ELECTRIC, WITH AN EDGE

Mathematical statistics are widely used in all aspects of social life. The statistical results have far-reaching influence as a basis for decision-making or judgment standards. Statistical analysis of the performance data of high Voltag distribution transformers can better understand the current situation of the high Voltage Distribution Transformer industry or provide a reference for related standard systems.

High Voltage Distribution Transformer production enterprises generally show small scale, low concentration, and backward equipment and technology. The overall status of the industry is far from the international advanced level.

With the gradual normalization of large-scale urban construction and urban network transformation, the incremental demand for distribution transformers will gradually stabilize, a large number of inferior enterprises will be eliminated, and the trend of resource concentration to superior enterprises is inevitable.

In recent years, the annual incremental demand for distribution transformers has been very large, and the trend is increasing year by year.

The huge stock of distribution transformers and the huge annual increase show that its loss indicators have a major impact on energy conservation, environmental protection, and carbon emissions. At the same time, because it is widely distributed in densely populated areas such as towns, streets, and blocks, its noise level has an impact on people’s lives. The impact of quality cannot be ignored.

The improvement of the performance level of distribution transformers should depend on the application of new materials, innovative designs, and the improvement of the technological level. It should not only improve the performance level by increasing the material consumption but should formulate reasonable performance index requirements according to the actual situation of the industry.

If the performance index is loose, it may cause the bad consequences of bad money driving out good money, which will cause resistance to the healthy development of the industry;

If the performance index requirements are too high and deviate from the overall level of the industry, it will increase manufacturing costs.

At the same time, it causes material waste, and even an inverted input-output ratio, which affects the enthusiasm of enterprises.

The performance index requirements of distribution transformers are clearly stipulated in relevant standards and revised from time to time according to changes in the situation to standardize the sound development of the high Voltage Distribution Transformer industry.

The products involved in this article come from a wide range of sources, mainly for products submitted for inspection by manufacturers or for random inspection by power companies, which are represented of the high Voltage Distribution Transformer industry.

The product test is completed by an authoritative organization. The technical level of the test personnel, test equipment, and testing instruments are all of the first-class levels, and the test data is true and reliable.

The test method is strictly in accordance with the requirements of GB/T1094.1, IEC 60076 -24:2020, JB/T501, and other standards.

Environmental conditions of the laboratory: There are no large factories and electrical equipment around the laboratory, the power supply voltage is stable, there is no external electromagnetic interference or radiation, and the external noise level is low;

There are heating facilities in the test room in winter and temperature adjustment facilities in summer. The temperature range is 10℃~30℃ for most of the year.

In severe winter or midsummer with a very short duration, the temperature shall not be lower than 5℃ or higher than 35℃;

The relative humidity of the air in the test room is kept below 80% all year round.

Power supply and test equipment: The power supply is taken from the substation inside the test room, and the voltage regulating equipment adopts a 500k VA induction voltage regulator to achieve stable voltage regulation;

The three-phase output voltage is approximately symmetrical, and the ratio of the highest phase-to-phase voltage to the lowest phase-to-phase voltage of continuous output is less than 1%;

The output power frequency meets the requirement of 50±1%Hz;

The harmonic content in the voltage waveform can be ignored.

Measuring instruments and equipment: measuring power analyzers, noise measuring instruments, voltage transformers, and current transformers are regularly verified or calibrated by the professional metrology department. The measurement system is in accordance with GB/T19001, GB/T16927, GB/T13499, and other standards. Periodic comparison or calibration to ensure the accuracy and traceability of the measurement data.

The test personnel have passed strict professional training and are qualified to work with certificates.

IEC 60076 -24:2020: Specification of voltage regulating power transformers

The high Voltage Distribution Transformer samples are taken from some samples submitted for inspection by manufacturers or power companies in the most recent period. They come from different regions, different manufacturers, and different using units. Although the number is limited, they are still representative.

The experiment was completed by the same group of people and the same measurement system to minimize the impact of measurement uncertainty on the data, thereby reducing the impact on the statistical results.

