How to Choose Pad Mounted Transformer?

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical

ELECTRIC, WITH AN EDGE

Battery storage system plays an important role in smart grid. In recent years, the battery storage system industry in China has developed rapidly and many demonstration projects have been established in the fields of renewable energy grid connection, distributed power generation and microgrid, power transmission and distribution, auxiliary services, and electric vehicle charging and switching. Among the various battery storage technologies, electric storage batteries systems are widely used.

In the engineering design and application of large-scale electric storage batteries systems, the overall cost and maturity of the technology are also crucial factors in addition to the advanced technology. The key technologies of large-scale electric storage batteries systems are studied, including long-life low-cost bess battery technology, high-performance bess battery management technology, bess battery combination application technology, bess battery management technology, and bess battery technology, The key technologies of large-scale electric storage batteries systems are studied, including long-life low-cost bess battery technology, high-performance bess battery management technology, bess battery combination application technology, and multiple topologies of electric storage batteries systems. The current research status, applications, advantages and disadvantages of the different topologies of electric storage batteries system are analyzed and summarized in a comprehensive manner.

Battery storage technology includes pumped storage, electric storage batteries, supercapacitor battery storage system, compressed air battery storage system, flywheel battery storage system, and other topologies. The battery storage technology includes pumped hydro storage, electric storage batteries, supercapacitor battery storage system, compressed air battery storage system, flywheel battery storage system and thermal storage, etc. The electric storage batteries technology is not restricted by geographical environment, and the megawatt battery storage system demonstration project is dominated by electric storage batteries. The electric storage batteries project is dominated by lithium electric storage batteries projects.

The U.S. electric storage batteries research and application occupies a leading position in the world, its battery storage system demonstration projects in the number of applications, installed capacity and applications are in the forefront, the application is mainly focused on ensuring power reliability and providing auxiliary frequency regulation services for the power grid. In recent years, the battery storage system industry in China has developed rapidly and many demonstration projects have been established, involving renewable energy grid connection, distributed generation and microgrid, power transmission and distribution, auxiliary services, electric vehicle charging and switching, etc. The cost of bess battery and electric storage batteries technology limit the further development of electric storage batteries in the grid. The cost of bess battery and electric storage batteries technology limit the further large-scale application of electric storage batteries in the grid.

In terms of technology, the inconsistency and “short board effect” of bess battery limit the scale of bess battery series and parallel connection, which makes it impossible to realize the large-scale application of electric storage batteries through simple electrical connection. On the other hand, in the scenario of scaled-up electric storage batteries, a large number of battery storage systembess batteries are bound to have more significant consistency differences due to different batches, aging characteristics, usage time, operating environment, and even different manufacturers (processes). This in turn poses requirements and challenges for the integrated design of battery energy storage system (BESS).

Currently, the application of electric storage batteries at the equipment level is limited by three factors:

(i)long cycle life and low cost bess battery technology; (ii) high precision and high performance bess battery management technology; and (iii) bess battery combination application technology. These 3 factors influence and restrict each other.

From the perspective of design, product standard, and production time, Daelim’s pad-mounted transformers are a great choice for your battery storage power station for the following reasons:

Compact and Space-Saving: Daelim’s pad-mounted transformers are designed to be compact and space-efficient, making them suitable for installation in confined areas, which is especially important for battery storage power stations where space is often at a premium.

Flexible Configurations: Daelim offers both radial and loop feed configurations, allowing you to choose the best design based on your power station’s specific requirements and circuit type.

Safety Features: The transformers feature sealed high-voltage and low-voltage compartments, ensuring safe operation and reducing the risk of accidents, which is crucial for battery storage power stations where safety is a top priority.

Compliance with International Standards: Daelim’s pad-mounted transformers are manufactured in accordance with international standards such as IEC, ANSI, IEEE, and CSA, ensuring their reliability and consistent performance.

High-Quality Materials: Daelim uses high-quality materials, such as aluminum or copper windings, in the production of their transformers, optimizing efficiency and durability.

Efficient Manufacturing Process: Daelim has a streamlined manufacturing process that ensures timely delivery of their pad-mounted transformers, helping you avoid delays in the commissioning of your battery storage power station.

Customization without Compromise: Despite offering customized solutions for your specific needs, Daelim maintains efficient production times, ensuring that your custom transformer is delivered promptly without sacrificing quality or performance.

In summary, Daelim’s pad-mounted transformers stand out in terms of design, product standard, and production time, making them a suitable choice for battery storage power stations. Their commitment to safety, customization, and adherence to international standards ensures that you receive a reliable and high-performing transformer that meets your specific needs.

