ELECTRIC, WITH AN EDGE

Mounted Transformer is currently widely used in Blockchain mining farms. As we all know, Mounted Transformers are used to move electricity from one circuit to another.

Daelim has many customers purchasing 1500 kva~ 5000 kVA Mounted Transformer. These customers are mainly from Ukraine, Russia, Ecuador, the United States, Canada, Venezuela and other major distribution countries of Blockchain Farm.

DAELIM has a selection of the transformer in its catalog. For over 20 years, the company has become one of the key transformer manufacturers that provide high-quality mounted transformers.

This article will explain Mounted Transformer for you in detail to facilitate your purchase.

1500 kVA Transformer and 2500 kVA Transformer

-We are a 1500 kVA Transformer 2500 kVA manufacturer, including the Distribution, dry-type, Pad-Mounted, and Single-Phase Transformer.

2000 kVA transformer, 3000 kVA transformer

-We are a 2000 kVA ~ 3000 kVA Transformer manufacturer, including the Distribution, dry-type, Pad-Mounted, and Single-Phase Transformer.

A mounted transformer is primarily used in two critical situations. One, you can use it for underground power lines and strategically place it in service drops. Two, you can use it to bring electricity to rural areas.

Correspondingly, the two usages feature the two types of mounted transformer: pad-mounted transformer and pole-mounted transformer.

A pad-mounted transformer is usually placed over a concrete pad.

It is primarily used for underground service and is enclosed in a grounded metal casing.

Since it’s encased, you can place it where it is accessible to the public.

The mounted transformer is highly favorable in a residential setting.

It reduces high voltage, making it viable for power electronics, appliances, and lighting.

One unit can light up a condominium or many houses. Nevertheless, you can still use it at an industrial level.

Correspondingly, you should place this kind of transformer in adherence with specified criteria regarding exterior building walls.

These recommendations are based on insurance industry best practices for placing one of these transformers outdoors.

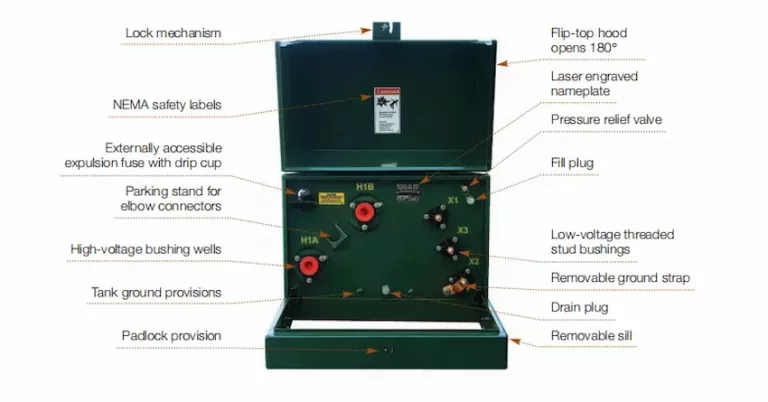

You can see a tamper-resistant design and a bottom entry for primary and secondary cabling inside a pad mounted transformer.

It also has lockable compartments with hinged doors and baffled ventilation holes.

Moreover, they are made within power levels ranging from 75 to 5000 kVa and frequently contain built-in fuses and switches.

A pad-mounted transformer diagram is characterized by a tank for immersing its core and coil assembly in oil.

It has a wire cabinet with high and low-voltage wiring compartments containing the transformer’s high and low-voltage bushings, respectively.

Manufacturers like DAELIM weld a cover on the tank to prevent unwanted access to the core/coil assembly.

Pad-mounted transformers are available in single-phase and three-phase variations.

It is a must that you know how to distinguish the two so you’ll know what you need.

Here are the differences between the two:

A pad-mounted transformer single-phase is a small machine that only has one set of windings.

It is frequently employed to convert long-distance and localized transmission currents into a home and light commercial power levels.

The transformer uses the ‘step-down, step-up’ principle to either increase or decrease the circuits’ voltage levels.

It reduces the voltage from a typical 8,000 volts to 120/240 volts or a secondary voltage.

While conventional pad-mount transformers are fastened to a concrete pad, small single-phase designs today are installed on a ‘polypad’ base.

The new design allows you to mount the machine on hard ground with no hassle.

A three-phase transformer comprises three sets of windings, including primary and secondary ones.

Each set is wrapped around one leg of the core assembly.

Essentially, it appears to be three single-phase transformers sharing a common core.

The transformer is also bigger than the other one in terms of voltage and size.

Under those circumstances, it gets more voltage than a single-pad mounted transformer.

It usually deals with around 13,000 volts and converts it to 120/208 or 277/480 volts.

It is intended for both indoor and outdoor use. You can install it dead-front on a concrete or flat and durable surface.

A pad-mounted transformer with three phases is ideal for apartment complexes, schools, shopping malls, and hospitals.

