM is one of the most renowned transformers suppliers around the globe. The company is committed to render only the best services and high-quality transformers that meet the client’s expectations and needs. DAELIM also offers reasonable quotes to each of their clients based on their corresponding requirements.

In this article, you will have a better understanding of the functions of a three-phase transformer. This will also give you further information about the 3 phase transformer before making an actual purchase.

A three-phase transformer is the type of transformer that operates with a three-phase electrical system. This is a conventional method of alternating current electric energy generation, transmission, and distribution. It is also typically used to increase or decrease the voltage in a three-phase system.

This phase is a kind of polyphase system generally used by electrical grids worldwide to transport energy. It is also widely used to run large motors and other heavy loads. This transformer consists of six windings, consisting of three primary and three secondary windings.

The 3 phase transformer is a transformer that runs with a three-phase electrical system. Basically, this transformer is utilized to step up or step down the high voltages in different stages of the energy transmission system. This transformer has been invented since 3-phase electricity is widely used for power distribution due to its capability to provide a balanced load.

These types of three phase transformer are built by winding three single-phase transformers on a single core. After that, they are put into an enclosure filled with dielectric oil, which executes various functions.

Since dielectric is a nonconductor of electricity, it can render insulation between the voltage windings and the case. It also assists in cooling and preventing the formation of moisture that can dwindle the winding insulation.

The working three-phase transformer working principle is the same as the single-phase, Faraday’s Law of Induction. Single-phase and three-phase transformers only differed in wiring configurations. To further explain this, it is better to take a look at three-phase electrical systems.

Three-Winding Transformer | Three-Phase Transformer | Daelim

Both single-phase and three-phase electrical systems utilize alternating current or better known as AC. AC is an electricity type, which regularly alters direction and amplitude, typically portrayed by a sine wave.

AC signals are composed of three main properties; period, frequency and amplitude. Both period and frequency define the time component of the wave, whereas amplitude determines the strength and magnitude of the electricity.

In the three-phase systems, the current has three peaks and three troughs running on three separate conductors. Alternating currents are out of phase by 120° from each other. In these types of electrical systems, the highest amplitude is reached more frequently for a given period. This helps produce power at a relatively steady rate.

