How to Choose Pad Mounted Transformer?

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical

ELECTRIC, WITH AN EDGE

When designing transformers, manufacturers consider the voltage and current needed to power the transformer in question. The transformer’s nameplate then lists this information in terms of VA (Volt-Amps). A 125 kva transformer refers to a transformer with a rated capacity of 125 kva.

This is known as the transformer’s rating. The transformer’s rating specifies the maximum voltage and current that can be safely applied to the transformer.

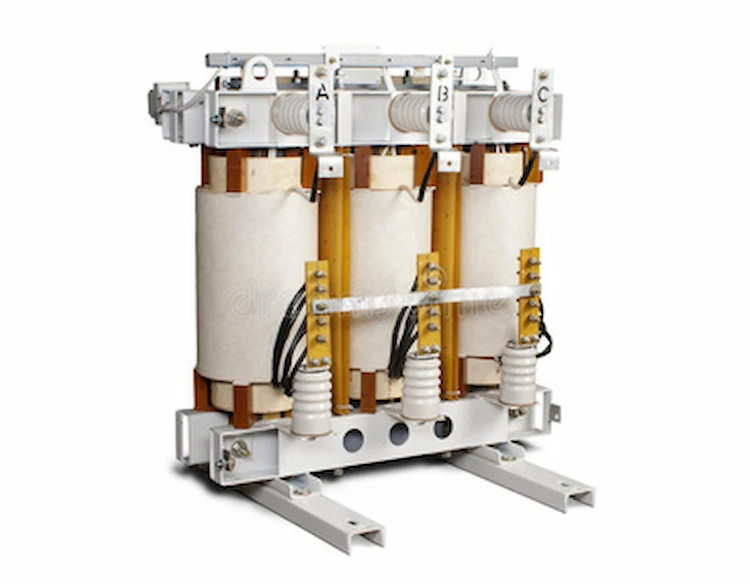

There are many types of 125 kva transformers, such as dry-type transformers, pole-mounted transformers, single-phase pad mounted transformers, etc.

Daelim, as an excellent manufacturer of 125kva distribution transformers, has more than 16 years of design and production experience.

A complete production monitoring process ensures that your transformers are well done during design and production.

At the same time, daelim has also obtained a number of international standard certifications including IEEE, CSA, ANSI, IEC and so on.

The 125kva transformer is a kind of Low-voltage transformer.

The primary voltage is 11kv, and the secondary voltage is 0.55kv for this 125 kVA transformer, an Oil Cooled Transformer.

No-load loss and no-load current can be efficiently reduced by the core’s 45° miter junction and step overlapping construction.

With cutting-edge technology and high-quality materials and components, our 125 kva distribution transformer has been built for long life and reliable performance.

Each transformer Daelim provided passed a complete acceptance test.

We have maintained a zero-fault rate record for more than a decade now. Oil-immersed power transformers are constructed in compliance with IEC, ANSI, and other international standards.

On the other hand, insulating oil in a 125 kva Transformer provides electrical insulation between the various electrified sections and preserves the metal surfaces from oxidation by acting as a protective coating layer.

Dissipation of heat, an additional benefit of the oil is that it helps dissipate heat.

Various power losses cause the cores and windings of 125 kva distribution Transformers to overheat during operation.

Conduction removes heat from the core and windings.

It transfers it to the surrounding tank, where it is subsequently radiated out into the environment.

It is essential to keep the viscosity, pour point, and flashpoint.

All bushings and penetrations should be inspected for oil leaks such as pressure taps, sample taps, etc., and oil levels at least once a month.

Cooling fans should be inspected twice a year to ensure they function correctly.

At least once a year, the transformer’s oil should be tested and analyzed, and the protection devices such as temperature relays, pressure switches, etc.

The primary bushings and the transformer’s top should be cleaned.

