ELECTRIC, WITH AN EDGE

It needs to be boosted before it can be transmitted to the grid. Solution: Generator Step-up transformers increase the voltage of this high-capacity electricity to be sent to the grid.

The best Generator Step-Up Transformers are designed to work with the existing infrastructure and equipment. They will keep your power grid safe and sound, reduce the risk of power loss, and help increase the efficiency of generators.

Also, step-up converters can convert the high-voltage AC power to 230 volts for household use. A generator transformer is a device that converts mechanical energy to electrical energy and back, cooling itself in the process.

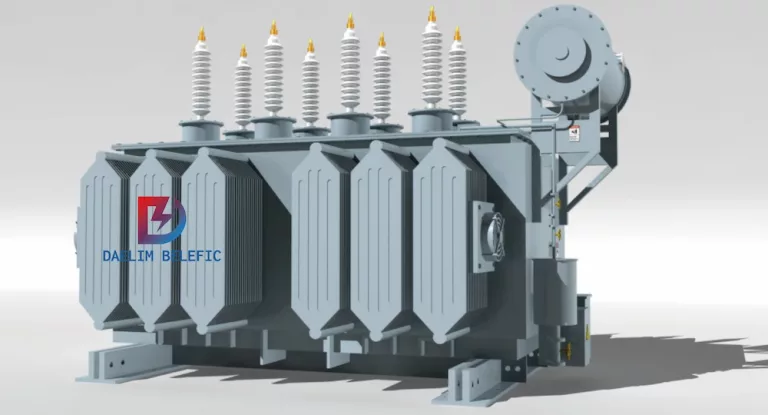

For years, Daelim has been supplying the power tools and industrial market with high-performing products. DAELIM transformers are high-performance, high-efficiency, and safe. DAELIM provides a high-efficient generator setup transformer that ensures your generator will always be able to provide power when you need it.

Daelim Belefic is a leading generator step-up transformer manufacturer, dedicated to providing high-quality and reliable transformers that meet the unique requirements of power generation facilities. With over 30 years of experience in transformer production and innovation, Daelim Belefic is a trusted and proven partner for power plant owners and operators.

Daelim Belefic’s generator step-up transformers are designed and manufactured to the highest industry standards, ensuring maximum efficiency and reliability in power generation systems. The company’s transformers are widely used in power plants, substations, and other large-scale facilities worldwide.

At Daelim Belefic, quality and customer satisfaction are always top priorities. The company’s advanced production equipment and technology, coupled with strict quality control procedures, ensure that all transformers are of the highest quality and meet or exceed customer expectations.

Daelim Belefic’s generator step-up transformers come in a wide range of capacities, from small units for small-scale facilities to large units for major power plants. The transformers are customizable to meet specific customer requirements, and the company’s experienced engineering team provides comprehensive technical support and services throughout the entire lifecycle of the transformer.

In addition to providing high-quality transformers, Daelim Belefic offers competitive pricing and timely delivery, ensuring that customers receive the best value and fastest turnaround times possible. The company also provides after-sales support, including maintenance, repair, and replacement services, to ensure that transformers continue to perform at peak levels over their lifetime.

Trust Daelim Belefic as your generator step-up transformer manufacturer and partner. Contact the company today to learn more about how it can help power your facility with high-quality, reliable transformers.

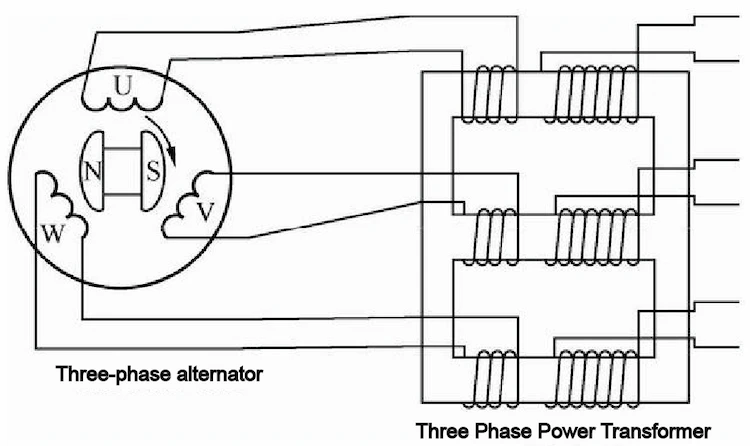

Generator Step-Up Transformer wiki will explain to you more about this transformer. Therefore, to make it short, Generators convert electrical energy into mechanical energy. A transformer is the only piece that makes the generator work. It takes in power from the outgoing wires and converts it into rotating magnetic fields.

