ELECTRIC, WITH AN EDGE

An electricity transformer box, also known as a transformer enclosure or distribution box, is a protective casing used to house electrical transformers in power distribution systems. These boxes are designed to safeguard transformers from environmental factors such as weather, vandalism, and unauthorized access, while also ensuring the safety of people and animals in the vicinity.

This article explains in detail the principle of residential electricity transformer box, how to layout, how to protect against lightning, how to reduce noise and everything else about Single phase pad mounted transformer.

Pofessional Manufacturer of Pad Mounted Transformer Substation Transformer,HV Power Transformer Single Phase Transformer IEEE/ANSI,CSA,DOE,AS/NZS,IEC and etc。standards. <br>

As the world becomes more interconnected, the demand for reliable and efficient energy solutions is at an all-time high. At the heart of these solutions are the unsung heroes of the power industry – electricity transformer boxes. These compact powerhouses play a crucial role in delivering electricity to homes and businesses worldwide.

Daelim Belefic, a leading manufacturer of transformers, has been pioneering innovations in this industry for over 15 years. With a commitment to outstanding quality that meets IEEE/ANSI/DOE/CSA and IEC Standards, Daelim is at the forefront of powering industries across the globe1.

Electricity transformer boxes play a crucial role in power distribution systems, providing a safe and secure environment for housing transformers. They are designed to withstand various environmental factors and protect the transformers from damage, ensuring reliable and continuous power supply to end users.

Materials and Construction: Transformer boxes are typically constructed using robust materials like galvanized steel, stainless steel, or fiberglass-reinforced polyester (FRP), which offer excellent resistance to corrosion, impact, and weather-related damage. The choice of material depends on the specific application, local climate, and other environmental factors.

Design and Features: Transformer boxes come in various designs and sizes to accommodate different types and capacities of transformers. They often feature hinged or removable doors for easy access, allowing maintenance personnel to inspect, service, and repair the transformer when necessary. Ventilation grilles or louvers may be included to dissipate heat generated by the transformer, preventing overheating and ensuring optimal performance. Locks and safety signage help prevent unauthorized access and ensure the safety of the public and animals.

Installation: Electricity transformer boxes can be installed in various locations, depending on the requirements of the power distribution system. For pad-mounted transformers used in underground distribution systems, the boxes are placed on the ground, often on a concrete pad. In overhead distribution systems, transformer boxes can be mounted on utility poles. In both cases, the boxes should be installed in accessible locations to facilitate maintenance and repairs.

In conclusion, electricity transformer boxes are vital components in power distribution systems, providing a protective environment for transformers and ensuring the safety of people and animals in the vicinity. By selecting the appropriate material, design, and installation method, electricity transformer boxes can ensure the long-lasting performance and reliability of transformers in various applications.

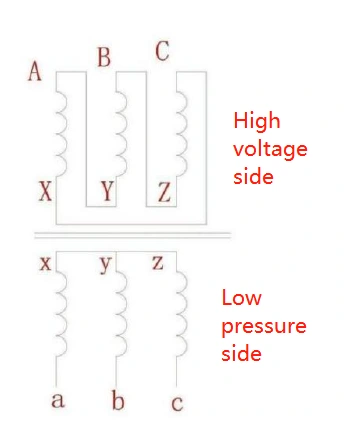

There are two types of transformers, namely dry-type and oil-immersed transformers. For high-rise residential areas, dry-type transformers are generally chosen because of their high short-circuit resistance and many advantages, such as good fire and explosion-proof performance, low noise pollution without a large installation area, and no need for extensive maintenance work. For the transformer connection using DYN11, this connection diagram and advantages are shown in Figure:

(1) Since the third harmonic excitation current is closed in the original winding, the total zero-sequence and third harmonic potential is close to zero, so the neutral low-voltage potential does not drift, so the quality of each output voltage is relatively high. At this stage, the third harmonic content in residential buildings is increasing, and this connection has good lightning protection characteristics, so it makes sense to set up DYN11 connections in residential communities.

(2) The zero-sequence impedance of the DYN11 connection is relatively small, which is better for eliminating single-phase short-circuit faults.

(3) DYN11 connection for access to single-phase unbalanced transformers are not subject to current limitations, so there is no restriction on access to the amount of load. Thus, the transformer is fully utilized.

Download Resource