How to Choose Pad Mounted Transformer?

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical

ELECTRIC, WITH AN EDGE

Transformer is the basic equipment of transmission and distribution, widely used in industry, agriculture, transportation, cities and other fields. The green of transformer use link is reflected in at least two aspects: low loss and low noise. energy efficient transformer (low loss) is important to enhance the efficiency of energy resources utilization and promote green low-carbon development. Transformer in the operation of the link of noise pollution must be paid attention to, otherwise it may affect social life.

There are two main types of measures to address the efficiency of power transformer noise pollution in the distribution room.

For example: the power distribution room door to fire insulation doors, windows with sound insulation double windows, walls to do sound absorption treatment, transformer base installed shock absorbers, etc..

Efficiency of power transformer has more types, different structures of transformers in the production of materials, production processes, production energy consumption and pollution emissions, etc. will be different. The author believes that energy efficient transformer should meet the characteristics of low production energy consumption and low pollution emission in the manufacturing process, and should meet the characteristics of high recyclability and low waste pollutants at the end of life. From this point of view, silicone rubber transformers are a good choice for the future.

Proper reactive power compensation can improve the efficiency of transformer use. The author believes that the intelligent efficiency of power transformer can be integrated with reactive power compensation units, thus realizing refined reactive power compensation.

In power distribution systems, there are two common types of reactive power compensation schemes: capacitor compensation and static reactive power generator (SVG) compensation.

Capacitance compensation uses shunt power capacitors for reactive power compensation, and the main drawbacks of this scheme are.

First, reactive power compensation is not fine enough.

Second, it cannot compensate capacitive loads.

Third, it has the risk of resonance.

In order to avoid the defects of capacitor compensation, static reactive power generator can be used for reactive power compensation, and realize fine reactive power compensation.

The advantages of using a static reactive power generator to realize refined reactive power compensation for transformers are reflected in the following aspects.

With the continuous changes in people’s life and social production, the power load also follows the changes (e.g., the capacitive load has been seen everywhere with the massive use of equipment such as inverters, uninterruptible power supply UPS, charging piles, etc.), therefore, reactive power compensation with SVG can compensate both inductive and capacitive loads. Table 3 shows the comparison of the output reactive power of different compensation schemes.

Technology name | Scope of application | Core technology and process | Main technical parameters | Comprehensive benefits |

Silicone Rubber Saving Energy Distribution Transformer Transformer Technology | High efficiency of energy-saving equipment | Using high-performance silicone rubber insulation materials and casting process, combined with active partial discharge elimination, defect tolerant main insulation, integrated silicone rubber casing to enhance surface insulation, etc., the production of silicone rubber castingefficiency of power transformer to meet energy efficiency level 2 transformer energy efficiency requirements, electrical and fire safety reliability, lifelong maintenance-free products. The main materials used, such as silicon steel, steel and silicone rubber, can be recycled, and the energy consumption of the production process is only 10% of that of conventional transformers. | Capacity: 100~2,500 kVA/10 kV; partial discharge ≤5 pC; 3-fold redundancy of main insulation; energy efficiency index >1; material recyclability >99%; combustion class F1; winding combustible mass <2%; noise <55 dB, <45 dB; long-term overload 20% allowed. | The product has overload capability and outdoor adaptability; with maintenance-free advantage. |

Solutions | Static reactive power compensation generator SVG (300 kvar) | Capacitance compensation (300 kvar) | Hybrid compensation: SVG (100 kvar) + capacitor compensation (200 kvar) |

Output reactive power | -300~+300 kvar | 0~300 kvar | -100~+300 kvar |

Description | Can compensate both inductive and capacitive loads | Compensate inductive load only | Can compensate inductive and capacitive loads at the same time, capacitive load compensation capacity 100 kvar |

SVG is based on power electronics technology and adopts IGBT as the power device. By detecting the load reactive current demand and controlling the IGBT precisely, i.e., corresponding to the reactive current required by the output load, it compensates the reactive power required by the load. Static reactive power generator can realize fine reactive power compensation.

The standard current and voltage input values of the loops and the measured values have an error of no more than 0.5%, which meets the requirements for refined compensation.

