ELECTRIC, WITH AN EDGE

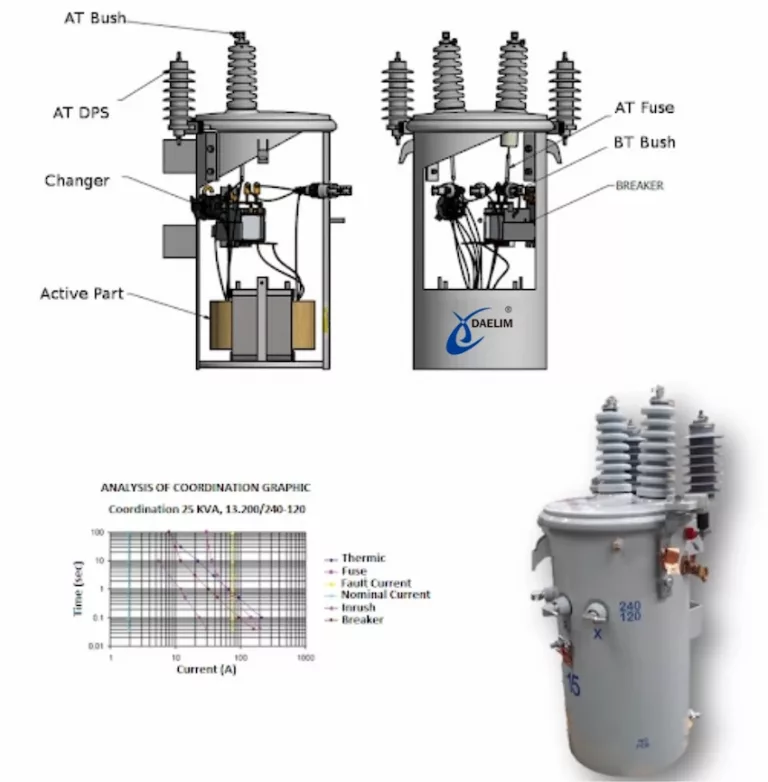

A completely self-protected transformer (CSP) is designed to protect electrical equipment from damage caused by lightning, switching surges, and severe overloads.

The power grid components are exposed to various environmental conditions that may cause the power grid components. Protect the grid components from these harmful environmental conditions with a reliable deterrent system.

Daelim is the world’s leading producer of CSPs. It has the most advanced transformer technology in the industry.

There is a variety of Daelim transformer products not only in Korea but also worldwide.

At Daelim Belefic, we are committed to providing high-quality electrical equipment, and our CSP transformers are no exception. With over 15 years of experience in the design, engineering, and production of electrical equipment, we have the expertise to meet your specific CSP transformer needs.

Our CSP transformers are designed to deliver optimal performance and reliability in a wide range of industrial applications. We use only the highest quality materials and adhere to strict manufacturing standards to ensure that our products meet or exceed all necessary safety and regulatory requirements.

At Daelim Belefic, we understand that every customer has unique requirements, and we pride ourselves on our ability to provide custom CSP transformer solutions that meet your specific needs. Our team of experts has extensive experience in transformer design and can work with you to develop a customized solution that is tailored to your specific application.

We are committed to providing our customers with the highest level of service and support. Our dedicated customer service team is always available to answer any questions you may have and to provide you with the guidance you need to make the best decisions for your business.

In addition to our commitment to quality and customer service, we are also committed to environmental sustainability. We use environmentally friendly manufacturing processes and materials to minimize our impact on the environment and to ensure that our products are as sustainable as possible.

Whether you need a standard CSP transformer or a custom solution, you can trust Daelim Belefic to deliver the quality, reliability, and performance you need. Contact us today to learn more about how we can help you meet your CSP transformer needs.

A CSP transformer is a device that converts electric power from one voltage to another.

These devices are used for several different purposes.

Transformers can be used at electric substations to lower high voltage transmission lines.

Power plants use these to step down voltage from an incoming transmission line.

A CSP transformer is a type of electrical transformer that is designed for use in concentrated solar power (CSP) plants. These types of transformers are specifically engineered to handle the unique requirements of a CSP plant, which include high-temperature operation and the ability to withstand rapid temperature changes.

CSP transformers are typically used to convert the electrical output of a solar field into a form that can be transmitted over long distances via a high-voltage transmission line. This electrical output is generated by a series of mirrors or lenses that concentrate sunlight onto a receiver, which is typically located at the top of a central tower. The heat generated by the concentrated sunlight is then used to produce steam, which drives a turbine that generates electricity.

