How to Choose Pad Mounted Transformer?

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical

ELECTRIC, WITH AN EDGE

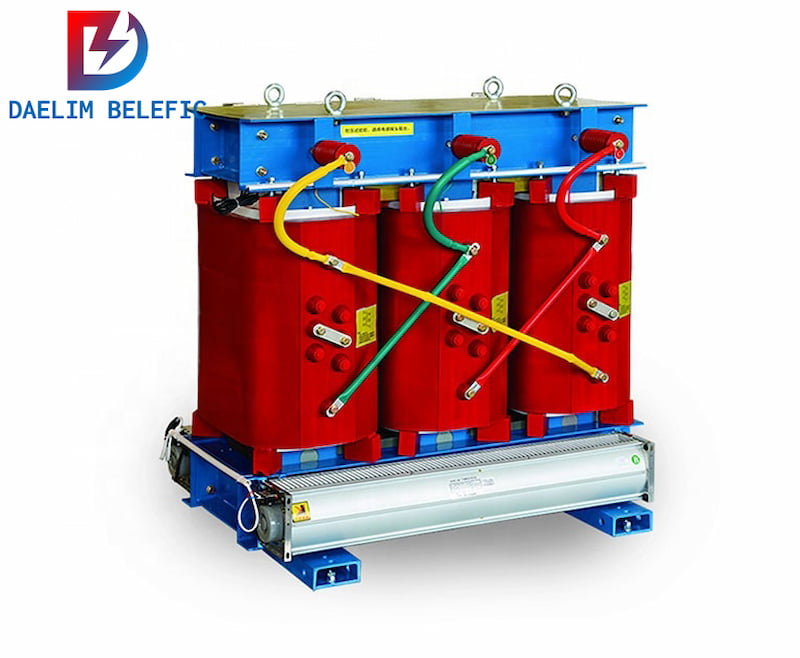

Dry-type transformer: It relies on air convection for cooling, and is generally used for local lighting and electronic circuits.

Transformers such as mechanical equipment, in the power system, general steam turbine transformers, boiler transformers, ash removal transformers, dust removal transformers, desulfurization transformers, etc. are all dry-type transformers, with transformation ratios of 6000V/400V and 10KV/400V, used for rated voltages of 380V Load.

Simply put, a dry-type transformer refers to a transformer whose core and windings are not immersed in insulating oil.

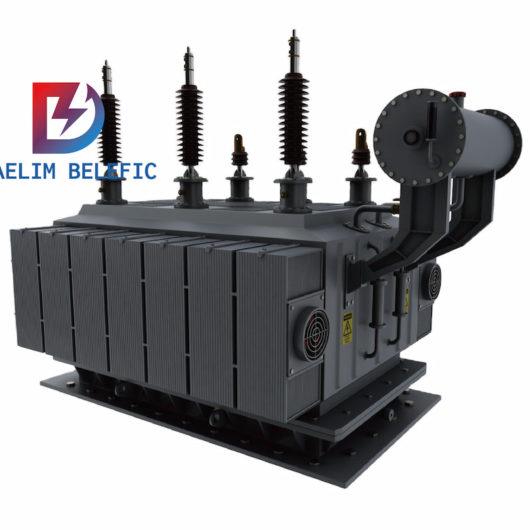

Compared with oil-type transformers, because dry-type transformers do not have oil, there are no problems such as fire, explosion, pollution, etc. Therefore, electrical codes and regulations do not require dry-type transformers to be placed in a separate room.

Especially with the new series, the loss and noise have been reduced to a new level, creating conditions for the transformer and low-voltage panel to be placed in the same power distribution room.

The dry-type transformer is a transformer whose core and winding are not impregnated in insulating oil, mainly through air convection and other ways to achieve cooling; flame-retardant, fireproof, explosion-proof, and environmental protection are its main features.

According to its composition structure, it can be divided into open type, closed type, and cast type. This article focuses on a 10 kV cast-in dry type transformer and lists its installation, operation, and maintenance points.

