ELECTRIC, WITH AN EDGE

Daelim as an Epoxy-resin Three Phase Dry Type Transformer Manufacturer is in line with IEC726、GB/T10228-1997 standards.

It has the characteristics of low loss, compact structure, lightweight, low noise, moisture resistance, high mechanical strength, flame retardant, etc. , Strong overload capacity, low partial discharge quality.

It is suitable for power transmission and distribution systems, especially for heavy load centers and places with special fire protection requirements.

Due to the versatility and benefits Three Phase dry type transformers offer, more and more commercials are considering using it over traditional oil type transformers, which is why choosing the right dry type transformer is just as important as selecting the right manufacturer.

Are you in need of a transformer that performs great in high moisture areas?

Then the Epoxy-resin Dry Type Transformer (E.R.T) is the superior choice, and lucky for you, DAELIM has the best E.R.Ts.

However, it is highly recommended that you understand first what you are purchasing.

This is to prevent any unwanted dangers or hazards that cheap and poorly-made dry type manufacturers bring.

In this article, you will learn how to find the right dry type transformer manufacturer with the professional help of DAELIM.

A Complete Guide to Oil cooled transformer

-Daelim is a professional oil-cooled transformer manufacturer, You can also call it:Oil-type Distribution Transformer, Single Phase Pad Mounted

Three Phase Epoxy-resin Dry Type Distribution Transformer Manufacturer

-If you’re looking for a professional Epoxy-resin Three Phase Dry Type Distribution Transformer Manufacturer, Daelim can be your best supplier.

Selection And Maintenance of 10 kV Dry-type Transformer

-This article analyzes the selection of 10 kV dry-type transformer and further elaborates the maintenance work of the Cast Resin Dry-type Transformer.

The first transformer was made back in 1885 by Ottó Bláthy but it was later on modified by William Stanley in the same year.

And not long after that, the following year, it was commercially used in the United States of America in 1886 with the design invented by William Stanley.

Transformers regulate the electricity of buildings to prevent electrical disruptions for security.

It can be both used to increase and decrease the voltage at the power generating station. This is to mitigate the transmission losses during the transmission.

The increase in voltage is called step up while the decrease in voltage is called step down. With both purposes to supply power to the building.

In other forms of application that consist of different voltages, transformers are of great help because they can adjust the voltage to a compatible level for the appliance to work.

An example of this is that when a specific appliance requires a specific amount of voltage, and when the voltage is not at the right level, it will simply not operate. With the use of a transformer, adjusting the voltage can be easily done. Resulting in a fully functional appliance with the right amount of voltage.

For normal use, a transformer is used to increase the voltage at the power generating station, also known as the step-up transformer. This is to minimize the transmission losses during the transmission of power.

In terms of decreasing the voltage in the distribution level, this is called step-down. The purpose of this is to supply power to the building.

Moreover, there are different appliances that are manufactured with different voltage requirements. In order for the appliance to operate, you need to adjust the voltage to a compatible level.

We can achieve that with the use of a Three Phase Dry Type Transformer. For instance, specific appliances require specific voltages to run, and Transformers are used to adjust voltages to that specific requirement.

Transformers are responsible for the basic components of both transmission and distribution of electricity in a power system. Without a transformer, the absence of it would pose a risk of electrical disruption or uncontrollable voltage that could cause explosion and fire.

One of the main functions of a Three Phase Dry Type Transformer is to regulate the voltage, this is why it is necessary to have one in your building (depending on the size).

To make it not sound confusing, the transformer basically works on the principle of Electromagnetic Mutual Induction (E.M.I).

There are other types of Transformers as well that serve their unique purposes. Should you require more information after this section, we can get you professional help here.

The core type transformer has two limbs, and the windings are contracted on two limbs of the core material.

Core type transformers are usually used as energy transformation, transfer cores, and power grids.

It still serves its main function when it comes to electrical transformer applications, which is to step up transmission and step down transmission.

For its components, the core type transformer has two limbs, and the windings are contracted on two limbs of the core material.

