ELECTRIC, WITH AN EDGE

Tesla Megapack is a large-scale energy storage solution designed to support the grid and renewable energy sources, providing storage for when the sun doesn’t shine, or the wind doesn’t blow, which is vital for the feasibility of sustainable energy. Introduced in 2019, it boasts three megawatt-hours of storage capacity, equivalent to 40 Tesla Model Y batteries, and includes a cooling system, a bidirectional inverter, and software for energy management.

This article will give you a comprehensive introduction to the Tesla Megapack, including its specifications, functions, security concerns, a security Case Study on the metapack, and of course, a recommendation for a transformer that will work with the Tesla Megapack (for selfish reasons).

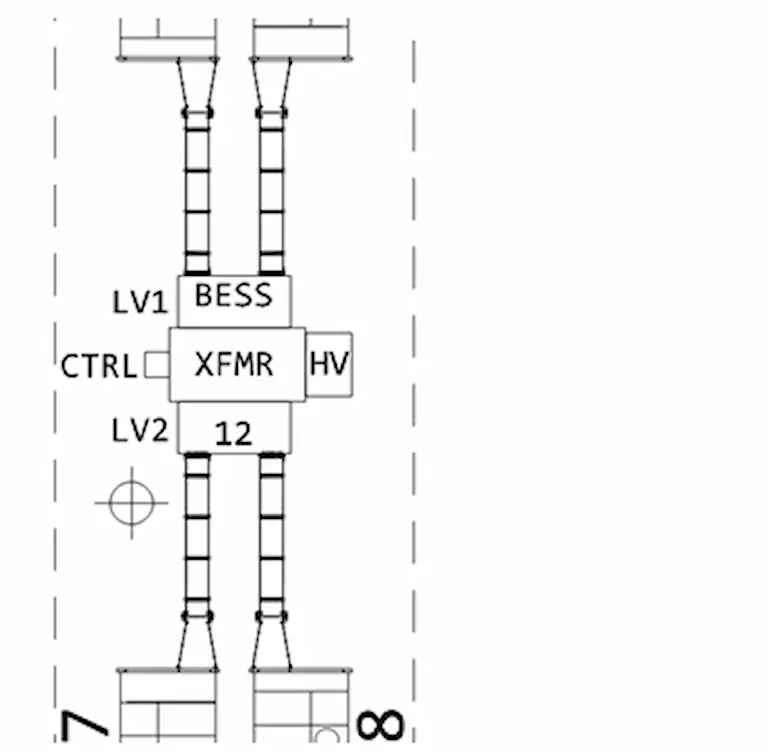

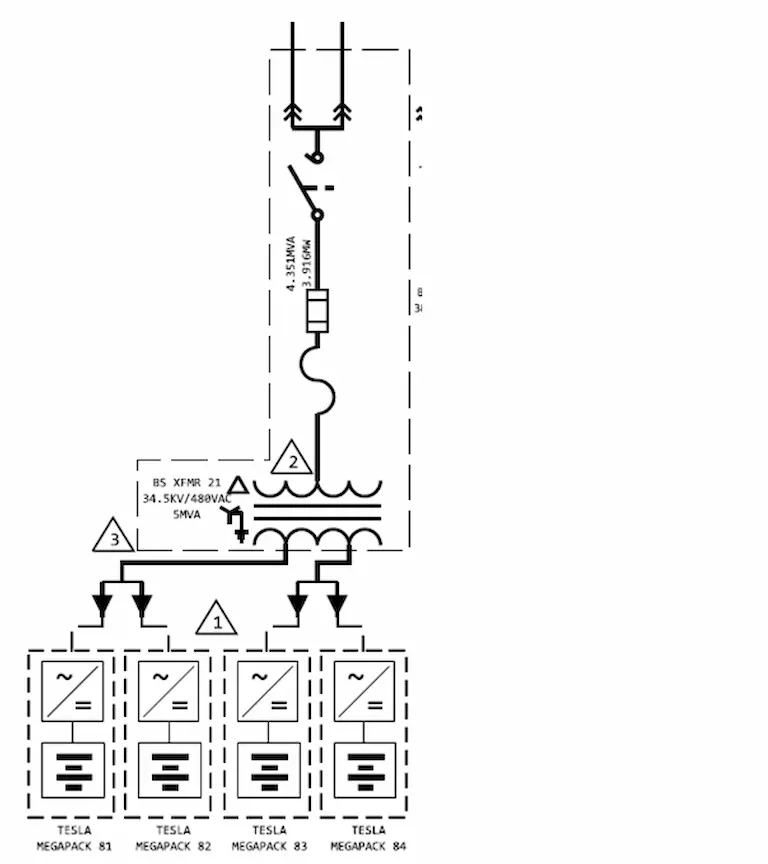

The Daelim Pad Mount transformer’s functional capabilities (5000KVA, 4200KVA, 2500KVA, 1250KVA) make it an excellent match for Tesla Megapack installments. Its special functions, such as eco-friendly air conditioning fluid, fan-less air cooling, and a split unit style, use a hard and ecologically mindful solution for enhancing power from the Megapack to the grid. This transformer enhances the Megapack’s capability to keep power efficiently, reliably, and scalably, making it a leading choice for large jobs aiming to support the grid and integrate renewable energy resources. The daelim transformer’s layout and features are thoroughly picked to match the Tesla Megapack’s functional criteria and safety and security requirements. From ecological factors to consider, such as making use of eco-friendly cooling liquid, to advanced fault and stress management systems, every aspect of the transformer is lined up with guaranteeing the risk-free, effective, and sustainable procedure of the Megapack installments. The incorporation of extensive monitoring and defense tools even more incorporates with Megapack’s advanced monitoring systems, permitting aggressive maintenance and functional adjustments as needed.

Feature | Specification | Detailed Compatibility | Applicable Standards |

