ELECTRIC, WITH AN EDGE

1250 kVA Pad mounted transformer is a complete set of power distribution device composed of high-voltage switchgear, power transformer and low-voltage power distribution device combined in one or several boxes according to different wiring methods.

Pad mounted transformer can be used in construction sites, residential quarters, streets, industrial and mining enterprises, airports, ports, etc., for receiving electric energy, transforming voltage, providing power and lighting power supply.

Pad mounted transformer can be installed indoors or outdoors. At present, the most widely used Pad mounted transformer on the market is the Pad mounted transformer with a voltage level of 1250 kva.

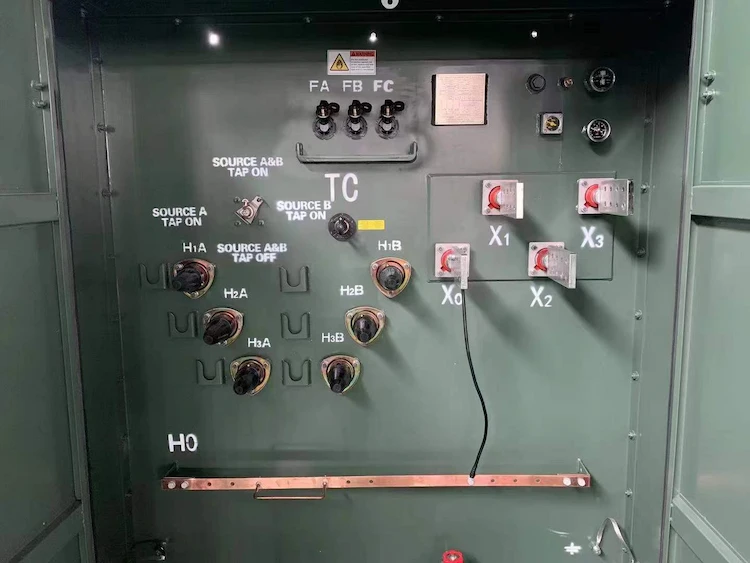

From the structural point of view, the Pad mounted transformer adopts a front-to-back layout, with the front part as the high-pressure chamber and the rear part as the low-pressure chamber.

There are high and low voltage terminals, load switch operating handles, no-load tap changer, plug-in fuse, pressure release valve, oil level gauge, etc. in the high and low pressure rooms.

The rear part is the oil storage tank and the heat sink. The Pad mounted transformer winding and iron core, high voltage load switch and backup protection fuse are installed in a high ignition point oil tank to form an integration.

Pad mounted transformer is a fully sealed structure, using concealed high-strength bolts and oil-resistant nitrile rubber gasket to seal the box cover. The transformer oil in the oil tank is the insulation, heat dissipation and arc extinguishing medium.

The 1250 kva transformer is known for its efficiency and reliability. It is built to last, ensuring that your operations run smoothly without any interruptions. Moreover, it is designed to meet the highest standards of safety, ensuring that your team and your facilities are always protected.

| Rated Power(KVA) | High Voltage(V) | Low Voltage(V) | Loss(W) | |

| No-load Loss(W) | On-load Loss(W) | |||

| 75 kva Transformer | 34500/ 19920 13800/ 7957 13200/ 7620 12470/ or others | 240 480 480Y/ 277 600Y 347 | 180 | 1250 |