For example, (SCB10-1000KVA/10KV/0.4KV):

S means that this transformer is a three-phase transformer, if S is changed to D, it means that this transformer is single-phase.

The meaning of C means that the windings of this transformer are resin casting solids.

B means foil winding, if it is R, it means winding winding, if it is L, it means aluminum winding, if it is Z, it means on-load voltage regulation (copper is not marked).

The meaning of 10 is the design serial number, also called the technical serial number.

1000KVA means the rated capacity of this transformer (1000kVA).

10KV means primary rated voltage, and 0.4KV means secondary rated voltage.

①Divided from the insulating medium: SCB series epoxy resin cast dry-type transformers, the insulating material is epoxy resin; SGB series H-class insulating non-encapsulated dry-type transformers, the insulating material is Nomak paper DuPont paint.

②From the core material: silicon steel sheet iron core dry-type transformer SCB, SGB series; amorphous alloy iron core series dry-type transformer: SCBH, SGB series.

③From the energy-saving sequence: SCB9 SCB10 SCB11 SCB13 SCBH15, SGB9 SGB10 SGB11 SGB13 SGBH15 series, etc.

Dry-type transformer; for example, (SCB10-1000KVA/10KV/0.4KV): S means that the transformer is a three-phase transformer, and if S is changed to D, it means that the transformer is single-phase. The meaning of C means that the windings of this transformer are resin casting solids. B means foil winding, if it is R, it means winding winding, if it is L, it means aluminum winding, if it is Z, it means on-load voltage regulation (copper is not marked).

The meaning of 10 is the design serial number, also called the technical serial number. 1000KVA means the rated capacity of this transformer (1000kVA). 10KV means primary rated voltage, and 0.4KV means secondary rated voltage.

1) Winding coupling method, meaning points: ** (not marked); self-coupling (O means).

(2) Phase number, meaning points: single-phase (D); three-phase (S). Electrician: www.dgjs123.com

(3) Insulating medium outside the winding, meaning points; transformer oil (not marked); air (G): gas (Q); molded solid casting type (C): wrapping type (CR): flame-retardant liquid (R).

(4) Types of cooling devices, meaning points; natural circulation cooling device (not marked): air cooler (F): water cooler (S).

(5) Oil circulation mode, meaning: natural circulation (not marked); forced oil circulation (P).

(6) Number of windings, meaning points; double winding (not marked); three winding (S); double split winding (F).

(7) Voltage regulation method, meaning points; no excitation voltage regulation (not marked): load regulation and suppression (Z).

(8) Coil wire material, meaning points: copper (not marked); copper foil (B); aluminum (L) aluminum foil (LB).

(9) Core material, meaning; electrical steel sheet (not marked); amorphous alloy (H). (10) Special purpose or special structure, meaning points; sealed (M); for series connection (C); for starting (Q); for lightning protection (B); for capacity adjustment (T); high impedance (K) Ground station traction (QY); low noise (Z); cable lead out (L); isolation (G); capacitor compensation (RB); oil field power lighting (Y); factory transformer (CY); full Insulation (J); Synchronous motor excitation (LC).

Dry-type transformers have low foundation requirements, usually integrated into the box transformer and installed together with the box transformer; the foundation requirements are standard, as long as the appropriate alignment path can be reserved, unlike oil transformers that need oil storage pools, etc.

Before installing 10 kV, dry-type transformers need to do detailed preparatory work to ensure the smooth implementation of the installation construction. The main initial work should be done in the following areas: to install the construction site verification and to ensure that the structure of electrical equipment and temporary lighting system facilities are complete.

The installation construction site temperature and humidity need to meet the installation construction standard requirements and safety hazard inspection work to eliminate safety hazards and the installation construction operations.

Installers and commissioning personnel need at least three levels of safety education to ensure that each staff has the appropriate qualifications; incredibly particular jobs/exceptional staff, such as electricians, welders, heavy lifters, etc., need to hold a license to practice. The installation plan, commissioning plan, and technical safety must be fully briefed, records of the briefings kept, and the electric equipment and construction tools used should have complete manufacturer’s information.