The static reactive power generator is set to reactive power tracking control mode, and the target reactive power setting value is adjusted so that the output of the device changes from the maximum inductive current to the maximum capacitive reactive current, and the measured reactive power data are shown in Table 6 (the maximum allowable deviation between the actual output value of the device reactive power and the setting value at steady state is no more than ±2.5%). The deviation of the actual output value of the static reactive power generator meets the maximum allowable deviation requirement.

Read on ABB Distribution Transformer Manufacturer

The static reactive power generator is not affected by system harmonics and does not amplify system or load harmonics. Refined reactive power compensation by SVG can solve the problem of harmonic amplification caused by capacitor compensation and reduce the risk of system resonance.

The intelligent transformer integrates the refined reactive power compensation unit and the distribution system is designed with the technical requirements for the transformer reactive power compensation capacity only.

Take the 2 000 kVA transformer distribution system scheme as an example, arranged in order from left to right: transformer cabinet, inlet cabinet, capacitor cabinet, outlet cabinet; transformer capacity is 2 000 kVA, capacitor cabinet capacity 600 kvar.

If a smart transformer is used, the refined reactive power compensation unit is designed to be integrated with the transformer, and the equipment is arranged from left to right: transformer cabinet, incoming cabinet, outgoing cabinet.

The traditional capacitor cabinet is eliminated and the reactive power compensation function is replaced by a refined reactive power compensation unit integrated in the smart transformer, which can compensate inductive and capacitive reactive power; the reactive power capacity (±600 kvar) to be compensated is marked on the smart transformer cabinet.

Read more:2021 A Complete Guide to Power Plant Transformer

Digitalization of distribution transformer efficiency is the basis for improving the efficiency of distribution transformer efficiency management. The author believes that intelligent efficiency of power transformer integrated with digital distribution transformer efficiency monitoring device can provide comprehensive monitoring of distribution transformer efficiency operation status, power supply quality This will improve the whole life cycle management of distribution transformer efficiency.

For efficiency of power transformer, operation monitoring and control involves electrical parameters (voltage, current, frequency, power factor, power, etc.), temperature system and data statistics (distribution transformer efficiency operation time, load factor, yearly maximum load, yearly maximum load utilization hours, etc.). (annual maximum load utilization hours, etc.).

The distribution transformer efficiency winding temperature directly affects the insulation life, and monitoring the distribution transformer efficiency winding temperature to ensure that the insulation system works in the right temperature range can extend the distribution distribution transformer efficiency.

The distribution transformer efficiency monitoring device obtains the real-time temperature of the three-phase windings through the temperature sensors pre-built in the distribution transformer efficiency windings, and automatically controls the heat dissipation system to control the distribution The temperature of the distribution transformer efficiency is controlled automatically to ensure the safety of the distribution transformer efficiency operation.

Read on: Distribution transformer silicon steel selection

Distribution transformer efficiency is a channel to provide electrical energy to the load, therefore, it is necessary to master the quality of distribution transformer efficiency power supply and digitalize the distribution transformer efficiency. Distribution transformer efficiency supply quality monitoring involves voltage/current harmonics, harmonic content, interharmonics, voltage drop and rise, three-phase unbalance, etc.

Monitoring voltage dips and spikes is particularly important for sites with high continuity requirements to help users identify and assess the impact of voltage dips or spikes on production.

According to EPRI statistics, more than 92% of the power quality events are voltage drop and rise, while other power quality events account for less than 8%, and the duration of voltage drop is generally less than 1 s.

Distribution transformer efficiency power supply statistics include two-way power statistics, active power, reactive power, demand, maximum demand (including time), etc.

Distribution transformer efficiency loss is an important index to evaluate the economy of distribution transformer efficiency. The distribution transformer efficiency loss level is usually judged by comparing the distribution transformer efficiency rated loss value.

However, the actual load loss of distribution transformer efficiency in operation is also affected by the load factor and temperature. distribution transformer efficiency monitoring devices can be used to determine the level of distribution transformer efficiency loss by comparing the actual operating time of distribution transformer efficiency, the real-time load factor and the temperature. The distribution transformer efficiency monitoring device can evaluate the load loss of the distribution transformer efficiency by the actual operation time of the distribution transformer efficiency, the real-time load rate and the winding temperature.

Based on wireless communication technology, the data collected and analyzed by the distribution transformer efficiency monitoring devices are shared with the distribution transformer efficiency management platform or third-party monitoring platform to improve the distribution transformer efficiency management.

