Stockage mobile de l’énergie pour une gestion globale de la qualité de l’électricité

Les stations de distribution du réseau électrique à basse tension assurent la transmission et la

ELECTRIC, WITH AN EDGE

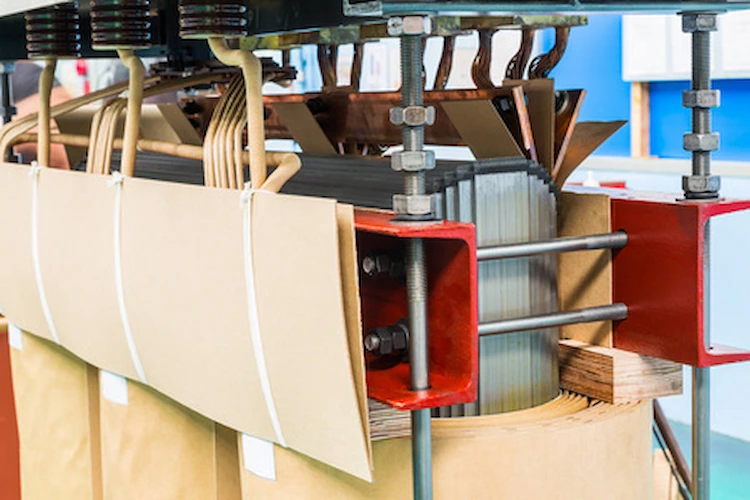

With its unique advantages of low loss and low noise, the 16 mva dry-type on-load voltage regulating resin-cast transformer has been installed in the city’s center and close to residential areas.

The first choice is the 35kV 16MVA on-load voltage regulating dry-type transformer. This paper introduces the design of the 35kV class 16MVA on-load voltage regulating resin-cast dry-type transformer.

Daelim purchases high-quality components and uses the highest quality raw materials to produce series of distribution transformers such as dry-type transformers, pole transformers, Pad mounted transformers, etc. At the same time, Daelim can also produce low-energy consumption, low-noise, maintenance-free for you power transformer.

Daelim est l’un des leaders de l’industrie chinoise des transformateurs depuis 15 ans, avec des concepts de conception de transformateurs de pointe. Daelim dispose d’une équipe d’ingénieurs en transformateurs de plus de 30 personnes qui peuvent vous fournir des services personnalisés. Daelim possède également des certifications industrielles telles que CSA, IEEE, ANSI, DOE, CS, etc., une assurance qualité des produits de haute qualité, pour aider les clients à développer rapidement leur activité dans le domaine de l’énergie.

Traduit avec www.DeepL.com/Translator (version gratuite)

Le transformateur régulateur de tension à sec de 35kV 16MVA a une gamme d’options plus large que le transformateur régulateur de tension sans excitation.

La capacité du transformateur sec de 35kV 16MVA pour les prises ne doit pas être modifiée.

Cela entraînera des problèmes tels que la distribution du gradient d’impulsion, l’équilibre ampère-tour et la force mécanique.

La performance et les caractéristiques globales du transformateur de type sec en résine du régulateur de tension en charge seront affectées par la sélection du changeur de prises.

Traduit avec www.DeepL.com/Translator (version gratuite)

L’enroulement basse tension utilise une structure cylindrique multicouche qui présente une distribution uniforme de la tension initiale. Il offre également une bonne résistance aux impulsions. Ceci afin d’augmenter la capacité du transformateur à résister à l’impulsion de la foudre.

Les enroulements haute tension sont équipés d’un système unique de compensation de cloison cylindrique segmentée.

Le transformateur à sec de 35kV 16MVA a une puissance électrique 3x plus élevée que le cylindrique segmenté ordinaire.

Cette structure peut ajuster les relations de configuration de chaque capacité électrique longitudinale et de chaque capacité électrique de terre de manière à atteindre l’état de compensation optimal de la cloison. Elle réduit le gradient de potentiel initial et améliore la capacité du transformateur à résister aux coups de foudre.

Une décharge partielle peut avoir un impact significatif sur la résistance de l’isolation des transformateurs à sec de 35kV 16MVA.

La structure segmentée cylindrique unique de l’enroulement élimine le potentiel local élevé.