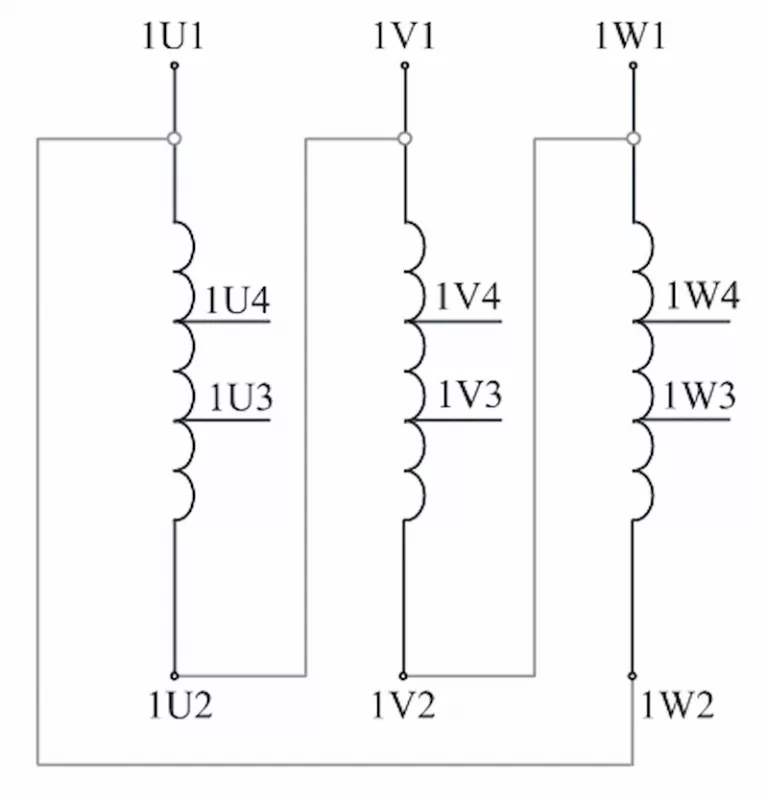

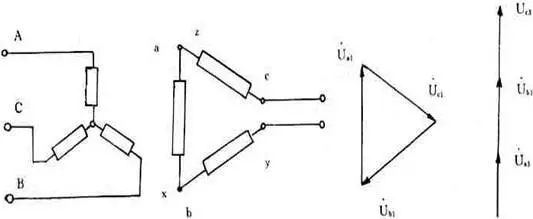

Connection Mode of Working Winding of Three-phase Transformer

The structure of a three-phase transformer constitutes three central parts:

One of the central parts of a threephase transformer is the steel core. The three-phase transformer’s steel core consists of three magnetic pillars and a magnet that closes the magnetic circuit. Furthermore, the steel core of a machine is crafted from electrical steel sheets, covering two sides with an insulating paint and formed collectively into the shape of a cylinder.

What is the Difference Between 1 Phase 2 Phase and 3 Phase Power?

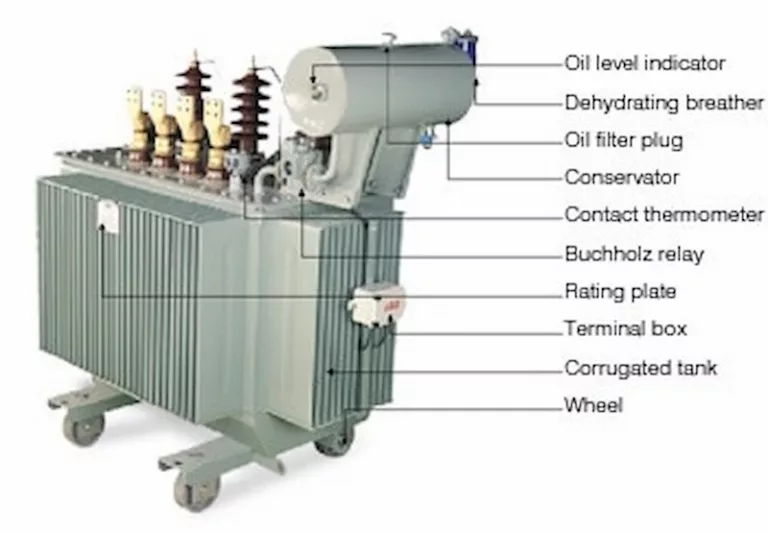

Another parts of the three phase transformer is the transformer enclosures. This plays a significant part in protecting and maintaining the life cycle of the transformer. The three-phase shell is typically made from steel, iron, contingent on the structure of the equipment and manufacturer.

Part of the use scenario is due to the high temperature and humidity environment, the three-phase transformer factory can also provide anti-corrosion coating steel shell.

Another parts of the three phase transformer is the machine winding. The machine winding consists of six copper windings which are insulated and wrapped around the cylinder. The winding receives the energy and transmits power out throughout machine operation.

What are the types of transformer windings ? What are the types of concentric windings?

Voltage regulators are used to alter the output voltage. Throughout loaded conditions, the output voltage of the transformer may recede. Thus, there is a need to regulate the voltage ratio by adjusting the tapping turns. The adjustment is done by using a tap changer, depending on the frequency with which it is needed to change the output voltage.

Thermometers are utilized for controlling the oil temperature.

Breathers are utilized to extract moisture from the air space above the oil level of the conservatoire, sustaining the dryness of the transformer oil.

Insulations serve as a barrier system, separating the windings from the core and the two windings from each other.

Transformer oil insulates and cools the generated heat from the core and windings. The oil has a high heat capacity that can carry and expel this heat. Oil flow can be produced either by the thermosiphon effect or by pumping.

The tank shields the cores and the windings from the outside conditions that can affect its functions. It also acts as a vessel for the oil.

An oil conservator is a separate container that holds the expansion of the oil as it can expand when heated.