Mounting Option | Pad Mounted | The pad-mounted arrangement is appropriate for the setup requirements of theapack, providing an easy installation process and guaranteeing secure and resilient positioning in different places, such as separated or difficult environments. | NEMA 250 |

Environmental Protection | Biodegradable cooling fluid (KNAN) | The use of KNAN liquid highlights a dedication to environmental sustainability, straightening with Tesla’s objective. KNAN fluid’s high flash point and fire point boost operational security, important for the large-scale deployment of Megapacks. | IEEE C57.147 |

Temperature Monitoring | Liquid level, temperature, and pressure/vacuum gauges | Makes it possible for accurate tracking of transformer conditions, lining up with Megapack’s sophisticated surveillance capabilities to ensure system integrity and protect against operational problems before they escalate. | IEEE C57.12.90 |

Fault Management | Automatic action fault pressure device | Boosts the reliability of the system by identifying and responding to uncommon stress rises in the transformer, which is important when handling the high power capacities of Megapack arrays. | IEEE C57.12.90 |

Voltage Regulation | 5-position tap changer with +/- 2.5% taps | Gives versatility in taking care of voltage degrees, ensuring that the output suits grid demands or compensates for any type of voltage drop, thus keeping the performance of power shipment from Megapack to the grid. | IEEE C57.12.00 |

Cooling Capacity and Efficiency | Air cooling, 65°C temperature rise | Guarantees the transformer’s reliable performance in varied ecological conditions, providing steadfast operational efficiency and strength, also when running at maximum capacity. | IEEE C57.12.00 |

Physical Security | Compartmental design with locking cabinet | Protects high voltage elements and facilitates risk-free upkeep operations, matching the Megapack’s emphasis on safety and safe gain access to. | IEEE C57.12.00, NEMA 250 |

Surge and Overvoltage Protection | High elbow surge arresters | Safeguards the Megapack and transformer from external electrical surges by short-term boosts in voltage.