Unlike traditional transformers, CSP transformers are designed to operate at high temperatures and are able to handle rapid temperature changes. They are typically filled with high-temperature, high-flash-point insulating fluids, such as synthetic esters or natural esters, which are able to withstand the extreme operating conditions found in CSP plants.

CSP transformers are typically available in a variety of sizes and configurations, depending on the specific needs of the CSP plant. They can be designed to operate at different voltage levels and frequency ranges, and can be configured for single-phase or three-phase operation. Additionally, they can be designed to meet a variety of industry standards, including IEC, ANSI, and IEEE.

A Complete Guide to Utility Electric Pole Transformer – Daelim

A CSP transformer is a type of transformer specifically designed for use in CSP plants. These transformers are used to convert the high voltage electricity produced by CSP plants into low voltage electricity that can be fed into the grid.

A CSP transformer, also known as a Completely Self-Protected transformer, is a type of transformer that is designed to protect itself from various electrical faults and abnormalities. Unlike conventional transformers, which require external protection devices such as fuses and circuit breakers, CSP transformers have built-in protection mechanisms that can detect and respond to electrical faults.

CSP transformers use a combination of sensors, relays, and trip switches to detect abnormal electrical conditions and respond accordingly. For example, if there is an overcurrent or overvoltage condition, the CSP transformer can automatically trip its internal switches to disconnect itself from the power source and prevent damage to the transformer.

Another advantage of CSP transformers is that they can be designed to be more compact and lightweight than conventional transformers, since they do not require external protection devices. This can be particularly useful in applications where space and weight are at a premium, such as in mobile power systems or remote locations.

In summary, CSP transformers are designed to be more self-sufficient and reliable than conventional transformers, providing built-in protection mechanisms that can respond to electrical faults and abnormalities. They can also be more compact and lightweight, making them a suitable choice for applications where space and weight are limited.

CSP stands for Compact Secondary Substation. A CSP transformer is a type of transformer used in compact secondary substations, which are self-contained outdoor substations designed to provide power distribution in residential, commercial, and industrial areas. The CSP transformer is typically a pole-mounted transformer that is used to step down high voltage electricity from the primary distribution system to a lower voltage suitable for the secondary distribution system. These transformers are designed to be compact, efficient, and reliable, making them an ideal solution for areas where space is limited or where traditional substations are not practical. CSP transformers are an important component of modern power distribution systems and play a critical role in delivering reliable electricity to homes and businesses.

A CSP transformer, also known as a Current-Split Protection transformer, operates in a unique way to ensure efficient and reliable power distribution. The transformer splits the incoming power into two or more equal parts, with each part feeding a separate load.

To achieve this, the CSP transformer has multiple secondary windings that are connected in parallel to the loads. This means that the current is split between the windings and the loads they supply. Each winding has its own protection mechanism that ensures that any faults or issues with one load will not affect the other loads, providing added security and reliability to the power supply system.

One of the key benefits of the CSP transformer is that it can help to reduce power loss, as the equal splitting of the incoming power means that each load only receives the exact amount of power it needs, without any excess. This can result in cost savings and increased efficiency in power distribution.

Overall, the operation of a CSP transformer is designed to provide a reliable and efficient power supply to multiple loads, while also ensuring protection and security for each load.

A CSP transformer works by stepping down the voltage of the electricity generated by the CSP plant. The transformer takes the high voltage electricity generated by the solar collectors and converts it to a lower voltage that can be fed into the grid.

A CSP transformer works by integrating multiple protective functions into a single transformer unit, which reduces the need for external protective devices and simplifies the installation process. These protective functions include overload protection, overvoltage protection, under-voltage protection, short-circuit protection, and thermal protection.

The transformer has built-in electronic devices that constantly monitor the transformer’s operating conditions and can quickly detect any faults. When a fault is detected, the transformer’s protection system will activate and isolate the transformer from the power source to prevent further damage. This feature ensures that the transformer remains functional even under adverse operating conditions and protects it from damage due to overloading, overheating, and other factors.

In addition to its protective functions, a CSP transformer also has other features that improve its efficiency and reliability. For example, the transformer’s design allows it to operate at a high level of efficiency, which reduces energy consumption and lowers operating costs. The transformer is also designed to operate silently, making it ideal for use in noise-sensitive environments.

Overall, a CSP transformer is a reliable and efficient solution for power distribution and protection. Its built-in protective functions and efficient design make it an ideal choice for a wide range of applications, including renewable energy projects, industrial applications, and power grid systems.

