How to Choose Pad Mounted Transformer?

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical

ELECTRIC, WITH AN EDGE

This paper analyses the 400kVA distribution transformer as a real object, focusing on its outlet short-circuit faults.

The 400kVA distribution transformer is a crucial device in the distribution network. Still, during its operation, it is susceptible to interference from short-circuit currents, which can lead to faults such as low-voltage outlet short-circuits, seriously endangering the stability of the equipment and even inducing safety.

This can seriously endanger the stability of the equipment and even lead to safety incidents.

Firstly, the faulty transformer was returned to the factory for dismantling and inspection. It was found that the 400kVA distribution transformer’s high voltage winding had deformed, and the mechanical strength of the winding had decreased.

Secondly, combined with the data obtained from the test of the 400kVA distribution transformer, it was concluded that the 400kVA distribution transformer had been subjected to repeated short-circuit current shocks on the low voltage side, the cumulative effect of which had caused the windings to deform and eventually led to insulation breakdown. Finally, according to the analysis of the cause of the fault, the corresponding maintenance measures and precautions are proposed, which have specific engineering application value.

The 400kVA distribution transformer, as an essential part of the distribution network, is often subjected to the impact of short-circuit currents under various operating conditions.

The transformer frequently suffers from short-circuit current impact test, the mechanical strength of the winding decreases, the cumulative effect makes the serpentine destabilization deformation, and then destroy the insulation strength of the winding, severe cases will make the equipment due to the loss of insulation capacity and burn, resulting in large area blackout, affecting the continuity of power supply.

After a short-circuit fault occurs in the transformer, the insulation capacity of the equipment decreases, and the damage rate is high. At this time, the transformer should be shut down as soon as possible for inspection, to develop an overhaul plan, to carry out relevant electrical tests and dissolved gas chromatography analysis tests in the oil, to carry out a comprehensive fault detection on the transformer, and then judge the degree of damage to the equipment and determine whether the transformer can continue to operate.

400kVA distribution transformer because of its small size, lightweight, easy handling, large spare parts resources, and other advantages, after the failure is generally not in the field to take oil samples for chromatographic analysis, only insulation resistance, ratio measurement, and other field test items, or lifting the cover on the appearance of the visible part of the initial inspection.

If the impact of continued operation, most of the direct return to the factory or to the maintenance workshop for further inspection and analysis of the fault, measured electrical test parameters, and analysis results can provide the relevant basis for the subsequent maintenance and operation of the equipment.

Through the analysis of a 10 kV 400 kVA distribution transformer winding short-circuit fault, the specific causes of the mark were found, and corresponding targeted maintenance measures, and precautions were proposed to provide some reference for the subsequent handling of similar faults.

In August 2017, a 400 kVA distribution transformer had an outlet short circuit accident; the transformer model: S13-M-400/10, rated capacity: 400 kVA, voltage ratio: 10 000 × (1 ± 2 × 2.5%) V / 400V, coupling group number: Dyn11.

As the 400 kVA distribution transformer suffered a strong impact from the export short-circuit current, resulting in a broken strand and local deformation of the A-phase high-voltage winding, a severe deformation of the low-voltage coil and a short-circuit between turns, eventually causing the 400 kVA distribution transformer to burn up in operation and causing interruption to the power supply. After the fault, the transformer was inspected using a crane, the DC resistance of the winding, the variable ratio test, and other relevant data were measured and diagnosed, the cause of the accident was analyzed, the type of fault was identified, and the corresponding targeted improvement measures were proposed.

On 20 August 2017, the faulty 400kVA distribution transformer was returned to the factory for inspection and treatment. After lifting the bell housing, the visible part of the transformer’s body was inspected for appearance. It was found that the high-voltage winding of phase A was out of round and deformed, the outer insulation tape was broken, and the inter-turn winding had severe displacement. B, C-phase appearance is not abnormal. The hood inspection is shown in Figure 1.

The actual situation of the low-voltage coils of each phase winding cannot be directly observed through the inspection of the body appearance of the lifting cover, considering that the high-voltage loops of phase A have been mechanically deformed, to be able to accurately judge the deformation of the low-voltage waves and find the causes of the equipment’s faults, and to formulate corresponding improvement measures and maintenance plans, further measurement, and analysis of the insulation resistance, DC resistance and variation ratio of this transformer.

The insulation test is mainly a test of the insulation resistance of the winding together with the bushing and core, and the measurement results after the fault are shown in Table 1.

Whether the core is earthed or not is an essential part of the insulation test, and this part is often easily overlooked in the measurements.

In the process of dismantling the transformer hood, the insulation between the winding and the core should be measured before the center grounding connection piece can be removed and the core to ground insulation tested.

Otherwise, the insulation resistance value of the low-voltage winding to the high-voltage winding, core, and shell often becomes the insulation resistance value of the core to ground.