Special attention must be paid to ensuring that the total weight of a transformer is guaranteed when considering the barge to be carried and that reinforcement measures are taken if necessary; in water transportation, the bumping wave of the ship must be taken into consideration, and the binding must be firm.kva

For specifications, a four-cylinder, four-stroke water-cooled engine with direct injection and water cooling conforms to ISO 3046 and BS 5514.

The exhaust manifold, stainless steel exhaust flexible connector, and turbocharger are all included with this package, cooled after cooling the radiator. A lubricant oil cooler that uses a plate-type design.

The air cleaner’s dry-type paper element can be replaced when the oil or fuel filter becomes dirty.

Single-bearing alternator flywheel housing with flywheel Starting the engine Lubricate and cool the engine with lubricating oil and a coolant first optional: Stamford or Crompton Greaves or comparable brushless alternator Thermal conductivity limited to Class “H” insulation, self-excited and self-regulated, Class “H” insulation a single-bearing revolving field Regulator of voltage automatically enclosure with good acoustics.

Moreover, silencer and SS exhaust below fitted on AVM to meet MOEF/CPCB noise emission regulations for engine alternator assembly drain plugs, air vent inlets and outlets, level indicators, and maintenance holes are included in the base rail with a draw-out fuel tank.

Sub-base fuel tank with a capacity of 11 hours at 75% load, 12 V dry, batteries with connecting connections and terminals, 90 percent gloss RAL9003 white pure polyester powder coated, base in black color.

White powder-coated control panel constructed using CRCA sheet, with water and lubricant oil drain holes situated on the outer surface, making maintenance and cleaning more accessible and convenient.

An MCCB has overload and short circuit safety features of the appropriate rating.

The KWh/PF/PF/PF/Frequency/Voc controller displays voltage, current, load on, and set running indicator lamps the right size current 125 kva transformers copper cable with incoming and outgoing terminations of sufficient capacity.

The control fuses have been appropriately wired and ferruled, and the power cables and conductors between the alternator and the control panel.

These units are widely used to measure apparent power in generators and transformers because they provide a unit of measurement equal to 1,000 volt-amps.

Current in a circuit is measured in amperes (Amps). This means that the voltage divided by the kVA equals the amps.

By multiplying 200 amps by 208 volts by 1.7332, you may determine the size of a transformer that will match the 200 amp panel’s current rating.

You would only get 56 KVA even if you let a 45 kva transformer be overloaded for a short time to a level of 125 percent.

First, multiply your goal by 1.732. You would only get 56 KVA even if you let a 45 kva transformer be overloaded for a short time to a level of 125 percent.

A few reminders state that you need to know the circuit’s power efficiency and voltage to compute amps from KVA.

It is necessary to multiply the KVA by 1,000 to get VA. The power factor is expressed as a decimal. Therefore multiply the VA by the power factor multiplier. Calculate the amps by multiplying the result by the voltage.

It is common knowledge that you would use more than one 50 kva to supply power to more than one 200 kilovolt service, so the 50 kva is 50000 volt-amps. Maintaining the current single-phase configuration is the best option.

When using 4.2 times the KVA of the transformer, you will get the secondary’s total load current.

To check, 180 amps are the equivalent to 150 kVA at 480 volts. You can feed it with a 200, but if it’s packed to the gills, the 200 will be pushed a bit. 416 amps at 120/208 volts and 3O kVA=150 kVA. This is only possible if you have a large circuit breaker in your panel. A 400 amp breaker or more is required if you don’t have one.

Look for the word “amps” on the label or inside the case of your 125 kva distribution transformer to find out how many amps it produces. Call or email the manufacturer if they don’t.

The amperage is printed right on the cover of some 125 kva distribution transformers. The case is marked with the names of other items. On the transformer itself, there are further markings.

You may work backward from there once you know how much current travels through your breaker when the electricity is turned off.

A decent place to obtain an amp meter is from an electrical supply store if, for example, your breaker pops when you touch it indicating that it’s a working circuit.