Transformers are not all created equally. A CSP transformer needs a different reset method than a traditional transformer.

It’s important to know the difference when working with CSP transformers to avoid any unnecessary damage.

For instance, anyone may have lost power to a CSP transformer as a result of a storm.

In case of a power outage, they will need to reset the transformer manually.

To restore power, you will need to switch off the power at the breaker for approximately 20 seconds, then switch it back on.

Resetting a CSP transformer is a straightforward process that can be accomplished in a few simple steps. Before resetting the transformer, it is important to understand that there is only one main breaker in a CSP transformer, which is different from conventional transformers that have multiple breakers.

To reset a CSP transformer, follow these steps:

Locate the main breaker on the transformer and turn it off. This will interrupt the power supply and cause the transformer to shut down.

Wait for a few minutes to allow the transformer to cool down before attempting to reset it.

Turn the main breaker back on by flipping the switch to the “on” position. This will restore the power supply to the transformer.

Check to see if the transformer has resumed normal operation. If it has not, it may be necessary to consult a qualified electrician to diagnose and repair any issues with the transformer.

It is important to note that resetting a transformer should only be done by trained professionals who have the knowledge and expertise to do so safely. Attempting to reset a transformer without proper training and equipment can be dangerous and may result in injury or damage to the equipment.

What is the Difference Between 1 Phase 2 Phase and 3 Phase Power?

If you are looking for a CSP transformer, then you’re in the right place.

Here is a list of features to look for in a CSP Transformer. These will give you more control over your electronics and appliances.

A high voltage isolating link is a feature that allows the transformer to be plugged in and disconnected.

It works without disrupting the power of the primary and secondary sections, which is important for taking a transformer out of service or for troubleshooting.

It also protects the transformer from damage during installation.

Without it, voltages of the power line will interfere with the voltage of the low-voltage side, which would be fatal.

Analysis of Performance Data of High Voltage Distribution Transformer

A CSP transformer overload switch is designed to prevent transformers from burning up if the load exceeds the capacity.

Overload switches are installed parallel with primary windings and open the circuit when the transformer voltage is high.

This feature prevents both transformer and equipment damage.

Circuit breakers are an important component of any CSP transformer.

It is the main safety device for the distribution system.

Also, it works by protecting the CSP transformer operation and all downstream equipment from overcurrents and voltage fluctuations.

These can be installed either locally or remotely, depending on the application.

Lightning arresters are a safety device that protects the electrical grid and the devices connected to it.

They protect from voltage spikes that occur when lightning strikes, which can cause outages and possible explosions.

The arresters help to prevent these hazards by diverting the strike’s energy and safely grounding it.

Signal lights can let you know if your device is on and off and has power.

All electrical equipment should have a signal light.

It is important because the operator cannot see the entire unit to ensure it is operating properly.

This light shows when electricity is flowing to connected equipment.

If there is no light or it does not stay on, there’s a problem with the power supply line.

If you have worked with pole mount transformers, you have most probably known about both CSP and conventional types.

Have you wondered what each means and how these two types differ from each other? Keep reading to learn more.

CSP transformers have several safeguards to avoid problems that could cause possible overloading or damage to transformers.

These features may not be present for conventional transformers.

Meaning that they usually need to be attached to a cutout switch.

In conventional ones, a pole-mounted transformer has two primary bushings.

It is used individually to provide single-phase power or banked with two similar transformers, providing three-phase power.

CSPs pole-mounted transformers with a primary bushing are utility-type transformers and are commonly used in residential applications.

The primary bushing is labeled “H1”. A grounding nut on the tank is labeled “H2”.

This transformer is connected between a phase and neutral.

They usually include a primary fuse, a primary arrester, and a secondary breaker with a weak link.

A CSP (Compact Secondary Substation) transformer is a type of electrical transformer that is designed for use in confined spaces. It is a compact unit that is installed on a concrete pad, and is used to step down the voltage of the electrical power from the primary distribution network to the level required by the local consumers.

The main difference between a CSP transformer and a conventional transformer is its size and configuration. CSP transformers are designed to be compact and can be installed in a small footprint. This makes them ideal for use in urban areas or other locations where space is at a premium.

Conventional transformers, on the other hand, are generally larger in size and require more space for installation. They are also more complex in design and have a higher capacity for power transfer.

