ELECTRIC, WITH AN EDGE

A mounted transformer is usually a distribution transformer with a lesser kilovolt-ampere rating that is mounted on a pad that is earthed on the ground, or above-ground that is mounted on a utility pole that is normally made out of wood or concrete.

Unlike in the past, distribution transformers and power transformers were large, or if not heavy. Now, there are small pad-mounted transformers and pole-mounted transformers that we usually see in public.

To fully understand what each type is, the two transformers will have their own section for thorough elaboration of their working principles, parts, etc.

To begin with, it is vital that you first understand what pad-mounted transformers generally are before we go through the complex pad-mounted transformer specifications.

pad-mounted transformers are transformers that are ground-mounted. It is also a distribution transformer, but of a smaller size and lesser kVA rating unlike big distribution transformers.

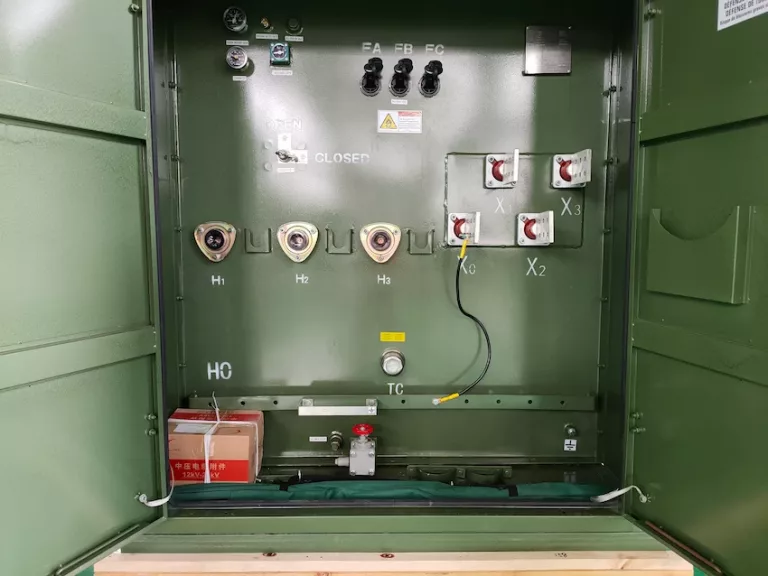

Pad-mounted transformers are locked in a metal cabinet to keep outside elements like pedestrians and animals from disturbing its operation. Moreover, they are mounted on a concrete pad, which is one of the biggest indicators to recognize a pad-mounted transformer.

Pad-mounted transformers are commonly found in residential subdivisions, which is why they are also named as “residential pad-mounted transformers”. One of the most common questions asked about pad-mounted transformers is that why is it safe to situate in a public or residential area?

For starters, the live contact points are enclosed in a grounded metal box, which means that this type of transformer is safe to place in public areas or residential locations. Moreover, unlike other high-voltage transformers, pad-mounted transformers do not need to be fenced. This goes the same for transformers in utility substations as well.

Most ground-mounted transformers are connected to underground utility distribution lines which leads to a term that you might be familiar with – “service drop”. The purpose of this is to step down the primary voltage on the utility distribution line towards the lower secondary voltage.This results in supplying the utility customer.

Nonetheless, it is also worth noting that a single mounted transformer has the ability to serve an entire building, and even many residences. No matter what your project is, you won’t have to worry about insufficient supply with mounted transformers.

When it comes to the ratings, pad-mounted transformers normally have ratings between 75 to 5000 kVA (kilovolt-amperes). The majority of mounted transformers have built-in fuses and switches with them as well. Specifically a Bayonet Fuse.

| Pad Mounted Transformer | ||||

| Rated Power (KVA) | High Voltage (KV) | Low Voltage (V) | Loss (W) | |

| No-load Loss (W) | On-load Loss (W) | |||

| 75KVA | 34.5KV/ 19.92KV/ 13.8KV/ 79.57KV/ 13.2KV/ 7.62KV/ 12.47KV/ 7.2KV or others | 240V 480V 480Y/ 277V 600Y/ 347V | 180 | 1250 |

| 112.5KVA | 200 | 1500 | ||

| 150KVA | 280 | 2200 | ||

| 225KVA | 400 | 3050 | ||

| 300KVA | 480 | 3650 | ||

| 500KVA | 680 | 5100 | ||

| 750KVA | 980 | 7500 | ||

| 1000KVA | 1150 | 10300 | ||

| 1500KVA | 1640 | 14500 | ||

| 2000KVA | 2160 | 20645 | ||

| 2500KVA | 2680 | 27786 | ||

In a typical mounted transformer setup. This includes a tank that is responsible for holding the cores and coil of the pad-mounted transformer in mineral oil, or better known as transformer oil. In terms of the wiring cabinet, it has both high and low voltage wiring compartments to enclose the high and low voltage bushings of the mounted transformer.

The main purpose of this is to prevent unwanted access to the core and coil assembly of the device that is held or stored in the tank of the enclosure. One of the common art practices of this is welding a cover that is for covering the top of the tank.