Long-life low-cost battery storage systembess battery technology has been the bess battery manufacturers strive to pursue the goal, the current application of large-scale battery storage systembess battery are sodium-sulfur bess battery, vanadium liquid flow bess battery, lead-acid bess battery and lithium bess battery. Sodium-sulfur bess battery and vanadium liquid flow bess battery are typical liquid battery storage systembess battery.

Japan is a leader in the development and application of sodium-sulfur bess battery. In comparison, vanadium liquid flow battery storage systembess battery has lower capacity density and energy conversion efficiency. Lead-acid bess battery and lithium bess battery are solid-state bess batteries, which have no special requirements for the site and are flexible in use. In recent years, lead carbon bess battery has been greatly improved in terms of life and performance. Lithium bess battery is the most widely used battery storage systembess battery, and its unit price has been decreasing with the continuous improvement of process and increase of production in recent years. The high cost of bess battery has limited its application.

The technology of bess battery ladder utilization provides valuable ideas and means to reduce the whole life cost of bess battery. The capacity decay of grid battery storage system is slower than that of conventional driving conditions, and it also follows a linear decay relationship. The use of retired automotive power bess batteries for grid battery storage system conditions can add about 3 years of service time, significantly extending the full life cycle of power bess batteries.

In the case that bess battery cost and cycle life cannot make a revolutionary breakthrough in the short term, bess battery laddering technology extends the service life of bess battery from another perspective, reduces its price/life ratio, and fully exploits the value of bess battery. 2018 National Key R&D Program The “Key Technology for Scale-up Engineering Application of Bess Battery” has supported the research on the secondary utilization of retired power bess battery in the power grid.

The dispersion of bess battery parameters and the short board effect caused by the difference of operating temperature are the key problems that limit the scale application of electric storage batteries. the larger the difference of bess battery units and the more the number of series and parallel connections, the more serious the short board effect.

Therefore, in all operating battery storage system systems, the DC side of each battery storage system power conversion system (PCS) is connected in series and parallel with bess batteries from a single manufacturer. The overall performance of bess battery is ensured by the strict selection and grouping of bess battery consistency by bess battery manufacturers.

Usually the DC side voltage of PCS is high and hundreds of single bess batteries need to be connected in series, so the short board effect is serious. A bess battery management system (BMS) with bess battery equalization capability can effectively reduce the impact of short board effect. For the battery storage system system, the management and control of energy is divided into four levels from bottom to top: bess battery unit, bess battery module, bess battery string and battery storage system system. The management of bess battery monomer is responsible for monitoring and solving the monomer inconsistency problems within the bess battery module;

The management of bess battery modules is responsible for monitoring and solving the inconsistency of bess battery modules within bess battery strings; the management of bess battery strings is responsible for monitoring and solving the inconsistency between bess battery strings connected in parallel. In these three levels, the object to be managed is bess battery, and the monitoring, balancing and SOC estimation of these three levels are all in the scope of bess battery management system. bess battery monomer is connected in series and parallel to form bess battery module.

Many chip manufacturers provide special chips for bess battery module management, which can basically realize the functions of data acquisition, equalization control and data communication. bess battery modules are mostly connected in series and parallel to form bess battery strings. At present, there is a lack of effective monitoring and equalization management means for bess battery modules. A bess battery string or several bess battery strings connected in parallel with battery storage system power conversion system (PCS) constitutes a battery storage system system. Table 1 lists the levels and requirements of bess battery management.

Due to the low voltage and limited capacity of bess batteries, the simplest and most economical solution is to connect bess batteries in series to a higher voltage and expand the capacity in parallel for overall management and control for circuit cost and efficiency reasons.

However, the simple series-parallel circuit does not have the ability to manage and control the bess battery, and cannot avoid the adverse effects of the short board effect of the bess battery. bess battery overall life decreases significantly, while the voltage increases after series connection and the internal resistance decreases after parallel connection, making the safety of the bess battery system greatly reduced. Therefore, the simple combination of series and parallel connection is not suitable for the large-scale application of bess battery.

Parallel connection of several or more bess batteries via DC/DC, parallel connection of battery storage systemPCS AC side, series connection of battery storage systemPCS AC side (i.e. cascade) are all forms of bess battery combination applications. In practice, there may also be a combination of these forms. In principle, only the combined application of bess battery realized by using power electronics topology has the ability to control bess battery, which makes it possible to differentiate control, manage and eliminate the short board effect of bess battery. In this sense, the topology of battery storage system PCS determines the combination of bess battery applications to a certain extent.

