Transformer Oil Uses

There are three main Transformer Oil Uses, one is insulation, the other is heat dissipation, and the third is arc suppression.

1. Insulation

Transformer oil has a much higher dielectric strength than air. The insulating material is immersed in oil, which not only improves the insulation strength, but also protects it from moisture.

There are three main Transformer Oil Uses, one is insulation, the other is heat dissipation, and the third is arc suppression.

1. Insulation

Transformer oil has a much higher dielectric strength than air. The insulating material is immersed in oil, which not only improves the insulation strength, but also protects it from moisture.

2. Heat dissipation

Transformer oil has a large specific heat and is often used as a coolant. The heat generated during the operation of the transformer causes the oil close to the iron core and windings to be heated and expanded. Through the upper and lower convection of the oil, the heat is dissipated through the radiator to ensure the normal operation of the transformer.

3. Arc suppression

On the on-load tap changer of oil circuit breaker and transformer, an arc will be generated when the contacts are switched. Because the transformer oil has good thermal conductivity, and can separate a large amount of gas under the action of the high temperature of the arc, and generate a large pressure, the arc extinguishing performance of the medium is improved, and the arc is quickly extinguished.

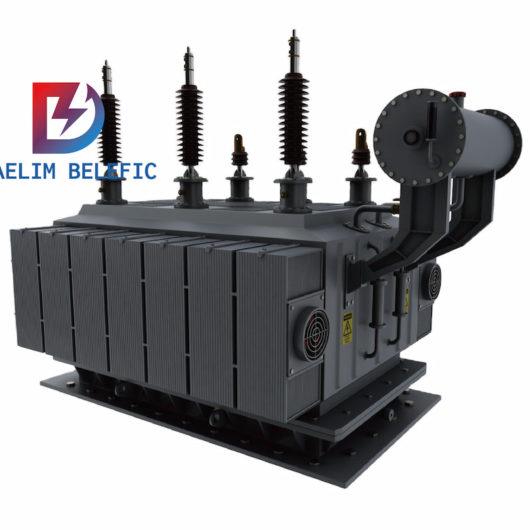

Transformer Oil Specification

1. The density of transformer oil should be as small as possible to facilitate precipitation of moisture and impurities in the oil.

2. The viscosity should be moderate, too large will affect the convection heat dissipation, too small will reduce the flash point.

3. The flash point should be as high as possible, and generally should not be lower than 136°C.

4. The freezing point should be as low as possible.

5. The lower the content of impurities such as acid, alkali, sulfur, and ash, the better, so as to avoid their corrosion of insulating materials, wires, fuel tanks, etc. as much as possible.

6. The degree of oxidation should not be too high. The degree of oxidation is usually expressed by acid value, which refers to the amount of potassium hydroxide (mg) required to absorb the free acid in 1 gram of oil.

7. The stability should not be too low. The stability is usually expressed by the sediment of the acid value test, which represents the oil’s ability to resist aging.

Share:

More Posts

How to Choose Pad Mounted Transformer?

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical factors, as these ground-mounted distribution transformers play a vital role

Function of the Pad Mounted Transformer: A Comprehensive Guide

The primary function of the pad mounted transformer is to serve as a critical distribution transformer that steps down higher primary voltage from utility distribution

Pad Mounted Transformer: Understanding Core Working Principle and Functionality

A pad mounted transformer operates through electromagnetic induction, serving as a crucial distribution component that converts high voltage electricity to lower, usable voltages for residential

Top Pad-Mounted Transformer Manufacturers in the World

When looking for the best pad-mounted transformer manufacturer, it’s important to find industry leaders known for reliability and innovative solutions. Pad-mounted transformers are essential in

Send Us A Message

-

SZ serie OLTC 1000kva Mini distribución 12kv Miniatura Subestación

Read more -

Transformador de potencia de bajas pérdidas precio del fabricante

Read more -

IEC estándar 10MVA 13.8KV 60Hz Transformador de potencia de baja pérdida fabricante precio

Read more -

Baja pérdida 1500kVA 13.8KV 60Hz Loop-feed Pad-mounted Transformador fabricante buen precio

Read more -

2500kVA 34.5KV 60Hz Loop-feed Pad-mounted Transformer precio de fábrica normas IEEE/DOE/ANSI trifásico

Read more -

Transformador trifásico de resina epoxi de tipo seco de clase 35KV

Read more -

Transformador trifásico de resina epoxi de tipo seco de clase 20KV

Read more -

Transformador trifásico de resina epoxi de tipo seco de clase 10KV

Read more -

Transformador de potencia 220KV trifásico de dos devanados OLTC

Read more -

Transformador de potencia trifásico de 220KV de dos devanados NLTC

Read more -

Transformador de potencia trifásico de tres devanados de clase 110KV

Read more -

Transformador de potencia trifásico de 66KV de dos devanados NLTC

Read more -

Transformador de potencia OLTC trifásico de dos devanados de clase 66KV

Read more -

Transformador de distribución trifásico sumergido en aceite de clase 35KV

Read more -

Transformador de distribución trifásico sumergido en aceite de clase 20KV

Read more -

Transformador de distribución trifásico sumergido en aceite de clase 10KV

Read more