These fields make the magnetic field reach its maximum potential and turn the generator’s turbine to produce mechanical energy.

You’ll learn about the different power generating processes in a power plant, the steam turbine, and the steam boiler. The steam turbine is what provides the main energy to drive the generator.

Steam boilers are used for removing heat from the water and transferring it to the cold water tanks. The generators start operating when this process is done.

The power plant is where the majority of the energy produced by the power company is generated. The electricity goes through a layering process before you can use it in homes and businesses. It starts as natural gas, which is then mixed with other chemicals like coal and oil. The plant uses steam to create energy that is then converted into electricity using turbines.

In a transformer, the power input from the supply side is used to step-up voltage from the supply source or a lower-voltage supply. The power input through a transformer is often AC, alternating current power.

The secondary winding of a transformer is referred to as the output winding. It is connected to a load, which may be an appliance or a fixture.

Additionally, a step-up transformer is an electrical device that changes the voltage of the power supply feeding it by a step-up ratio, meaning it can handle greater amounts of voltage before becoming saturated.

The term is used in the household electrical industry to refer to fuses, circuit breakers, or similar devices to protect against overcurrents.

Usually, a step-up transformer is a device used to increase the voltage of an alternating current. It does this by employing rotating electrical conductors or magnets in contact with each other or sometimes utilizing a commutator.

A generator step-up (GSU) transformer is a type of power transformer used in power plants to increase the voltage of the electricity generated by the generator so that it can be transmitted over long distances. The GSU transformer is typically located at the power plant and steps up the voltage from the generator’s output voltage to the transmission voltage level.

The GSU transformer works by taking the electrical output from the generator and increasing its voltage through a process of electromagnetic induction. The transformer consists of two coils, the primary and secondary, which are wound around a magnetic core. When an alternating current is passed through the primary coil, it generates a magnetic field which in turn induces a voltage in the secondary coil. By adjusting the number of turns in the primary and secondary coils, the transformer can step up or step down the voltage level.

In a power generation system, the GSU transformer plays a critical role in ensuring that the electricity generated by the generator can be transmitted over long distances to meet the demands of consumers. By increasing the voltage of the electricity, the GSU transformer reduces the amount of current required to transmit the power, which in turn reduces the losses associated with power transmission. This is important because the longer the distance of the transmission line, the higher the losses, which can lead to a reduction in the amount of power that can be delivered to the end consumer.

Overall, the GSU transformer is a critical component in the power generation and transmission process. It plays an important role in ensuring that the electricity generated by the power plant can be efficiently and effectively transmitted to meet the demands of consumers.

Not all transformer systems are created equal, and you’ll want to know the difference before you go shopping. The difference is how the electricity moves: a Step-Down generator moves power from a higher voltage to a lower voltage.

In comparison, Step-Up transformers move power from a lower voltage to a higher voltage.

power transformer solutions for oilfields

Step-Up transformers generate a higher voltage at the primary winding. In contrast, Step-Down transformers generate a lower voltage at the primary and reduce it for secondary and tertiary windings.

As a result, step-down transformers are used for applications that require high power and small size.

Additionally, Step-up and step-down transformers can be set up to generate a certain voltage so that the voltage output is more suitable for the given application. To use a step-up transformer, the input voltage must be higher than the output voltage.

Step-Up and Step-Down Generator Transformers transform the 120 volts AC input into a 12 volts DC output. In other words, it takes 12 volts from a power source and transforms them into 120 volts. This precise voltage makes these devices very useful in many applications, especially those involving electronics.

Note that the step-up transformers are generally more costly than step-down transformers. Still, they do allow for higher power levels. If you want to run very high power levels, the step-up transformer is your best option.

A Step-Up Transformer is a simple, cost-effective way to increase the voltage of a power distribution system. The transformer only needs a few power lines and can be installed in minutes without modifications. Step-Up Transformers help improve the distribution system’s reliability and safety.

Usually, a Step-Up Transformer is a type of transformer that integrates the power to produce alternating current (AC) into its secondary coil. The primary coil consists of an iron core, and the secondary coil is made up of two windings. One winding is connected to the power line, and the other winding is connected to the load.