A, B, and C three-phase winding high-voltage winding and core to ground insulation are normal, while low-voltage winding and high-voltage winding, low-voltage winding and core and low-voltage winding and shell insulation resistance are zero, and low-voltage winding in the innermost layer near the core, which can be presumed that the insulation layer between low-voltage winding and core has lost insulation capacity.

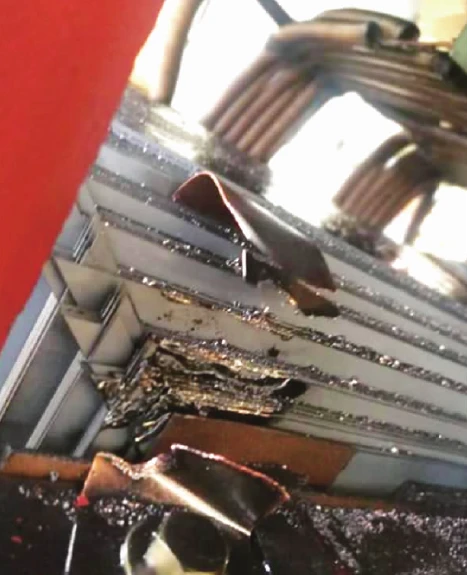

At the end of the insulation test, the coils were dismantled, and the 400kVA distribution transformer was observed to have broken insulation between the LV winding and the core. The core silicon steel showed signs of severe overheating, verifying the accuracy of the insulation resistance measurement results.

It can be seen that after a short-circuit fault in the equipment, the short-circuit current caused deformation and heating of the winding. The cumulative effect exacerbated the degree of insulation damage, resulting in insulation breakdown between the winding and the core and severe damage to the core silicon steel sheet. The scorching of the core silicon steel sheet is shown in Figure 2.

Measuring the DC resistance of the winding is one of the most effective methods of testing the longitudinal insulation of a 400kVA distribution transformer.

When the 400kVA distribution transformer is subjected to the test of impact short-circuit current, the resistance loss increases, and the weak parts of the coil and lead connection become hot. The heat is concentrated in the oil tank and cannot be dissipated in time, resulting in the weak parts breaking or even breaking due to heat, the DC resistance becomes significant, and the three-phase unbalance rate exceeds the standard.

When a metallic turn-to-turn short circuit occurs between layers or turns of a phase winding, the insulation capacity of the winding decreases or even loses its insulation capacity, causing the DC resistance of the phase to decrease.

The 400kVA distribution transformer high voltage winding is triangularly connected, and when the winding is not disconnected from the connecting wire, the measured DC resistance is the line resistance. To locate the faulty phase more quickly during fault diagnosis, the line resistance needs to be converted to phase resistance.

Comparing the factory measured three-phase DC resistance data with the three-phase DC resistance data after the fault, it was found that the unbalance rate of the three-phase winding after the mark was 4.99%, which was much higher than the 2% warning value specified in the protocol.

The DC resistance data of the A-phase high-voltage winding after the fault is obviously significant, increasing the unbalance rate of the three-phase direct resistance. It is presumed that the A-phase coil may be burned or the winding is broken.

Comparing the DC resistance measurement data of each phase of the transformer at the factory with the DC resistance measurement data of each step after the fault, the DC resistance of the low-voltage side of the a-phase was significantly reduced, and the error with the initial value was 2.21%.

It is assumed that the A-phase coil has deformed, and there is a local inter-turn or inter-layer short-circuit fault in the winding, which leads to the DC resistance exceeding the limit. However, the cause of the defect cannot be determined by the DC resistance data alone.

To further determine the cause of the fault in the 400kVA distribution transformer, a ratio test was carried out. Compared to the DC resistance measurement, the analysis of the ratio test results made it easier to detect a short circuit between the winding turns.

The ratio error has exceeded the limit and is much greater than the 1% warning value specified in the regulations. The positive value of the ratio error indicates that the 400kVA distribution transformer has a short-circuit fault on the low voltage side. Comparing the three-phase ratio error, the ratio error of AB/ab is the largest, and the 400kVA distribution transformer is Dyn11 wired, thus inferring that the short-circuit fault mainly occurred in the A-phase low-voltage winding.

According to the electrical test data and conclusions, combined with the winding deformation apparent phenomenon found when lifting the cover, comprehensive analysis to get the 400kVA distribution transformer outlet short circuit fault causes are as follows.

By comparing and analyzing the factory test data and the measurement data after the fault, it was found that the data of the 400kVA distribution transformer A-phase winding had changed significantly and exceeded the warning range specified in the regulations; through the insulation test, it could be inferred that the 400kVA distribution transformer a-phase low-voltage winding and the core between The insulation has been broken down.

The DC resistance test found that the DC resistance on the high-voltage side of phase A had increased, thus presuming that there might be burned or broken strands in the winding of phase A.