Read my article on Transformer Step Down , Everything You Need To Know

energy efficient transformer is a transformer and its group components in the whole life cycle stage of the product, that is, from material selection, transformer design and production, operation and maintenance and recycling process in line with energy and material saving, low-carbon environmental protection and reusable requirements of the transformer.

At the same time, products that meet the development concept of energy efficient transformer must also have the characteristics of safety and reliability, lower noise, lower maintenance cost and easy monitoring.

The main technical characteristics of energy efficient transformer are reflected in energy saving, material saving, environmental protection and safety.

Green manufacturing of transformers includes green manufacturing, green product design, green selection of raw materials, green use of products and green product functions.

The transformer and its components should meet the requirements of energy saving, low-carbon environmental protection and recyclability in the whole life cycle stage of the product, that is, in the process of raw material selection.

The design, production, operation and maintenance of transformers should meet the requirements of low comprehensive energy consumption, high resource utilization, low ecological and environmental hazards, high material utilization or maximum re-utilization, and reduction of waste and harmful substance emissions in the recycling process, etc. It should meet the requirements of the new objectives and tasks of the four links of source control, process optimization, end-of-pipe treatment and waste recycling.

Electricity is a necessity for people’s production and life, green energy, energy saving and emission reduction concept continues to gain popularity, energy saving and emission reduction is a worldwide problem, and transformers as an important tool for power transmission and transformation, accordingly, has become a common concern.

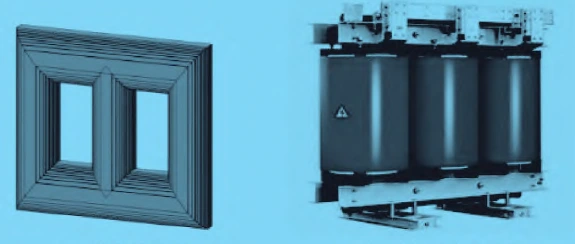

Conventional transformer has disadvantages such as unbalanced three-phase magnetic circuit, high noise, poor short-circuit resistance, and can only reduce conventional transformer loss by increasing material consumption, which means conventional transformer will face elimination.

There are higher standard requirements for distribution transformers in terms of energy consumption requirements, noise requirements, green manufacturing, etc. The transformer manufacturing industry can only embark on the road to sustainable development through transformer technology innovation and green manufacturing of transformers. Actively promote and promote the development of energy efficient transformer is the general trend, the imperative.

Keep on reading: 2500 kVA Transformer Used For Bitcoin Mining (Step-by-step Guide)

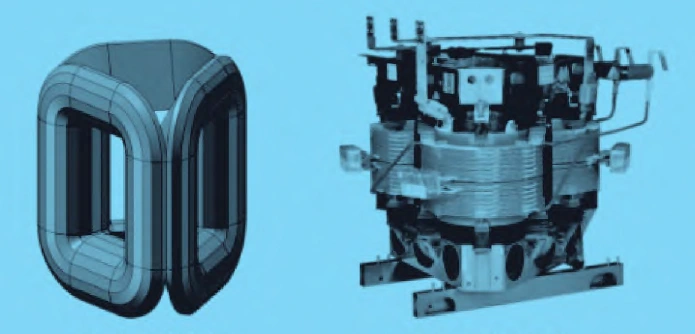

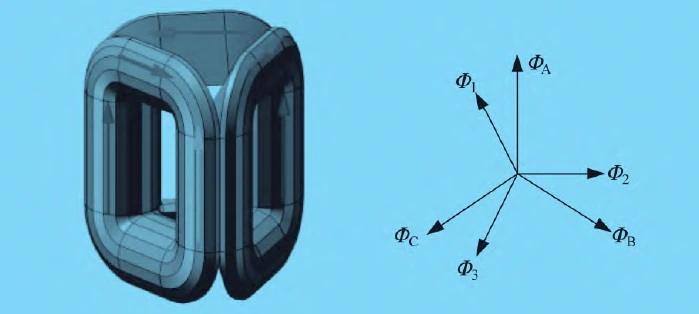

The efficiency of power transformer is composed of a three-dimensional core and an open efficiency of power transformer with the following four advantages.