In terms of other prior art tank covers, there are models that secure the carriage with bolt-nut assemblies, and it includes some means for shielding the nuts. Shielding is necessary for protruding past the top of the ank cover for some inches that is to be trapped in the edge of the cover.

Moreover, the wiring cabinet of a mounted transformer involves the left and right side walls and also the left and right doors that are lockable (swings open) which expose the high and low voltage wiring compartment. These doors are integrated to swing in the direction on which side they are for a complete and wide open.

However, the right and left side walls are naturally fixed in place.

It is highly recommended that pad-mounted transformers are to be located in accordance with specific guidelines. This is to respect the exterior walls as well as the fire code. These guidelines are normally based on the insurance industry which is the recommended practice for the location of one of the pad-mounted transformers outdoors.

When it comes to placing the mounted transformer indoors, there must be an inspection for the mounted transformer to ensure the safety of the building and its occupants. The mounted transformer must pass the fire code in order for it to safely operate indoors.

Compared to pole-mounted transformers that are static devices, which is a device with no moving parts in them. Pad-mounted transformers are expected to have more components in them.

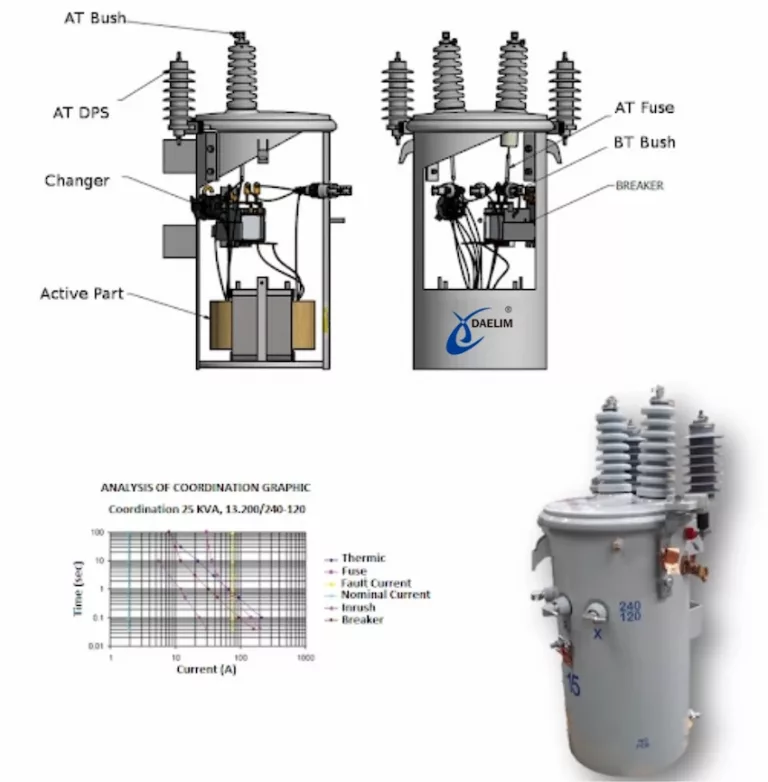

This is also the reason why pole-mounted transformers only look like barrels since they have very few components in them.

Focusing on the parts of mounted transformers, here are some of its components that are elaborated below:

As mentioned, the majority of mounted transformers have a Bayonet or Bay-O-Net Fuse with them for security purposes. But what does it actually do?

For starters, the Bay-O-Net Fuse is designed to be compatible for two-fuse protection schemes with a current-limiting backup fuse. This design clears secondary faults and overload currents with the help of the Bay-O-Net fuse. In fact, even high level faults are cleared by current-limiting fuses.

Of course, mounted transformers have bushings, this includes both pole-mounted transformers and pad-mounted transformers. Basically, a transformer bushing is an insulating device that is in charge of facilitating the passage of energized, current-carrying conductors through the tank (grounded) of the transformer.

High voltage bushings or HV bushings are basically designed for higher voltage ratings for the high voltage winding.

On the other hand, low voltage bushings or LV bushings are the exact opposite of high voltage bushings. They are specifically designed to terminate the transformer’s internal low voltage leads which are located at the tank wall. Moreover, this provides a standard connection that is threaded for the purpose of an external low voltage cable circuit.

Pad-mounted transformers have a tap changer with them, and its function is to regulate the output voltage of a transformer. The process of doing this is by altering the number of turns in one winding, which changes the turns of the ratio.

Basically, there are two types of tap changers. On-load tap changers (O.L.T.C) and de-energized tap changers (D.E.T.C.)

Now that you know the basics of what a pad-mounted transformer is, it is appropriate to learn the next type of mounted transformer, which is the pole-mounted transformer.

For starters, a pole-mounted transformer is basically a distribution transformer that is mounted on a utility pole that is either made out of wood or concrete. Moreover, you would normally see this type of transformer in public.