For the first time, you can power up your entire home with a single piece of hardware. With Step-Up Transformer, you’ll never have to worry about dead outlets again.

A Complete Guide to Three-Phase Distribution Transformers

Suppose the UPS power in your business is interrupted during a blackout or an extended power outage. In that case, this transformer ensures that your appliances will continue to work.

Unlike standard transformers, the Step-Up Transformer has a unique design that allows for a smaller footprint and a lower profile. This means it will fit in tighter areas where other transformers may not.

It also allows for even more headroom and power options. The Step-Up Transformer can be custom-configured to meet your specific needs.

The Step-Down Transformer is one of the most important transformers in an electrical power system. It typically transforms electricity at high voltages (HVAC) up to lower voltages (LVAC), which can be used for commercial, residential, or industrial purposes.

The transformer reduces the voltage by stepping down the voltage until it reaches the final desired voltage.

Additionally, this power electronic device converts a three-phase alternating current to a direct current voltage. It is popular due to the complexity of its engineering design, which makes it suitable for high-power applications such as electric motors and industrial machinery.

Three Phase Epoxy-resin Dry Type Distribution Transformer

Lastly, a Step-Down Transformer will be your best option if you’re looking for a steady voltage supply. This type of transformer is used in homes, businesses, and industries.

Compared to an AC power supply, this transformer offers the consistent voltage you need without the fluctuations in reserve that are often experienced with an AC power supply.

The Generator Step-Up Transformer is a tool that allows an electric power station to produce electricity from renewable sources.

It generates electricity from intermittent sources such as wind and solar, which can supply a fraction of the energy required by the power station. This type of equipment is very effective at stabilizing the grid and connecting more renewables into the grid.

Additionally, a generator step-up transformer is an electrical device that increases a direct current (DC) electric power supply by changing multiple low-voltage alternating current (AC) power supplies.

It is done by connecting the high voltage DC output to one or more low voltage AC input circuits to increase the voltage across the power supply.

The Generator Step-Up Transformer is a source of energy for industries and homes. It provides reliable, clean, and consistent power for a fraction of the cost of traditional generators with efficient use of fuel.

This type of generator can provide management with the lowest emissions rate, which will also help protect the environment by decreasing pollution.

Lastly, remember that the Generator Step-Up Transformer is a versatile and economical 50kVA power solution that you can apply in many industries and homes. Whether you’re looking to improve the reliability of your organization or expand the capabilities of your home, our solutions will boost your productivity and quality of life.

Sometimes generators can fail due to many different things.

When subjected to adverse conditions, your generator will often fail, such as in an area with heavy humidity or near something that produces a high amount of electromagnetic interference. There are also other possible causes for this type of failure.

The cause of a generator step-up transformer failing is typically due to fires, water damage, an overload condition, or the power company simply stopping service. To avoid these problems in the future, make sure that you have a system checklist in place with preventive maintenance tasks for your generator step-up transformer.

When it fails, The first thing to do is check the fuse. If the fuse is blown, you will need to replace it. Once that’s done, you can check out your circuit breaker. If there is no power coming in, you will need to replace the circuit breaker.

After replacing the circuit breaker, make sure you test the transformer with a voltmeter or simple multimeter before plugging it in again.

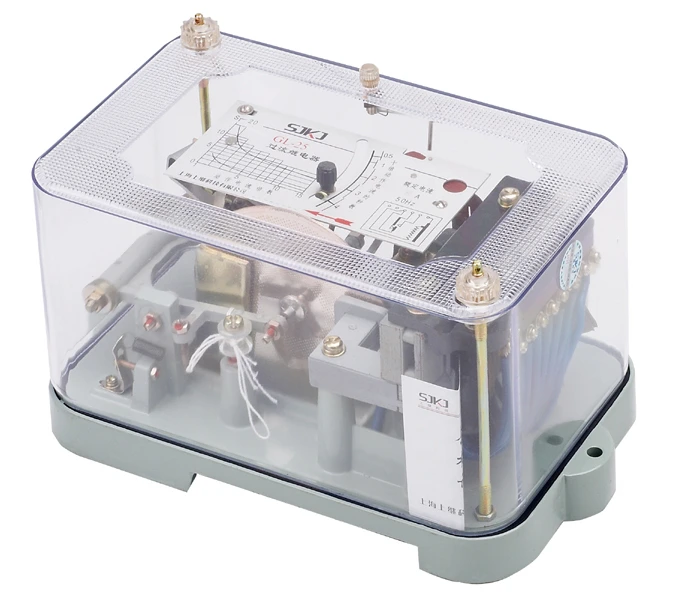

It is important to have quality, fail-safe protection for a transformer to ensure all equipment is connected. This type of Generator Step-Up Transformer protection is called a thermal overload relay, and it’s designed to provide the proper voltage on the line regardless of the operating temperature.

