How to Choose Pad Mounted Transformer?

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical

ELECTRIC, WITH AN EDGE

Combined with the sudden occurrence of inter-turn failure of dry type power transformer in the process of operation, analysis of inspection results, identification of the root cause of dry transformer failure, replacement of faulty dry type power transformer.

This paper briefly analyzes the main factors affecting the longitudinal insulation of dry type power transformer in the manufacturing process and proposes corresponding countermeasures to solve the problem.

The problem of inter-turn short circuit is solved by increasing the partial discharge test in the preventive test and paying attention to the subsequent factory inspection and handover test of the new dry type power transformer.

As a key equipment of distribution network, the reliability of dry type power transformer is crucial to the reliable operation of distribution network. Epoxy resin cast dry type power transformer (dry transformer for short) has excellent electrical performance, good tolerance to short circuit and lightning shock, easy maintenance, no explosion and fire, etc., and is widely used.

Due to the influence of age, installation, manufacturing process, quality control and testing methods, power distribution failures caused by internal faults of dry transformers occur from time to time.

By analyzing the fault cases at work and putting forward suggestions for prevention and maintenance, it is of great guidance for the safe and reliable operation of distribution networks.

Daelim, as a specialized manufacturer of transformers, has been widely appreciated for its extremely fast design and delivery. daelim guarantees the quality of the transformers along with the delivery time. daelim’s transformers are certified by IEC, IEEE, ANSI, CSA, etc. and are widely used in North America, South America, Europe, Australia, etc.

The structure is divided into main insulation and longitudinal insulation. The main insulation is the external insulation, referring to the insulation of the coil and other structures, which can be divided into inter-phase insulation, winding-to-ground insulation and insulation between different windings in the same phase. Longitudinal insulation is the internal insulation, referring to the insulation of the coil of the same phase, which can be divided into inter-turn, inter-layer and inter-segment insulation from inside to outside.

The dry transformer is subjected to the electric field, heat and other factors during operation. Insulation material under the influence of electric field, heat and other factors, insulation performance gradually decline, when more than the critical point, insulation is breakdown, resulting in short-circuit fault.

The faults of dry transformer can be classified as follows.

① phase-to-phase short circuit.

② single-phase grounding short circuit.

③ turn-to-turn short circuit within the winding.

④ overload.

⑤ High winding temperature of dry type power transformer.

The inter-turn and inter-layer short circuit of resin cast dry transformer is more common.

Most of the reasons for inter-turn short circuit are that the resin contains air gap or resin ratio is abnormal in the casting process, which causes the resin to be unfilled at the inter-turn insulation or the resin is not well integrated with the insulating paint of the electromagnetic wire, resulting in partial discharge at the place first, thus causing the insulation structure between the turns to be damaged.

One day, the supervisory control room reported that the front cabinet breaker (VCB) of the low-voltage distribution room tripped, the low-voltage total incoming circuit breaker (ACB) of the dry type power transformer automatically tripped, the low-voltage bus contact breaker (ACB) automatically closed, and the back-end load was carried by the dry type power transformer on the opposite side.

After the duty officer arrived at the scene, he found that there was smoke and the front switchgear tripped. Through emergency disposal measures, after isolating the high and low voltage side of the dry type power transformer, he opened the door of the dry type power transformer enclosure and found that there was ash spraying from the inner wall of the C-phase high-voltage coil, the lower part of the insulation cylinder had melted material dripping down, and the high-voltage coil The resin layer has cracked, initially identified as C-phase high-voltage coil failure.

On the spot of the fault transformer high voltage coil DC resistance test, resistance values are: A-phase 365.8 mΩ, B-phase 367.2 mΩ and C-phase 340.1 mΩ, C-phase DC resistance is small, judged to be C-phase high-voltage coil short circuit.

According to the production number of the dry type power transformer, the original data of the dry type power transformer production was retrieved, including raw material incoming inspection, production process records, production equipment records and factory test data were normal.

The data from the handover test were all in the normal range, and the operating environment was good, with an ambient temperature of 25 ℃ and a load factor of 20% or less before the failure.

After the dry type power transformer was returned to the factory, it was found that the resin end face and inner wall were expanded and cracked after disassembling the high voltage coil, as shown in Figure 1 and Figure 2. The inner resin layer of the coil was peeled off, and the inner resin layer of several cracked parts of the coil was peeled off, and the wires were uncovered layer by layer, and finally a short circuit was found at the back of the coil (low voltage side position), and the short circuit was located at the second layer of wires. The conductor scorch is shown in Figure 4, and the situation was judged to be a short circuit between turns.