| IEEE C62.11 |

Operational Flexibility | Secondary side equipped with a load break switch | Allows for secure interference and isolation for upkeep or in emergency scenarios, improving the operational flexibility and security procedures of the Megapack installations.

| IEEE C37.20.3 |

Current and Overload Protection | Bayonet fuses on the secondary side | Makes sure the transformer and the Megapack system operate security against extreme current scenarios. | IEEE C37.41 |

Transformer Rating | Dual transformer rating of 5000KVA 4200KVA 2500KVA 1250KVA | Provides ample capacity for stepping up the low voltage output from Megapack to grid-compatible levels, ensuring reliable energy distribution even at peak load conditions. |

Primary Voltage | Three-phase 480Y/277 x 480Y/277 Wye-N | Matches the output characteristics of Tesla Megapack, allowing for seamless integration without requiring extensive modifications or additional conversion equipment. |

Secondary Voltage | Three-phase 34500V Delta | Suitable for feeding into the local utility grid, enabling the effective transmission of stored energy over long distances with minimal losses. |

Temperature Rise | 65°C65℃ | Ensures reduced heat waste and increased reliability, suitable for varying installation environments including indoor and outdoor locations. |

Surge Arresters | High elbow surge arresters on the secondary (medium voltage) side | Protects the system from over-voltage and transient voltage spikes, critical for maintaining the operational integrity of the Megapack in fluctuating grid conditions. |

Load Break Switch | Equipped on the secondary (medium voltage) side | Enhances operational flexibility and safety by allowing isolation of the transformer during maintenance or in emergency situations. |

Protection Fuses | Bayonet fuses on the secondary (medium voltage) side | Provides additional protection against over-current conditions, safeguarding both the transformer and the Megapack system during operation. |

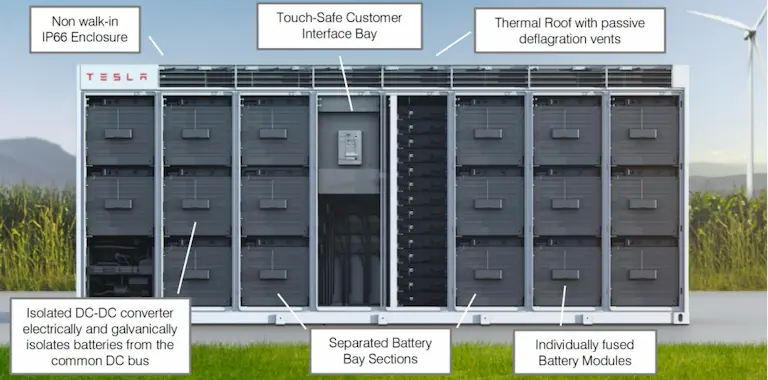

The simplest way to look at a megapack is as a box full of batteries. A power bank the size of a shipping container. Aside from the battery cells, each unit has a liquid cooling system the same as the battery pack in a Tesla vehicle. There’s a bidirectional inverter to allow energy to flow in and out of the batteries, and an AC main breaker and controls. Tesla says the Megapack takes up 40% less space, requires a 10th of the parts to build, and can be assembled ten times faster than alternative energy storage solutions.

The Megapack was introduced by Tesla in 2019 with three megawatt hours of energy storage capacity. This is a staggering amount of energy in one box. The average Tesla vehicle battery pack, like the one in a model Y, is 75 kilowatt hours of energy. There are 1000kW in a megawatt, so one mega pack is equal to 40 model Ys worth of energy. And the Mega Pack uses that storage capacity to regulate the flow of energy, filling up when the supply is plentiful and then discharging at times when energy is scarce. Kind of like a rain barrel that stores water during the wet season to use when it’s dry. Just don’t drink that. All rain is poison.

Now, in case you hadn’t heard, there are two fundamental ways to use a megapack installation, either as a support system for an existing power grid, or in combination with energy generation from wind and solar, as a support for an existing grid is the most common use for this kind of storage system right now.

