How to Choose Pad Mounted Transformer?

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical

ELECTRIC, WITH AN EDGE

The numbers on transformers aren’t just a decoration; they bear important meaning. This guide is dedicated to the 5000 KVA Transformer, from how it works to the particular specs and the various types of transformers available. You’ll also get to know how to pick the perfect transformer for your specific needs.

Before getting in touch with a firm like DAELIM that deals in transformers, there are a few things you’ll need to know. Depending on your needs, their range of transformers can fit any application needed.

Transformers are not just a one-way device; but can also be used as a generator, where alternating currents are stepped up to higher voltages. As such, various industries rely on transformers for various reasons. Here’s what you need to know about transformers.

The 5000 kva transformer is an electrical device that transfers electrical energy between two or more circuits. Transformers are used to match voltages in a power system to provide compatibility of the system’s phases and their respective electric loads.

In electronics, a transformer is a type of electronic component that can transfer electrical energy from one circuit to another. The 5000 kva transformer transfers power by alternating the electric current in one circuit with an identical electric current in another circuit via electromagnetic induction.

The 5000 kva transformer can be used to reduce the voltage of a source, such as a battery, by being connected between the battery and a load. Conversely, a transformer can be used to increase the voltage of a source by being connected between two identical sources and no load.

Daelim is a world-famous manufacturer, offering high-quality and reliable transformers. Daelim 5000 kVA Transformer is one of their famous products which has more than 10 years of experience in the power industry. And the most excellent point about it is that it comes at an affordable price for anyone to buy. That’s why this transformer has become a bestseller globally in no time and achieves outstanding performance in the transformer market with high efficiency and reliability.

There is no doubt that the Daelim 5000 kVA Transformer is one of the best-known and most trusted models in the world today. It has been widely acclaimed by users worldwide, thanks to its high quality, wear-resistance performance, and long service life. Daelim 5000 kVA Transformer has been widely recognized as one of the best products in the market for its high efficiency and reliable performance.

A transformer changes the voltage of electrical energy by transferring the power through electromagnetic induction from one circuit to another. It’s a form of electromagnetic device that uses mutual induction to function.

Generally, a transformer comprises two or more coils of wire wound around a common magnetic core. The number and size of the coils in the transformer determine how much voltage can be transferred from one circuit to another. Transformers are used in power plants, substations, and homes to step-up or step-down voltages for electric power distribution.

Additionally, transformers are made for specific voltages, ranging from a few kilovolts up to a 5000KVA Transformer, and can only be used on low-voltage or high-voltage lines. The coils produce an electromagnetic field when current is passed through them.

This field induces an electric current in the next coil in the circuit, which is then passed on to the next coil until it reaches its destination. Transformers work by using this principle of induction to change the voltage level of electricity being delivered.

The 5000 kva transformer is an electrical device that provides electricity over a long distance. The size of the transformer depends on the voltage and current being supplied, but most are rated at 5000 kVA or more.

The 5000 kva transformers are used in large utility companies such as public utilities to provide power for transmission and distribution grids across long distances or for remote locations which would otherwise require high-end substations and transmission lines.

The 5000 kva transformers are devices that change the voltage of alternating current.

They function by using electromagnetic induction. Transformers match voltages and step voltages up or down depending on the needs of various applications. Voltage is defined as electrical pressure, which means voltage can be increased or decreased as desired. High voltage has high pressure, and low voltage has low pressure. Transformers allow lower voltages to be sent over long distances, then transform them back to higher voltages for local use.

The primary benefit of using a transformer is efficiency because it allows for less energy loss in transmission, saving money over time. Since the voltage is regulated and can be adjusted, it is safer than sending a direct high-voltage current over long distances. Using transformers to transmit current instead of direct transmission can increase the distance that electric companies can send electricity, increasing the number of people and places with access to power.