Through the dissection observation, the fault location is located in the normal winding area inside the coil, there is no tap and no welding point in this area, and it is located in the inner layer of the line diagram, there is no possibility of the coil in the transportation and operation process due to knock caused by the fault.

From the dissection process, it was observed that the normal part of the conductor epoxy resin in the interlayer and conductor turns penetrated sufficiently.

Five consecutive turns of conductor ablation were observed in the short circuit area, and three turns of conductor were completely fused in the most serious part, which can be confirmed as the location of the origin of the fault.

It is inferred that the direct cause of the fault is the short circuit between the turns of the second layer conductor of the C-phase high-voltage coil, forming a short-circuit current, the short-circuit conductor heats up rapidly and burns the interlayer insulation, resulting in a short circuit between the first two and second three layers, and the heat generated is released from the upper end of the inner wall of the coil, resulting in a carbon black phenomenon on the upper end of the inner wall of the coil and the corresponding low-voltage coil surface.

Lorem ipsum dolor sit amet, consectetur adi

The surface of the electromagnetic wire is covered with a layer of insulating varnish, two turns of wire side by side winding, even if one wire varnish damage, the other wire varnish is intact, can also withstand the normal inter-turn voltage. The failure of the three turns of wire fused phenomenon.

After checking the records of other processes of the coil, the pouring records showed an abnormal phenomenon. When the pouring was almost finished, the pouring equipment showed an abnormal alarm for the ratio of pouring material during one stroke of feeding, and then stopped pouring to check and found that the seal of the curing agent in and out of the material was broken, and finished pouring after replacing it.

It is inferred that the casting alarm was caused by an abnormal ratio of resin and hardener, which was injected into the defective part of the coil, resulting in poor fusion of resin and wire insulation layer in this part and long-term operation, resulting in air pockets and partial discharge.

Long-term partial discharge led to a slow decline in insulation performance inside the coil, and when the insulation decline reached a critical point, the insulation was broken through, eventually causing a short-circuit fault between the turns of the conductor, resulting in this sudden failure.

In summary, the root cause of this failure was the abnormal ratio of the casting resin that led to the partial discharge overload, which eventually caused the turn-to-turn short circuit and the dry type power transformer failed to operate.

piscing elit。Ut elit tellus、luctus nec ullamcorper mattis、pulvinar dapibus leo。

In the manufacturing process of dry type power transformer, it is often easy to latent process local defects in the casting process stage, and in the factory test of dry type power transformer, the partial discharge amount is very small, which causes the partial discharge test data also within the national standard requirements, so that the dry type power transformer with hidden problems into the operation.

During the maintenance test of dry type power transformer, these defects cannot be detected by AC withstand voltage test, and the partial discharge test is not conducted due to the site and other reasons, so the hidden faults are not found and eliminated in time.

In the operation of dry type power transformer, human intuition cannot detect small partial discharges, and only with the help of partial discharge measuring instruments can partial discharge phenomena be detected.

In the short term, a single discharge will not have a significant impact on the internal insulation of dry type power transformer, but in the long term, the partial discharge will gradually expand, and the compound generated by this process will accelerate the damage to the insulation structure, forming a cumulative effect, and when the critical point is exceeded, the inter-turn insulation will be penetrated and an inter-turn short circuit will occur, and the short-circuit heat formed will damage the inter-layer insulation, forming an inter-layer short circuit, resulting in a sudden failure.

Short-time partial discharge does not necessarily cause damage to the medium of the entire channel, but the electrolytic effect of the discharge accelerates the oxidation of the insulation and corrodes the insulation, thus reducing the life of the dry type power transformer. The degree of damage depends on the discharge performance and the degree of damage to the insulation under the action of the discharge.

During the long-term operation of dry type power transformer, the internal insulation performance gradually decreases, and the long-term serious partial discharge accumulates and causes insulation breakdown.

If the partial discharge of dry transformer seriously exceeds the standard, the service life is generally about 5 years, the internal insulation aging and breakdown will lead to inter-turn short circuit, some even 2 to 3 years to lead to inter-turn short circuit.

Since partial discharge is one of the main reasons for short circuit between turns of dry type power transformer, it is necessary to pay enough attention to partial discharge.

There are various types of partial discharges, one of which is the form of partial discharge that occurs on the surface of the insulation. If the energy is high, the life of dry type power transformer is affected when discharge traces are left on the surface of the insulator.