In this case, the Megapack installation will pull energy from the grid to charge up during periods of low use, like in the middle of the night, and then it will hold that energy and wait until a period of high demand arises. Like a hot evening when everyone is blasting air conditioning and cooking and watching TV and all of that. At these critical times, there can actually be more demand for electricity than the grid is able to provide, and that can lead to rolling blackouts.

So this is the point where the Megapack will discharge its stored energy back into the grid to boost the overall supply and prevent it from becoming overburdened. Before solutions like the Megapack came about, the only way to deal with this problem was by using natural gas fired peaker plants. So when the demand for energy is about to overwhelm the supply, these peaker plants will kick on and start burning natural gas to generate more electricity for the grid.

These peaker plants are very expensive, very inefficient, and very bad for the environment. Plus, they don’t even work very well because they need time to get up and running before they can reach peak output, so they aren’t nimble enough to cope with sudden fluctuations in the energy supply. As of 2020, open cycle gas turbines give an electricity cost of up to $200 per megawatt hour every time that they are activated. Each megapack with 300 megawatt hours of capacity costs about $1 million. Tesla’s standard warranty covers that for 15 years, so that would be about 22,000 per megawatt hour per year, or about 60 bucks per megawatt hour per day. So considerably cheaper and considerably better for the environment.

And then when you consider that a peaker plant needs an entire giant building constructed with a staff to operate and maintain it, it needs to be linked in with a supply of methane gas, which first has to be extracted from the ground and then burned to create a few metric tons of CO2 as a byproduct. Or you could have a small field full of batteries that just sit there and function autonomously. Tesla can deploy a one gigawatt hour power plant in less than three months on just three acres of land, about four times faster than a traditional fossil fuel power plant with the same capacity.

The Megapack system is monitored and controlled by Tesla’s autonomous software platform called Power Hub, so it doesn’t need oversight by humans to function. And Tesla only requires one small maintenance check per year and one round of significant maintenance once every ten years. The ten year checkup is just to replace the cooling. Pump and door gaskets, plus topping up the coolant fluid.

This has led to several counties in California already moving to replace their natural gas peaker plants with giant megapack installations。

