ELECTRIC, WITH AN EDGE

Are you worried about the failure of the dry-type transformer you bought?

This article will give you a detailed description of the common faults and treatment methods of dry-type transformers.

Common faults of dry-type transformers include: core overheating, abnormal noise (internal and external).

Failure to solve these faults in time will result in a significant reduction in the service life of dry-type transformers.

At the same time, this article will also cite specific cases and data to analyze the iron core overheating problem.

Daelim is a professional dry-type transformer production plant. Has 15 years of design and production experience. The solution of these dry-type transformers is a summary made by daelim engineers.

If you have other questions, you can also tell daelim. Daelim will provide you with professional answers.

Three Phase Epoxy-resin Dry Type Distribution Transformer Manufacturer

-If you’re looking for a professional Epoxy-resin Three Phase Dry Type Distribution Transformer Manufacturer, Daelim can be your best supplier.

Dry-type Transformer Model List

-What are the models of dry-type transformers, the product models of dry-type transformers and their alphabetical order and meaning.

Detailed explanation of the difference between dry-type transformers and oil-immersed transformers

-This article will compare the difference between dry-type transformers and oil-immersed transformers in terms of price, model, application.

Taking power plant A as an example, the power plant’s dry-type transformer 24B (parameters shown in Table 1) was put into operation in April 2019.

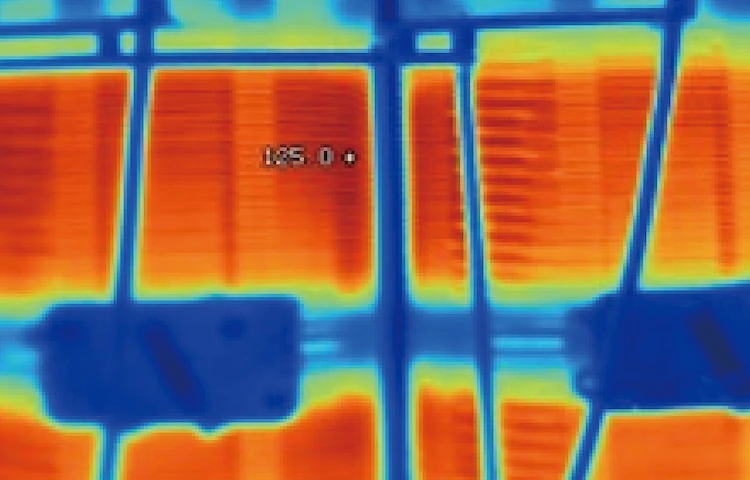

In April 2020, during infrared inspection, it was found that the transformer core was overheated. At that time, the maximum temperature of the core reached 111 ℃.

In order to understand the temperature change of the iron core in time, infrared tracking monitoring is adopted.

In October 2021, the infrared detection data (Table 2) was retrieved, and the data showed that the maximum temperature of the iron core reached 137 ℃.

After a power outage inspection, it was found that the insulating paint on the surface of the iron core was cracked and even fell off .

model | SC9-4000/35/10 | Connection group number | Yd11 |

Rated Capacity | 4 000 k VA | Insulation class | F |

frequency | 50 Hz | cooling method | AN/AF |

Phase | 3 | Insulation level | LI170 AC70/LI75 AC35 |

Primary side | Gear | Rated voltage /V | Current /AA |

| 1 | 36 750 | 70 |

| 2 | 35 870 |

|

| 3 | 35 000 |

|

| 4 | 34 130 |

|

| 5 | 33 250 |

|

Secondary side |

| 10 000 | 243 |

Time | Reference temperature /℃ | Temperature rise /℃ | Measuring part | Measuring temperature /℃ |

April 2020 | 25 | 86 | Transformer core | 111 |

Jun-20 | 30 | 88 | Transformer core | 118 |

Aug-20 | 29 | 91 | Transformer core | 120 |

Oct-20 | 17 | 96 | Transformer core | 113 |

Dec-20 | 26 | 97 | Transformer core | 123 |

Feb-21 | 31 | 100 | Transformer core | 131 |

April 2021 | 28 | 101 | Transformer core | 129 |

Jun-21 | 16 | 104 | Transformer core | 120 |

Aug-21 | 31 | 106 | Transformer core | 137 |

Oct-21 | 30 | 106 | Transformer core | 136 |

(1) The iron core is overheated due to the frictional heat generated by the long-term operation of the transformer.