The Generator Step-Up Transformer is the latest addition to our range of AC and DC transformers.

This new transformer offers a highly efficient design that allows higher voltage regulation, better power factor, and more intelligent load sharing for increased efficiency and power quality. It also features an advanced safety device that can identify faults and avoid leading to a dangerous situation.

Additionally, the operation of a transformer without protection may lead to overheating and damage. When the thermal time constant of the transformer is reached, the relay opens the circuit and interrupts the load current. The winding will cool down, thus restoring its normal operating condition.

electric Pole Transformer | Single Phase Transformer

A thermal overload relay is a common protection device found in power transformers and other electrical equipment. Its main function is to protect the transformer against overheating. By simulating the temperature of the transformer’s windings, it protects the transformer from thermal overloads.

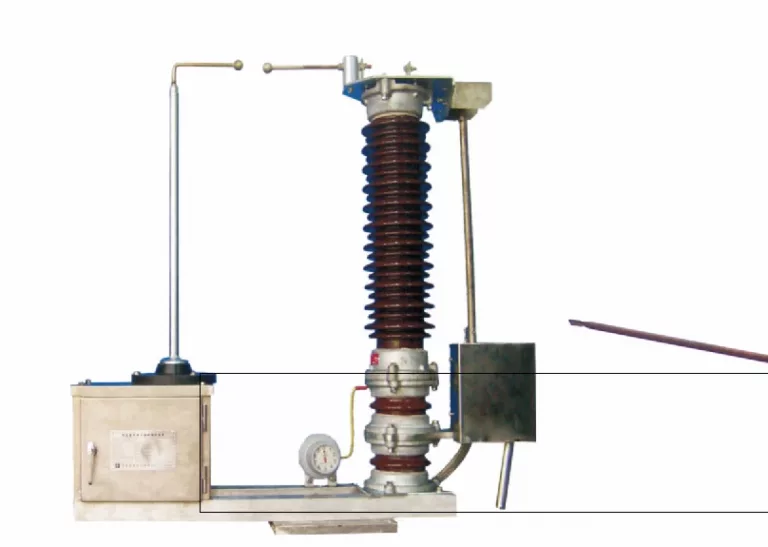

The Restricted Earth Fault Relay is designed to withstand transient fault current, which means it will work even if the power transformer experiences an unbalanced operation. You can use it anywhere since its input and output terminals are adapted for any electrical system.

Without a Restricted Earth Fault Relay, the protection circuit will not detect the fault and disconnect power to the transformer. The relay is connected in a closed path. It does not respond even if there is an unbalancing in-phase current on the power transformer.

Furthermore, the Restricted Earth Fault Relay is an instrument for protecting distribution lines against direct lightning strikes. It is designed to operate in uninsulated conductors. This instrument will only respond if there is a fault current difference of 120% or more on either phase of the power transformer.

Circuit breakers are most often used with electrical motors and generators. They protect the load, preventing damage to the equipment and the surrounding environment.

A circuit breaker automatically trips when a current is too high or when it overheats. The mechanism automatically resets when the current is safe again.

Additionally, they act as resettable fuses that automatically operate electrical switches to prevent overload or short-circuiting electrical circuits. These devices are designed to trip the circuit breaker if it senses an abnormal current, voltage, or impulse.

If any of these occurs, the circuit breaker trips, and the power is cut off.

Station Safety Layout refers to the arrangement of the electrical circuits and apparatus on a circuit board. It includes such elements as circuit breakers, fuses, and outlets.

Station safety layout is important because it ensures the safe use of electrical circuits and apparatus. For this reason, the design must be both functional and aesthetically pleasing.

Additionally, a station safety layout converts the electrical distribution network (electricity distribution over a geographical area) into a safe and reliable system. This allows energy to flow from power generation, transmission, and distribution areas to households and businesses with minimal loss or interruption of supply.

Overcurrent relays are devices used to protect large electrical circuits from overloading.

