ELECTRIC, WITH AN EDGE

A 2000 kVA (kilo-Volt-Ampere) transformer is a critical component in electrical power distribution systems. These transformers are designed to handle a high capacity of electrical energy, specifically 2000 kilo-volt-amperes. In essence, a transformer of this capacity functions to modify electrical voltage and current levels, adapting them to the needs of the system it serves. The “kVA” rating indicates the transformer’s apparent power handling capability, encompassing both real and reactive power.

In power distribution systems, 2000 kVA transformers play a pivotal role. They are often employed in medium to large-scale industrial, commercial, and utility applications. These transformers can step down high transmission voltages to lower levels suitable for commercial or industrial use, or vice versa, ensuring efficient transmission and minimizing power loss.

Pofessional Manufacturer of Pad Mounted Transformer Substation Transformer,HV Power Transformer Single Phase Transformer IEEE/ANSI,CSA,DOE,AS/NZS,IEC and etc。standards

2000kva oil-immersed transformer consists of iron core, low voltage coil, high voltage coil, body insulation, high and low voltage leads, voltage regulating switch, oil tank, bushing and other accessories.

The 2000kva oil-immersed transformer adopts a three-phase wound iron core structure, and the iron core material is made of high-quality grain-oriented magnetic silicon steel sheet.

The iron core is manufactured with advanced technology, with low loss and low noise. The structure is fully considered to reduce loss and overexcitation to meet the requirements of heat dissipation and transportation. The grounding of the iron core is led out from the top of the fuel tank by a bushing with a power frequency withstand voltage of 3KV. bottom of the transformer. The insulation material of the body is made of high-quality high-performance high-density cardboard. The high and low voltage leads are made of soft copper, and the oil tank adopts a bell-shaped structure to reduce the factor of oil leakage.

The 2000kva oil-immersed transformer adopts a corrugated oil tank with a fully sealed structure. The top of the oil tank is equipped with high and low voltage bushings, pressure relief devices, oil level indicating devices and gas relays.

The nameplate and temperature indicating device of the 2000kva transformer are installed on the side of the transformer and in the observation position.

A jack device is installed at the bottom of the 2000kva oil-immersed transformer shell, and a horizontal traction device is installed at the lower part to facilitate the movement of the transformer without lifting equipment.

The body, oil tank, cooler and related connection parts of the 2000kva oil-immersed transformer have been tested to ensure no leakage or deformation.

Transformers and metal outer surfaces are treated with anti-corrosion treatment.

The 2000kva dry-type transformers currently on the market are mainly epoxy resin cast dry-type transformers with a rated capacity of 2000kva.

This transformer is cast with a thin layer of epoxy resin for good insulating properties.

And this transformer also has excellent short-circuit resistance and lightning shock resistance.

The shell of the 2000kva dry-type transformer is made of stainless steel, which is safe and reliable, and the protection level reaches IP20. It has excellent mechanical strength and will not deform under the action of short-circuit electric power. Low loss, low temperature rise and high efficiency.

2000kvA dry-type transformers are generally used indoors at an altitude of 1000 meters or less, and can work normally at a high temperature of 40 degrees Celsius.

Due to the safety and reliability of the 2000kvA dry-type transformer, it is directly installed in the docks, power plants, residential areas and other places with large power consumption.

2000 kva pad mounted transformer refers to a pre-installed transformer with a rated capacity of 2000 kva. It integrates transformers, low-voltage electrical equipment and high-voltage equipment into a compact layout.

2000 kva pad mounted transformer has the characteristics of strong complete set, small size, compact structure, energy saving and environmental protection, beautiful appearance, low noise, safe and reliable operation, and movable.

The 2000kva pad mounted transformer is currently the most widely used distribution transformer in the city, and it belongs to a type of oil-immersed transformer. Because of its easy installation, good integrity and convenient maintenance, it is widely used in residential communities, commercial complexes, factories, mines, oil fields and other places.

Here are the key specifications for a 2000 kVA transformer, presented in a tabular format for clarity:

| Specification | Details |

|---|---|

| Voltage Ratings | Primary: Up to 35 kV, Secondary: 208Y/120 to 25000 V (typical) |

| Current Ratings | Primary: Varies with voltage level, Secondary: Based on output voltage and 2000 kVA rating |

| Impedance | Typically 5-7%, impacts voltage regulation and short circuit performance |

| Cooling Methods | Options include oil-filled (standard), dry-type, and forced-air cooling systems |

| Efficiency | High efficiency, typically >98%, low energy loss |

These specifications provide a comprehensive overview of the key features of a 2000 kVA transformer, including voltage and current ratings, impedance, cooling methods, and efficiency considerations. This information is crucial for electrical engineers and professionals in making informed decisions regarding transformer selection and application.