Process factor, core weight and core material affect the transformer no-load loss. Continuous winding makes full use of the orientation of the silicon steel sheet, reducing the no-load loss by 30%. Using the fully annealed process, the process factor of three-dimensional rolled core can reach 1.01 ~ 1.05, while the process factor of stacked core is 1.15 ~ 1.35. Due to the improved structure and process, the weight of the core is reduced by about 25%. The core material with thinner thickness can be used, which has wider space for improvement in material selection.

Compared with the flat core, the three-phase magnetic circuit of three-dimensional coil core has no joints; the magnetic lines of force and the core material are in the same direction of easy magnetization; the annealing process completely restores the magnetic properties of silicon steel; the no-load current is 70% lower than that of the flat core.

The yoke part of the three-dimensional coil core saves about 15% of silicon steel sheet than the stacked core, and the single frame is rounded, saving about 5% of silicon steel sheet, the material utilization rate is close to 100%, about 5% higher than the stacked core, and the silicon steel sheet material usage drops about 25% on average.

The filling factor of the three-dimensional rolled core is 0.970-0.985, and the filling factor of the core column of the stacked core and flat rolled core is 0.890-0.925.

Stereo core section filling factor is high, the effective area of the same, stereo core column diameter is small, thus reducing the length of the coil wire, saving winding wire, but also to reduce the load loss.

Open type three-dimensional coil core efficiency of power transformer without casting molds, the design and production process is not limited by the mold, design solutions are flexible, the production process is more environmentally friendly and quality control, less defective products, high pass rate. The use of environmentally friendly insulation materials will not cause pollution to the environment.

The coil can be decomposed and recycled, and the process will not cause harm to the environment.

The core has no joints, the magnetic force line and the direction of easy magnetization of the material are exactly the same, and the core is a self-stabilizing structure, no clamping is needed. The operation noise is lower than 45dB(A) and can be lower than 38dB(A), which is 10-25dB(A) lower than the stacked core transformer, effectively solving the “neighbor avoidance effect”.

The three-dimensional coil core structure can greatly reduce the stray magnetic field around the transformer. Space leakage is small, only half of the traditional structure of the transformer, reducing the surrounding electric field magnetic field strength.

The three-dimensional roll core structure and NOMEXⒸ aramid insulation paper, PIF polyimide film and German ELANTAS one-component environmentally friendly insulation paint make up a strong insulation system, the insulation paper is heat-resistant and flame retardant, and the products are mainly carbohydrates, which is safer. Non-encapsulated structure, no explosion.

Planar core A-C magnetic circuit is longer than the magnetic circuit of A-B and B-C. The magnetic circuit of the three single frames of the three-dimensional coil core is the same length and the shortest.

Different specifications, different shapes of the monolithic stacked into a flat core poor connectivity, when the transformer is impacted, the production process after the removal of the inserted upper yoke is easy to be washed away. Long structure of the clamped pieces of poor stability and span, easy to deformation.

Non-circular concentric type coils with inconsistent force at all points. The three-dimensional coil core is continuously wound, with a strong core and uniform and symmetrical three-phase force.

The clamps are triangularly welded into a single frame structure with high overall strength; the three-phase coils are uniformly compressed. Round concentric coils, uniform force in the spoke direction.

The air channel of the coil is eliminated in the adjacent part between the phases of the planar core.

B-phase coil is influenced by other two-phase coils, and the hot spot temperature rise is high.

Coil is encapsulated by epoxy resin, poor heat dissipation.

Stereoscopic rolled iron core round coils with uniform air channels.

Three-phase coils with positive triangular arrangement, low hot spot temperature rise.

Coil is pie type structure, large heat dissipation area.

In summary, the efficiency of power transformer no-load loss, no-load current and load loss are far better than the national standard, and have the outstanding features of low noise (as low as 38 decibels), moisture-proof and fire-proof, strong overload capacity, low temperature rise, small local discharge, small electromagnetic radiation, no cracking of coils, no bursting potential, etc., which are very Cost-effective, suitable for various transmission and distribution fields, has been widely used in power grids, government projects, photovoltaic, wind power, nuclear power, steel, petrochemical, electronics, ports and terminals, high-rise buildings, data centers and other fields.

Energy-efficient open type three-dimensional core efficiency of power transformer no-load loss, no-load current is lower than the traditional ordinary transformer, effectively reducing electricity consumption, thereby reducing electricity costs.