The size of a transformer depends on the amount of voltage being supplied. A 5000 kVA transformer will provide 5000 kilovolt-ampere (kVA) at 110 volts with a 60 Hz frequency and 1000 kVA at 2000 volts with a 25 Hz frequency. These voltages are nominal voltages, which means a voltage range is possible within an acceptable range.

Commonly transformers are used in alternating current (AC) systems where power is transmitted at less than line frequency (50 or 60 Hz). A simple example can be seen in any AC electric shaver: The motor inside the electric shaver is powered by an AC adapter that plugs into an electric outlet; but because of the low frequency, it is not possible to run the motor directly from that line power so a transformer steps down the voltage from line level to household level.

The 5000 kva transformer may be a device that steps up or steps down alternating current. The term transformer is most often used to refer to electrical devices that change the voltage level and/or frequency of the alternating current. Transformers are usually compact, but some transformers capable of producing large amounts of power are huge in size. Transformers are widely used in power supplies, and electrical substations and to provide services to customers, such as fast-tracking radio or television broadcasts.

The live front-three phase radial feed pad-mounted transformer provides numerous advantages to you as a consumer. Also, the accurate and effective cut copper power transformer aids in performance enhancement, whatever the transformer specification.

Burrs are also eliminated due to the tight margins of error used in industrial production. Every element is individually layered to avoid humidity intrusion and is electromagnetically stabilized to reduce axial loads if there’s a faulty current.

This is the transformer to get if you’re trying to save money on power while also being environmentally friendly. Improved productivity will help enhance your unit’s value while helping you save some money as the owner by guaranteeing reduced energy bills and lowering the overall cost of ownership.

When searching for the ideal transformer, it’s essential that you understand the specifications of the unit you’re considering.

Here are some of the 5000 KVA transformer specifications to be aware of:

Rating: 5.000 kVA

Primary Voltage: 230/460V

Secondary Voltage: typically 240V, but other voltages can be specified by the customer

Rating Details: Primary voltage is rated primary voltage in volts, and secondary voltage is rated as secondary voltage in volts (A) to be applied to both primaries and secondaries.

Transformator Type: Dpdt-T or Dpdt-T & Feeder Breakers for 480Y/277V operation with 6 circuits on the transformer per phase (480Y/277V) and 12 on the feeder breaker. The circuit configuration is 4 on one phase of the transformer and 4 on another phase.

Number of Circuits: 6 per phase per transformer and 12 per feeder breaker (480Y/277V)

Current Rating: 480Y/277V at [1.6A/3A] for 3 circuits or 480Y/120V at [1.6A] for 6 circuits. Note that feeding both transformers for 480Y/277V is only allowed on a single-phase system (two voltages will be fed from one transformer).

On a two-phase system, the current rated on the feeder breaker is 480Y/277V at either 1.6A or 3.0A per phase.

Short Circuit Rating: 480Y/277V at [3.0A] for 3 circuits or 480Y/120V at [1.6A] for 6 circuits

Primary Voltage Rating: 5,000 kVA from a single transformer and 10,000 kVA from a two-transformer arrangement (5,000/10,000 kVA)

Secondary Voltage Rating: 240 V (240 V)

Number of Interconnections: Typically 4 on the primary side and 4 on the secondary side for a single transformer. Depending on the country interconnected to, there may be more requirements.

Interconnection Layout: Typically 3 transformers per phase and either one or two feeder breakers per transformer. However, in some cases where the primary voltage levels do not match, there may be more or fewer circuit breakers on each transformer or feeder breaker depending on the exact voltage difference between the primary voltages.

The transformer core comes with three limbs, so it is categorized as a three-phase transformer. Different “limbs” are connected to various phases of the transformer. The engineering makes sure that there’s a 120-degree difference between all three power lines.

Ampacity, that is, the overall amps a transformer can manage when completely loaded, is crucial in deciding the appropriate size of the transformer. With a transformer 250KVA, for example, engineers have to calculate this into amps, a value showing how much the transformer can handle. This value is directly proportional to the total KVA so it would be a 250 000-watt load in the example given.