| 112.5 kva Transformer | 200 | 1500 | ||

| 150 kva Transformer | 280 | 2200 | ||

| 225 kva Transformer | 400 | 3050 | ||

| 300 kva Transformer | 480 | 3650 | ||

| 500 kva Transformer | 680 | 5100 | ||

| 750 kva Transformer | 980 | 7500 | ||

| 1000 kva Transformer | 1150 | 10300 | ||

| 1500 kva Transformer | 1640 | 14500 | ||

| 2000 kva Transformer | 2160 | 20645 | ||

| 2500 kva Transformer | 2680 | 27786 | ||

| Tachnical Data for Pad Mounted Transformer | |||||

| Rated Power(KVA) | Dimension(mm) | Weight(kg) | |||

| W | D | H | Oil Weight | Total Weight(kg) | |

| 75 kva Transformer | 1390 | 910 | 1430 | 120 | 645 |

| 112.5 kva Transformer | 1420 | 920 | 1430 | 138 | 729 |

| 150 kva Transformer | 1510 | 980 | 1530 | 201 | 989 |

| 225 kva Transformer | 1600 | 1000 | 1660 | 230 | 1195 |

| 300 kva Transformer | 1660 | 1080 | 1680 | 260 | 1415 |

| 500 kva Transformer | 1810 | 1160 | 1790 | 325 | 1905 |

| 750 kva Transformer | 2030 | 1300 | 2030 | 535 | 2755 |

| 1000 kva Transformer | 1651 | 1549 | 1854 | 650 | 3235 |

| 1250 kva Transformer | 2210 | 1470 | 2150 | 748 | 5835 |

| 2000 kva Transformer | 2380 | 1600 | 2220 | 950 | 6430 |

| 2500 kva Transformer | 3070 | 1650 | 2330 | 1020 | 8865 |

The problem of common oil tank between high-voltage electrical components and transformers

Pad mounted transformer generally requires no maintenance for 12 years.

This requires that in such a long operating time, the transformer oil as the insulation, heat dissipation and arc extinguishing medium is not polluted and the insulation performance cannot be reduced below the standard requirements.

Load switches are usually operated under no-load conditions, and arc carbonization is rarely generated at this time.

However, if the load current is switched off or the fault current is switched on, the arc generated will quickly cause the transformation oil to be carbonized and blackened.

After repeated operations, the insulation performance of the transformer oil will be significantly reduced, and in severe cases, the internal flashover breakdown of the transformer will occur.

The heat generated by the Pad mounted transformer during operation generates high oil temperature, which makes it work with other high-voltage electrical components in a high-temperature environment for a long time. The conductive contact surface is easy to oxidize, which reduces the service life of the component.

The temperature rise of the top oil surface of the oil-immersed transformer should not exceed 55°C, and the allowable ambient temperature should not exceed 40°C.

In this way, the highest oil temperature for normal operation of the Pad mounted transformer can reach 95°C.

The reliability of load switches and high-voltage fuses will be reduced if they operate at such high temperatures for a long time.

Pad mounted transformer and high-voltage electrical components are changed from a common box to a separate box.

Put the windings, iron cores and high-voltage electrical components of the Pad mounted transformer into two independent ones and fill them into the transformer tank.

Transformer oil tank (lower oil tank), high-voltage electrical component oil tank (upper oil tank).

The upper and lower fuel tanks are independent of each other and separated by a 90~100mm isolation layer.

The two oil tanks are only electrically connected, the oil circuit is blocked, and the oil medium does not interfere with each other.

In this way, when the load switch breaking current and the fuse are blown due to a fault, the carbonization and deterioration of the transformer oil caused by the arc will not affect the lower tank, and the insulation performance of the lower tank transformer is guaranteed.

At the same time, due to the existence of the isolation layer, the influence of the heat generated during the operation of the lower oil tank transformer on the upper oil tank is reduced, and the temperature rise of the upper oil tank is lower, which ensures a low temperature environment for the operation of high-voltage electrical components and ensures the reliability of operation.

kv is kilovolts. kv is the unit of voltage.

KVA is kilovolt ampere, which is the measurement standard of power.

KVA = KiloVolt-Ampere, formula definition: kVA is the capacity in the transformer, Chinese: kilovolt-ampere.

The guaranteed value of the output capacity of the transformer in the rated state. The unit is expressed in kilovolt-amperes (kVA). The design value of the rated capacity of the primary and secondary windings, etc. It belongs to the physical unit, kilovolt-ampere, and generally refers to the maximum transformation capacity of the transformer.

Volt-Ampere (Volt-Ampere Characteristic Tester of Transformer) is the unit of total power; Watt is the unit of active power;

Total power * efficiency = active power, kVA kVA is the apparent power, which includes active power and reactive power.

Kilowatt kW is the active power. Kilowatt (kW) = kilovolt-ampere (kVA) multiplied by the power factor. The kilovolt-ampere kVA is the apparent power, which refers to the capacity of the equipment (usually a transformer);

Kilowatt kW is the active power, which refers to the active power consumed by your equipment (usually power equipment); there is also a reactive power, Qvar, which refers to the power consumed by the inductive load in the equipment.