When the oil absorbs the heat found in the system, it then delivers the heat to the cooling cooler. The cooler or cooling system accumulates hot oils and cools them down via air or water-cooled tubes then reverts them to the windings and core.

The gas actuated relay collects free gas bubbles from the transformer tank. When you notice the presence of free gas, it shows a fault inside the transformer.

These systems are safety devices used to reduce overpressure in oil flashing due to short circuits.

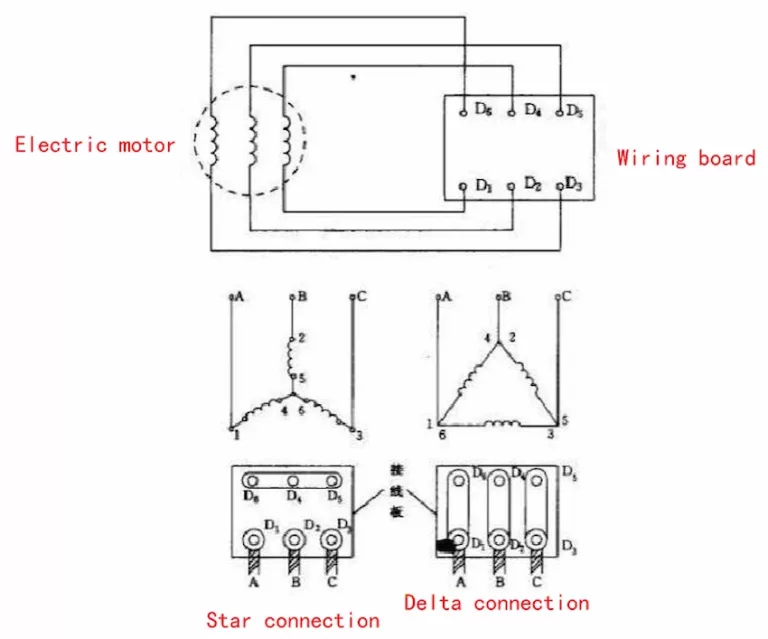

This type of three-phase transformer operates with six windings, three for the primary and another three for the secondary. Each winding can be linked in either star or delta configurations. These windings can be seen as separate single-phase windings.

Therefore, three single-phase transformers can be attached to build a three-phase transformer. There are three fundamental parts of a transformer and these are the following:

The primary winding takes electrical power and generates magnetic flux when it is attached to an electrical source.

This refers to the magnetic flux generated by the primary winding. The flux crosses through a low reluctance path connected with secondary winding forming a closed magnetic circuit.

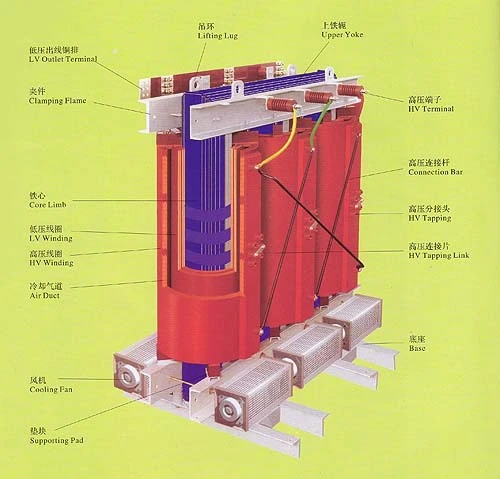

The secondary winding supplies the desired output voltage due to shared induction in the transformer. The construction of a three-phase transformer is quite similar to the single-phase transformer. Its core is also constructed either in core type or shell type. The low voltage (LV) and high voltage (HV) windings of the 3-phases are put on the three limbs of the core.

In the core type of 3 phase transformer, the core is split into three limbs. Each limb conducts both high voltage (HV) and low voltage (LV) windings of the three phases. Now, the generated flux made by the primary winding will then be linked to the secondary windings.

The low voltage winding (LV) is placed on top of the core limb and the high voltage winding(HV) is placed on the low voltage (LV) winding. This is because the amount of insulation needed is low to insulate the low voltage winding from the core.