(2) The quality of silicon steel sheets is also one of the reasons for the overheating of the iron core.

Inferior silicon steel sheets will increase the work done by the transformer in working conditions, and excessive friction will cause the iron core to overheat.

(3) The radiator fails and the transformer cannot dissipate heat normally when the transformer is doing work, causing the iron core to overheat.

(4) The rated voltage of the transformer will be set during the design operation. If the voltage is too large in actual operation, it will cause the iron core to overheat.

Investigate based on the above reasons that may cause the iron core to overheat.

After inspection, the power plant’s dry-type transformer 24B carries only 75% of the rated load, and there is no overload operation;

In response to the dry-type transformer material issue, the silicon steel sheet manufacturer was consulted, and the results showed that the silicon steel sheet of this batch was produced in strict accordance with the dry-type transformer production requirements, and the material quality level was high;

Then the transformer radiator was checked, and it was found that the radiator was operating normally and there was no abnormal operation of the radiator;

Finally, the nameplate of the dry-type transformer was checked, and it showed that the rated voltage of the transformer was 36 750 V, but during the operation of the power plant, the transformer was actually operating at a minimum voltage of 37 000 V.

Severely exceeding the rated voltage, resulting in increased saturation of the transformer core and increased core loss.

This will cause the iron core to overheat and affect the service life of the dry-type transformer.

The cause of overheating of the dry-type transformer core is that the actual operating voltage of the transformer exceeds the rated voltage.

In response to this problem, the power plant should initiate a spare parts procurement plan to purchase the required spare parts in a timely manner.

Fully consider the maximum voltage in the actual operation of the power plant, and redesign the rated voltage of the dry-type transformer.

After trial operation for a period of time, use infrared continuous tracking and monitoring to observe whether the iron core temperature is at a normal level.

Abnormal sound is one of the common faults in the operation of dry-type transformers.

As the work time of the transformer increases and the work intensity increases, the transformer will inevitably be overloaded, causing it to be in a state of fatigue during operation and make abnormal noises.

According to different degrees of damage to different parts of the transformer, the transformer will also emit different sounds.

Taking the power system of Power Plant A as an example, the maintenance personnel heard various sound states when the transformer was working while inspecting the operation of the transformer, indicating that the transformer was faulty.

The maintenance personnel should first judge the abnormal sound location, and then take corresponding measures based on the abnormal sound location.

According to the above reasons that can cause the internal sound of the dry-type transformer to be investigated one by one, it was finally found that the power plant’s dry-type transformer tap was loose and was not found in time, resulting in abnormal internal sound of the transformer.

Maintenance workers should take their own safety protection measures first, and check the connection of the tap gear and the safety status of the resistance after power failure, and then deal with it appropriately according to the inspection results.

In addition to the abnormal internal sound of the transformer, there will also be abnormal external sound.

This requires maintenance personnel to calmly respond when judging the abnormal sound of the transformer, and first determine the abnormal sound location. If the external sound is abnormal, the cause should be analyzed from the following perspectives:

(1) The transformer runs for a long time, “fatigue” does work, and overloads operation, which makes the transformer bear excessive pressure during operation, and then produces abnormal sound.

(2) The actual operating voltage of the dry-type transformer does not match the rated voltage. If the actual operating voltage is too high, it is easy to overexcite the transformer, causing the transformer to operate abnormally, causing abnormal external sound and shortening the service life of the transformer.

(3) Loss of phase operation, this is a problem that often occurs in the working state of the transformer, it will cause the transformer to appear over-excitation, and make the transformer emit a very sharp sound under the normal working state.

(4) Short-circuit or grounding on the low-voltage side causes abnormal sound on the outside of the transformer.

(5) The floating potential does not affect the operation of the transformer, but it will cause abnormal sound when the transformer is working (in this power system, all parts of the transformer, including bolts, pull plates, etc., are sprayed with paint, which affects the performance of the parts to a certain extent. The contact between the two is affected by the leakage magnetic field, which can easily lead to the floating potential of the transformer).

(6)Transformer resonance. Maintenance personnel should check the installation position of the transformer.

If the installation position of the transformer is not standardized, such as the floor of the transformer installation site being too thin, resonance will occur due to the hollow drum of the transformer installation site, and noise will occur.