Yes, these are the barrel-like shaped machines that are mounted in utility poles. So, what does it do? Well, like pad-mounted transformers they are capable of distributing electricity to a single building or multiple buildings. But it has several other functions as well that will be elaborated as you go through this article.

Since pole-mounted transformers are electric utility distribution transformers, a lot of buildings depend on it for supplying electricity (this depends on the setup) which explains why there are a lot of distribution lines connected to a single pole-mounted transformer.

In terms of its location, they are basically situated in public areas similar to pad-mounted transformers but above-ground. This type of transformer is mounted on a pole that is at the level of overhead cables.

Pole-mounted transformers usually range between 16 kVA -100 kVA, and they can transform 11.000 Volts to 33,000 Volts down to a voltage that could be as low as 400 Volts.

Pole-mounted transformers are also considered a common breadbox transformer that is utilized for converting distribution voltages to 120/240 volt power that is for home and other common building use.

| Rated Power (KVA) | High Voltage (V) | Low Voltage (V) | Loss(W) | |

| No-load Loss(W) | On-load Loss(W) | |||

| 5 | 34500 19920 13800 7957 7957 13200 7620 12470 7200 or others | 120-240 240-480 347 600 | 19 | 75 |

| 10 | 36 | 120 | ||

| 15 | 50 | 195 | ||

| 25 | 80 | 290 | ||

| 37.5 | 105 | 360 | ||

| 50 | 135 | 500 | ||

| 75 | 190 | 650 | ||

| 100 | 210 | 850 | ||

| 167 | 350 | 1410 | ||

| Rated Power (KVA) | High Voltage (V) | Low Voltage (V) | Loss(W) | |

| No-load Loss(W) | On-load Loss(W) | |||

| 5 | 34500 19920 13800 7957 7957 13200 7620 12470 7200 or others | 120-240 240-480 347 600 | 35 | 75 |

| 10 | 50 | 120 | ||

| 15 | 65 | 195 | ||

| 25 | 105 | 290 | ||

| 37.5 | 140 | 360 | ||

| 50 | 180 | 500 | ||

| 75 | 250 | 650 | ||

Pole-mounted transformers are also used in extensive rural areas since they are reasonably small in size and mass. They are fairly easy to install on single pole structures and larger units as well. They are approximately 7 to 10 meters above ground, which makes it unreachable for pedestrians or animals to reach.

However, it is without a doubt that this type of mounted transformer is exposed to harsh climates. This is the reason why it is shaped in a barrel form in order to reduce accumulation of water from rain. Moreover, pole-mounted transformers are made out of corrosion-resistant materials.

The barrel itself is armored with protective coatings to prevent rust from occurring. In coast regions, zinc is a common spray that manufacturers use for added protection. When it comes to highly corrosive areas like near shorelines or beaches, the material of the pole-mounted transformer will usually be made out of stainless steel.

Unlike pad-mounted transformers, pole-mounted transformers are typically single-phased. However, vector designations determine the number of primary bushings, and these transformers are connected to a three-phase bank.

Pole-mounted transformers also have primary and secondary windings like other transformers, and the material could also be either made out of copper or aluminum. Back in the early years of transformer development, aluminum has always been the common material for the windings.

The tank cover is the cover that protects the inside components of the pole-mounted transformer from outside elements such as rain, debris, animals, etc. This lid is secured tightly and depending on the manufacturer, it may or may not have a lock.

Some pole-mounted transformers have cooling fins with them, but depending on where you are located, the majority of pole-mounted transformers usually don’t have any cooling fins, but then again this depends on the manufacturer.

In the case that the pole-mounted transformer has cooling fins, the purpose of this is to increase the outer surface area of the tank. This enhances the tank cooling capacity for optimum performance.

However, the winding resistance and power loss of the transformer will be drastically reduced which means this increases the transformer’s efficiency.

A pole-mounted transformer’s primary bushing functions the same way as with other transformer primary bushings. This facilitates the passage of energized conductors that are carrying a current through the grounded tank of the transformer.

The bushings are used for low voltage windings or windings that are usually solid type with an epoxy insulator but it could be porcelain as well.

Mounted transformers are excellent compact distribution transformers that are easy to install and operate with a little maintenance, you can expect these types of transformers to last for decades.

If you are looking for a transformer that is easy to maintain, it is best to choose pad-mounted transformers over pole-mounted transformers simply because of the fact that pad-mounted transformers are easier to access since they are mounted on a pad that is earthed on the ground, unlike pole-mounted transformers that require you to use a ladder to reach it.

If you have any questions or clarifications, do not hesitate to contact DAELIM’s team of professionals for immediate accommodation.

When you find that the existing Mounted transformers cannot meet your needs, Daelim’s team of transformer designers can help you provide design and production according to your specific requirements.

Fifteen years of production and design experience has allowed Daelim to accumulate a wealth of experience in transformer design to escort your power business.

Download Resource

ELECTRIC, WITH AN ENGE-- DAELIM BELEFIC

After filling in the contact information, you can download the PDF.