To a 2 500 kVA open three-dimensional volume core efficiency of power transformer, for example, using the new 1-stage three-dimensional volume core open efficiency of power transformer than the traditional 3-stage 10-type transformer, can save electricity costs about 1.7 million yuan per year, equivalent to reduce carbon dioxide emissions of about 1.8t 8t, its carbon reduction value is about 1,000 yuan, total annual energy saving and carbon reduction economic benefits of a single product can reach 1.8 million yuan.

It is three-phase balanced; low noise, the lowest can be 38 decibels; low loss, super first-class energy efficiency.

Strong overload capacity, small electromagnetic field strength (radiation), has been highly recognized by the community, is the green energy efficient transformer recommended by the Green Association.

The global requirements for environmental protection, energy saving and disaster prevention are getting higher and higher, and countries are putting forward higher requirements for transformer energy saving level. In the future, green low-carbon, energy efficient transformer will become the mainstream, three-dimensional coil core transformer has ushered in a period of comprehensive development.

In the choice of transformer raw materials to give priority to non-polluting, recyclable materials, open type three-dimensional coil coreefficiency of power transformer in line with global requirements for the development of transformers, and the structural characteristics of the product and safety and environmental protection characteristics, so that its application in special areas more and more widely.

Open type three-dimensional core efficiency of power transformer is expected to gradually replace the traditional epoxy resin cast transformer, become the development direction of the transformer industry, the future market prospects are broad.

Distribution transformers are the equipment with the largest energy loss in the distribution network, and their efficiency can be improved to save a lot of energy. Reducing the energy consumption of transformers is of great significance to the energy saving of the whole power system.

Transformer green performance should be throughout the whole life cycle of material selection, manufacturing, process, use and recycling, etc. The concept of green manufacturing should be considered at all stages, and the following main performance indicators and targets should be controlled.

(1) High resource utilization (material saving, i.e., saving the amount of silicon steel sheet, copper and other resources).

(2) Low energy consumption

(3) No harm or minimal harm to the ecological environment (environmental protection, i.e., the choice of fire-retardant insulation materials, low content of combustible materials; production process to avoid or minimize the process does not match the requirements of environmental protection; low noise and radiation during operation, etc.).

(4) High utilization rate of materials or can be reused to the maximum extent.

(5)Less waste and toxic gas emission in the recycling process, and less energy consumption in the recycling process.

Read more Step-Up Substation and Its Significance In Power Distribution

Currently energy saving transformer, in addition to amorphous alloy transformers, there are also three-dimensional volume transformers, silicone rubber transformers, environmentally friendly insulating oil transformers, etc..

In this paper, the more mature application of three-dimensional volume efficiency of power transformer on the market, for example, to explain the energy saving transformer product performance and applicable characteristics.

Each single frame of the three-dimensional coil core is formed by a number of silicon steel strip sheet continuous winding by the opening machine curve shear opening, after winding each single frame cross-section is close to the semicircle, the cross-section of the whole assembly is close to the whole circle, high space utilization. Unlike the traditional flat stacked iron core is by the longitudinal shear production line and cross-shear production line, the silicon steel strip processing into a certain shape of silicon steel sheet, and then the silicon steel sheet according to the ladder type cross-section way stacked.

There is no seam in the magnetic circuit of three-dimensional coil core, the three phases are equal in length, symmetrical, and all are the shortest, so the reluctance is greatly reduced, and the cross-sectional filling factor of the core column is high and close to circular, so it has many advantages such as material saving, low loss, low noise, high environmental protection factor, and three-phase balance.

(1)No-load performance is improved significantly, the no-load loss of three-dimensional rolled-core transformer is theoretically 30% to 40% lower than the traditional stacked-core transformer no-load loss.

(2) Noise reduction is obvious, in line with environmental protection requirements. Take 200 k VA as an example, tested by the authority, the three-dimensional triangular coil core transformer prototype is only 33.6 d B, the plane stacked iron core transformer prototype is 51 d B.

(3) AC phase, AB phase, BC phase magnetic circuit is equal and shortest arrangement, to achieve the three-phase magnetic circuit of complete symmetry, to ensure the three-phase voltage balance.

(4) Low no-load current. In the operation of the grid system to reduce the losses of the operating network, increase the power factor of the grid, improve the utilization rate of power system equipment, as well as save the input of reactive power compensation.

(5)The cross section of three-dimensional rolled iron core is nearly circular, while the cross section of stacked iron core can only be stepped, so its space filling factor is 4% to 6% higher than that of stacked iron core.

