How to Choose Pad Mounted Transformer?

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical

ELECTRIC, WITH AN EDGE

Discuss the optimization effect of Transformers for the textile industry capacity. Taking the workshop of a cotton spinning enterprise with 50,000 spindles as an example, the unit price of electricity consumption was comprehensively analyzed. On the basis of the operating conditions of the electricity load and the working characteristics of the equipment, the optimization theoretical calculation was carried out by using the demand coefficient method, and the power distribution was reasonably determined. transformer capacity.

On the premise of ensuring safe operation, choose a green energy-saving transformer with a smaller size. After the distribution transformer capacity is optimized, the basic electricity cost can be saved by 324,000 yuan per year. It is considered that the optimized distribution transformer operates safely and stably, and the economic benefits are more obvious.

The transformer capacity of every 10,000 spindles of cotton spinning enterprises is 1000 kVA~1200 kVA, and the transformer capacity of every 10,000 spindles is reduced by 100 kVA. On the basis of saving the initial investment, the annual basic electricity cost can be saved by 36,000 yuan.

The load rate of Transformers for the textile industry is usually designed at 85%, and the load rate is mostly lower than 85% after the actual operation. The main reason is that the demand factor does not match the design, and the selection of the simultaneous utilization factor of the equipment is relatively conservative. In order to save unit power consumption and reduce basic electricity expenses, this study takes the transformer capacity optimization of a 50,000-spindle spinning workshop of a cotton spinning company as a case to introduce the effect before and after the transformation.

Looking to power your textile factory with high-quality and reliable transformers? Look no further than Daelim Belefic! As a leading manufacturer of transformers according to IEC 60076, Daelim Belefic is committed to providing safe and dependable products to its customers.

Our transformers meet minimum performance and quality standards, ensuring smooth and efficient operation of your textile factory. By following the guidelines and requirements specified in IEC 60076, we ensure the safe and reliable performance of our transformers over their lifespan, contributing to the overall stability and reliability of electrical power systems.

Adherence to various international standards, such as IEC 60076, GB 6451, AS NZS 60076, CSAC88-16, ANSI/IEEE C57.12.00, and GOST R 52719, means our transformers meet specific requirements for different regions and countries. You can be confident that our transformers are designed and operated in a safe manner, with various safety aspects such as insulation levels, temperature rise, and overloading covered.

With our transformers powering your textile factory, you can enjoy increased productivity, reduced risk of downtime, and economic benefits. Choose Daelim Belefic for high-quality, safe, and reliable transformers for your textile factory.

At present, the electricity fee implemented by the enterprise is mainly composed of two parts: the basic electricity fee and the electricity cost of electricity: the basic electricity fee is 30 yuan/kVA per month, calculated according to the capacity of the transformer; 0.315 0 yuan/(kW h), flat electricity 0.645 1 yuan/(kW h). The production method of the enterprise is continuous production, and the proportions of peak power, flat power and valley power are basically the same.

The comprehensive power consumption before optimization is 0.7607 yuan/(kW·h), of which the basic electricity fee is 0.0823 yuan/(kW·h), and the electricity cost is 0.6784 yuan/(kW·h). Compared with the electricity cost of 0.0635 yuan/(kW·h), the cost exceeds 0.0188 yuan/(kW·h) (basic electricity price difference). The original design load rate of the spinning workshop is up to 92%, and the basic electricity fee is charged at 30 yuan/kVA per month. The above data show that the reduction of the basic electricity fee in the unit price of electricity per kilowatt-hour can be achieved by increasing the load rate of the transformer.

Transformers for the textile industry had a configuration capacity of 4 500 kVA (1 set of 2 000 kVA + 1 set of 2 500 kVA) before transformation, and the average load rate of transformers was 60% to 70%, which is somewhat different from the load rate of about 85% in the design. The gap causes the no-load loss of the transformer to be too large. If the transformer capacity is too large, it will not only increase the primary investment of equipment, but also increase the operating cost, which will increase the monthly capacity electricity fee and cause unnecessary waste. Choosing an energy-saving transformer with a smaller capacity can reduce the no-load loss of the transformer and reduce the basic electricity bill.

The calculation load of textile enterprises is mainly calculated by the demand coefficient method, so the analysis of various power lighting load characteristics and equipment working characteristics has an important impact on the actual demand coefficient and simultaneous coefficient, and then the transformer capacity can be rationally optimized to achieve the purpose of saving investment and efficient operation.

The medium and low voltage AC power loads in the spinning workshop include lighting loads and power loads, among which power loads include textile host loads, air conditioning and dust removal equipment loads, lighting and auxiliary loads, etc.

The main load of the textile main engine is the load of textile machinery equipment, and the installed capacity of the main equipment is 5077.6 kW. Air-conditioning and dust removal equipment loads are equipped with 7 sets of air-conditioning rooms in total, with a total installed capacity of 1 116 kW; the deep well water pump is 112 kW. According to different lighting areas, the lighting load is divided into work area lighting and office area lighting. The lighting in the working area is generally always on, with a total capacity of 100 kW.

The need coefficient method is used.

When using the requirement coefficient method, firstly, the electrical equipment should be grouped by type, and the electrical equipment of the same type should be grouped into one group, and the equipment capacity Pe of the electrical equipment in this group should be calculated.

For continuous power loads (such as air conditioning units, etc.), the equipment capacity is the rated power marked on the equipment nameplate. The main equipment of the enterprise is continuous working textile equipment, and the capacity of the equipment is the sum of the capacity of the motors of the equipment.