L’une des meilleures façons de réduire les décharges partielles est de prévenir les fissures de contrainte et d’éliminer les bulles.

Les enroulements des transformateurs secs de régulation de la tension en charge de la classe 35kV 16MVA sont fabriqués avec des fils de cuivre de haute qualité. Les extrémités et les sections sont ensuite remplies de nattes de fibres de verre multidirectionnelles sans trame. Le tout est coulé sous vide et séché.

Leurs coefficients de dilatation thermique sont presque égaux.

L’isolation composite de la résine et de la fibre de verre est de (1618]x10-6/K. Dans le même temps, le coefficient de dilatation du conducteur en cuivre dans l’enroulement est de 17×10-6/K.

La fissuration est causée par la contrainte entre les conducteurs de l’enroulement et les matériaux isolants en raison de la dilatation thermique, et le contrat à froid est éliminé.

La tension de décharge partielle de l’isolation solide peut atteindre 8MV/m (structure d’électrode à plaque à broches, 50Hz ; 90), ce qui est la capacité de décharge partielle du transformateur à sec de régulation de tension en charge de classe 35kV 16MVA. Toutes les valeurs mesurées sont inférieures à 6pC.

Traduit avec www.DeepL.com/Translator (version gratuite)

Le transformateur de régulation à sec de classe 35kV 16MVA doit disposer d’une dissipation thermique adéquate pour garantir un fonctionnement sûr et fiable, même après une augmentation de 50 % de sa capacité.

Nous avons installé des passages d’air de refroidissement dans les deux colonnes du noyau du transformateur à sec de 35kV 16MVA. Cela augmente la surface de dissipation de la chaleur de 35%.

Le bobinage du transformateur à sec de classe 35kV 16MVA utilise des types cylindriques multicouches et segmentés. Des passages d’air de refroidissement axial sont placés entre chaque couche afin de garantir une bonne dissipation de la chaleur pour chaque tour et couche ; analyse et calcul de l’élévation de température du point chaud, et distribution de l’enroulement.

Il est essentiel de sélectionner un transformateur OLTC 35kV 16MVA avec une capacité maximale de fonctionnement continu (19MVA) refroidie à l’air naturel pour garantir que le transformateur OLTC 35kV 16MVA puisse répondre aux exigences de sécurité et de fiabilité d’une augmentation de capacité de 50% en fonctionnement à refroidissement forcé.

L’amplitude maximale de la rotation ampère déséquilibrée du transformateur à sec de 35kV 16MVA est de 2,9% à la prise minimale. Cela indique que la distribution d’ampères de l’enroulement est raisonnable. Elle peut être calculée comme suit :

Force mécanique axiale de court-circuit de l’enroulement : Fi=98kN.

Contrainte des fils de l’enroulement basse tension s = 14,1MPa Contrainte admissible des fils de cuivre 156,8MPa

La contrainte des fils d’enroulement haute tension : s = 7,8MPa contrainte admissible du fil de cuivre 156,8MPa

Calcul de la capacité de résistance aux courts-circuits des composants critiques d’un transformateur de 16 MVA.

La capacité des composants critiques des transformateurs à sec 35kV 16MVA à résister aux courts-circuits sous l’action du court-circuit axial mécanique pour 98kN est calculée comme n=3.

Les données montrent que l’action mécanique du court-circuit réduit la contrainte sur les composants critiques du transformateur à sec de 35kV 16MVA. Ceci est en accord avec le facteur de sécurité n=3.

Electric Arc Furnace Transformer, Get The Best Price Now

Les transformateurs des réseaux urbains doivent être peu bruyants.

Deux parties composent le bruit d’un transformateur de type sec coulé en résine à refroidissement automatique par air. La première est la vibration du noyau de la source sonore.

La seconde est le bruit de vibration dû à la force électromagnétique de l’enroulement. Des expériences ont montré que les valeurs de bruit du transformateur sous charge sont peu élevées par rapport à l’absence de sac.

Cela est dû à la résistance mécanique unique et aux structures tampons élastiques utilisées pour comprimer et soutenir l’enroulement fixe.