Shell type transformers are commonly used for low voltage applications and in low voltage power circuits including electrical circuits.

For the components of the shell type transformer, its core has three limbs and two windows. Both windings are contracted on the central limb specifically, one over the other.

The arrangements of these windings can also be done with one limb.

Lastly, the spiral core transformer has a similar construction to the wheels of spoke.

There are other types of Transformers as well that serve their unique purposes. Should you require more information after this section, we can get you professional help here.

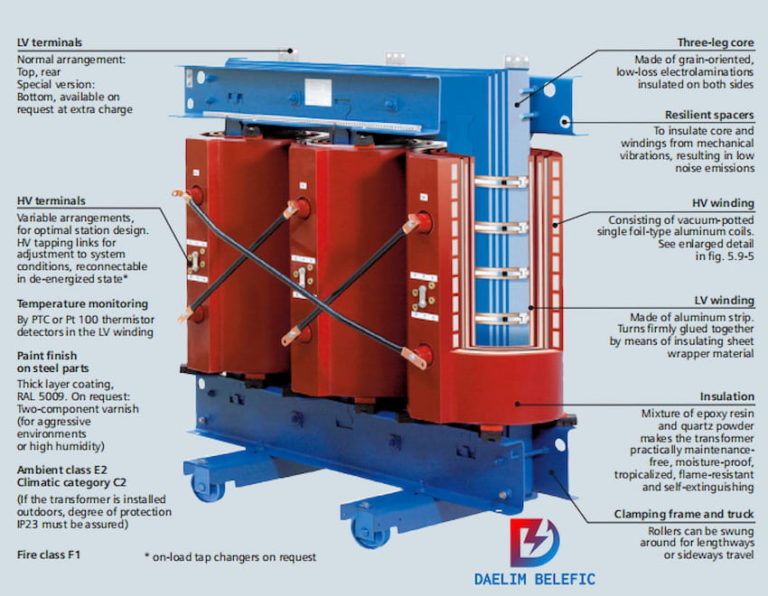

A dry type distribution transformer is a type of transformer that does not depend on any insulating liquid. Unlike other transformers, its core and windings are sealed in a tank with pressurized or forced air inside.

The term “Dry Type” means that the cooling medium for this type of transformer is normal air ventilation. As aforementioned, dry type transformers do not require insulating liquid, oil, or silicone unlike other types of transformers.

This is because dry type transformer is designed to withstand its purposes with only air as its cooling medium.

The term “Dry-Type” is also a reference to its insulation medium which is dry air. The core, windings, and coil are all regulated or insulated by air as opposed to oil or liquid immersion.

Dry-type Encapsulated 3-Phase Distribution Transformerss are transformers that do not depend on any insulating liquid. Unlike other oil type transformers. Its core and windings are sealed in a tank with pressurized or forced air inside.

A dry type transformer like the C.R.T is a classification or type of transformer that never uses any insulating liquid. Its windings and core are kept in a sealed tank that is supplied with a specific amount of pressurized air.