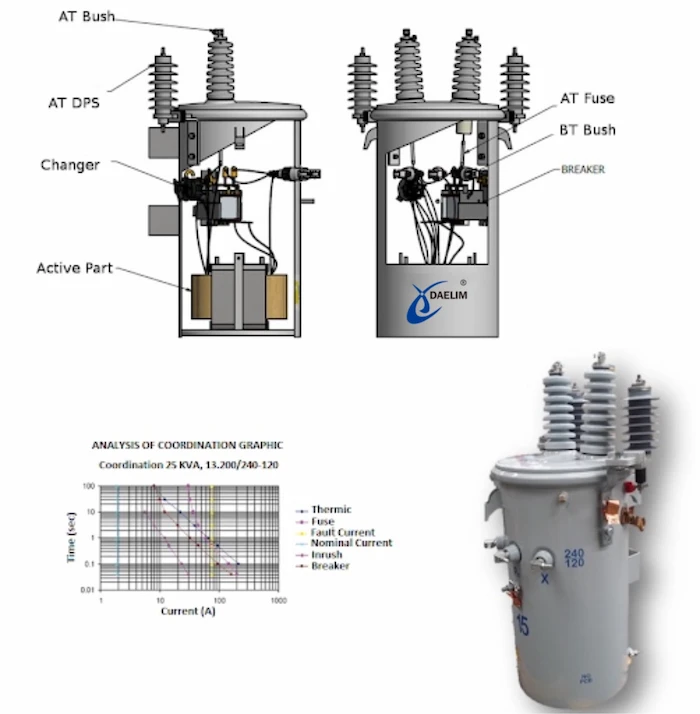

Another type of mounted transformer is the pole-mounted transformer.

It is placed on a wooden or concrete electric service pole.

Most companies put this kind of transformer at the same level as overhead cables.

A pole-mounted transformer is primarily used in sending electricity to most rural areas.

They are also appropriate for industrial lighting, light commercial loads, and other power applications.

Manufacturers like DAELIM noted the reliability and durability of pad-mounted and pole-mounted transformers when faced with extreme weather.

These qualities are more shown in the specification of pole-mounted transformers because they are primarily located in remote places.

Their tanks are designed to prevent the accumulation of water and other corrosive materials.

A pole-mounted transformer is usually cylindrical.

Surge arresters and safety fuse connections are frequently included with pole-mounted transformers.

Aside from those features, it has lifting lugs, bushings, and oil fill plug, and a low-voltage neutral grounding strap.

Some pole-mounted transformers have additional internal fault detectors, wildlife guards, customized tap ranges, and storm tappers.

These transformers range in power from 16 kVA to 100 kVA.

They can convert voltages ranging from 11,000 to 33,000 volts to 400 volts low.

Residents are less likely to be injured when you install transformers on poles.

There is a low possibility that someone will climb up and damage the transformer, injuring themselves.

Like the pad-mounted transformer, this kind also has two types. Here are their differences:

Pole-mounted transformers are usually single-phased.

These transformers are intended for use in electric utility power distribution systems under normal operating conditions.

A single-phase pole-mounted transformer has only one set of windings and works the same as other single-phase transformers.

They are compact and light.

The transformer doesn’t use too much space, and its weight is not detrimental to the pole’s capacity.

Moreover, it has low voltages of 120/240, 240/480, and 277.

On the other hand, a typical single-phase pole-mounted transformer has high voltages of 2,400 to 34,500. The transformer is used in residential and low-usage areas.

Typically, pole-mounted transformers are single-phase.

However, vector designations dictate the number of primary bushings and how the transformers in a three-phase bank can be connected.

A three-phase pole-mounted transformer is usually shaped like a rectangular metal box.

It’s much bigger than a single-phase one because it has more bushings and sets of windings.

With more capacity, it’s typically used in industrial compounds and big farms that use irrigation pumping loads.

A ground-mount transformer is often associated with a pad-mounted transformer. However, the two are quite different.

A ground-mount transformer doesn’t necessarily need a pad underneath.

As long as the place where you will place it is flat, it’s good to go.

A three-phase transformer uses a ‘step-down’ principle that converts high voltage to a lower one.

Ground-mount transformers are primarily used in urban and industrial areas.

A typical transformer is made to last 30 to 50 years. However, different factors determine the lifespan of a transformer.

You should consider the type of weather it’ll be subjected to and the place where you’ll install it.

DAELIM ensures you that its mounted transformers can reach the maximum life expectancy of a transformer.

The secret behind it is they have been following international standards like ANSI, IEEE, IEC, etc.

Like most transformers, a pole-mounted transformer is filled with oil.

For a pole-mounted transformer, most of them are filled with highly refined high-grade mineral oil.

It serves as both electrical insulation and cooling for the transformer’s windings.

A mounted transformer is like any other electrical transformer.

However, it is important to realize that this kind of transformer plays a huge role in the transportation of electricity and regulation of it in rural and urban areas.

If you’re a business owner, mounted transformers substantially improve your business’s ability to use power safely.

Finding the right electrical transformer for your needs might be tough.

Good thing there are manufacturers like Daelim to help you choose.

Daelim ensures that every mounted transformer is made with high-quality materials and adheres to global safety standards.

ELECTRIC, WITH AN ENGE-- DAELIM BELEFIC

After filling in the contact information, you can download the PDF.