A 2000KVA transformer can carry a load of 1700 kW if it is all electrothermal (resistive) loads.

But if all of them are inductive loads such as motors, they will be discounted by 60%, which is a motor load of 1200 kilowatts.

If there are both, then 30% off (1400KW) or 20% off (1600KW), it depends on which load accounts for more proportion.

In fact, according to the regulations of the Electric Power Bureau, the maximum load is 85% of the full load, which is 1700KVA. Maximum line current is 2586 amps.

Calculate like this: 1700KVA÷380V÷1.732=2.5859446KA=2585.9949A≈2586A≈2600A.

The transformer did not shut down this statement, it should be withdrawn from operation. It can be realized by switching off operation.

The basic principle is to cut off the circuit breakers and isolating switches on the high and low voltage sides of the 2000kva transformer.

To turn off the transformer, it is necessary to power off the upstream of the 2000kva transformer. The upstream high-voltage power supply of the 2000kva transformer has a circuit breaker and a drop insurance.

Stop the low-voltage side load first, and disconnect the low-voltage side circuit breaker. Then stop the high-voltage side power supply of the 2000kva transformer, and pull the high-voltage side circuit breaker to the test or maintenance position.

The input voltage of a 2000 kVA transformer is 380 volts, but the voltage into the transformer needs to be determined according to the voltage of the power supply system, generally 10 kV, 30 kV, etc.

For SF6 circuit breakers, the selection method is the same as that of vacuum circuit breakers, but in power distribution systems, vacuum circuit breakers are mostly used.

1. Select the type of circuit breaker according to the cabinet type of the transformer. For indoor fixed 10KV switchgear, most of them use ZN28 vacuum switch, equipped with a spring operating mechanism, which can be operated by AC, DC electric operation, or manual operation;

For indoor removable 10KV switchgear (such as KYN type), VS1 type vacuum switch can be selected, equipped with a spring integrated operating mechanism, which can be operated by AC, DC electric operation, or manual operation;

2. Select the rated current of the circuit breaker. Generally, there are four types of power distribution circuit breakers: 630A, 1000A, 1250A, and 1600A. You should calculate the load current flowing through the circuit breaker according to the load situation, and then select the rated current after leaving a margin; for a 2000KVA transformer, its Rated current I=2000/(1.732*10)=115.5A, a 630A circuit breaker can be selected initially, but it should also be verified;

3. Verify the breaking current of the selected circuit breaker. Calculate the short-circuit current value of the installation site of the circuit breaker, and compare it with the breaking current value of the circuit breaker initially selected. After leaving a margin, the breaking current value of the circuit breaker should be greater than the maximum short-circuit current value of the installation site, so as to ensure In the event of a short circuit, the circuit breaker can operate reliably and remove the fault without damage to itself. Generally, the rated short-circuit breaking current values of 10KV vacuum circuit breakers are mostly 20KA, 25KA, 31.5KA, 40KA, corresponding to the above 630A, Four rated currents of 1000A, 1250A and 1600A; if the installation site of the 2000KVA transformer is relatively close to the outlet of the substation, and the maximum short-circuit current value is 26KA, then the rated short-circuit breaking current of the 630A switch is 20KA, which cannot meet the requirements of the point of use It is necessary to choose a circuit breaker with a rated current of 1250A and a rated short-circuit breaking current of 31.5KA.

4. Check other cases. Such as phase-to-phase distance, installation size, interlocking situation, whether there is blocking, whether it has an overcurrent coil, whether it has a voltage loss, etc.

If your factory equipment does not work all day, the critical load is very close to the capacity of the transformer, and the load is relatively stable. Then you can choose a 2000Kva transformer.

But if the equipment in your factory needs to be switched on and off every day, the load changes are relatively large, and there are people on duty, then you can consider using two units to run in parallel.