It comes with a mixed voltage range and a frequency of 60Hz and has various accessories, including:

There are many advantages of a 5000 kVA transformer such as that your area will be able to withstand power surges. If there is an incident such as a storm with heavy winds or lightning, you can rest assured that the 5000 kVA transformer will stand tall in your community.

As well as this, the quality of electricity will be enhanced by 20% due to its increased capacity. This has a number of benefits including reducing transmission loss and resulting in cheaper rates for electricity. The process of maintaining the transformer is also much easier when it comes to a 5000 kVA transformer than with smaller ones which require more regular maintenance visits and more frequent checks on individual equipment units.

Another very prominent feature of a 5000 kVA transformer is the increased safety for your business. This is in case of lighting failure or any other emergency, the transformer will automatically switch over to the backup units which are set well in advance. This feature greatly helps if your main power source fails, as the 5000 kVA transformer will immediately be able to transfer power to your business.

Transformer losses are usually the largest cost in electrical distribution. The electrician has to keep the voltage and frequency at the most efficient levels while maintaining a constant current. Since current is directly proportional to the voltage squared and inversely proportional to the resistance, the power loss is greatest when the current is at its rated value. At this point, transformer losses are due primarily to I^2R losses and only a small portion of it is due to core losses.

On the other hand, if the current is below its rated value, transformer losses consist mainly of core loss that can not be helped by keeping it at low voltage and low frequency. Therefore, in order to keep costs at a minimum while maintaining an efficiency high enough for satisfactory operation, transformers have to operate at their maximum continuous rating most of the time.