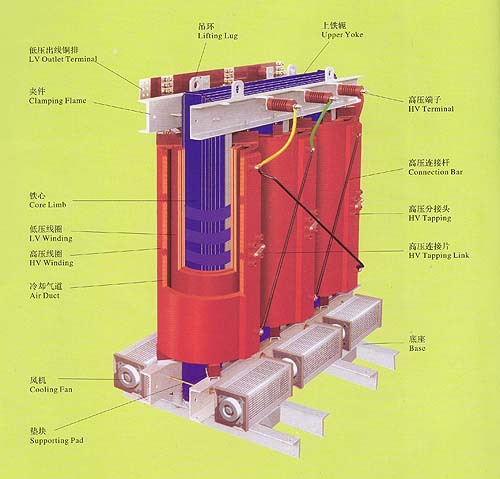

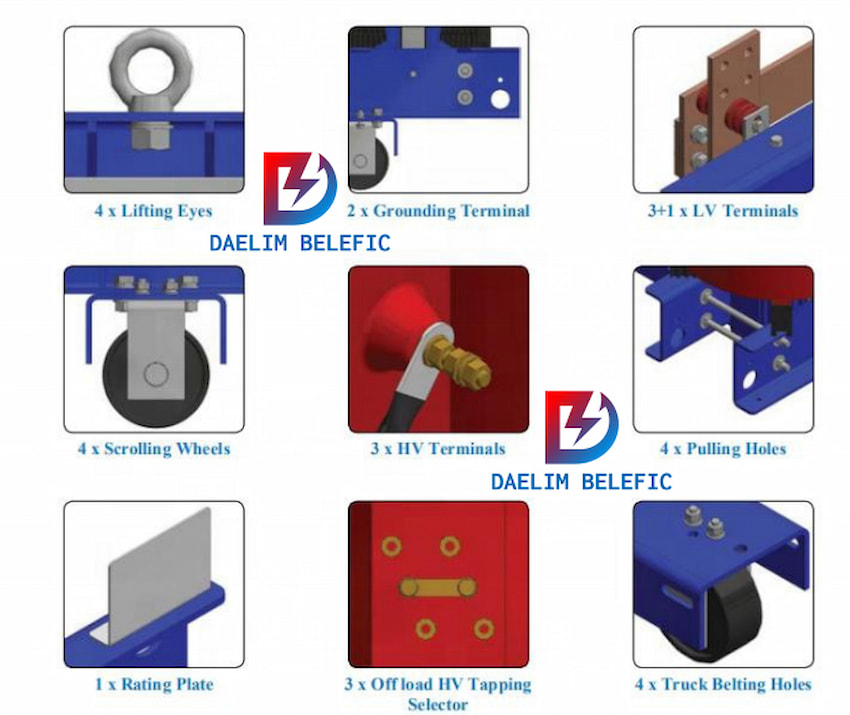

The mechanical properties below are what you commonly hear from others, each part has its own role and is essential for the Dry-type Encapsulated 3-Phase Distribution Transformers to work.

So, it is important for you to learn what each part does so that you will not have a difficult time identifying a specific part when it needs to be fixed or replaced.

The windings in dry-type transformers are often made up of copper or aluminum with a coating of thin insulation that contains higher temperature class and insulation class. This is to give extra durability and longevity.

A static device is a device that converts one form of energy to another without physical movement. For dry type transformers, there are no moving parts in it since it is a static device.

This element is one of the contributors to its low maintenance, which a lot of consumers are interested in.

Three Phase Dry Type Transformers contain a rectangular-shaped soft magnetic laminated core, which is designed to carry both large input and output power transmission.

The purpose of a laminated core is to reduce eddy current and to maximize the permeability for the flux linkage in the secondary winding.

The core in the transformers is composed of laminated sheets of steel, with a little air gap in between them.

The conservator in dry type transformers store additional cooling oil that can be used or recycled after a short period of time. This means that even though dry type transformers do not require oil, they can still be added with liquid insulators.

But since the cooling medium of dry type transformers is air, pressurized air, or forced air only. There is no liquid insulation required.

Breathers absorb moisture content from the air which sucks in while the oil gets expanded or contracted.

Since there is no oil in Dry-type Encapsulated 3-Phase Distribution Transformerss, the air as its cooling medium is already enough to cool the transformer.

The electronic relay or also known as the Buchholz relay is responsible for securing the windings by protecting the windings from overheating.

Overheating has a great possibility of destroying the Dry-type Encapsulated 3-Phase Distribution Transformers and even setting it up in flames or explosion.

Three Phase Dry Type Transformer are the only transformers that perform well in high-moisture areas, and are commonly used for small to medium voltage applications. In terms of utility purposes, they are highly recommended.

The windings in dry transformers are made of copper or aluminum that are sealed in varnish. Yes, there are different variations for your preference.

Depending on your application and the environment of where you plan to place your transformer, DAELIM provides professional help to accommodate your concerns. When it comes to your personal preference, DAELIM offers different variants as well to attain your needs.

