ELECTRIC, WITH AN EDGE

The installation of the main transformer in the entire power system is very important.

During the installation of the transformer, the relevant operating requirements should be strictly followed to improve the construction quality of the transformer installation to ensure the stable operation of the transformer and the continuous and safe supply of power.

The installation of the transformer in the entire power system is very important.

The installation of the transformer is not only related to the normal operation of the entire power system, but also related to the subsequent power safety.

Therefore, during the installation of the transformer, it must be operated strictly in accordance with the construction requirements. After the installation is completed, the quality of the entire installation shall be inspected and controlled in time, and the transformers that do not meet the standards shall be removed and replaced in time.

No problems in any process or details are allowed to ensure the durability and safety of the power supply system.

If the installation process of the transformer does not meet the standard operating process, the consequences are very serious.

Not only will it hinder economic development, it may also threaten the personal safety of residents.

Therefore, the stability and safety of the installation and operation of the transformer must be ensured, so as to ensure the smooth and safe operation of the power system, thereby providing a guarantee for improving social benefits.

Transformer installation is an important guarantee for the stability of a regional power system.

Transformer installation is very difficult, with very complicated technology and control standards. During the construction process, a little carelessness will lead to the installation of transformers that do not meet the standards. Therefore, you should be more careful in some places that require special attention. Must be high quality and high standards According to the construction process requirements, the construction is carried out to ensure that the installation of the transformer meets the process and standards.

Otherwise, once there is a problem in a small link, it will cause a series of follow-up chain reactions and paralyze the entire power supply system, which will not only affect the production and life of the society, but also cause a serious waste of social resources.

Therefore, for the installation of transformers, we must improve the control standards and pay great attention to the places that are particularly prone to errors. The following is an analysis of the places that are prone to problems during the installation of the transformer.

Selection and Capacity Calculation of Transformers Used in Substations

First of all, before construction, the length of the transformer steel plate should be determined according to the actual use and installation conditions, and the weight of the transformer can be estimated in advance according to the material of the transformer.

Secondly, the safety of the transformer is also very important, and specific issues should be considered before installation.

In addition to ensuring the safety of the transformer through the construction process and quality control during the installation of the transformer, attention should also be paid to the production process of the transformer itself, whether the materials used meet the standards, and whether the entire transformer meets the quality standards. Before the formal installation, corresponding measures should be taken. After the test is passed, the formal installation can be carried out.

If the test fails, it should be replaced in time.

Again, you should also check the inclination angle of the protection bracket before installation. This is also very important for the stability and safety of the transformer, and it must be accurately confirmed.

Finally, the construction personnel should keep in mind the construction process, and each person should be clear about the work steps carried out by themselves and other personnel to ensure the smooth progress of the construction process and the quality of the transformer installation.

According to the current selection criteria for 500kV substation transformers, it is necessary to predetermine the capacity, transformer, voltage regulation method, and cooling method to understand whether each content meets the specified requirements and standards.

After measuring the performance of the 500kV substation transformer, it is necessary to ensure that the nitrogen pressure value is always maintained at 0.01 ~ 0.03Pa, so that the transformer surface is in a state of no water accumulation for a long time, and the installation can be carried out on the basis of no oil leakage in the insulating oil tank.

In addition, it is necessary to conduct a comprehensive inspection of the entire site environment, including weather conditions, climate conditions and operating conditions, to ensure that the site meets the operating requirements of the 500kV substation transformer.

When determining the corresponding main transformer, ensure that it meets the specific installation conditions, clean the insulating oil in time, and effectively use routers, oil purifiers and other facilities to ensure that the quality of the insulating oil added and the requirements of the transformer meet the corresponding requirements. condition.

In addition, the radiator needs to be cleaned up in time.

Three functions and performance requirements of transformer oil

Regularly clarify whether there are any abnormal noises in the fan relays and oil pumps, and check whether the pressure value fluctuates through the sealing test, and effectively check the sealing effect of the related devices.

When opening the pipeline, it is necessary to inject the processed insulating oil in time to ensure that the insulating oil can submerge the iron core inside the tank, check the high seat, casing and test whether they meet the specific installation requirements, and make corresponding adjustments And analysis.