The three-phase winding consists of three core limbs that are 120° apart from one another. In a core type, three-phase transformer, one limb functions as the return route for the magnetic flux of the two limbs. The total of fluxes in two limbs is equal to the flux in one limb that serves as the return track.

The construction of the shell type three-phase transformer is not typically used. This type of three-phase transformer has five limbs where the core encloses the windings built on the three limbs. The other two limbs found between phases keep the three limbs together, forming a unit.

This also provides a return route for the fluxes.

The construction of this type is comparable when three single-phase transformers are placed on each other’s side. In contrast to core type construction, each phase has its individualistic magnetic circuit and return way for flux. Therefore, the three phases are more independent in shell-type form.

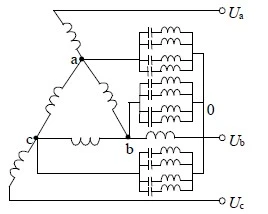

The three-phase transformer connections have two primary forms, the delta, and star. In order to understand these two better, see the given details below.

In the Delta or mesh connection, three windings are attached on both ends, creating a closed loop. Both ends are connected to a terminal, having no neutral point and use ground connections instead.

This connection type can also be configured as a high leg system by grounding the focal point of one phase. The voltage in this configuration measured across the line opposite to the center-tapped phase and ground is higher than measured across terminals.

Transformer three-phase dual power supply automatic switching

In a Star connection (wye connection), there are three windings and four terminals. One end of the three windings is fastened to a regular neutral point or terminal, while the others form the three phases of the circuit.

The whole core structure, be it a core type or shell type, is placed inside the transformer tank saturated with oil with their windings. The three-phase winding connections are made inside the transformer tank. The primary and secondary terminals of the three phases are taken out of the tank by bushings for outside connections. The most generally used three-phase transformer winding connections are, Star-to-Star, Delta-to-Delta, Star-to-Delta, and Delta-to-Star.

Star-to-star connection type works on both small currents and high voltages, making it cost-effective for transformers. In this type of connection, the primary and secondary terminals of three-phase windings are linked, forming the letter Y.

In delta-to-delta connection, one end of a three-phase winding coil is attached to the end of another coil. When connected this way, you will notice that it will take the form of a delta, typically seen as a triangle. The delta-connected windings can produce large currents with low rates of voltages.

Star-to-delta connection is a type of winding connection used when you need to reduce the voltage levels. In this connection, the transformer’s neutral primary winding is earthed.

The delta-to-star connection is a combination of delta-connected winding on the primary side and star connection. The delta-star connection is utilized when there is a need to increase the voltage levels.

This connection type is most suited for distribution purposes because of its 3-phase and 4-wire system at the secondary side. However, its applications are restricted due to the existence of a phase shift between the primary and secondary winding.

The basic three-phase transformer working principle is relative to a single-phase transformer like on mutual induction. The alternating supply is given to the primary windings and generates an EMF( electric magnetic field) in the secondary winding. The amount of generated electric-magnetic field will depend on the count of secondary turns, be it a step-up or step-down transformer.

When it comes to transformers, a three-phase transformer has several advantages compared to the single-phase one, such as the following:

A three-phase transformer has lesser weight compared to the single-phase

A three-phase transformer costs less than three single-phase transformers, which are of equal ratings.

A three-phase transformer utilizes less space than the single-phase transformers as it is smaller than the single-phase transformers.

You will only have one unit (a 3-phase transformer ) to handle, and it is already pre-wired, making it much easier and smoother to assemble and insta

A three-phase transformer unit is more economical. Three-phase transformers are more practical for providing large loads and large power distribution. This is because the exchange in connection from single-phase to three-phase will not boost energy costs on your electricity bill. Thus, your electricity consumption will remain the same as they depend on the wattage of your machines, not on the electricity connection.

When the number of phases increases in the system, the DC voltage becomes smoother and more beneficial.

Three Phase Epoxy-resin Dry Type Distribution Transformer Manufacturer – Daelim

A three-phase power only needs lesser conducting materials compared to one-phase to transmit and distribute electrical power. Therefore, when it comes to the cost, this type of phase is more cost-effective.