Only the oil-immersed high Voltage Distribution Transformer 200kVA/10/0.4k V specification products are counted. The core structure includes silicon steel planar laminated core, silicon steel three-dimensional wound core, and amorphous alloy core.

The statistical results of no-load loss, load loss, and short-circuit impedance data conform to the law of normal distribution, and the distribution curve presents a bell-jar shape, symmetrical about the average axis.

No-load current and sound power level due to insufficient data effective bits and a small number of samples, resulting in the measurement results mainly concentrated in a few discrete values, and the statistics of the results are relatively simple.

Three-Winding Transformer | Three-Phase Transformer | Daelim

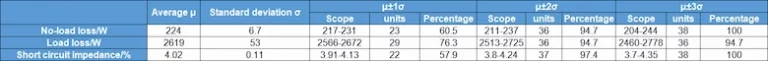

A total of 38 samples of silicon steel planar laminated core distribution transformers are counted, of which the no-load loss value is between 204W~244W, the load loss value is between 2 460W~2 778W, and the short-circuit impedance value is between 3.7% and 4.35%. Statistics The results are shown in Table 1.

No-load current: It is widely distributed from 0.14% to 0.36%, and there are not many repeated figures. This fully shows that the joint of the laminated core has a great influence on the no-load current. Different processes and uncertain factors in the lamination process cause greater uncertainty in the no-load current.

Sound power level: Of these 38 samples, only 32 units have been tested for sound level. The sound power levels are between 43d B and 47d B, of which 43d B accounts for 4 units, accounting for 12.5%; 44d B accounts for 2 units, Accounted for 6.3%; 45d B accounted for 16 units, accounting for 50%; 46d B accounted for 4 units, accounting for 12.5%; 47d B accounted for 6 units, accounting for 18.7%; the sound power level of samples above 80% did not exceed 46d B.

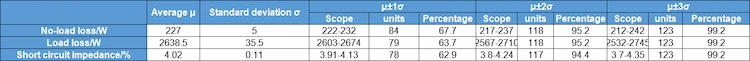

A total of 124 silicon steel three-dimensional wound core high Voltage Distribution Transformer samples are counted, of which the no-load loss value is between 212W and 242W, the load loss value is between 2 532W and 2 745W, and the short-circuit impedance value is between 3.7% and 4.35%. Statistics The results are shown in Table 2.

No-load current: The distribution range is between 0.11% and 0.26%. Because there is no joint between the iron core pieces, the no-load current has a small dispersion and is concentrated in a limited number of values. Among them: 0.11% accounts for 72 units, accounting for 58.1 %; 0.12% accounted for 49 units, accounting for 39.5%; 0.13% had 1 unit, 0.2% and above had 2 units, and the two together accounted for 2.4%, which is in a small probability range. Sound power level: Among the 124 samples, only 85 units have been tested for sound level. The sound power levels are between 43d B and 47d B, of which 43d B accounts for 1 unit, accounting for 1.2%; 44d B accounts for 24 units, Accounting for 28.2%; 45d B accounted for 41 units, accounting for 48.2%; 46d B accounted for 11 units, accounting for 12.9%; 47d B accounted for 8 units, accounting for 9.4%; the sound power level of samples above 90% did not exceed 46d B.

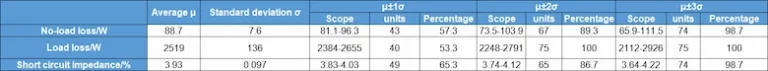

A total of 75 samples of amorphous alloy iron core distribution transformers are counted, of which the no-load loss value is between 65.9W and 111.5W, the load loss value is between 2 112W and 2 926W, and the short-circuit impedance value is between 3.64% and 4.22%. , The statistical results are shown in Table 3.

No-load current: The distribution range is between 0.05% and 0.38%. The no-load current of more than 80% of the samples is less than 0.2%, and the no-load current of only one sample exceeds 0.3%. The no-load current dispersion is likely to be affected by the seams at the openings.