Construction equipment, measuring devices, etc. need to be tested for quality, carefully check whether they are within the validity period, if there are quality problems or expired, need to contact the manufacturer for replacement.

Open-box inspection of transformers is an integral part of the work to ensure the quality of 10 kV dry-type transformers. Open-box inspection is mainly participated by the supply unit, general contracting unit, construction unit, supervision unit, owner’s representative, and other relevant personnel to ensure the fairness of the inspection.

10 k V dry-type transformer unpacking inspection should first check its appearance, including whether the packaging box is intact, whether the appearance of bruises, scratches, damage, mechanical damage, rust, insulation parts are defective, cracks and other defects, if there are quality defects, after confirmation of the parties involved in unpacking inspection, to contact the supplier unit to return; if there is no above quality defects, need to Verify the transformer model further carefully, specifications and specific parameters are in line with the provisions of the tender documents and design drawings, and the transformer factory manual, quality inspection reports, factory test reports, certificates of conformity, etc. to check to ensure that the transformer quality documents and information complete.

The installation of a dry-type transformer needs safe and reliable grounding, and the base of a dry-type transformer also needs to have reliable grounding. The process of installing a 10 k V dry-type transformer is complicated and involves more functions, and the installer should have high construction technology level.

The base channel steel shall be determined according to the requirements of the design drawings, and its surface shall be treated with anti-rust and anti-corrosion treatment before installation to ensure the quality of installation.

10 kV dry-type transformer to use upright with packaging handling, outdoor handling operations to do a good job of moisture, rain measures, using a crane for handling, to ensure that the crane has sufficient bearing capacity and maintain a certain angle to prevent the transformer tilt.

Ground transportation can be carried out by the rolling bar method; this transportation method is safer and will not damage the transformer.

10 k V dry-type transformer is generally fixed by welding connection, to be anti-corrosion treatment of the welding place, to ensure that the welding connection will not be corroded. The nuts of the transformer installation should be tightened several times to ensure the quality of the relationship.

For transformer bus bar (row) installation, bus bar (row) should be cleaned, bus bar (row) should be insulated, and heat-shrunk outside except for the bolt connection, bus bar (row) bolt connection should be protected, bus bar and transformer cover should be fixed with insulator support. The safety distance between the bus bar and transformer cover should meet the design standard and technical specifications.

Bus bar through the bolt to install flat washers and spring washers have been fastened to mark the excellent nut.

Grounding installation is a vital construction procedure to improve the safety level of the transformer, transformer low-voltage side neutral busbar and transformer shell to be connected with the grounding busbar fastened, and other prominent parts of the separate installation of grounding lines, resistance to being consistent with the requirements of the design program.

When dry-type transformers are installed in the box transformer, we must pay attention to the safety distance of the high-voltage side, and we need to pay attention to the high-voltage side to set aside enough safety distance during the alignment and construction.

(1) Before sending power to the dry-type transformer, it is necessary to check whether the electrical connection conforms to the specification standard and whether the safety distance of each part conforms to the standard provisions. The interior of the transformer should be cleaned without dust.

(2) transformer ratio and connection group are appropriate, and DC resistance measurement of the winding, if necessary, dry processing.

(3) The voltage ratio, transformer group, and polarity of all tap-heads of the winding.

(4) AC withstand voltage test of the winding.

(5) Temperature controller, fan, and other ancillary devices such as inspection.

10 kV dry-type transformer installation there are some difficult and more complex parts of the construction, the construction unit needs particular attention, such as pre-buried plate construction, pre-buried plate installation often appear elevation and level does not meet the standard provisions of the problem, the need for installers to higher elevation part of the cutting or grinding processing if lower than the elevation will need to increase the pad iron.

The transformer in the indoor underground transport is a tricky part of the construction, such as it can not be lifted at once and needs long-distance transport; you can add logs under the transformer channel to effectively solve this problem.

