ELECTRIC, WITH AN EDGE

A transformer is a commonly used device in the electrical and electronic industries. There are many different types of transformer currently on the market.

Such as dry-type transformers, step-up transformers, step-down transformers, pad-mounted transformers, ,distribution transformer etc.

Thus, a transformer became essential equipment in the industrial electrical sector and specific other fields.

More often, transformers are used to solve electrical issues.

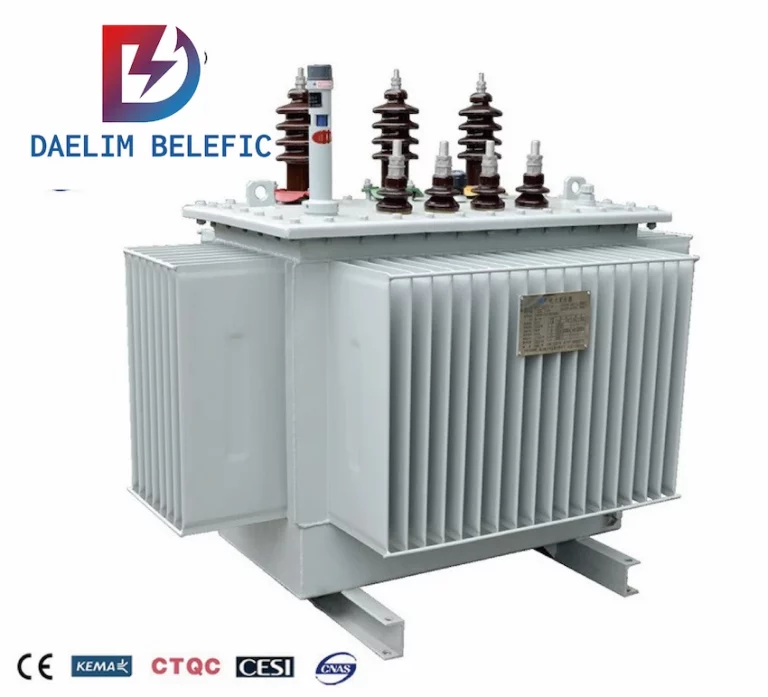

However, due to varying needs, manufacturers like the Daelim Company develop various kinds of transformers.

Daelim Company has been in business for about 15 years, offering customers a variety of transformers to choose from.

Daelim’s products are used in the power system and all others in the particular industries involved in the process.

So, if you are looking for a company that can offer you quality products and reliable operation, Daelim is the brand to purchase from.

To better understand what to purchase, we will go through the different types of transformers and their application in various fields.

Pofessional Manufacturer of Pad Mounted Transformer Substation Transformer,HV Power Transformer Single Phase Transformer IEEE/ANSI,CSA,DOE,AS/NZS,IEC and etc。standards

Transformers are constructed in a variety of ways. It may have many coils or windings on both the primary and secondary sides, affecting the voltage level.

The transformer is classified into three types based on the voltage level produced: Step down, Step up, and an isolation transformer.

Step-Down Transformers are utilized in both the electronic and electrical fields.

A step-down transformer reduces the voltage across the secondary output from the primary voltage level.

This transformer has many applications in electronics from 5V, 6V, 9V, 12V, 24V, or in some cases, 48V.

Step Down Transformers are needed to convert the single-phase power outlet voltage 230V AC to the appropriate low voltage level.

Additionally, transformers act as one of the primary requirements for the Power segment.

It also works in power adapter circuits and mobile phone charger circuits.

Step-down transformers are used in electrical distribution systems that operate at extremely high voltages to offer a low loss and cost-effective solution for long-distance power delivery needs.

Step-up transformers convert a low primary voltage into a high secondary voltage. For this ratio, the number of turns in the secondary winding is more than that in the primary winding.

Step-up transformers are often used in electronics in stabilizers, inverters, and other applications where there is a need to convert a low voltage to a much greater voltage.

In electrical power distribution, a step-up transformer is used to raise the voltage level before distribution.

An isolation transformer converts no voltage levels. The primary and secondary voltages are always the same. As a result, the number of turns in the isolation transformer’s primary and secondary windings is just the same.

The isolation transformer is mainly used to separate the primary and secondary circuits. Its primary use is to prioritize safety and cancel noise transmission from primary to secondary or vice versa.

Iron Core Transformer is made up of multiple soft iron plates.

The flux linkage of the iron core transformer is relatively high due to the strong magnetic characteristics of iron.

As a result, the iron core transformer has high efficiency.

A range of core plates are available on the market, depending on the core size and frequent shapes like E, I, U, L. E type cores.

For example, cores are created of thin plates that resemble the letter E.

Transformers transfer energy by channeling electromagnetic flux via a core material.

However, the flux density produced by various core materials differs.

There were two main types of transformers according to the construction of core materials.

The core material of an Air-Core transformer is not a physical magnetic core.

This transformer’s flux linkage is entirely made of air.

The primary coil of this transformer is fed with alternating current, which creates an electromagnetic field surrounding it.

Compared to physical core materials such as iron or ferrite core, this transformer has low mutual inductance.

Air core transformers work on wireless charging systems, where the primary windings are built within the charger, and the secondary windings are built inside the device.

A dry-type transformer is a static device with no moving components that employ ecologically beneficial temperature insulation systems.

The term “dry” refers to the fact that the system is cooled by natural airflow rather than oil, silicone, or a liquid to cool the coils and electrical core.