Analysis of the winding ratio data after the fault showed that the phase A twisted ratio error was much greater than the warning value, thus inferring that there was a short circuit between turns in the winding of this 400kVA distribution transformer.

Further analysis showed that the 400kVA distribution transformer had been subjected to repeated short-circuit currents on the low voltage side of the a-phase outlet, generating a large amount of heat in the low voltage winding, which could not be dissipated in time in the tank, resulting in a sharp rise in winding temperature and reduced thermal stability.

At the same time, the short-circuit current flowing through the electrical equipment will produce electromagnetic stress; short-circuit electromotive force is hundreds of times the mechanical pressure on the winding during regular operation of the transformer, making the mechanical strength of the winding decreased. As the current direction of high-voltage winding and low-voltage winding is opposite, the short-circuit stress makes the high-voltage winding in the outer layer of the tank expand outward by tensile force, and the low-voltage winding in the inner layer contract inward by compressive strength.

The coils are squeezed and stretched between each other so that the insulation distance between the turns of the winding, winding, and core changes, resulting in a decrease in the insulation strength and mechanical stability of the equipment, and then a short circuit between the turns, winding disconnection, core burn, and other faults.

The cumulative effect of the short-circuit current on the transformer caused the winding deformation to intensify and the insulation damage to expand, which was the main reason why the 400kVA distribution transformer suffered a short-circuit fault at the low-voltage winding outlet.

The equipment is in long-term fault operation; the cumulative effect of short-circuit current causes insulation breakdown between the low-voltage winding and the iron core, and the vast short-circuit current makes the iron core burn. At the same time, under the short-circuit stress, the A-phase high-voltage winding also underwent irreversible deformation, causing the winding wire turns to embed and the wire to break. This eventually led to the destruction of the 400kVA distribution transformer and caused an interruption to the power supply.

By making a preliminary judgment on a 400 kVA distribution transformer outlet short-circuit fault and the reasons for its occurrence, combined with crane inspection, DC resistance test, ratio test, and insulation test to diagnose the fault, analyze the causes affecting the 400 kVA distribution transformer outlet short-circuit and propose corresponding Preventive measures are presented.

(1) Due to a large number of low-voltage load-side connection lines and the complexity of the use scenario, the 400kVA distribution transformer is often subjected to sudden short-circuit currents under various operating conditions in a conventional operating environment and is prone to short-circuit faults. Therefore, appropriate measures should be taken in a timely manner to reduce the likelihood of faults occurring.

Pay attention to the details of the 400kVA distribution transformer core, winding and tap changer during the equipment assembly process, improve the product manufacturing process, prevent the increase of magnetic leakage caused by loose bolts, broken leads, deformation of the core, and other problems, so that the transformer oil tank internal overheating, insulation strength is reduced; try to use heat-resistant and high mechanical strength of Insulation materials, optimize product performance, to improve the equipment short-circuit resistance.

2) For a 400kVA distribution transformer, which is frequently impacted by short-circuit current, even if the equipment can still operate normally, it may lead to mechanical instability or loss of insulation capacity of 400kVA distribution transformer winding due to minor deformation.

Therefore, attention should be paid to the daily maintenance and management of the 400kVA distribution transformer, actively carrying out various maintenance plans, keeping track of the relevant operational data records, and establishing an online testing data system for the operation of the equipment.

The 400kVA distribution transformer operating in the harsh operating environment should be as short as possible to shorten the overhaul cycle, the timely judgment of winding health status, to avoid the formation of safety hazards due to the failure of equipment not found in time, resulting in the interruption of power supply in the operation of equipment.

(3) When analyzing the cause of faults in faulty equipment, the type of fault should not be judged by a status quantity alone but should include a comprehensive analysis of the measurement results of tests such as DC resistance, insulation resistance, variable ratio, and dielectric loss value, and then combine them with the 400kVA distribution transformer’s load condition and operating status to make a comprehensive diagnosis. The corresponding measurement data should be compared with. If there is a significant deviation from the previous data, special attention should be paid even if the data is still within the normal range.

If necessary, a hood check should be carried out to fully consider the cumulative effect on the 400kVA distribution transformer winding, reduce the probability of latent faults, improve the fault diagnosis capability of the 400kVA distribution transformer, and ensure the reliable operation of the equipment.

A typical case of a 400kVA distribution transformer suffering from deformation of the winding after an outlet short circuit shock is analyzed. The type of fault and the degree of hazard is judged using a comprehensive diagnostic analysis combined with the test results through a crane inspection.

The specific measures to improve the operational reliability of the 400kVA distribution transformer in the event of an outlet short circuit fault were proposed to accumulate data and experience in fault diagnosis for the safe operation of future equipment.

Download Resource

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical

The primary function of the pad mounted transformer is to serve as a critical distribution

A pad mounted transformer operates through electromagnetic induction, serving as a crucial distribution component that

After filling in the contact information, you can download the PDF.