There is another kind of discharge intensity is higher, occurring in the cavity or sharp angle electrode, concentrated in a few points of the local discharge form of corrosive discharge, this discharge can penetrate deep into the interior of the insulating paper material, resulting in a decrease in insulation strength, and eventually lead to breakdown.

As the short-time induced voltage test (ACSD) is an important method to verify the withstand strength of the main insulation as well as the longitudinal insulation of the dry type power transformer, the partial discharge test is used as an effective means to detect invisible defects in the internal insulation of the dry type power transformer. The partial discharge test is a quality control test to verify whether there is an excessive amount of partial discharge under the transformer.

Therefore, the ACSD additional partial discharge test can detect the dry type power transformer with hidden defects of turn-to-turn short circuit in time for predictive maintenance and replacement.

In order to thoroughly solve the fault and ensure the maintenance quality, the dry type power transformer manufacturer replaced the faulty dry type power transformer with a new dry type power transformer of the same model and conducted a strict handover of the new dry type power The new dry type power transformer was subjected to a strict handover test, and the test data met the requirements of national standards. The new dry type power transformer has been installed and running well since then.

In order to exclude that the same batch of dry type power transformers did not have such hidden faults, the dry type power transformer manufacturer made a detailed and complete plan to conduct short-time induction withstand voltage (ASCD) and partial discharge measurement on all dry type power transformers in operation in the same batch. The test was carried out on all dry type power transformers of the same batch in operation.

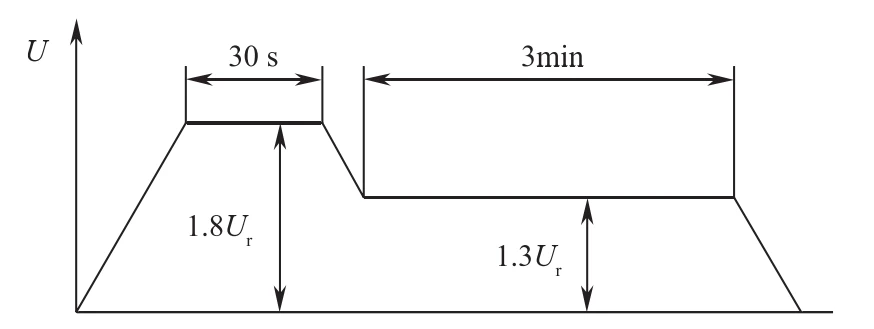

Considering that the dry type power transformer has been in operation for 3 years, the partial discharge test is conducted on the dry type power transformer first, and when the partial discharge detection value is less than the standard value of 10 p C, then the induction withstand voltage test is conducted to prevent the insulation from being broken down directly by the induction withstand voltage test first. The partial discharge test pressurization procedure is shown in Figure 6 (Ur is the rated voltage of 10 k V).

The induction withstand voltage test is performed at 70% of the factory AC withstand voltage (20 kV).

By testing the partial discharge of the same batch of dry type power transformers in operation, no dry type power transformer with excessive partial discharge was found, which ruled out the fault as a batch longitudinal insulation quality problem and ensured the safe and stable operation of the dry type power transformers in operation. The fault was ruled out as a batch longitudinal insulation quality problem, which ensured the safe and stable operation of the operating dry type power transformer.

Since the internal insulation fault of dry type power transformer is hidden, it is difficult to be detected by human senses in the daily operation and maintenance process. type power transformer.

Subsequent attention is paid to the factory inspection of dry transformer, focusing on the process records, quality control cards and factory tests of the raw material incoming inspection, coil winding, vacuum casting curing and assembly process of dry type power transformer. If abnormalities are found, objections will be raised in time to avoid the flow of unqualified parts into the next process and to guarantee the product quality of dry type power transformer at the source.

Pay attention to the handover test of dry transformer, which is the last process before dry type power transformer is put into operation, to ensure that only qualified dry type power transformer can be put into operation.

Since the insulation fault (especially short circuit between turns) of dry transformer is difficult to be detected, once it occurs, it will cause interruption or switching of power distribution and affect the safe and stable operation of important loads. It is necessary to pay attention to the factory inspection, handover test and preventive test of dry type power transformer to avoid the occurrence of similar faults.

Download Resource

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical

The primary function of the pad mounted transformer is to serve as a critical distribution

A pad mounted transformer operates through electromagnetic induction, serving as a crucial distribution component that

After filling in the contact information, you can download the PDF.