The guaranteed value of the output capacity of the transformer in the rated state. The unit is expressed in kilovolt-amperes (kVA) (volt-ampere VA and megavolt-ampere MVA are not commonly used). Because transformers have high operating efficiency, usually the primary and secondary windings (transformer windings) The design value of the rated capacity of the deformation tester is equal.

KVA is the capacity in the transformer, KVA is the apparent power, and its size is related to the power factor.

1 kilovolt (kV) = 1000 volts (V)

1 volt (V) = 1000 millivolts (mV)

Kilovolts are greater than volts and greater than millivolts, and the progressive rate is 1000.

1 volt (V) = 1000000 microvolts (μv)

1 megavolt (MV) = 1000000 volts (V)

KW is the unit of power, and KW is kilowatt.

The kilovolt ampere (kVA) is a measurement standard for power, which is 1 kilovolt ampere.

kVA is equivalent to the current in a circuit generated by the voltage of that line. It is usually measured in a transformer, that is, it is a unit of current.

Kilowatt refers to the power of an electrical appliance, that is, the unit of power.

The rated capacity represents the guaranteed value of the output power of the transformer under rated working conditions, and is the apparent power of the transformer.

That is, the ability of the transformer to output the maximum electric power, and the actual output power of the transformer should not be confused with the capacity.

The unit is volt-ampere (VA), kilovolt-ampere (kVA), and megavolt-ampere (MVA).

KVA application examples

Power factor cosΦ=0.8 Active power is P=1kW

Then tanΦ=0.75, so the square of apparent power S=square of P+square of P*tanΦ

That is S=1.25kVA

When the power factor is 1, 1kVA=1kW

1MVA=1000kVA

A 1250 kVA transformer’s load capacity is influenced by several factors, including the power factor, the type of load, and environmental conditions. For a typical power factor of 0.7 to 0.8, a 1250 kVA transformer can handle a load of 900 to 1000 kW. However, this can vary based on the specific characteristics of the load and operational conditions.

To accurately determine the load capacity, it’s crucial to consider the nature of the load (whether it’s resistive, inductive, or a mix) and the power factor. For loads with a lower power factor, the actual kW capacity might be less than the maximum. It’s also important to factor in ambient temperature and cooling efficiency, as these can affect the transformer’s ability to handle load without overheating.

Calculating the kVA rating of a three-phase transformer involves a slightly different approach than a single-phase transformer. The formula is:

[ \text{kVA Rating} = \frac{\text{Voltage (V)} \times \text{Current (A)} \times \sqrt{3}}{1000} ]

This calculation takes into account the phase-to-phase voltage in a three-phase system. The factor of (\sqrt{3}) (approximately 1.732) is used to convert the product of voltage and current (VA) into kVA, reflecting the three-phase power’s root mean square (RMS) value. This calculation provides a more accurate representation of the transformer’s capacity in a three-phase power system.

A 100 kVA transformer’s load sustainability depends on its design and specifications. Typically, such a transformer can sustain a load of 80 to 85 kVA, considering it’s advised to operate transformers at 80-85% of their maximum capacity to account for power surges and ensure longevity. The actual kW load capacity will depend on the power factor of the connected load. For a typical power factor of 0.8, this would translate to a sustainable load of approximately 64 to 68 kW.

When calculating the bussing rating for a transformer, it’s essential to consider factors like the rated voltage, the type of bussing material (copper or aluminum), and the expected load current. The bussing rating should be sufficient to handle the maximum load current without overheating.

Distribution transformers, including those with a capacity of 1250 kVA, are designed with overload protection to prevent damage due to excessive loads. When overloaded, transformers generate excessive heat, which can degrade insulation and lead to failure. Modern transformers are equipped with thermal overload relays or electronic monitoring systems that detect high temperatures and disconnect the transformer to prevent damage.

It’s important to understand that these protective mechanisms are designed to safeguard the transformer in extreme conditions. Regular monitoring and proper load management are crucial to avoid frequent tripping and to ensure the transformer operates within its safe load capacity.

Understanding the technical aspects and operational limits of 1250 kVA pad mounted transformers is crucial for their effective and safe usage. Regular maintenance, adherence to safety standards, and proper load management are key to achieving optimal performance and longevity.

KW and KV cannot be converted.

Because according to the definition of electric power P, it is known that P=UI, and then according to the dimensional analysis, W (watt)=V*A, so 1KW=1KVA. Electric power is a compound unit.

After filling in the contact information, you can download the PDF.