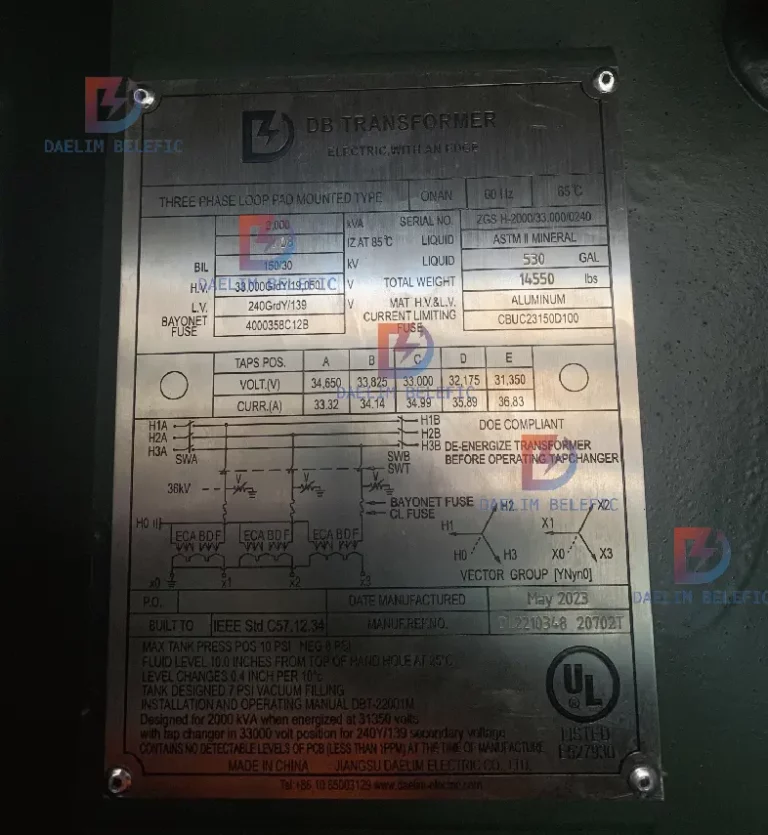

Transformer nameplates provide essential information needed for the safe and efficient operation of the transformer. Understanding the data on these nameplates is crucial for electrical professionals.

| Nameplate Item | Significance |

|---|---|

| Rated Power (kVA) | Transformer’s capacity; here, it’s 2000 kVA |

| Voltage Ratings | Primary and secondary voltages for which the transformer is designed |

| Frequency | Operating frequency, indicating compatibility with the power source |

| Phase | Single or three-phase, dictating the type of electrical system |

| Impedance (%) | Affects voltage regulation and fault current levels |

| Temperature Rise | Maximum temperature rise above ambient at full load |

| Cooling Method | Method of cooling, crucial for installation environment |

| Insulation Class | Determines the operating temperature range |

In summary, a transformer’s nameplate is a critical reference that contains all necessary data for safe and efficient operation, maintenance, and compliance with electrical standards.

Because the rated capacity of the transformer multiplied by the coefficient = rated current.

Therefore, the primary side current of 10KV/0.4KV, 2000KVA power transformer: I1=2000/(1.732*10)=115.47A,

Secondary side current: I2=2000/(1.732*0.4)=2886.83A.

A 2000 kVA transformer supplies a low-voltage power distribution cabinet. What size universal switch do I use in the low-voltage power distribution cabinet?

If 10KV/0.4KV

Transformer primary side current: 116A Secondary side current: 2880A

The main input circuit breaker selects 3000A-3500A

Can be equipped with three 1000A outlet cabinets.

The main busbar can use 80*8 copper busbar, but it is recommended to use 100*10 copper busbar.

Do you need to make sure that your 2000kva transformer is an oil immersed transformer? Or a dry-type transformer? ,

The requirements for the environment are different between them.

Under normal circumstances, the 2000kva transformer can be below 1000 meters above sea level. If you have special requirements, such as high altitude, frequent lightning activities, wet tropics, dry tropics or areas with severe salt spray, etc. You can negotiate with the manufacturer, generally can meet the requirements.

The no-load loss of a 2000kVA dry-type transformer is 3050W, and the load loss is 14450W. If it runs at full load, the loss per day is multiplied by 24 hours.

Load loss 14450*24H=346800W

No-load loss is 3050W*24H=73200W

The installation requirements of most countries are that the safe installation distance of two 2000kva dry-type transformers is more than 1 meter. The author recommends that you choose a safe distance of more than 1.5 meters.

High pressure to low pressure and ground is greater than 1000 megohms, high pressure to ground, low pressure to ground is also greater than 1000 megohms is qualified.

You can use a 2500 volt megohmmeter to measure.

Since the transformer is a large-capacitance device, the measurement will take a period of time. When the speed reaches 120/MIN or more, the normal operation is more than 30S.

Note: After the measurement, keep its speed until it is separated. Otherwise, it is easy to damage the instrument due to the discharge of the device under test..

If the measurement can meet the above parameters..

Prove the equipment is in good condition!

Yes, unless the power factor COSΦ is less than 0.5, there will be problems! Is the transformer loss will be larger! As long as the power of the equipment below is not greater than the maximum active power that the transformer can output, there is no problem!

According to the conventional power factor of 0.95, a 2000KVA transformer will output 1900KW of active power at full load.

However, the economic operating capacity of the general transformer is about 80% to 85%, so that the loss of the transformer will not be too high, and the service life will be longer!

So as long as the reactive power compensation is in place and the power factor is not lower than 0.85, it can be used!

Download Resource

After filling in the contact information, you can download the PDF.