(1) Adjust the operating load of the dry-type transformer, and appropriately reduce the operating load of the transformer according to the transformer’s rated voltage.

(2) According to the power consumption of the power plant, appropriately adjust the operating voltage of the transformer.

Use a multimeter to measure the low-voltage side voltage data, observe the low-voltage side voltage output, and compare with the rated voltage of the dry-type transformer.

If the output voltage of the low-voltage side is higher than the rated voltage of the transformer, it means that the transformer has over-excitation phenomenon, causing abnormal external sound.

The maintenance personnel should eliminate the overexcitation phenomenon by increasing the tapping position and restore the normal external sound.

At the same time, the actual voltage of the transformer is adjusted according to the rated voltage of the transformer.

(3) For the transformer operating under phase loss, use a multimeter to measure whether the voltage output values of the low-voltage side of the transformer are within the normal range.

If the voltage output value does not meet the requirements, the maintenance personnel should immediately cut off the power and check to see if the power circuit on the high-voltage side of the transformer is disconnected.

Then take the correct response measures according to the specific situation.

If the power circuit on the high voltage side of the transformer is disconnected, the maintenance personnel should immediately replace the wires to restore the normal operation of the transformer.

(4) Check the voltage on the low-voltage side of the transformer, solve the short-circuit problem, and adjust the grounding state according to the status of the low-voltage side loop.

Affected by the paint on the surface of the transformer parts, as the working time of the transformer increases, there will be varying degrees of looseness between the parts, which makes the parts of the transformer poorly contacted and generates a floating potential.

The maintenance personnel can use a scraper to scrape the paint off the transformer parts to ensure that the transformer parts are in good contact and eliminate the floating potential.

(5) For the transformer resonance phenomenon, one is to check whether the transformer steel plate is loose.

If there is any looseness, you need to tighten the housing screws. If the transformer housing steel plate is accidentally stepped on and deformed during installation, the deformed part can be adjusted appropriately during the maintenance process;

The second is to check whether the fans are loose or not, take reasonable countermeasures according to the site conditions, and help restore the operation of the fans by tightening the fan bolts.

If the transformer resonates due to the looseness of other parts of the transformer, the corresponding parts need to be tightened.

Strictly follow the transformer installation specifications and install the transformer in a suitable location.

The installation and maintenance should be carried out according to the manufacturer’s technical requirements. If the manufacturer has related maintenance requirements for special parts, the corresponding signs should be affixed to indicate the situation.

Some large-scale event venues have higher requirements on the power system. To avoid power system failures, it is very important to arrange power system maintenance personnel to regularly inspect and repair transformers.

The maintenance schedule should be formulated according to different environmental conditions in large-scale event venues.

For sites with a small flow of people and a cleaner overall environment, the transformer can be inspected once a year;

For sites with a large flow of people and a dirty environment, it is recommended to inspect the transformer every three to six months.

The firmware inspection is very necessary, at least once a year, the inspection contents include:

(1) Check all parts of the dry-type transformer and tighten them regularly. If the threads appear slippery, they should be replaced in time;

(2) Considering the easy corrosion of metal parts, the metal parts of dry-type transformers should be inspected regularly, and the corroded parts should be replaced in time;

(3) Check the insulator, check whether the insulating material on the surface of the insulator has fallen off, and replace the aging insulating parts in time to ensure electrical safety and prevent electric shock accidents.

Dry-type transformers are widely used in power systems in various places and have the advantages of convenient maintenance and good fire resistance.

However, improper selection or improper use of dry-type transformers will not only affect the service life of the transformer itself, but also have a great impact on the entire power system.

This paper analyzes the common faults of dry-type transformers in Power Plant A and the causes of transformer faults, and proposes targeted countermeasures, which are beneficial to promote the normal operation of the power system of the power plant.

If you find that the existing distribution transformer types or power cannot meet your requirements. You can choose to tell Daelim. Daelim has a team that has always had a wealth of design transformers, and can give you a specific design plan in the shortest time.

Daelim’s distribution transformers comply with IEEE, ANSI, CSA, IEC certification, and are used in North America (such as Canada, the United States, Mexico), South America (such as Ecuador, Chile), Europe (such as Spain, Lithuania) and some Asian countries. Daelim even has a professional installation team that can provide you with installation services.

ELECTRIC, WITH AN ENGE-- DAELIM BELEFIC

After filling in the contact information, you can download the PDF.