These are the common applications for Dry type distribution transformers:

It is very common for chemical industries to use dry type distribution Three Phase Dry Type Transformers as their choice of transformers, because its design is built to be environmentally-friendly and less flammable compared to oil type transformers.

As you know, chemical industries are exposed to dangerous elements and fire hazards, which is why the best choice for them are dry type distribution transformers.

Forests are highly risky because they are prone to fire, which can easily spread out at a very fast rate.

For industries that are near forests or high-risk fire areas, they use dry-type distribution transformers in order to prevent fire.

Dry type distribution transformers are commonly used substations as well as this is more suited for the area because of its safer mechanical components.

Since there are a lot of buildings in residential complexes, the risk of using oil-type transformers is just too high to be applied in residential complexes.

A fire could easily start and could spread easily.

The same goes with villages, as this can also be dangerous for the people living in close distances.

Large buildings are known to always choose dry distribution areas because they prefer an environmentally-friendly transformer around.

When it comes to apartments, dry type distribution transformers do an excellent job at regulating the circuits in apartments, and it is simply more reliable than oil type transformers.

There are plenty of Three Phase Dry Type Transformers out there, and to check which one is best for your project, you can scroll through DAELIM’s list of products.

Here are widely used Dry-type Encapsulated 3-Phase Distribution Transformers that can be found normally in commercials and industries.

Vacuum Pressure Impregnated transformers or V.P.I transformers serve a purpose that is self-explanatory due to their name.

This type of transformer is vacuum pressure impregnated with high-temperature varnish to protect its environment and surroundings.

In the construction process, there are a few dip processes that are added to encapsulate the coil.

Coatings are cured in the oven shortly after.

This Dry-type Encapsulated 3-Phase Distribution Transformer was designed to withstand harsh and high moisture or wet environments.

Cast coil transformers are transformers that have their windings cast in resin.

The cast coil transformer is also known to be the alternative to medium-voltage and liquid-filled transformers such as oil-type transformers.

Cast coil transformers are more environmentally friendly compared.

A resin Dry-type Encapsulated 3-Phase Distribution Transformer does not have insulating liquids immersed in the magnetic circuit and windings.

Rather, they are cast with an epoxy resin mixture that is suited for commercial uses.

As there are two sets of winding, one is called the primary winding and the other one is called secondary winding.

When you energize the primary winding, a magnetic flux is created which is the same flux that links to the secondary winding.

There is no guaranteed safety if you use another type of Dry-type Encapsulated 3-Phase Distribution Transformer for high moisture prone areas.

The C.R.T is specifically designed for that, which is why it is best to choose the safest option rather than a skeptical one.

Not all transformers are dry-type, there are other types of transformers as well that serve different functions.

For Three Phase Dry Type Transformers like the C.R.T, these are power transformers with epoxy resin encased in their windings.

When it comes to the installation process, it is much easier since they do not require cooling oil.

With a lot of similarities in the definition above, Epoxy-resin Three Phase Dry Type Transformer or Epoxy Resin Cast Current Epoxy-resin Dry Type Transformer is a dry type and its internal windings are coated with epoxy resin for its insulation.

This is common in instrument transformers wherein the primary function of it is to step down or decrease the high voltage and currents.

As aforementioned, they are commonly used in high moisture-prone areas but they are also used in buildings and near buildings because Epoxy-resin Dry Type Transformers are environmentally safe.

However, they are flammable but not to the extreme level of other transformer types.

Three Phase Dry Type Transformers can be found in industrial buildings, factories, malls, hospitals, and other commercial areas.

And the list goes on…

Three Phase Epoxy-resin Dry Type Transformer manufacturer designed dry-type transformers in a way that requires little to almost no maintenance at all.

This is one of the many reasons why commercials love Dry-type Encapsulated 3-Phase Distribution Transformers.

But even so, it is important to check once in a while for these few maintenances:

Never do maintenance on your transformer while it is on or when it has energy flowing in it.