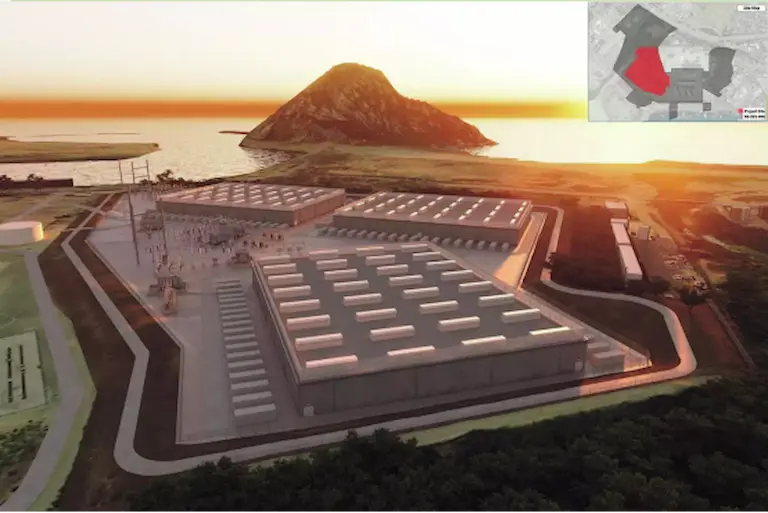

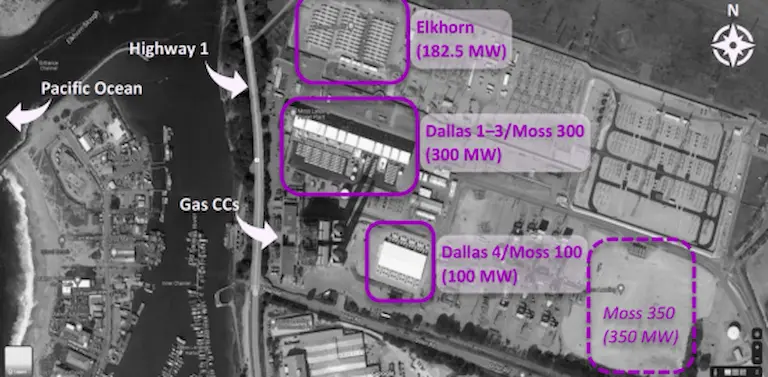

The largest of them so far being the Elk Horn Battery at Moss Landing. This battery was commissioned in June 2022, with 256 Megapack units installed on 33 concrete slabs. The total energy capacity is 730 megawatt hours, while power output is up to 182MW for up to four hours at a time during periods of high demand. The other common way to use a megapack is as a regulator for green energy generation, like solar and wind power.

You can get full time energy supply from solar panels, but only if there is significant battery storage in between. The Megapack will charge up during times of peak energy production, and then as the sun fades, the grid will switch over to the megapack for supply until the sunlight returns. Admittedly, it is a very delicate balancing act, and to make this work as a full time energy source for a community of any decent size, it’s going to require a lot of solar panels and a lot of megapacks, but it can be done.

The state of Hawaii is a great example of that. Hawaii already has the largest installed solar capacity per capita, and the islands plan to use 100% green energy as soon as the year 2045. By this September, Hawaii will have shuttered their last coal burning power plant and replaced it with a large scale installation of Tesla Megapacks. The Kapolei Energy Storage facility will rank as one of the biggest battery systems in the world, with a capacity of 565 megawatt hours. Hawaii is taking things one step further by putting a new level of responsibilities onto their battery installation. The state says that the Tesla Megapack will function as something called a black start device, which can restart the island’s electrical grid in the event of a natural disaster, operating kind of like a grid scale pacemaker.

With the rapid expansion of market demand, Tesla’s energy storage production is also developing rapidly. In 2021, Tesla Megapack have all been manufactured at Giga Nevada, which is convenient because that’s also where Tesla makes all of the battery cells and packs. They are able to make about four gigawatt hours worth of storage products per year in the Nevada factor.

By 2024, the new factory in California will be officially put into operation, which will significantly increase production capacity. Tesla says their goal is 40 gigawatt hours per year.

In addition, a facility situated in Lathrop, California10,000 Megapack is capable of giving power to around 3,600 families for one hour.

According to Reuters, Tesla’s upcoming factory in China is anticipated to create 10,000 lithium-ion Megapacks annually.

According to Reuters, Tesla prepares to build a manufacturing facility in China that can generate 10,000 lithium-ion battery packs each year.

“Tesla [is] opening up Megapack factory in Shanghai to supplement outcome of Megapack factory in California,” Tesla proprietor Elon Musk stated in a tweet on April 9. This was revealed by Elon Musk on his Twitter in 2023.

Tesla Megapack systems are already online in Texas, Alaska, and Australia. They include rows of huge, white rectangular units that Tesla supports with a 20-year guarantee. The company stated they are secure and have gone through comprehensive fire examinations.

According to details found on Tesla’s internet site, the battery packs offer defense versus power outages in extreme weather conditions, lower reliance on gas turbines, and deal emergency power supply to metropolitan locations. Tesla sees this as a crucial move to maintain grid security and prevent blackouts.