Dry-type transformers, unlike liquid transformers, do not need the use of fireproof vaults or catch basins, and there is no need to worry about toxic gas venting.

Because dry-type transformers are significantly safer, they can be installed inside and closer to loads, making the whole system more efficient.

Transformers can also be categorized according to their winding order:

A two-winding transformer contains two distinct windings for each phase.

The alternating current input may provide the primary winding, while the secondary can be linked via the load.

These two windings are electrically isolated yet magnetically linked.

An autotransformer’s primary and secondary windings are physically and magnetically linked in series.

Transformers can be categorized based on their purpose or function in various electrical systems. Here are some common types:

Power Transformers: Used in transmission networks for stepping up or down the voltage. They are typically found in power plants, substations, and at the receiving end of power lines. Power transformers are designed for high-efficiency operation at full load.

Distribution Transformers: These transformers are used in the distribution network to step down the voltage for end-user connectivity. They are smaller in size compared to power transformers and are designed for maximum efficiency at lower load capacities, as they do not operate at full load all the time.

Instrument Transformers: This category includes Current Transformers (CTs) and Potential Transformers (PTs) used for measurement and protective relaying in electrical systems. CTs provide a current in its secondary which is proportional to the current in its primary, while PTs step down the voltage to a safe level for metering devices or protective relay equipment.

Isolation Transformers: Designed to decouple two circuits, these transformers allow AC power to be taken from one device and fed into another without electrically connecting the two circuits. They can protect against electric shock and suppress electrical noise in sensitive devices.

Autotransformers: These are transformers where the primary and secondary coils have part of their windings in common. Autotransformers are often used for small voltage correction in the supply system.

Pulse Transformers: Specifically designed for processing pulse signals. They are optimized for transmitting rectangular electrical pulses with fast rise and fall times.

Audio Transformers: Used in audio circuits to isolate signal paths or match impedances between different stages of audio amplifiers, mixers, or signal processing equipment.

Three-Phase Transformers: Used in three-phase power systems and can be configured in various ways (delta or wye connections) to suit the power supply and load requirements.

Single-Phase Transformers: Used in single-phase power systems, mainly for lower power applications.

Outdoor/Pad Mounted Transformers: Common in suburban and rural areas, these transformers are designed for outdoor installation, with robust casings to withstand environmental factors.

Dry-Type Transformers: These do not use liquid for cooling but are air-cooled and are used in various industrial, commercial, and urban applications.

Oil-Immersed Transformers: These transformers use oil as both an insulator and a coolant. They are commonly used in power networks.

Each type of transformer serves a specific need and is designed to suit its role in the electrical distribution and transmission network.

Power transformers are mostly utilized in high-voltage transmission networks.

It has the following ratings: 400kv, 200kv, 110kv, 66kv, and 33kv.

They are used in generating stations and transmission substations that need a large capacity transformer.

The power transformer is bigger than the distribution transformer and is built for maximum efficiency of 100 percent.

The distribution transformer is also known as the consumption transformer.

It converts a low, medium voltage supply to the voltage required by residential appliances and industrial equipment.

Distribution transformers are designed to lower voltage for distribution to customers or commercial usage.

This machine has excellent voltage management and can run 24 hours with maximum efficiency at 50% load.

As previously stated, Isolation transformers have primary and secondary windings that operate independently of one another.

Each primary or secondary winding has a particular volt-ampere characteristic depending on the ratio of turns between primary and secondary districts.

Moreover, it reduces the possibility of electrical leakage in the device enclosure and ensures safety while in operation.

The most typical use for an instrument transformer is to securely separate the secondary winding when the primary supply is high voltage and high current.

The measuring equipment, energy meters, or relays attached to the secondary side of the instrument transformer will not be damaged.

Three sets of primary and secondary windings make up a three-phase transformer.

Each pair of windings was wrapped around a different leg of an iron core assembly.

It is utilized in industries for the production, transmission, and distribution of electric power.

This transformer’s construction is economical, and it may be connected using Star and Delta type connectors.

You may make greater use of this type of transformer by using a 3-phase transformer calculator.

Due to the use of electricity (current) as a primary resource for production, various industrial applications need specific industrial transformers.

Arc furnaces, ladle furnaces, and high-current rectifiers are widely used in industries like electricity distribution, chemical industry, and many others to produce power at low voltage levels.

The type of transformer you will purchase should always fit your needs.

As mentioned, different types of transformers are designed for various user types.

So, how many types of transformers are there?

There are numerous of them, and some may not have been mentioned above.

But regardless of the number of transformers available, what is important is that these transformers can supply your needs and be made by premium manufacturers for long-lasting use.

Don’t look anywhere else. DAELIM can provide you with a quality and inexpensive transformer, proven and tested over decades.

9+FAQ About the Three-Phase Step-Up Transformer

-Are you tired of having to step up or down your power manually? The Three-Phase Step-Up Transformer helps you step up or down your power quickly and easily.

Selection And Maintenance of 10 kV Dry-type Transformer

-This article analyzes the selection of 10 kV dry-type transformer and further elaborates the maintenance work of the Cast Resin Dry-type Transformer.

15+FAQ ABOUT THE 3 PHASE PAD-MOUNTED TRANSFORMER

-3 PHASE PAD-MOUNTED TRANSFORMER is a highly integrated transformer. It is widely used in power systems. Learn more about 3 PHASE PAD MOUNTED TRANSFORMER (including how to buy them) in this new guide.

After filling in the contact information, you can download the PDF.