Sound power level: Among the 75 samples, only 60 units have been tested for sound level. The sound power level is distributed between 44d B and 50d B, of which 44d B accounts for 5 units, accounting for 8.3%; 45d B accounts for 21 units , Accounting for 35%; 46d B accounted for 11 units, accounting for 18.3%; 47d B accounted for 12 units, accounting for 20%; 48d B and above accounted for 11 units, accounting for 18.3%; sample sound power level above 80% No more than 47d B.

Due to the small number of samples and other factors, the statistical results in Tables 2 and 3 are different from the normal distribution law, but it is still possible to get a glimpse of the general situation of the high Voltage Distribution Transformer industry.

From the statistical results, for the sample of 200k VA/10/0.4k V oil-immersed silicon steel core distribution transformer, in terms of no-load loss, the no-load loss of the planar laminated core transformer and the three-dimensional wound core transformer are basically the same.

Under the current technological level, the three-dimensional wound core transformer has no obvious advantages in terms of consumption reduction, and there is no need to formulate a separate standard for it. It is more appropriate to classify it as a silicon steel core transformer of ordinary structure;

In terms of sound power level, among the three different core structures, the sound power level of the three-dimensional wound core structure is relatively low and the dispersion is relatively small, and the sound power level of the amorphous alloy iron core transformer structure is relatively high and the dispersion is relatively high. However, overall, the sound power levels of these three types of core structures are not much different.

Standard requirements can be unified; in terms of short-circuit impedance, the dispersion of the short-circuit impedance of the three types of transformers with different core structures is not large, and the short-circuit impedance of 80% of the samples is within the range of 4.0±5%.

To verify whether the distribution changes of other specifications and capacity comply with the above rules, more and more extensive statistical data are needed, and interested colleagues can conduct further research.

The statistical results show that the progress of the high Voltage Distribution Transformer industry is very obvious in recent years.

There are many types of standards related to the performance parameters of distribution transformers. Here, we only consider several types of standards that are generally recognized and widely used in the industry. These standards are compared to the performance parameters of 200k VA/10/0.4k V oil-immersed distribution transformers.

For oil-immersed distribution transformers with 200k VA/10/0.4k V specifications, the results are compared with the statistical results.

The main factor affecting the no-load loss is the material, and the relationship with the core structure transformer is not obvious. From the current industry status, it is more appropriate to define the no-load loss as two types of silicon steel core transformers and amorphous alloy core transformers;

Regarding the sound power level and no-load current, no matter what kind of core can be unified requirements, appropriate recommended values are determined according to the current overall level of the industry to promote and guide the healthy and healthy development of the high Voltage Distribution Transformer industry.

Among the 75 samples of amorphous alloy core transformers in statistics, 10 samples have no-load loss less than 75W, accounting for 13.3%;

There are 59 samples with no-load loss less than 95W, accounting for 78.7%;

There are 74 samples with no-load loss less than 105W, accounting for 98.7%. It is foreseeable that with the continuous improvement of the technical level, there is still a lot of room for the amorphous alloy core high Voltage Distribution Transformer to reduce consumption.

Scientific statistical analysis of the performance data of high Voltage Distribution Transformer products will help to better understand the current situation and development prospects of the high Voltage Distribution Transformer industry.

It has a certain reference value for the preparation (revision) of relevant standards of transformer products, and it is hoped that qualified departments or enterprises can strengthen this work.

If all relevant parties can cooperate with each other to achieve joint data statistics across regions and enterprises, it will be able to more accurately reflect the present and future of the transformer industry.

For oil-immersed distribution transformers with 200k VA/10/0.4k V specifications, based on the above statistical analysis results, the following conclusions are roughly summarized:

If you want to grasp the distribution of the performance parameters of the series products. It is necessary to conduct a large amount of data statistics and analysis on the performance parameters of the series products.

When you need to find more than just existing transformers, Daelim’s Transformer Service Center can help you design and produce distribution transformers that meet your unique needs.

We have our own factory and a professional team of engineers, which can design and modify application requirements that meet all your conditions.

Download Resource

ELECTRIC, WITH AN ENGE-- DAELIM BELEFIC

After filling in the contact information, you can download the PDF.