And that’s going to be thanks in large part to a new battery chemistry that will make it easier and cheaper to produce the Megapack. It’s very likely that these new specs we are seeing right now describe the Megapack storage system with lithium iron phosphate or LFP cells. It’s a new battery chemistry, and Tesla, along with other electric vehicle manufacturers, have started using it for lower range cars with reduced performance. The cells don’t use many of the high cost metals that are typically associated with lithium ion batteries, like nickel and cobalt. Instead, LFP cells use just lithium and iron in their cathode. The trade off is a reduced energy density. The storage capacity per kilogram of cell material is about 25 to 30% lower. In a vehicle. That’s going to translate to lower range and slower acceleration, but a megapack does not move, so all they need to do is build the box bigger and put more batteries in it, in this case to. Tesla went so much larger with the new megapack that it actually exceeds the capacity of the older unit, even with the lower density battery cells.

So they are telling us that if we order a Megapack today, then the unit we receive will be the new XL sized LFP Megapack made in California. And that would also indicate that by the time 2024 rolls around, the production rate of the Megapack should be approaching the 40 gigawatt hour per year capacity, which will hopefully translate to lower cost per unit and shorter wait times for delivery. And that will bring sustainable energy one massive step closer to being achievable in our lifetime. Hopefully, that puts things into perspective on how important batteries are to the future of energy, and why the Megapack is a far better solution to an age old problem. How do you think the Megapack will change our energy landscape? And have you seen one of those installations go up where you live?

Let’s talk about Tesla Megapack energy storage system. No, it’s not as flashy or exciting as a car like the model S plaid, but we are going to wager that the Megapack is a significantly more important invention. Megapack is the answer to the biggest long standing problem with green energy. For years, we always said wind and solar in any discussion about sustainable energy, but we were leaving out a critically important third side of the green energy triangle, which we now know is storage, because the sun doesn’t always shine and the wind doesn’t always blow, and that renders green energy unreliable at best and not particularly sustainable. So we need a way to store the energy and save it for later, which is a simple idea with a very complicated answer. Because to do that, you need batteries and a spectacular amount of them. Then you need the inverters and cooling systems that make them work and keep them safe. You need software that can link them all together and manage the flow of energy effectively. And you need to be able to do this at a massive scale, at a price point that makes it all worthwhile. Tesla was the first company that was able to check all of those boxes with the Megapack, a product that is equally as important to the green energy revolution as the solar panel and the windmill.

Tesla Megapack stands for an advanced improvement in large energy storage remedies, created to sustain renewable resource systems, grid solutions, and framework jobs. As a highly advanced and reliable energy storage space system, the Megapack provides unmatched efficiency and adaptability for a variety of applications.

Tesla Megapack is an all-in-one utility-scale energy storage space system, created to provide a thorough solution for energy storage space requires ranging from 1 MWh to over 1 GWh. This system is a pivotal part in the transition to renewable energy, supplying a scalable, reputable, and effective method for saving and dispatching electric power.

Streamlined Solution: Megapack includes battery systems, a two-way inverter, heat management system, and air conditioning main breaker in a solitary, pre-assembled housing. This integrated design makes it possible for swift and cost-efficient installation while keeping first-class performance and dependability.

Optimization Software: Developed along with the Megapack hardware, Tesla’s exclusive software program can autonomously manage cost and discharge cycles, predict local energy patterns, and deal smooth SCADA combination. This enables the assimilation of co-located renewables and participation in energy markets.

Boosted System Safety: Safety is a vital interest in Megapack, featuring parallel DC/DC converters, incorporated heating & cooling at the cell level, and devoted danger airing vent. The style meets international safety and security standards, assisting in simplicity of permitting.

Tesla’s advanced upright assimilation guarantees top-notch integrity, as it deals with equipment style, sourcing, and software application advancement in-house. This extensive strategy permits customized optimizations, such as the Megapack cooling system, which supplies remarkable thermal administration while maintaining HVAC energy usage in check.

Cost-Effectiveness: Megapack’s style dramatically minimizes design, procurement, and building (EPC) prices. Delivered totally put together and pre-tested, setup calls for only seismic anchoring and the connection of a/c conductors and an interaction wire.

Global Service Footprint: Tesla supports Megapack with a detailed service offering, covering all components throughout the item life. Clients benefit from a single point of contact, backed by Tesla’s functional fleet information, which educates upkeep models and efficiency warranties.