CSP transformers also have a more simplified construction, which makes them easier to operate and maintain. They typically have a single main breaker that controls the supply of power, whereas conventional transformers may have multiple breakers and switchgear.

Additionally, CSP transformers can be more cost-effective than conventional transformers due to their simpler design and smaller size. They also have a lower environmental impact, as they require less insulation material and can be designed to be more energy-efficient.

Overall, the main difference between a CSP transformer and a conventional transformer is their size and complexity. CSP transformers are compact and easy to maintain, making them an ideal choice for use in confined spaces and urban areas, while conventional transformers are more powerful and better suited for larger-scale applications.

Some breakers have a red signal light, warning that the load has landed on a value close to tripping points.

When the signal light is lit, it signifies that an electric circuit is open.

If the breaker operating handle is turned off, the light shuts off.

Transformers must not be operated under load conditions that can cause transformers to overheat, hence a red light.

It’s an indication of an overload on transformers.

When such conditions exist, a larger transformer is recommended as a substitute to avoid impairing the life of the smaller unit.

Fuse cutouts are combined fuse and switch in overhead distribution lines to protect distribution transformers from current surges and overloads.

A cutout has three components. First is the cutout body.

It has an open C-shaped frame that supports the fuse holder.

The ribbed porcelain or polymer insulator electrically isolates conductive portions of assemblies from the support to which insulators are fastened.

The second is the fuse holder, which is an insulating tube containing the replaceable fuse element. When the contained fuse melts, it opens the circuit.

Fuse holders drop out of the upper contact and hang from a hinge at the lower end.

This hanging fuse holder lets you see that the fuse has operated and assurance that the circuit is open.

The third is the fuse element, which is the replaceable portion of the assembly.

It melts and breaks the circuit when the electric current through it exceeds its rated current value.

Conventional transformers are a device that transfers power by electromagnetic induction used for converting alternating current to direct current.

It is a static machine that passes electrical energy from one end to another without changing the frequency.

It has two separate windings, namely the primary and secondary windings.

They are both electrically insulated, and their winding circuits are connected electrically and magnetically.

Daelim has been committed to the development of transformer technology for decades.

Daelim is the only transformer manufacturer in Korea with a complete product line of transformers to meet all needs.

The complete range of Daelim transformers is designed to have the best attributes in the industry.

Contact Daelim now to learn more.

CSP transformers typically have only one main breaker, which is located in the secondary winding. This breaker is used to isolate the transformer from the distribution system in case of a fault or maintenance work. In contrast, conventional transformers may have multiple breakers, depending on their design and application. However, some CSP transformers may have additional circuit breakers or protective devices to ensure safe and reliable operation. It is important to follow the manufacturer’s instructions and safety guidelines when operating or servicing a CSP transformer.

CSP transformers offer several benefits, including high efficiency, low noise, and high reliability. They are designed to operate in harsh environments, including high temperatures and extreme weather conditions. CSP transformers are also designed to withstand high levels of voltage fluctuations, ensuring stable and reliable performance.

CSP transformers offer several benefits over conventional transformers. Here are some of the advantages of using a CSP transformer:

Overload Protection: CSP transformers are designed with built-in overload protection, which helps to prevent damage from current overloads. The transformer is able to sense when the current exceeds the rated value and can automatically shut down or reduce its output to protect the equipment and prevent damage.

Space-saving Design: CSP transformers are smaller and lighter than conventional transformers, making them ideal for installations where space is limited. This also reduces the installation cost and makes the transformer more portable.

Cost-effective: CSP transformers can reduce the overall cost of the power distribution system by eliminating the need for additional protective devices, such as circuit breakers or fuses. This results in lower installation and maintenance costs, making the CSP transformer a cost-effective solution for power distribution.

Improved Reliability: CSP transformers offer improved reliability due to their advanced protection features. The transformer is designed to operate in a wide range of environmental conditions and can withstand high levels of shock and vibration.

Energy Efficiency: CSP transformers are highly energy-efficient, which can help to reduce the operating costs of the power distribution system. The transformer is designed to operate with low losses, which reduces the amount of energy that is wasted in the form of heat.

Overall, CSP transformers offer several advantages over conventional transformers, including improved reliability, space-saving design, and cost-effectiveness. The built-in overload protection and energy-efficient operation make them an ideal choice for power distribution systems that require high levels of reliability and performance.

CSP transformers are specifically designed for use in CSP plants, while conventional transformers are used in a wide range of applications. CSP transformers are designed to operate in harsh environments and withstand high levels of voltage fluctuations. They are also designed to be more efficient than conventional transformers.