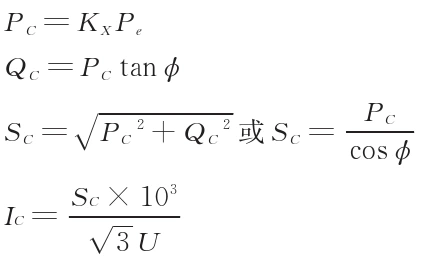

According to the equipment capacity Pe of the electrical equipment group, the calculation load of the equipment can be calculated.

In the formula: KX is the demand coefficient of the equipment group, Pe is the equipment capacity of the equipment group (kW), ϕ is the power factor angle of the electrical equipment, U is the rated line voltage of the electrical equipment (V), and IC is the calculated current (A).

The above formula is suitable for calculating the calculated load of the three-phase electrical equipment group, and the determination of the calculated current is particularly important, because the calculated current is an important basis for selecting the cross-sectional area of the wire and the switching capacity. Single-phase equipment is rarely used in this enterprise and will not be introduced here.

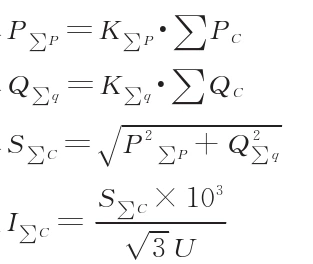

After the electrical equipment is grouped by type, multiple electrical equipment groups are connected to the distribution main line or the low-voltage busbar of the substation. Considering that each electrical equipment group does not run at the maximum load at the same time, the power distribution main line or the substation The calculated load of the power station should be equal to the sum of the calculated loads of each electrical equipment group multiplied by a simultaneous factor.

Among them: K∑P and K∑q are simultaneous coefficients of active power and reactive power, generally taken as 0.80~0.90 and 0.90~0.97;

∑PC is the sum of active power calculation load of each electrical equipment group (kW);

∑QC is the sum of reactive power calculation loads of each electrical equipment group (kVA);

U is the rated line voltage (V) of the electrical equipment.

It should be noted that because the types of each electrical equipment group are different, their power factors are also different. In general, the total apparent calculated load cannot be calculated according to S∑C=P∑P/cosϕ, and the total apparent calculated load or calculated current cannot be the sum of the apparent calculated load or calculated current of each group of electrical equipment Sum.

The demand coefficient is obtained according to statistical methods under certain conditions, and is related to factors such as the working nature of electrical equipment, equipment efficiency, equipment quantity, line efficiency, production organization and process design. These factors are integrated into a coefficient for calculation, that is, the demand coefficient, sometimes called the demand coefficient.

Obviously, in different regions and in different types of buildings, for different groups of electrical equipment, the demand coefficients of electrical loads are also different. In actual engineering, an appropriate value should be selected from the table for load calculation according to the specific situation. Generally speaking, when the number of equipment in the electrical equipment group is large, the demand coefficient should take a smaller value; otherwise, it should take a larger value. When the utilization rate of equipment is high, the demand coefficient should take a larger value; otherwise, it should take a smaller value.

The spinning workshop was equipped with 2 transformers before optimization, 1# transformer with 2 500 kVA and 2# transformer with 2 000 kVA. We used the long-term statistical data as the basis for determining the demand coefficient. The electricity load will not be adjusted.

The 1# transformer is planned to be replaced by a 2 000 kVA energy-saving transformer, and the 2# transformer is planned to be replaced by a 1 600 kVA energy-saving transformer.

The optimized load rate of 1# transformer is 83.70%, which is close to 85% of the economic load; the optimized load rate of 2# transformer is 91.92%, which is 85% higher than the economic load.

Solution: After the transformer is put into operation, according to the actual load conditions, transfer part of the low-voltage load through the connection cable between the 1# transformer and the 2# transformer, so that the load rates of the 1# transformer and the 2# transformer are both about 85%. , the natural power factor cosϕ is 0.85, tanϕ is 0.62, the power factor cosϕ achieved after compensation is 0.92, the total compensation capacity is 450 kVA, the calculated total capacity (including transformer copper loss) is 1 673.99 kVA, a 2 000 kVA transformer is selected, and the transformer load The rate is 83.70%.

The natural power factor cosϕ is 0.85, tanϕ is 0.62, the power factor cosϕ achieved after compensation is 0.93, the total compensation capacity is 400 kVA, the calculated total capacity (including transformer copper loss) is 1 470.87 kVA, a 1 600 kVA transformer is selected, and the transformer load rate 91.92%.

This transformation requires the purchase of a new energy-saving transformer with a capacity of 1600 kVA, with a unit price of 150,000 yuan; the cost of the transformer and low-voltage circuit adjustment project is 50,000 yuan; the 2500 kVA transformer can receive 200,000 yuan after disposal. Based on comprehensive calculations, the Transformers for the textile industry capacity optimization transformation does not require capital investment.

After optimizing the capacity of the 1# transformer and the 2# transformer, the basic electricity fee can be reduced by 324,000 yuan per year, and the unit price of electricity consumption can be reduced by 0.0188 yuan/(kW·h) compared with that before optimization. The economic benefit is obvious. Optimizations can be implemented.

The scheme is technically feasible and has obvious economic benefits, and the company’s production leadership group unanimously agreed to transform it after discussion. The engineering department organized personnel to carry out the implementation. After the transformation, the actual load rate of 1# transformer was 80%~92%, and the actual load rate of 2# transformer was 80%~90%. At present, it has been in stable operation for 5 years, and has saved a total of 1.62 million yuan in basic electricity costs. The economic benefits are obvious, and it is worth popularizing for textile enterprises with relatively stable loads.

Download Resource

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical

The primary function of the pad mounted transformer is to serve as a critical distribution

A pad mounted transformer operates through electromagnetic induction, serving as a crucial distribution component that

After filling in the contact information, you can download the PDF.