In battery energy storage system bess, PCS realizes the bi-directional flow of energy between battery storage system system and grid, and its performance directly affects the electrical performance of battery storage system. The topology of PCS is the topology of electric storage batteries system, which directly determines the electrical structure and integration method of battery energy storage system bess. Under the current constraints of power device performance and bess battery characteristics, different topologies can achieve different ranges of electric storage batteries system capacity levels. electric storage batteries applications, the use of circuit topology modularity to reduce bess batteries directly in series and parallel, thus refining the granularity of bess battery management and power control, which reduces the difficulty of bess battery screening and grouping on the one hand, and increases the means of bess battery management and control on the other.

In terms of the number of power levels, PCS has single-level and dual-level; in terms of topology, the current mainstream applications and research focus on two-level, three-level and multi-level structures.

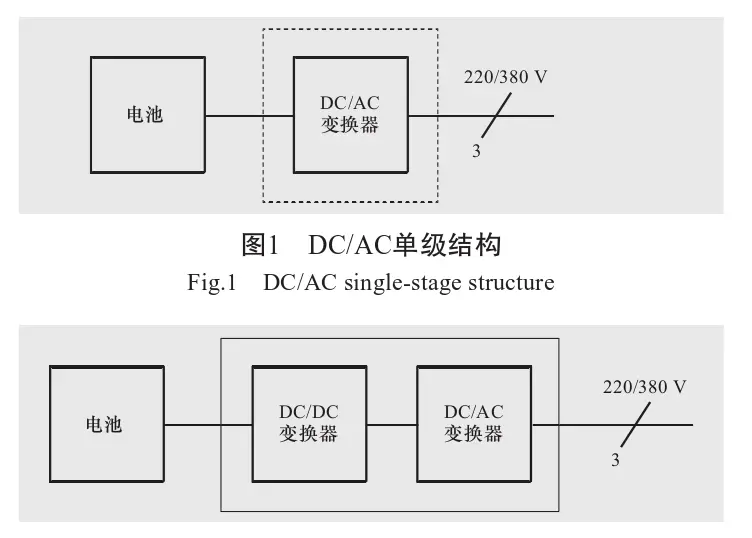

Single-stage PCS connects the bess battery directly to the DC bus end of the power converter, and then connects to the grid after inverting the power converter, the advantage of this structure is simple structure and high efficiency, the disadvantage is that the high outlet voltage of the bess battery group leads to hundreds of bess batteries in series, and the wide voltage range makes the converter modulation ratio optimization design more difficult. The two-stage PCS adopts DC/DC+DC/AC two-stage structure, which has the advantages of lower DC-side voltage, reduced number of series-connected bess batteries, simplified converter modulation ratio design, and high bess battery utilization, and the disadvantage of lower efficiency. At present, PCS topology has various forms, suitable for different power levels and applications`.

At present, two-level single-level and two-level PCS are used in demonstration projects (see Figure 1 and Figure 2 for the structure), in which the single-level type is dominant.

Constrained by the size of the bess battery series connection, two-level battery storage systemPCS DC side voltage 600 ~ 800 V, are used low-voltage grid, mostly for low-voltage 220/380 V occasions. Therefore, the individual capacity is small, from a few kilowatts to megawatts, most of which do not exceed 500 kW. in the need for large-capacity occasions using multiple PCS parallel connection to improve battery storage system system capacity, the use of step-up transformers into the medium-voltage grid. Two-level battery storage system PCS mostly use LCL filtering to improve the quality of grid-connected current while reducing cost and volume, and its control loop is high order and complex to control, which is prone to stability problems when multiple machines are connected in parallel under weak grid.

In order to increase the capacity of battery storage system and improve the power quality, scholars have studied the application of three-level converters in electric storage batteries. The three-level battery storage system converter needs to control the average DC current injected into the DC neutral point to obtain the equalization of the upper and lower bess battery groups. Under the same device conditions, three-level battery storage system converters can obtain higher output voltage and higher capacity than two-level battery storage system converters, and the direct output voltage can reach several kilovolts and the single unit capacity can reach several megawatts, which is suitable for applications with large single unit capacity requirements. At present, the three-level battery storage systemPCS is still in the research stage, and no practical application has been reported.