This device has been in use since the late 1800s and continues to be a crucial component in modern electrical systems. In simple terms, an overcurrent relay is a device designed to interrupt current at its source before it can cause damage or destruction of equipment or appliances.

Additionally, this device protects the wires and equipment in your home or business from overload, overvoltage, and short circuits. They use the power of the system’s current to switch off any fault, so there is no damage to any other parts of your electrical system.

You should put three important controls in place to ensure the proper functioning of the transformer:

Voltage is controlled by a switch or potentiometer and can be manually adjusted, while a microcontroller controls performance and frequency. These controls ensure that the transformer will perform as desired for years to come.

Voltage and performance control ensures that the transformer will perform as desired. Without these controls, your transformer might not function properly. The designer of the transformer sets these controls to help ensure its functionality.

The generator step-up transformer configuration and setup is a process that allows you to create an electrical power source from the standard voltage of the utility grid. This process is not for everyone. It’s needed if you want to generate your power on-site, such as if your house is off-grid.

Generator step-up transformers can be configured in different ways depending on the specific requirements of the power generation system. The three most common configurations are the two-winding configuration, the three-winding configuration, and the auto-transformer configuration.

Using step-up transformers can be difficult, but it’s important to note that the process is quite straightforward. You need to make sure that your power source is compatible with this transformer and that you install the correct size of the cable.

Also, make sure that you test both of these components before beginning the installation.

The best generator step-up transformer configuration will depend on the size of your station. Generally, you’ll want to install a step-up transformer that matches the voltage of your incoming power source and outputting voltage as determined by the needs of your facility.

Distribution Transformer Selection of An Office Building

As a transformer is a complicated device, electrical professionals will always be the best decision-makers on the best transformers for individual uses. There are also many different transformers available to choose from, so it’s up to you to figure out which transformer would work best for your needs.

This is the simplest and most commonly used configuration for a GSU transformer. In this configuration, the primary winding is connected to the generator and the secondary winding is connected to the transmission line. The voltage is stepped up from the generator voltage level to the required transmission voltage level.

This configuration is used when there are multiple generators connected to the same transformer. In this configuration, the primary winding is connected to the generators and the two secondary windings are connected to the transmission lines. This configuration allows for more flexibility in the power system as each generator can be connected to a different transmission line.

In this configuration, the primary winding and the secondary winding are connected together in a series of coils, and the voltage is stepped up or down depending on the number of coils used. This configuration is used when a large voltage change is not required, and it is more efficient than the two-winding configuration.

Choosing the appropriate configuration for a GSU transformer depends on the specific requirements of the power system and the load demand. The configuration selected must ensure that the transformer can handle the voltage and current levels required, while also providing reliability and efficiency.

Generator Step-Up Transformers (GSUs) are essential components in a power generation system. The specifications of a GSU transformer are crucial to ensure safe and efficient power generation. Here are some key specifications of GSU transformers:

Power rating: The power rating of a GSU transformer is the maximum amount of power it can handle. It is typically measured in megavolt-amperes (MVA) or gigawatts (GW).

Voltage rating: The voltage rating of a GSU transformer is the maximum voltage it can handle. It is typically measured in kilovolts (kV) or megavolts (MV).

Frequency rating: The frequency rating of a GSU transformer is the operating frequency of the system. In most countries, the standard frequency is 50 Hz or 60 Hz.

Impedance: The impedance of a GSU transformer is the total opposition it offers to the flow of alternating current. It is typically measured in percent or ohms.

Insulation class: The insulation class of a GSU transformer is the level of insulation it provides to the system. It is typically classified into Class A, Class B, Class F, Class H, and Class R.

Cooling method: The cooling method of a GSU transformer is the method used to dissipate heat generated during operation. There are two types of cooling methods: liquid cooling and air cooling.

Vector group: The vector group of a GSU transformer is the arrangement of the primary and secondary winding phases. It is typically represented by a series of letters, such as YNd1, YNd11, Dyn5, or Dyn11.

It is essential to ensure that the specifications of a GSU transformer match the requirements of the power generation system. A mismatch in any of the specifications could result in system failure, downtime, or safety hazards.

GSU transformers are the lifeblood of the power grid, so they must be constructed to be both highly reliable and long-lasting. They must also have a good heat dissipation capability to protect them from being destroyed by excessive temperatures or high voltage.

They can also offer other features such as redundant control systems, automated monitoring, and supervision systems.