It will only take less space to install.

In a three-phase transformer, a common core is distributed in all three units. So, when a unit is faulty or damaged, the whole three-phase transformer must be shut down entirely. This is why the cost of defective units is much higher and more difficult to get repaired.

The repair cost for 3-phase transformers is higher compared to the single ones because each component must be changed, which is costly. This is why in service recovery, the cost of the spare unit is more expensive than the single-phase transformers.

Another downside of the 3-phase transformer is that it’s self-cooled. Therefore, the transformer’s power is also reduced at the same time.

Another drawback for this type of transformer is that once one of the three phases is faulty, the entire unit must be replaced. This is because the error can get transported to the other two phases.

One of the disadvantages of a three-phase transformer is the entire unit shuts down when one phase is at fault. This is due to the core that is shared for all three units. In other words, if one unit is broken, the core of the faulty unit would instantly drench due to the absence of an opposing magnetic field.

Without the opposing magnetic field, there will be an immense escape of magnetic flux to the metal’s core enclosures. This can increase the metallic parts’ heat that can cause fires in some cases. Thus, it is critical to remember to shut down the three-phase transformer if you find that one of the phases is faulty.

Three-phase power is the standard system of AC power generation, transmission, and distribution. It is a polyphase-type system commonly used by electric grids worldwide to transport electrical energy or power.

The three-phase has three alternating currents that are 120 electrical degrees apart from each other. Each leg of ac reaches a maximum voltage, solely separated by 1/3 time of a complete cycle. Simply put, the power output never drops to zero and remains constant. This is why most commercial and industrial businesses always opt for three-phase when it comes to transformers.

In the three-phase power supply, it’s best to remember that you will need three conductor wires and one neutral wire. The three conductor wires should be 120-degree apart from one another.

There are two classes of circuit configurations in a three-phase power supply. These are the Delta and the Star. The Delta configuration doesn’t require any neutral wire, and only the high voltage systems utilize it. On the other hand, the Star requires both ground wire and a neutral wire.

In connecting transformers, you could be attaching them to single-phase and 3-phase power sources along with single and three-phase loads. Avoid making any wrong connections to prevent the equipment that may also result in damages.

In this phase and voltage, you have three conductors. Thus, you must connect all three conductors for three-phase voltage and connect any pair for a single-phase voltage.

Three-phase power and dual voltage connection involve three hot conductors and a grounded neutral conductor. In this connection, you have to connect the three hot conductors for 3-phase power. For lower, single-phase voltage, you can connect two or three hot conductors.

A three-phase transformer plays an essential role in transmitting power. This machine is primarily used worldwide for industrial purposes to generate electrical power, transmit and distribute. They are typically used and installed in places that consume a remarkably enormous amount of electricity, such as hospitals, apartments, industrial buildings, transformer stations and more.

3 phase transformers are used in many industries, including manufacturing, health care, electrical contracting and many more. These mentioned industries need a reliable and consistent source of power to keep their operations running smoothly, which can be found in three-phase transformers.

These transformers can carry large loads and large power distributions efficiently that are highly required by many large industries. Most power generating channels are in three-phase nature, and the voltages range from 13.2 kV to 22 kV.

To decrease the power loss to the distribution end, the power is transmitted at much higher voltages like 132 kV to 400 kV. So, if there’s a need for higher voltages, a three-phase step-up transformer is used.

On the other hand, at the end of transmission, a step-down three-phase transformer is used to step down these high voltages to levels 6600, 400, 230 volts, etc. This is why 3 phase-transformers are ideal when it comes to power distribution for large industries as they can balance the power perfectly.

These transformers are highly dependable in converting substantial amounts of energy from the primary source into a form they can utilize for various machines and building utilities.

The difference between a single and three-phase transformer is that a single-phase transformer only needs two wires, namely Phase and Neutral. The phase wire carries electricity from the source to any electrical appliance attached to it. Moreover, the neutral wire sends the circuit back to the original power source.