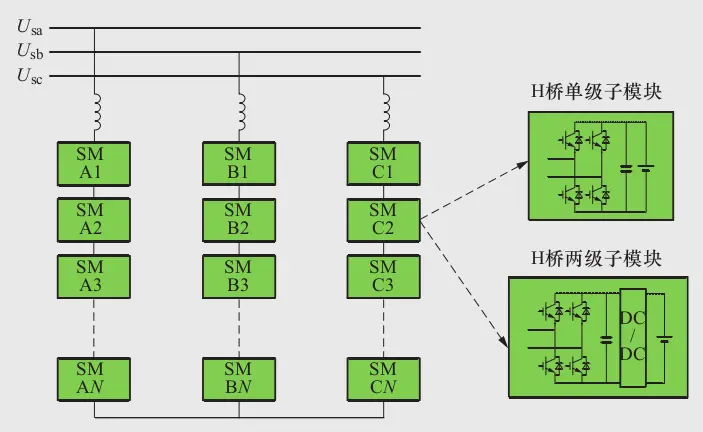

Multilevel PCS is divided into cascaded H bridge (CHB) and modular multilevel converter (MMC), CHB and MMC structure has a high degree of modularity, excellent output characteristics and simple voltage expansion. The PCS based on the above two structures has a granularity of power control as a sub-module, which can promote the ladder utilization of bess battery from the perspective of circuit control. Bypassing a sub-module in case of its failure can achieve redundant fault-tolerant operation. By differential control of different sub-modules, the structure can also realize intra-phase equalization and inter-phase equalization of the BESS.

Japanese scholars studied the CHB topology applied to electric storage batteries in 2008 and built a laboratory validation system of 200 V/10 kW/3.6 kWh to verify the power control and intra-phase and inter-phase equalization control . the CHB-BESS topology is shown in Figure 3.

Based on this, a 500 kW/1.5 kV cascaded H bridge based battery energy storage batteries system (CHB-BESS) was further realized in 2014, which is a three-phase star The CHB-BESS is a three-phase star-connected system with six sub-modules per phase, connected to the grid via a 1.5 kV/6.6 kV step-up transformer. Its CHB-BESS uses PCS and battery storage systembess battery arranged centrally respectively, and its PCS of CHB structure is shown in Figure 4.

CHB-BESS has no common DC bus, so it can only be applied to AC grid. Many scholars have conducted research on CHB-BESS.

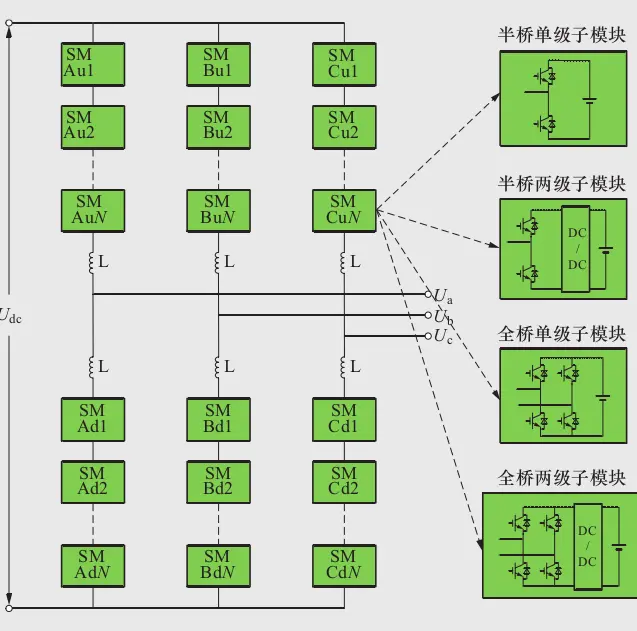

Modular multilevel converter based battery energy storage system (MMC-BESS) is a promising topology in scaled-up electric storage batteries. It is a very promising topology for scaled-up electric storage batteries, and is currently being studied in conjunction with battery storage system for solar power access, as battery storage power station energy buffer for electric vehicle charging and traction system, etc.

MMC-BESS has two types of bess battery arrangement: centralized arrangement in common DC bus and decentralized arrangement in sub-module. By combining MMC-BESS with battery storage system for solar, the distributed battery storage system for solar is connected to the DC side of the MMC submodule, and the battery storage system is centralized on the common DC bus. The simulation results show that the MMC decentralized battery storage systembess battery has the best efficiency and the CHB-BESS has the best efficiency. The simulation results show that the MMC decentralized battery storage systembess battery has the best efficiency, the CHB-BESS has the second best efficiency, and the MMC centralized battery storage systembess battery on the common DC bus has the lowest efficiency.

According to the power flow direction, MMC-BESS has 12 different operation modes, which is much more complicated than MMC-HVDC, and its control strategy needs to be studied in detail. Figure 6 shows the topology of MMC-BESS with decentralized access to battery storage systembess battery.

Since each sub-module in the MMC structure is controllable, the granularity of the MMC-BESS power control of the bess battery is a sub-module.