Ingress Ratings: The major unit is ranked IP66/NEMA 3R, while the thermal system is rated IP20.

Dimensions and Weight: The typical device has measurements of 7168 mm (width) x 1659 mm (depth) x 2522 mm (elevation), with a delivery weight of up to 25,400 kg (56,000 lb).

Megapack is developed to operate efficiently in temperature levels varying from –30°C to 50°C (–22°F to 122°F), making it ideal for usage in diverse settings.

Ingress Ratings: The major unit is ranked IP66/NEMA 3R, while the thermal system is rated IP20.

Dimensions and Weight: The typical device has measurements of 7168 mm (width) x 1659 mm (depth) x 2522 mm (elevation), with a delivery weight of up to 25,400 kg (56,000 lb).

Megapack is developed to operate efficiently in temperature levels varying from –30°C to 50°C (–22°F to 122°F), making it ideal for usage in diverse settings.

Qualifications: Megapack cells are NRTL listed to UL 1642, with the system conference UL 1973, UL 9540, UL 9540A, UL 1741 SA, IEC 62619, and IEC 62477-1 standards.

Inverter Size: Available in sizes up to 1573 kVA for 2-hour arrangements and approximately 929.5 kVA for 4-hour configurations, scalable in increments of 71.5 kVA.

Air Conditioner Voltage and Frequency: Supports 380– 505 V A/c 3-phase, with a small frequency of 50 or 60 Hz.

Ingress Ratings: The major unit is ranked IP66/NEMA 3R, while the thermal system is rated IP20.

Dimensions and Weight: The typical device has measurements of 7168 mm (width) x 1659 mm (depth) x 2522 mm (elevation), with a delivery weight of up to 25,400 kg (56,000 lb).

Megapack is developed to operate efficiently in temperature levels varying from –30°C to 50°C (–22°F to 122°F), making it ideal for usage in diverse settings.

Megapack is a customizable energy system capable of being sized according to customer needs.

AC Power /Energy Available per Megapack1 |

|

Below are specifications for selected system sizes. A light Megapack is optimized for global payload limits. A standard Megapack has the maximum number of energy modules.

AC Power / Energy | Round-Trip System |

Available per Megapack1 | Efficiency1 |

2-Hour Standard 1264.5 kW / 2529 kWh | 87% |

2-Hour Light 1011.6 kW / 2023.2 kWh | |

4-Hour Standard 741.2 kW / 2964.8 kWh | 90% |

4-Hour Light 523.2 kW / 2092.8 kWh |

1 Nominal energy and RTE at 25°C (77°F) including thermal management loads, Day 1

Inverter Size (at 480 V AC) | 2-hour: Up to 1573 kVA 4-hour: Up to 929.5 kVA (Scalable in increments of 71.5 kVA) |

AC Voltage | 380–505 V AC 3-phase |

Nominal Frequency | 50 or 60 Hz |

Ingress Ratings | IP66/NEMA 3R (Main enclosure) IP20 (Thermal system) |

Enclosure Dimensions | W: 7168 mm (282 1/4 in) D: 1659 mm (65 1/4 in) H: 2522 mm (99 1/4 in) |

Maximum Shipping Weight | Standard: 25,400 kg (56,000 lb) Light: 18,600 kg (41,000 lb) |

Operating Ambient Temperature | –30°C to 50°C (–22°F to 122°F) |

Lithium-Ion Cells | NRTL listed to UL 1642 |

System | NRTL listed to UL 1973, UL 9540, UL 9540A, UL 1741 SA, IEC 62619, IEC 62477-1 IEEE 1547 Compliant to grid codes and safety standards of all major markets |

Protocol | Modbus TCP / DNP3 / Rest API |

Megapack (all variants) | 1462965-XX-Y (Where X is a number between 0-9 and Y is a letter. Changes to these do not affect product ratings.) |

Connection Compatibility: Every Megapack is specifically crafted to be linked to a 480V A/C 3 stage system, assuring that it can perfectly incorporate with current infrastructure.