On the other hand, a three-phase transformer only works through three wires, inclusive of a neutral wire and three-conductor wires. This is created by winding three single-phase on one core. Transformers are placed in an enclosed place, jammed with dielectric oil to reach the specified voltage.

It’s best to remember that 3-phase transformers have six coils, distributed impartially on both the primary and secondary sides.

When it comes to the power supply systems, it has two classifications, namely single phase-system and three-phase system. The single-phase is typically used in a place where there’s less power needed and working for small loads. On the other hand, three phases are widely used in large businesses, such as factories and other industrial enterprises, where immense power is needed.

Another significant difference between the two is that the single-phase has one neutral wire and one conductor compared to the three-phase having one neutral wire and three conductors for circuit completion. A single-phase carries 230V, while a three-phase carry 415V. The single-phase is also less efficient and economical compared to the three-phase.

The single-phase is best used for home appliances, while the three-phase is ideal for large industries and running heavy loads. To know more about the difference between the two, see them all below.

There are several manufacturers of three-phase transformers like Daelim that guarantee energy savings for extensive electricity distribution. In terms of power supply, the three-phase power is more efficient, as it can transmit trifold the power of a single power supply.

Three-phase transformers are typically used for generating and distributing power. You can find these transformers in high-power industrial loads like motor drives, rectifiers among other equipment. It can also be used in applications that need a step up or step down of transmission lines and electrical grid station power generation.

There are three types of 3-phase transformers, the sealed-type, the open-type and the dry-type.

The sealed type of three-phase transformer cools itself through its expansion blades. The blades will automatically expand when the temperature gets high in the VH, and the air blows directly through the blades that cool the machine down.

In this type of three-phase transformer, its cooling cycle is through the extra tank and the fan blade. The only discrepancy between the open-type and sealed-type is the auxiliary oil tank.

A dry-type transformer is a type of transformer with coils wrapped in epoxy resin. Contrary to the standard transformer, its magnetic cores and windings are pressurized by air. This type of transformer can overcome the drawbacks of oil transformers. This transformer is used in particular circumstances such as dense pollution, higher air humidity, extra cold surroundings temperature.

Three Phase Epoxy-resin Dry Type Distribution Transformer Manufacturer – Daelim

Daelim has been dealing with designing, engineering and manufacturing high-quality transformers for more than 15 years. Our company consists of experts and ad professionals in this field. Our team has brilliant researchers and a production team that help form and deliver exceptional and efficient transformers to various businesses and homes.

Our team undergoes intensive and methodical training committed to continuous advancement on the quality guidelines and systems. It is also our mission to meet the expectations and needs of our valued customers to earn their trust and fulfill their needs. This way, we can forge a strong and long-term partnership with our clients.

BEIJING DAELIM GREEN EP TECHNOLOGY CO., LTD. is built by the experience and expertise of the people working passionately for the company. Each staff works incessantly with the thought of giving the best possible products to each of our customers. It’s in our best interest to innovate a product like a three-phase transformer to put our clients at an advantage in running their business without any interruptions when it comes to power.

We also offer product customization based on your company’s needs and demands. With us, you can expect high-level products and quick execution abilities without sacrificing the quality of the products. We also ensure that each of our clients feels special with our top-notch customer service. So, if you’re looking for transformers for your home or business, our company is always open for you.

We always stand by our company’s mission, which is to meet our customer’s needs. This is why if you choose us for your transformer’s needs, you will never go wrong with Daelim!

Three-phase transformers have similarities with other transformers. They both have advantages and disadvantages. Nonetheless, when it comes to practicality in terms of industrial and commercial use, the 3 phase transformer is much more efficient.

If you are currently looking for a reliable transformer for your establishment, it is time to contact DAELIM professionals. This way, you can get the answers to your questions and concerns right away.

When you need to find more than just existing transformers, Daelim’s Transformer Service Center can help you design and produce distribution transformers that meet your unique needs.

We have our own factory and a professional team of engineers, which can design and modify application requirements that meet all your conditions.

Download Resource

After filling in the contact information, you can download the PDF.