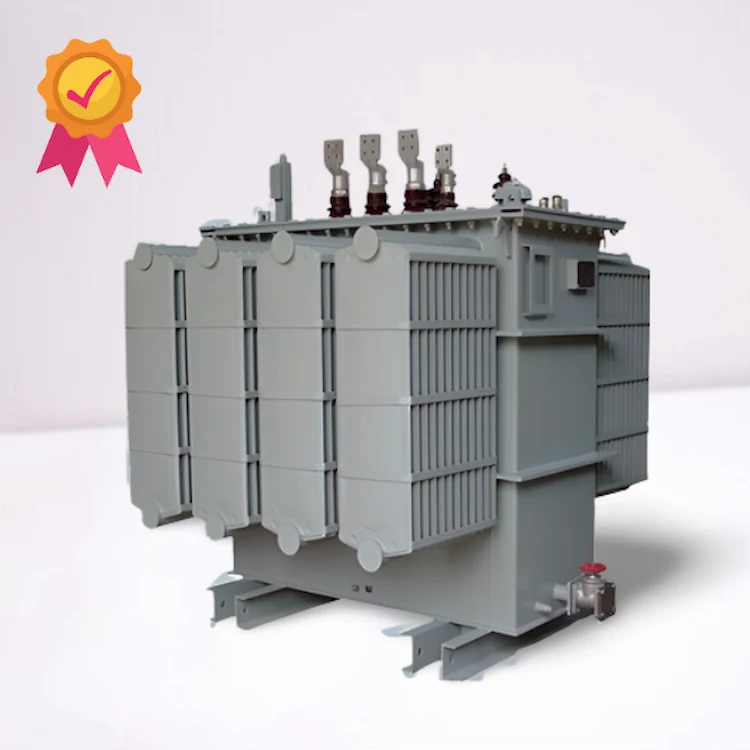

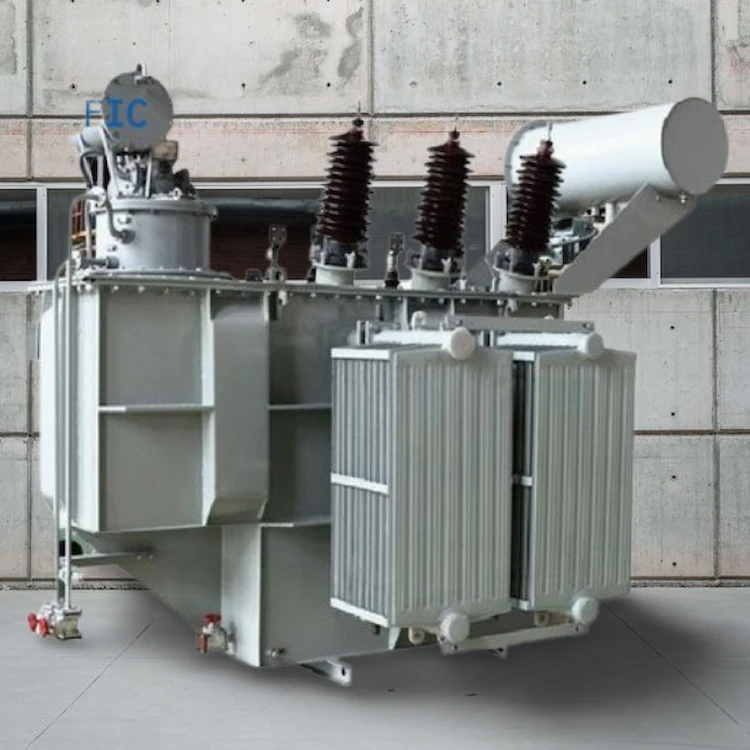

There are two main types of 5000 KVA transformers: distribution and oil-immersed transformers.

Transformer design as it can be scaled up is a cross between electrical and mechanical engineering. All transformers use the same basic design, but they differ in the construction of the various windings and core shapes and materials. The design process takes into account such factors as load current and usage, size limitations, cost and material availability.

A 5000 kVA transformer is a device designed to transfer electrical power over long distances by using electromagnetic induction. It is commonly used in electric utility systems to convert high-voltage, low-amperage power from the distribution system into lower-voltage, high-amperage power that can be used locally or elsewhere. These are usually of the three general types:

Distribution transformers are a type of isolation transformers and, at their most basic, help convert large voltages to standard output voltages such as 240/120 V.

The types available include:

They don’t usually reach ratings of 200MVA, though there are some available at 5000MVA. Also, they frequently do not perform to their full potential. These are designed for maximum efficiency at lower potentials.

The voltage alterations need to be as minimal as possible to achieve better efficiency. As a result, they’re designed to contain a small leakage reactance.

Also known as oil-filled transformers, these are a type of voltage transformation machines that use oil cooling to lower the heat produced during running.

The body is set up in reinforced steel petroleum tanks filled with lubricant oil. When the transformer is turned on, heat from the winding and heating element is converted first into transformer oil, then into the coolant fluid.

It can also be divided into two types based on capacity:

These are very reliable as they perform well in a spectrum of uses, from producing renewable power to minor industries. Owing to their large capacity, the transformer can save energy while significantly reducing loss of energy, conserving energy supplies, and lowering consumption costs. ‘

Additionally, the oil contributes to cooling the inner core, enhancing its longevity and electrochemical characteristics.

The operation of a single-phase transformer is based on the relationship of mutual induction in a transformer. The primary winding (1) of the transformer is connected to the transmission or distribution line, while the secondary winding (2) is connected locally among the users. The primary and secondary windings are wound around the same core, with opposite magnetic polarities.

In operation, electric current flowing through the primary winding produces a magnetic field that induces an equal but opposing field in the secondary winding. As power flows from the transmission lines into one end of the primary coil and out through its other end, an equal amount of power flows into one end of the secondary coil and out its other end.

The power that generated in the secondary winding is in the form of an electromotive force (EMF), which is a measure of voltage. The EMF changes direction from positive to negative and back again as the power flows through the transformer. The change in magnetic field along with counter-changing electrical current flow in opposite directions causes lines of flux to flow from one end of the transformer to the other. This is called Faraday’s law of induction, which states that lines of flux continuously flow through any closed circuit, even though they do not move during their passage.