Dry-type transformer dust is too large; when the regular operation, there will be a strange sound, which is caused by the discharge caused by dust. The dust needs to be blown and treated regularly.

Most dry-type transformers are installed in the box and placed outdoors, so it is necessary to pay attention to water and moisture problems. Watering in the green belt often leads to the problem of water in the box transformer in the field operation and maintenance, which endangers the operation safety of dry-type transformers and energized equipment, so it is necessary to pay attention to the waterproof problem.

Regular inspection and maintenance to prevent temperature abnormalities and keep ventilation The primary heat dissipation method of dry-type transformers is air-cooled. Most are equipped with cooling fans or natural ventilation to dissipate heat. Generally, dry-type transformers are fitted with temperature display modules and over-temperature alarms, and other devices to pay attention to the accidents caused by abnormal temperatures.

The commissioning personnel should use a DC tester to measure the DC resistance at each connection of the 10 kV dry-type transformer to ensure that the DC voltage and current at each junction are following the standard.

The resistance of the 10 kV dry-type transformer windings to each other is to be tested to ensure compliance with the design standard and to determine the resistance value of the windings without neutral point lead-in.

The DC resistance of 10 kV dry-type transformers may be exceeded due to structure and other problems and needs to be tested to ensure that the difference does not exceed 2% of the factory parameters of this transformer. The temperature of the winding DC resistance during regular operation should be calculated to ensure that the winding temperature does not affect the safety of the transformer.

Commissioning personnel need to check the voltage ratio of each tap and the voltage ratio change law to determine, to ensure that it is consistent with the transformer factory parameters, the allowable deviation to be compatible with the actual power consumption of the power project. To check the polarity of the 10 k V dry-type transformer lead wire to ensure that the lead wire polarity is consistent with the factory standard parameters. To measure the insulation resistance and absorption ratio of the winding connection bushing to ensure that the insulation resistance is not less than 70% of the factory test value of the transformer.

In 10 kV dry-type transformer construction conditions, the temperature is about 25 ℃, humidity ≤ 80%, should be measured using the measurement table, and the coil to ground insulation resistance to be more than 500 MΩ.

Suppose the construction site is found to be too humid. In that case, the measurement area should be dried to ensure that the humidity in the measurement area is within the normal range to ensure the accuracy of the commissioning results. The fasteners of each core insulation should be tested, such as the insulation resistance of the core-piercing bolts, tying steel strips, and winding pressure rings, to ensure that there is no flashover or breakdown during the measurement and that the quality of this part is qualified. To carry out the winding, connected bushing AC withstand voltage commissioning.

In the AC withstand voltage commissioning of a 10 kV dry-type transformer, the standard voltage on the primary high-voltage side should be 28 kV for 60 s, and the commissioning voltage on the secondary low-voltage side should be 2. 6 kV for 60 s. No flashover, breakdown, or discharge problems occur during commissioning, which proves that the commissioning work is of qualified quality. When commissioning, the 10 kV dry-type transformer’s high voltage side is shorted to the test voltage, and the low voltage side needs to be grounded after the short circuit.

The DC resistance of the transformer winding needs to be grounded and discharged to ensure that there is no current in the resistance to ensure the safety of subsequent commissioning. Any flashover or breakdown in the entire commissioning process indicates a problem with the 10 kV dry-type transformer, and the next step is to determine the part that has the fault or issue.

Commissioning personnel needs to carry out temperature control commissioning of 10 kV dry-type transformer to ensure that the temperature control commissioning device performance is intact, the resistance of its various places to measure to ensure that the opposition to meet the 10 kV dry-type transformer commissioning standards, according to the transformer factory parameters to set different areas of the temperature alarm threshold, the temperature of each measurement point to detect if the alarming phenomenon is the detection of the part of the temperature abnormal If there is a disturbing phenomenon, it means that the temperature of the detected position is weird. There is a fault problem, which needs further verification.

The transformer should be shocked to close the commissioning before the commissioning is carried out to check whether the connection protection lock is standard, to carry out at least five shock tests at normal voltage, each interval of at least 300 s, if each commissioning is no abnormal phenomenon, it means that the quality is qualified.