The main difference between a CSP transformer and a conventional transformer is the level of protection they offer. While conventional transformers require external protection equipment, such as fuses or circuit breakers, to protect against overloads, short circuits, and other electrical faults, CSP transformers are completely self-protected and do not require any additional equipment.

CSP transformers feature a built-in protection system that includes a combination of temperature sensors, a differential relay, and a Buchholz relay. This system is designed to detect and respond to abnormal operating conditions in real-time, protecting the transformer from damage and preventing any disruption to the electrical system.

Another difference between CSP transformers and conventional transformers is their cost. While CSP transformers typically have a higher upfront cost than conventional transformers, their self-protective features can save significant costs in the long run by eliminating the need for external protection equipment, reducing maintenance costs, and minimizing downtime due to transformer failures.

CSP transformers are also more compact than conventional transformers, making them an ideal choice for applications with limited space. Additionally, because they are self-protected, CSP transformers can be installed in remote or harsh environments where access to external protection equipment may be limited or difficult.

In summary, CSP transformers offer several advantages over conventional transformers, including enhanced protection, reduced maintenance costs, and greater flexibility in installation. While they may have a higher upfront cost, their long-term benefits can result in significant cost savings and improved reliability in electrical systems.

If a CSP transformer has tripped due to an overload or a fault, it may need to be reset in order to restore normal operation. Here are the steps to follow in order to reset a CSP transformer:

Identify the cause of the tripping: Before attempting to reset the transformer, it is important to identify the cause of the tripping. This could be due to an overload, a fault, or an external issue such as a lightning strike. If the cause is not addressed, the transformer may trip again immediately after being reset.

Disconnect the load: To reset the transformer, the load must be disconnected. This can be done by opening the circuit breaker or switch that controls the load.

Wait for the transformer to cool down: A CSP transformer has a built-in thermal protection feature that will trip if the transformer gets too hot. After the transformer has tripped, it is important to allow it to cool down before attempting to reset it.

Press the reset button: Once the transformer has cooled down, locate the reset button on the transformer. This is typically located on the front of the transformer and labeled “reset” or “CSP reset”. Press the button firmly to reset the transformer.

Reconnect the load: After the transformer has been reset, the load can be reconnected by closing the circuit breaker or switch that controls the load.

Monitor the transformer: After the transformer has been reset, it is important to monitor it to ensure that it is operating correctly. If the transformer continues to trip, or if there are other issues, it may be necessary to seek professional assistance.

It is important to note that resetting a CSP transformer should only be done by a qualified electrician or technician who is familiar with the transformer and its operation. Improperly resetting a transformer can result in damage to the transformer, as well as create a hazardous situation for anyone in the vicinity.

A completely self-protected (CSP) transformer is a type of transformer that is designed to provide comprehensive protection against a range of faults and overloads. These transformers are equipped with built-in protection devices and features, such as fuses, circuit breakers, and temperature sensors, that automatically respond to abnormal conditions, providing a high level of safety and reliability.

Unlike conventional transformers, which require external protective devices, CSP transformers are designed to be self-sufficient and require little to no maintenance. They are ideal for use in applications where space is limited, and there is a need for a compact and reliable transformer solution.

CSP transformers provide numerous benefits, including reduced installation and maintenance costs, improved safety and reliability, and increased efficiency. They are commonly used in a range of applications, including in the power, industrial, and commercial sectors.

In addition to the built-in protection features, CSP transformers are designed to be highly efficient, with low losses and high levels of energy conservation. They are also environmentally friendly, with reduced emissions and a longer lifespan compared to traditional transformers.

Overall, a completely self-protected transformer offers numerous advantages, including comprehensive protection, improved safety and reliability, increased efficiency, and reduced maintenance and installation costs. These transformers are an excellent choice for a wide range of applications, and their use is likely to continue to increase as technology advances and demand for energy-efficient solutions grows.

Daelim Belefic is a leading manufacturer of high-quality CSP transformers. With more than 15 years of experience in the industry, they have the expertise and knowledge needed to provide their clients with the best products and services. Whether you are looking for a new CSP transformer or need to replace an existing one, Daelim Belefic has the solutions you need.

When you need to find more than just existing transformers, Daelim’s Transformer Service Center can help you design and produce distribution transformers that meet your unique needs.

We have our own factory and a professional team of engineers, which can design and modify application requirements that meet all your conditions.

Download Resource

After filling in the contact information, you can download the PDF.