A two-phase transformer consists of one primary and two secondary coils. The three coils are usually enclosed in a common housing and mounted on the same base. They are arranged in a wye pattern, with the primary and secondary windings forming an angle of 120 with each other.

The two independent coils of this type provide for greater flexibility than the single phase transformer when energizing balanced three-wire distribution circuits. Because of the unbalanced load current in either one wire or another set, there is often a difference between the high-low current ratings of single-phase transformers and their rating based on actual balanced loads.

This type of transformer is used in much larger three-phase transformers. Two primary windings are placed side-by-side in the transformer housing, while the second and third windings are placed above and below the first. The transformer housing is placed on top of a structure for support, with either two or three legs, depending on the size of the unit.

The two legs of each three-phase transformer are connected to positive and negative alternator poles. Each secondary winding attaches to a terminal block that sits inside an insulated enclosure mounted on the base around its periphery. The next step is to determine how much current can be drawn from each terminal block.

Minting new bitcoins to get more in circulation looks a lot like obtaining valuable stones from the land somehow. As a result, it has become known as ‘bitcoin mining.’ Because of this, it relies on a steady supply of power for mining to fulfill the process properly.

As such, manufacturers need to get transformers involved as one of the primary components to start a Bitcoin mining power system. The transformer plays a role in converting the voltage from one grid to a stage capable of providing a mining power supply. Transformers ranging from 1000kVA to 5000kVA are often used in these crypto power/crypto farm power mines.

A power transformer is principally responsible for energy transmission and reception and is used in much higher voltages. As a result, the voltage ratio of a power transformer ranges from 756kV to 11kV. A power transformer typically has a higher MVA rating than a distribution transformer and is designed to achieve optimal efficiency. As such, they’re much larger.

On the other hand, distribution transformers are used in transmission lines with much smaller voltages. As a result, such infrastructure will reduce (step down) the power output and incidental caliber of a power distribution network to a calculated scale. This is called the end-user safety level, and it applies to residential and commercial users.

While bearing a semblance to power transformers, distribution transformers have voltage ranges from 33kV to 430V.

At its most basic, a transformer has three standard sectors, namely:

A transformer is a device for changing the voltage of alternating current (AC) electricity. It usually consists of two or more coils of wire wound around an iron core or ferromagnetic material. The primary coil is connected to an AC power source, and the secondary coil is connected to equipment that uses the converted AC power.

Transformers are useful in AC-to-AC conversion, and power-supply applications, to isolate different circuits and potentially step up or reduce voltages if required. Transformers may also be used in applications where it is necessary to step up (increase) or step down (decrease) voltage and/or current levels through the use of multiple coils wound on a common iron core.

There are many reasons why an uninterrupted power supply is needed. One of these reasons is that the system must be able to run everything from water pumps to steam turbines. In addition, it needs to sustain a certain level of voltage to continue running.

When there are sudden power losses, such as due to a storm or outage, the system needs enough energy stored in its transformer bank so it can keep running until external power returns or backup generators come online.

Another important reason is that the power transformers must be able to compensate for voltage drops in the electrical lines. If this is not done, other systems will go offline, resulting in a complete shutdown of operations.

Power transformers are used to step down high-voltage electricity from the transmission grid (or from nearby generators) to low-voltage power that can be used further along the distribution line.

The most popular oil used in electrical transformers is a dielectric fluid called transformer oil. These can be broken down into three types:

Apart from this, you also have paraffinic oils, those not as popularly used as transformers oils.

Not all transformers are the same, and the differences aren’t always obvious to an ordinary eye. As such, you should make sure you understand what various-sized transformers are built to handle. Knowing the specs and features of the generator is key, whether you’re using the generator for residential or commercial purposes.

When you need a trained expert to break down how the 5000 KVA transformer works, get in touch with DAELIM.

Download Resource

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical

The primary function of the pad mounted transformer is to serve as a critical distribution

A pad mounted transformer operates through electromagnetic induction, serving as a crucial distribution component that

After filling in the contact information, you can download the PDF.