(6) The utilization rate of silicon steel sheet of three-dimensional rolled core is about 100%; the utilization rate of silicon steel sheet of stacked core is about 95% after cutting.

(7) High degree of mechanization in production, no need for manual operations such as cross-cutting of stacked cores, manual stacking and disassembly and insertion of yokes, reducing 5 to 6 processes and making quality control easy.

The insulation system of efficiency of power transformer mainly has two types of epoxy resin and Dupont NOMEX paper, namely SCB type and SGB type. In recent years, with the increasing concern for green manufacturing, energy saving and environmental protection, the application ratio of NOMEX paper and environmental impregnation paint insulation system for SGB type transformers is also increasing day by day.

The main insulation of the coil of the three-dimensional coil transformer adopts NOMEX paper and environmental protection insulating varnish, both of which belong to R(C) grade insulation and are UL certified, with excellent electrical and mechanical properties, and are highly flame-retardant and environmentally friendly insulating materials with good moisture resistance, easy recycling and natural degradation, which are not harmful to the environment.

At the same time, the amount of combustible materials is only 1/8 of the efficiency of epoxy resin casting power transformer, which can effectively reduce the accident loss caused by fire.

Under the same main material cost: compared with SCB type stacked iron core transformer, SGB-RL type open type three-dimensional rolled iron core efficiency of power transformer operation is more economical, and noise, weight, volume significantly reduced, while the recycling rate is high;

Compared with SCBH type amorphous alloy transformer, SGB-RL open type three-dimensional rolled iron core efficiency of power transformer is slightly more costly to operate by 2%, while the noise, weight and volume are significantly reduced, and the recovery rate is high.

Stereo rolled iron core and conventional stacked iron core transformer comparison, electromagnetic field performance, with no-load loss (current) low, low load loss, surrounding electric field / magnetic field strength is small, temperature field distribution uniform, three-phase magnetic circuit balance, short-circuit resistance, etc.; resource savings, with less copper materials, silicon steel materials to save obvious advantages; operation and maintenance, with low annual operating costs, electricity costs less, etc.; operating environment In terms of sustainable development, it has the advantages of long operating life and environmental protection and can be recycled, so it is a new technology product with green product performance.

Read more about 4000 kVA Transformer For Bitcoin Mining Farm

The development of green technology has made the selection of efficiency of power transformer in civil building another new technical product. In the project design, electrical designers should pay more attention to some parameters reflecting green performance indicators in green building, such as energy efficiency, noise, weight, environmental protection and recyclable elements, in addition to the conventional electrical performance parameters for comparison after completing the electric load calculation and transformer capacity determination.

Green building application specifications, in the types of energy efficient transformer capacity using the comprehensive energy efficiency cost method (TOC) than the selection, green selection, focusing on the following requirements:

(1) Meet the requirements of the energy-saving product certification rules and the general rules for the evaluation of the ecological design of electrical and electronic products.

(2) Meet the new energy efficiency limit value and energy efficiency level requirements, and suggest that in the green building star evaluation, two-star and three-star evaluation mark items should meet energy efficiency level 1; one-star evaluation mark items should be no less than energy efficiency level 2.

(3) provides for places with high load capacity requirements, it is recommended to use the requirements of class H and above, as well as the proposed requirements for process environmental protection and recyclability.

(4) put forward the requirements of noise control.

Energy efficient transformer manufacturing needs to include the scope of green manufacturing in addition to the basic attributes of transformer green such as safety, low noise, reliability, low maintenance costs and other elements.

The open type three-dimensional core efficiency of power transformer achieves green design, material saving, power saving, safe and reliable, recyclable and dismantleable without damage to the environment, is in line with the green manufacturing, energy saving and environmental protection efficiency of power transformer, its whole life cycle in line with the concept of green manufacturing.

In this paper, by describing a broad definition and listing some of the more recognized products or processes and materials, we can have a relatively clear understanding of the advantages of energy efficient transformer and open type three-dimensional coil core efficiency of power transformer, which is conducive to the promotion and development of energy efficient transformer and energy efficient transformer manufacturing plant.

Download Resource

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical

The primary function of the pad mounted transformer is to serve as a critical distribution

A pad mounted transformer operates through electromagnetic induction, serving as a crucial distribution component that

After filling in the contact information, you can download the PDF.