This can pose danger to you and your surroundings especially if you have flammables or chemicals nearby,

Accumulation of dust can be a problem if it becomes a pile or in many amounts. Dust can pollute the air inside the tank and it can disrupt the core and windings of the transformer.

So, if your Dry Type Distribution Transformer is in an area that is exposed to dust, then do consider regularly checking or cleaning it every once in a while.

To avoid directly touching the parts, you may use a vacuum or compressed air to do so.

Since the cooling medium of Dry Type Distribution Transformer is air, there should be sufficient exposure to air in where your Dry-type Encapsulated 3-Phase Distribution Transformer is placed.

This is to prevent it from overheating since air is very important for it to cool down.

You can also use forced air or pressured air into the transformer to give it time to cool down.

Dry Type Distribution Transformers are known to be loud, so it cannot be avoided that you hear it every time you pass by, to which you will grow accustomed. This gives you the opportunity to listen to its sound characteristics.

You will be able to tell the difference between a healthy sound against a scrappy one. So, if there is an unusual sound, it is highly recommended that you check it or call for professional help.

Cooling fans easily collects dust, which is why rubbing it off or cleaning it every now and then is a great way to keep your fans clean and the insides of your transformers too.

You have the option to wipe it or better yet, use a vacuum or compressed air to effectively remove dust from your fans.

Although a dry transformer is a static machine, there might be pieces of hardware both inside and outside the Three Phase Dry Type Transformer that are loose, which is why you should look out for that as well.

The filters protect the inner components of the transformer, however, it is prone to be filled up with dust every now and then which is why replacing filters is also essential in maintaining a dry-type transformer’s health condition.

This is to prevent clog and the restriction of airflow that will disrupt the circulation inside the Three Phase Dry Type Transformer.

Discoloration is a sign of an occurring electrical problem that will grow worse overtime if not treated immediately.

Electrical problems can be complicated, and if you are not certain what the problem is, then do not hesitate to call for professional help.

This is simply more than “without them, there would be no transformers”. Dry type transformer manufacturer are highly skilled in what they create and they are responsible for the high-tech design of dry type transformers.

Aside from that, Three Phase Dry Type Distribution Transformer manufacturer prioritizes your safety. Transformers are known to be extremely dangerous if not properly operated, which is why Three Phase Dry Type Transformer manufacturer not only provide you with high-quality dry type transformers but also give you advice and other important information.

For you to be well-informed about the characteristics of dry type transformers, DAELIM created this extensive article about this type of transformer.

And to start, here are the fundamentals.

Dry type transformer manufacturer are difficult to find, especially if you are not well-knowledgeable about the field of transformers.

Which is why we listed you factors that you should consider for choosing the best manufacturer.

If the Manufacturer of the dry transformer you are interested in has years or even decades of experience in the industry, then that is a brilliant starting element.

However, this should not be your only basis as there are still many more factors to consider as well.

Years of experience is a good start, and excellency is its reputation’s last name.

If you are able to see their customer reviews, then that’s great! Because this promotes transparency and better reputation.

Seeing satisfied customers will make you want to be a part of them, and this will help you secure your choice as well.

DAELIM offers countless services for your convenience. manufacturer understand that purchasing transformers is no easy decision, which is why services to help and guide you as a consumer is very important.

Quality should be a prime factor as well because you are dealing with electricity here.

A poorly-made transformer will only do more harm than good. Dry Type Distribution Transformer manufacturers that have quality control are what you should prefer.

This is to keep you and your surroundings safe from low-quality dry transformers that carry danger with it.

Price should be a great determiner for you as well because there are a lot of overpriced dry transformers available in the market out there,

Their quality might be good, but spending too much money is just unnecessary.

The best dry type transformer manufacturer give their customers a fair quote.

Now that oil type transformers are often mentioned, the question that is probably on your mind is: what is it?

There are two types of transformers commonly used in industries which are either oil type transformers or dry type transformers.

Each transformer has its pros and cons, and you will get to know of each thoroughly.