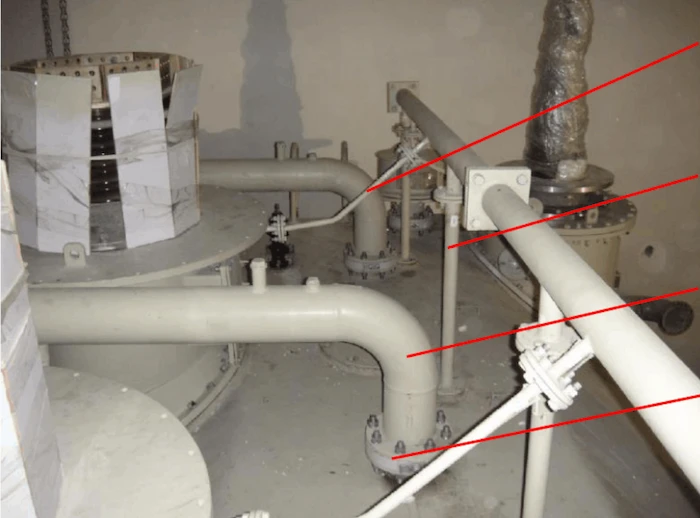

When installing the radiator, it is necessary to check whether the standard of the equipment can meet the specific installation requirements of 500kV substation transformers, effectively meet the basic setting standards of the index, complete the installation of the oil guide pipe according to the drawing, and specify the corresponding cooling bracket, and the cleaning will be completed Make effective connections between the cooling bracket and the oil guide pipes, and make sure that all the pipes are connected correctly.

When installing the casing CT, always pay attention to the wiring installation conditions in different areas. According to the performance of different types of casing, the pressure equalizing ball and the lead are connected comprehensively to ensure that they can be sealed when the conductive tube head is opened, thereby effectively To understand whether there are foreign objects inside.

Finally, it is hoisted in a horizontal position, and the inverted chain is effectively used to slowly and stably lift it up to achieve standardization of operation.

In transformer installation, oil pressure is an important content to ensure the normal operation of 500kV substation transformers.

In the transmission and distribution processing of the device, it is necessary to fully rely on the SF interrupter device and the hydraulic system to complete the closing operation, otherwise, once there is an oil leakage, it is easy to cause the internal oil pressure to decrease, the action error or the equipment refuses to move.

In the lockout protection device, equipment refusal can easily lead to abnormal transmission and distribution. This situation has become an important concern for the operation and maintenance of the main transformer of a 500kV substation.

When solving this type of problem, it is necessary to do a good job of post-precautions to ensure that once an oil leak is found, it can be inspected on site in time. Identify the cause of the oil spill and take targeted measures to solve such problems. Damage to the sealing device can easily cause oil leakage in the equipment.

Generally speaking, the number of people in remote areas is small, and there are many types of animals and plants.

To carry out operation protection work in this situation, it is necessary to timely verify the on-site environment and prevent animals from entering the substation as much as possible.

A humid environment will increase the risk of the main transformer, and it must be dried.

During this period, it is necessary to install moisture-proof devices such as protective fences and protective nets to reduce the indoor humidity and ensure the normal operation of the main transformer.

Safety measures to prevent moisture and air from entering the transformer

The most important thing is the fixation of leverage.

Only when the lever position is fixed and reasonable can the jam be effectively avoided. If the lever position is deviated, it will easily cause the jam of the entire system.

At the same time, it is necessary to frequently lubricate the transformer device. The relevant staff should lubricate the parts of the transformer in time according to the local humidity and climatic conditions, especially the part of the switching device must be paid attention to.

In addition, the integrity of the contact should be checked regularly. In places where friction or turning occurs frequently, the contact often breaks or is damaged.

Once the contact is broken, if it is not handled in time, the entire power supply system will be paralyzed. For this, the relevant departments should send special personnel to conduct regular inspections of the contacts, and report the damaged contacts to their superiors in time. Replace in time.

In addition, it must be operated strictly in accordance with the relevant process standards. For the switching of the order of the components, the installation must be installed in strict accordance with the installation sequence in the manual to ensure that it can be installed in the correct position to play its maximum role and interact with other parts. coordination.

During the trial operation and acceptance work, basic data testing, performance data testing, and insulation testing must be done well.

Ensure the 500kv main transformer load standard requirements.This article mainly analyzes the following aspects:

When using the instrument to test the tap transformation ratio of a 500kV single-phase main transformer, it is necessary to check whether all taps meet the operating requirements of the transformer against the experimental data.

Generally, in the inspection process, the tap transformation ratio can show obvious regular changes, and both sides have clear marks.

When testing the load loss, short-circuit impedance and other functions of the 500kV single-phase main transformer with the help of short-circuit experiments, it is necessary to apply professional instruments and meters to adjust the parameters such as DC resistance.

Effectively analyze the loss and current value on the basis of the no-load test, so as to clarify whether the single main transformer operation index is qualified.

The performance of the system can be effectively evaluated through the methods of insulating oil experiment and insulation resistance detection.