The Megapack’s size and weight are significant, its measurements determining 347 inches vast, 65 inches deep, and 110 inches tall. It can manage an optimum weight of 84,000 lbs, showcasing its solid construct and storage space capacity.

The Megapack has been carefully tested and licensed to satisfy the most stringent industry standards, including IP66, UL 1973, UL 9540, UL 9540A, and UL 1741, in addition to IEC 62619, offering assurance of its safety and security, integrity, and efficiency.

Since its introduction in 2019, the Megapack has actually undertaken significant enhancements, including a notable increase in power ability from 3 megawatt hours to 3.9 megawatt hours. These developments have actually resulted in adjustments in its measurements, with the unit currently determining 6 feet much longer, two inches bigger, and one foot taller. Additionally, the weight has actually boosted by 64% to almost 84,000 extra pounds.

Among the most substantial developments in the Megapack is the alternative to select in between a two-hour or four-hour duration design. The four-hour variation basically uses half the power output of the two-hour version to run for two times as long, supplying adaptability to satisfy details project demands.

The Tesla Megapack represents an innovative alternative for large-scale energy storage space on the grid, offering outstanding performance, adaptability, and dependability. Its considerable power storage space ability, long lasting construction, and updated performances make it an outstanding selection to facilitate the shift towards renewable resource sources, maintain grid security, and drive a lasting tomorrow.

Tesla Megapack, as an advanced utility-scale energy storage solution, incorporates sophisticated safety measures and technologies to mitigate potential risks associated with large-scale lithium-ion battery systems. However, like any energy storage system, it is not devoid of safety challenges.

The occurrence at Moss Landing focused around the Elkhorn Battery Energy Storage Facility, a crucial part of California’s energy system focused on boosting grid stability, incorporating renewable resource, and backing the state’s clean power goals. This facility includes a big collection of Tesla Megapacks, developed for storing a big amount of energy and rapidly sending it to the grid.

A Tesla Megapack at the place experienced a fire on September 20, 2022. Safety devices at the facility functioned as created, separating the battery storage from the power grid. Emergency situation -responders took care of the situation efficiently, with firemans utilizing techniques to have the fire within the Megapack and stop it from infecting nearby units.

A defective installment of equipment led to water going into the system, which caused the battery cells to exceedingly warm up and stir up. This was due to an inadequately fitted vent guard that removed a close-by umbrella shutoff, enabling water to get in the Megapack and trigger the cells to get too hot, inevitably bring about a thermal runaway.

The recent occasion underscored the important demand for exact installment methods when it pertains to complex energy storage space systems. The slightest variance in the installment of tools can cause extreme effects, emphasizing the relevance of precise focus to information throughout both the arrangement and inspection stages.

Improved Inspection and Quality Assurance: Implementing strenuous evaluation routines and quality control procedures throughout and after installment to discover and remedy potential issues prior to they bring about safety occurrences.

Enhanced training for installment staff will certainly concentrate on Megapack systems’ information to ensure a complete understanding of the value of appropriately installing each part.

Advanced Monitoring Systems: Upgrading the center’s tracking capabilities to identify early signs of water access or other threats that might cause overheating or fire, paired with automatic closure mechanisms to avoid escalation.

Arranged Maintenance Inspections: Setting up a routine schedule for assessments to recognize indications of damage or possible problems that might compromise the system, such as inspecting the problem of vent guards and umbrella valves.

Improving the emergency situation feedback prepare for the website by integrating understandings got the current event. This includes creating details tactics to attend to similar scenarios, with the objective of protecting staff and decreasing damage to equipment and the nearby environments.

By attending to the root causes of the Moss Landing incident and applying these remedies, operators can considerably minimize the threat of future incidents and improve the total safety and integrity of large battery storage space facilities.