The main difference of both is that dry type distribution transformers have a natural cooling medium which is air.

On the other hand, oil type uses oil and other insulating liquids.

It is important to keep this in mind if you are looking for a transformer with good longevity: Oil filled transformers have a higher energy efficiency which results in higher lifespan than dry type transformers.

Oil type transformers back then were widely used, but when dry type transformers were invented, consumers were starting to shift to it.

But why?

Each transformer has its pros and cons and it serves different aspects as well.

Depending on your personal preference, below are the advantages and disadvantages of both transformers.

The Dry type uses natural air or forced air to cool the core and internal windings.

Whereas, the oil type transformer is dependent on mineral oil for cooling.

Mineral oil exposed to public areas is dangerous since it is highly flammable.

It has been reported that almost 70%-80% of all transformer failures are due to internal winding failures which result in fire or explosion.

It is perfectly safe for the public since its cooling medium is only air.

This is one of the main reasons why consumers choose dry-type transformers over oil-typed transformers.

The dry-type transformer only requires little to almost no maintenance at all. There is no special maintenance needed for its condition to stay pristine. Compared to the oil-type transformer, it does require maintenance and it should be on a regular basis.

Sample oil is regularly taken on at intervals to see whether or not it is contaminated.

Furthermore, once the breather is installed in the transformer, it will require a replacement after a certain amount of time.

The Dry Type Distribution Transformer has more noise than oil type transformers. The noise occurs because of Magnetostriction, due to this, the laminated cores are contracted or disturbed everytime air comes in contact with the magnetic field.

All the steel sheets vibrate which makes the noise. Also, there is also noise coming from the windings and load noise.

Therefore, the noise is more prominent on dry type transformers than of the oil type ones.

Dry-type transformers do well in high moisture areas because of their build design.

They are very easy to maintain as well compared to oil-type transformers.

A lot of consumers are also considering it because of its environmentally-friendly characteristic which is its less-flammable build.

Here are other benefits from dry-type transformers:

DAELIM offers low-cost installation to their dry-type distribution transformers for your convenience.

It is known that installation costs for oil-type transformers can be more expensive but you can contact DAELIM for a better offer.

As you know by now, there is no oil in dry type distribution transformers, this is because its cooling medium is using only pressurized air or forced air.

There is without a doubt that dry-type distributions transformers are durable.

In fact, they are very adaptable to certain environments that oil-type transformers cannot withstand.

They are less flammable, and they do not contain any oil.

This advantage right here is already a purchasing consideration because mineral oil can be expensive.

There is absolutely little to no maintenance for dry-type distribution transformers because of the mechanical properties that make them almost independent of care.

The oil in oil-type transformers is highly flammable.

Whereas, in dry-type distribution transformers there is oil involved.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

So what does this have to do with being a disadvantage? Well, this makes liquid testing unneeded.

You will need technical personnel to clean and regularly check up on it.

Or you can do it yourself but you need to learn it first.

When it comes to the transformer’s windings, there are electric breakdowns between the turns or parts of the windings which is a major issue because chances are, this leads to partial discharges before an electric breakdown.

Yes, dry-type distribution transformers are known to be louder than oil-type transformers.

This is because of the air disturbing the sheets of metal within the transformer, which makes a metal-banging sound.

Oil-type transformers do have a higher standard energy efficiency which gives them longer longevity than Three Phase Dry Type Transformers.

Oil transformers are also known to be less noisy compared to the metal-clanking noise from dry-type transformers its steel components produce.

However, since oil is required for its cooling, oil-type transformers will cost you more since mineral oil can be expensive, depending on where you purchase it.

Not only that, its maintenance is high as well.

There is a lot you should regularly check and clean on oil-type transformers compared to dry-type ones.

When you need to find more than just existing transformers, Daelim’s Transformer Service Center can help you design and produce distribution transformers that meet your unique needs.

We have our own factory and a professional team of engineers, which can design and modify application requirements that meet all your conditions.

Download Resource

After filling in the contact information, you can download the PDF.