For example, suppose you want to calculate the size of the generator you need. In that case, you can use the following formula: Watts x Volts = Amps. So, if you wanted to know how many amps your generator would need, multiply your Watts by the voltage of your power source.

When it comes to sizing a generator step-up (GSU) transformer, there are several factors to consider to ensure it is appropriately matched to the generator it will serve. Here are some of the key factors to keep in mind:

Generator output: The most critical factor to consider is the generator’s output rating. The GSU transformer must be sized to handle the full output of the generator without exceeding its capacity.

Voltage requirements: Another important factor is the voltage requirements of the grid that the generator will be connected to. The GSU transformer must be rated to match the voltage level of the grid.

Phase configuration: The phase configuration of the generator must be considered, whether it is single-phase or three-phase, and the GSU transformer must be appropriately configured to match it.

Fault current: The transformer must be rated to handle the potential fault current that may occur in the system. This includes both the generator’s fault current and the fault current of the grid.

Ambient conditions: The ambient temperature and altitude of the installation site must be taken into account to determine the correct cooling method for the transformer.

Future expansion: It is always wise to consider the possibility of future expansion and the need for additional generators. This may require a larger transformer than would be required for the initial installation.

Once these factors are considered, the size of the GSU transformer can be calculated based on the output rating of the generator. Typically, the transformer is sized so that its capacity is slightly higher than the generator’s output rating to allow for any future expansion or changes in the system.

It’s essential to ensure the GSU transformer is correctly sized to ensure safe and efficient power generation and transmission. Incorrect sizing can lead to system failures, which can result in costly downtime and repairs.

Transformers take high voltage power from a power plant and transform it so you can use it for machinery. They are made of coils of wire that contain copper, iron, or other metals, constantly changing shape to resist the flow of electricity.

Transformers have been around since the 1800s and have been an essential part of people’s everyday lives ever since.

A generator step-down transformer is designed to decrease the voltage generated by a power plant to a level that can be distributed to consumers, whereas a generator step-up transformer is used to increase the voltage produced by a power plant to a higher level, so that it can be transmitted over long distances with less energy loss.

The main differences between step-up and step-down transformers lie in their configurations and specifications. While step-up transformers typically have higher power, voltage, and frequency ratings, step-down transformers are designed for lower voltage applications and typically have lower power ratings. Step-up transformers also typically have a higher impedance and are designed to handle more energy, while step-down transformers have a lower impedance and are designed for a smaller load.

The decision to use a step-up transformer is based on the distance that power needs to be transmitted and the amount of power that needs to be transmitted. When power needs to be transmitted over long distances, a step-up transformer can be used to increase the voltage to reduce energy loss during transmission. This is because the higher the voltage, the lower the current required to transmit the same amount of power. When power needs to be distributed over a shorter distance to consumers, a step-down transformer can be used to reduce the voltage to a safer and more usable level.

In general, step-up transformers are used for long distance power transmission, while step-down transformers are used for local distribution of power to consumers. The choice of transformer depends on the specific application and the required voltage levels for the system.

The Generator Step-Up Transformer is the only product of its kind on the market. This device can power water pumps, lift the water to trees, or make electricity. Remember never to leave this product unattended and not touch the wire connections when plugged in.

Additionally, the Generator Step-Up Transformer is a device that you can easily install in any location. It provides you with the power needed for your home, office, or property. This power solution offers outstanding performance and will provide you with reliable energy without the hassle of installation.

Daelim Generator Step-Up Transformer is a great tool for homeowners who want to save money on their power bills. Fortunately, Not only does Daelim have 15 years of valuable experience in this field, but Daelim also constantly complies with necessary international standards. This is to assure the customers that Daelim’s products are safe for use and of high performance and quality.

In conclusion, a generator step-up transformer plays a critical role in power generation systems. It is important to understand its configurations, specifications, and sizing when selecting the right transformer for your power generation needs. Daelim Belefic, a leading transformer manufacturer, offers high-quality generator step-up transformers with advanced technology and comprehensive technical support. Contact us to learn more about our products and services.

We have more than 15 years of experience in the design and production of step-up transformers. It can meet the needs of step-up transformers that cannot be achieved by your standard products. And we will assist you in the whole process, until the transformer operation.

Download Resource

ELECTRIC, WITH AN ENGE-- DAELIM BELEFIC

After filling in the contact information, you can download the PDF.