If excessive noise problems occur during the operation of the 10 kV dry-type transformer, the installation details are to be checked to ensure that each installation connection meets quality standards. To consider eliminating the noise problem, combine with the actual environment of the distribution room, install effective sound-absorbing materials to improve the sound-absorbing effect of the distribution room, and also effectively eliminate noise and reduce noise intensity by slowing down coil vibration and setting up damping structures.

The damping damper is an effective treatment measure for the noise problem of a 10 k V dry-type transformer, which has a good noise reduction effect.

Commissioning personnel need to check the voltage ratio of each tap and the voltage ratio change law to determine, to ensure that it is consistent with the transformer factory parameters, the allowable deviation to be compatible with the actual power consumption of the power project. To check the polarity of the 10 k V dry-type transformer lead wire to ensure that the lead wire polarity is consistent with the factory standard parameters. To measure the insulation resistance and absorption ratio of the winding connection bushing to ensure that the insulation resistance is not less than 70% of the factory test value of the transformer.

In 10 kV dry-type transformer construction conditions, the temperature is about 25 ℃, humidity ≤ 80%, should be measured using the measurement table, and the coil to ground insulation resistance to be more than 500 MΩ.

Suppose the construction site is found to be too humid. In that case, the measurement area should be dried to ensure that the humidity in the measurement area is within the normal range to ensure the accuracy of the commissioning results. The fasteners of each core insulation should be tested, such as the insulation resistance of the core-piercing bolts, tying steel strips, and winding pressure rings, to ensure that there is no flashover or breakdown during the measurement and that the quality of this part is qualified. To carry out the winding, connected bushing AC withstand voltage commissioning.

In the AC withstand voltage commissioning of a 10 kV dry-type transformer, the standard voltage on the primary high-voltage side should be 28 kV for 60 s, and the commissioning voltage on the secondary low-voltage side should be 2. 6 kV for 60 s. No flashover, breakdown, or discharge problems occur during commissioning, which proves that the commissioning work is of qualified quality. When commissioning, the 10 kV dry-type transformer’s high voltage side is shorted to the test voltage, and the low voltage side needs to be grounded after the short circuit.

The DC resistance of the transformer winding needs to be grounded and discharged to ensure that there is no current in the resistance to ensure the safety of subsequent commissioning. Any flashover or breakdown in the entire commissioning process indicates a problem with the 10 kV dry-type transformer, and the next step is to determine the part that has the fault or issue.

Commissioning personnel needs to carry out temperature control commissioning of 10 kV dry-type transformer to ensure that the temperature control commissioning device performance is intact, the resistance of its various places to measure to ensure that the opposition to meet the 10 kV dry-type transformer commissioning standards, according to the transformer factory parameters to set different areas of the temperature alarm threshold, the temperature of each measurement point to detect if the alarming phenomenon is the detection of the part of the temperature abnormal If there is a disturbing phenomenon, it means that the temperature of the detected position is weird. There is a fault problem, which needs further verification.

The transformer should be shocked to close the commissioning before the commissioning is carried out to check whether the connection protection lock is standard, to carry out at least five shock tests at normal voltage, each interval of at least 300 s, if each commissioning is no abnormal phenomenon, it means that the quality is qualified.

If excessive noise problems occur during the operation of the 10 kV dry-type transformer, the installation details are to be checked to ensure that each installation connection meets quality standards. To consider eliminating the noise problem, combine with the actual environment of the distribution room, install effective sound-absorbing materials to improve the sound-absorbing effect of the distribution room, and also effectively eliminate noise and reduce noise intensity by slowing down coil vibration and setting up damping structures.

The damping damper is an effective treatment measure for the noise problem of a 10 k V dry-type transformer, which has a good noise reduction effect.

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical

The primary function of the pad mounted transformer is to serve as a critical distribution

A pad mounted transformer operates through electromagnetic induction, serving as a crucial distribution component that

After filling in the contact information, you can download the PDF.