During the movement of the transformer, due to various reasons, such as friction, the corresponding heat will be generated. The installation of the cooling system is very important.

The transformer can be fully cooled to protect the transformer and ensure its normal operation.

First of all, before the installation of the cooling system, the inspection work must be done. It is basically the same as the inspection work of the casing.

In addition, the cooling system also needs to be tightly sealed. Before and after installation, the cooling system’s sealing should be fully checked whether it meets the standards.

Secondly, compared to other systems, the cooling system has more parts, so during the installation process, it is necessary to fully ensure that each component of the cooling system meets the installation location and installation standards.

Finally, it is necessary to ensure that the cooling system is working vertically, and regularly check the cooling system to prevent the cooling system from tilting due to rain, debris, etc.

In the construction of a 500kV substation, the installation of the main transformer is an indispensable installation process, which is related to the overall operation quality and efficiency of the substation.

Therefore, electric power personnel should optimize installation technology and procedures, improve the efficiency and quality of production and operation of electric power enterprises, strengthen inspection and maintenance, and enhance their own sense of responsibility and safety, so as to ensure the safe and stable operation of substations.

In addition, it is necessary to simulate the natural environment and voltage environment of the transformer installation area to ensure the objectivity of the test results, so that the transformer can operate stably in each area, and ensure the stability of the local power supply system.

As mentioned above, the transformer and its auxiliary equipment should be regularly tested and supervised, and the test results should be reported to facilitate subsequent inspection work and ensure its long-term operation.

After the overall installation work is completed, a comprehensive inspection and debugging of the transformer should be carried out. Once any problems are found, they should be dealt with in time. For some problems that cannot be dealt with, the transformer should be replaced in time.

In the process of transformer operation and commissioning, the method of full-voltage impulse closing is mainly adopted.

Generally, 5 times of closing are required, and the first closing time should be less than 10 minutes. In this way, the staff can discover the internal problems of the transformer in time.

After completing this experiment, if there is no abnormality in the operation of the transformer, it is necessary to continue the operation and debugging of the transformer under the half-load state.

At this time, it is necessary to arrange special recorders and special quality monitoring personnel, who can judge the actual situation inside the transformer by the sound of the transformer at this time.

For example, under normal circumstances, the sound of the transformer will increase as the external pressure increases, but the sound at this time is still relatively uniform.

If the inside of the transformer makes noise, it indicates that there is a problem with the installation inside the transformer.

In addition, there will be different sounds such as oil leakage of the transformer and the fracture of some internal parts. These sounds can be used to determine the specific fault location and specific problems.

At the construction site, the transformer must be refilled with oil.

When refilling oil, it is necessary to formulate reasonable measures in time to ensure that all the air in the insulating oil is exhausted and to ensure that it is in a vacuum state.

After the oil filling work is completed, keep the insulating oil in the static state inside the power transformer for about 6-10 hours, then unscrew the bleed valve of the Buchholz relay, and quickly check whether there is air or gas inside. Its emissions.

At the same time, the electric strength test of the transformer oil is also required. After refilling the transformer below 10kV, park it for more than 24 hours before proceeding to the next operation.

①During the transformer handover test, the following specific goals need to be completed:

②When conducting the transformer handover test, it is necessary to strictly implement the regulations and technical standards issued by the local power supply department and relevant management departments.

Among them, the handover test of oil-immersed transformers or dry-type transformers needs to implement the relevant provisions of Chapter 10 in the experimental standards promulgated by the country.

③Know the methods and precautions for testing transformers in advance. Clarify the measurement method of DC resistance, and do a good job in the voltage drop method.

Generally speaking, single-arm bridge and double-arm bridge are more commonly used voltage drop methods.

When the three-phase resistance has been measured, the difference between the resistances will exceed the corresponding standard. At this time, in addition to analyzing whether there is a test error, some other factors need to be considered, otherwise it may cause the test to be inaccurate And inaccurate.

The normal operation of the main transformer affects people’s daily life.

Even if the installation process and quality control standards are very strict, relevant personnel need to complete the installation and commissioning of the transformer with high quality in accordance with the standards, to ensure the normal operation of the transformer, and to provide convenience for people’s production and life.

There are many styles of main transformers on the market. If you find that the existing transformers cannot meet your needs, Daelim can design and produce the main transformers you need. With 15 years of design and production experience, Daelim has cultivated an experienced design team. We can design an efficient and stable main transformer for you.

Download Resource

ELECTRIC, WITH AN ENGE-- DAELIM BELEFIC

After filling in the contact information, you can download the PDF.