MMC-BESS, as a combination of MMC and electric storage batteries, although it is the same modular multilevel structure as flexible DC transmission and has many similarities with MMC in terms of technology, its submodule circuit structure is different, the number of modules differs greatly, and the modulation method, submodule equalization, submodule control, main circuit voltage level and parameter design There are special features in the modulation method, submodule equalization, submodule control, main circuit voltage level and parameter design, etc.

The power control, module equalization, bridge arm equalization, phase equalization and equalization gain limitation of MMC-BESS are theoretically analyzed and simulated, and the equalization control principle used is the same as that of CHB-BESS. The modulation, power control, bess battery equalization and redundancy control of the two-stage MMC-BESS are investigated.

Its equalization function is realized by using the redundancy function of submodules, specifically: the submodule with the largest SOC is redundantly withdrawn from charging, and the submodule with the smallest SOC is redundantly withdrawn from discharging, thus realizing the equalization of SOC.

The modulation, phase-to-phase equalization, and power control strategies of the MMC-BESS are studied, and the phase-to-phase equalization is achieved by using the loop control of the common DC bus.

The battery storage system for solar module is connected to the dc terminal of MMC-BESS, and the dc port is operated with variable voltage to achieve the maximum power tracking of the battery storage system for solar power generation, and the battery storage system for solar power generation and bess battery charging can be realized by one level of power conversion. The DC port is operated with variable voltage to achieve the maximum power tracking of battery storage system for solar power generation.

Like the H-bridge cascade-based battery storage system system, the MMC structure battery storage system system PCS control granularity is one battery storage system module. When applied to low and medium voltage microgrids/distribution networks, by increasing the number of modules per phase, the voltage level of a single module can be reduced to less than 100 V, or even 48 V, 36 V or 24 V.

The reduction of module voltage increases the granularity of bess battery management and reduces the stress on the bess battery management system. In such low voltage situations within the module, power MOSFETs have an advantage over IGBTs in terms of efficiency. Due to the reduced voltage of the individual modules and the reduced power of the modules, the efficiency of the battery storage system system can be further improved by using soft switching technology.

Since the direct series-parallel connection of bess battery is avoided and the difference of bess battery characteristics is isolated in the form of modules, even if different types of bess battery are used in each module, as long as they are supplemented with a suitable and perfect bess battery management system, even different bess battery capacities can be used in the MMC structure of the battery storage system. Even if different types of bess batteries are used in each module, even bess batteries with different capacities can be mixed in the MMC structured battery storage system as long as they are complemented by a suitable and perfect bess battery management system.

In the engineering design and application of large-scale electric storage batteries system, the choice of technology route, in addition to considering the advanced technology, the overall cost and technology maturity are also crucial factors. Reasonable bess battery laddering can effectively reduce the whole life cycle cost of bess battery, which is beneficial to the application of electric storage batteries.

The topology of electric storage batteries system determines the electrical scale and performance of electric storage batteries application. Two-level PCS technology has the highest maturity of single machine, but the capacity of single machine is small, and the stability problem caused by the interaction between PCS in large-scale parallel connection is difficult to solve in a short time.

From the topology characteristics and the application of cascaded H-bridges in related fields, the CHB structure PCS stand-alone capacity can reach 10-20 MW at grid voltage of 10 kV, and 40-50 MW at grid voltage of 35 kV, so few units are required to constitute a large-scale electric storage batteries system.

And because CHB-BESS only needs to use inductive grid connection, the order of single machine control model is low, and the control loop model and coupling of battery storage system station in parallel operation is much lower than that of low voltage parallel connection of small capacity electric storage batteries system, so it is not easy to have stability problems.

MMC-BESS based on the PCS composition of the MMC is still in the initial stage of research, most of the research is referred to the study of MMC-HVDC transplantation. In view of the special characteristics of the operation and control of MMC-BESS and its mode of operation is far more complex than MMC-HVDC, the current research on MMC-BESS is not yet comprehensive.

The common feature of both CHB-BESS and MMC-BESS is that the differences in bess battery characteristics are isolated in the form of modules. When achieving the same capacity, MMC-BESS and CHB-BESS are an order of magnitude lower than the bess battery series-parallel scale of two-level BESS, which greatly reduces the pressure of bess battery equalization while refining bess battery management. Conversely, the MMC-BESS and CHB-BESS can achieve an order of magnitude higher capacity than the two-level BESS at the same bess battery series-parallel scale. Thanks to the modular topology with relatively independent power control capability for each sub-module, it is possible to use different steps and different types of bess batteries in each sub-module.

Download Resource

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical

The primary function of the pad mounted transformer is to serve as a critical distribution

A pad mounted transformer operates through electromagnetic induction, serving as a crucial distribution component that