L’enroulement est enroulé autour de la colonne du noyau de fer et agit comme un mur d’isolation. Il est essentiel de se concentrer sur la source du bruit pour réduire le bruit du transformateur.

37.5 KVA Transformer ,Get The Best Price Now

a. Le matériau du noyau est une feuille de silicium à grains orientés, à haute perméabilité magnétique et à faible magnétostriction.

b. La précision de l’usinage de la partie centrale peut être améliorée (écart de dimension de 0,1 mm, bavure = 0,01 mm).

c. Le processus d’empilage utilise une stratification par paliers à cinq niveaux qui réduit efficacement la zone de jointure et la densité magnétique locale.

d. Ajustez la taille du noyau de fer et diminuez le coefficient proportionnel entre les dimensions géométriques et les dimensions géométriques du noyau de fer (Kpc = 0,01 mm).

du noyau de fer (Kpc = 0,3) de sorte que la fréquence naturelle du noyau de fer (Fz =168Hz) ne dépasse pas la fréquence fondamentale de la magnétostriction, les troisième et quatrième hautes fréquences, et évite ainsi la résonance.

e. Le dispositif permet de comprimer l’enroulement, qui est composé de la pince du noyau de fer, de l’entretoise, de la plaque de traction et de l’anneau de traction. Le ressort papillon et le clou de pression en acier entrent en contact avec la pince et le bloc d’amortissement tandis que le sol absorbe le bruit des vibrations, la dilatation thermique et la contraction de l’enroulement. Cela garantit que l’ensemble du corps est comprimé.

La plaque d’attache en acier peut également satisfaire la tension des pinces inférieure et supérieure. Elle a une bonne action de serrage sur la colonne centrale (la déviation relative des colonnes centrales est inférieure ou égale à 0,05%).

Cela évite que le desserrage ne provoque des déviations dans les tôles d’acier au silicium du noyau. La magnétostriction est augmentée par la flexion. La vibration du noyau de fer due à l’attraction électromagnétique entre les joints des tôles d’acier au silicium et les laminages est également diminuée. Les pertes et le bruit sont considérablement réduits.

25 KVA Transformer ,Get The Best Price Now

Transformateur à sec de 35kV, 16MVA avec résine de régulation coulée, résine de régulation de la tension en charge.

L’interrupteur sélectionné est un changeur de prises en charge de type VT fabriqué par une société allemande MR. Cet interrupteur utilise des contacts à vide pour fournir des contacts d’arc.

Il est basé sur le principe de la résistance de transit rapide. Une conception monophasée avec une régulation linéaire de la tension à 9 niveaux peut être connectée à un groupe de commutateurs triphasés 3 CVT, qui est utilisé pour la régulation de la tension pour les enroulements triphasés à connexion Y/D.

Sa facilité de câblage, sa belle apparence et son absence de pollution en font un appareil idéal pour la régulation de la tension en charge des transformateurs de type sec.

mini substation transformer, everything you need to know

Afin de réduire les décharges partielles, il est nécessaire de mettre en place des transformateurs à sec en résine à grande échelle pour réguler la tension en charge.

Tout d’abord, il faut sélectionner un changeur de prises approprié pour réguler la tension en charge des transformateurs à sec.

Ensuite, le choix d’un type de bobinage et d’une structure d’isolation appropriés est essentiel. Pour améliorer la résistance aux chocs du transformateur sec de régulation de tension en charge de classe 35kV 16MVA, il est nécessaire d’analyser et de calculer la température et l’augmentation de température des points chauds de l’enroulement.

Cela permettra au transformateur sec de régulation de tension en charge de classe 16MVA de 35kV d’être refroidi par air forcé et de s’auto-refroidir. Capacité de dissipation de la chaleur. Il est essentiel d’utiliser des méthodes et des mesures de conception à faible bruit.

Download Resource

Les stations de distribution du réseau électrique à basse tension assurent la transmission et la

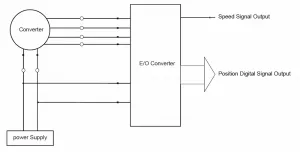

Principe du résolveur (transformation du signal)) Le signal de sortie du résolveur est un signal

Guide complet des normes de transformateur de distribution Cet article vous donne des informations