When you touch your circuit breaker, you’ll know exactly how much current it’s carrying, allowing you to find the right size.

When it comes to large transformers, it is not uncommon to have two distinct windings on the same core, one to handle 120V and the other 240V. 150 kVA is equal to 150,000 watts with a power factor of one.

Voltage is measured in volts, while watts are used to express power. In other words, a 150 kW system produces 150,000 watts every second.

On the other hand, 150 kW is a big power rating since it exceeds the threshold of 100 kW. It can be used in both commercial and heavy industrial settings.

Since 100 kW is less than 150 kW, it is also regarded as having considerable power.

A power output of 30 kW is deemed little since it is smaller than a power output of 100 kW. Residential and modest industrial use are both possible.

So, 150 kVA is a significant power, while 30 kVA is negligible.

To provide an example, a 125 kva distribution transformer rated at 100 VA can withstand 100 volts at a current of one amp.

It stands for kilovolt-amperes, or 1,000 volt-amperes, and the kVA unit stands for that.

To put it another way, it’s the same thing as having 1,000 VA in your transformer, but it’s only capable of handling 100 volts at 10 amps of current.

The kilovolt (kV) or megavolt (MV) rating of a transformer is commonly used (MV). Small transformers should be utilized when the voltage is more than 25 kV or 50 MV.

As the secondary voltage rises, so does the current flowing through the transformer.

This means that the current drawn from an external source, like a battery, decreases when the primary side of the transformer is linked to a source with a constant voltage.

To illustrate this point, if the secondary voltage is increased by a factor of two, the current will be reduced by half. If the secondary winding is linked to a variable load, it can also function as a variable resistor.

There will be 5 amps of current flowing through the secondary winding when the resistance is only 5 ohms. Still, the current will drop to 2.5 amps when the resistance is only 10 ohms.

Many transformers are available, from small devices that can take up to roughly 20 amps to extensive systems that can manage hundreds of amps.

Transformer power must be increased if voltage drop exceeds operational limitations.

When using a North American distribution subsystem with an output voltage range of 240 to 13,800 volts, North American motors are rated 230 to 2,300, 4,160 to 6,900, or 13,800 volts.

The motor’s voltage is determined by the speed and weight of the load. To maintain a constant voltage across the windings, the generator must supply less current when the voltage is higher.

Thus, the primary side voltage multiplied by the primary side current determines the amount of power that can be delivered through a transformer.

As a result, higher voltage allows for the transmission of greater power. This can cause secondary components to overheat and fail, which can be dangerous.

To handle the low voltages, low-voltage transformers contain larger cores and thicker magnetic material layers. It is also necessary to provide extra insulation around the core and between the magnetic material layers.

Because of the reduced risk of electric shock, it does not necessitate personal protective equipment (PPE) during maintenance tasks. In addition, installing and maintaining systems with lower voltage is less expensive.

High voltage makes transmission lines with smaller cross-sections and lighter weights possible.

Therefore, an isolation transformer with 150 kVA rated power phases, dry type air self-cooling cooling technology, converts 240 volts to 120 volts. This transformer is appropriate for many applications because of its low running costs and low heat emissions.

Thus, a temperature alarm is typically included in isolation transformers with power outputs of more than 150 kVA.

The alert will sound if the transformer’s temperature increases above 150 degrees. Manually suspending or stopping the transformer is required at this point. Continue to use after the transformer temperature has stabilized.

Losses in the 125 kva transformer determine the rating it can achieve because of temperature rise. However, the temperature can be kept below acceptable ranges with the correct cooling system.

To specify, the higher the transformer’s rating, the more efficient the cooling system must be, and vice versa. The losses in an electrical machine determine a machine’s rating in a cooling system.

The maximum power a gadget can use, create, or transfer determines its rating. Even though they’re not all the same, they’re all different when it comes to kVA (kilo-volt-ampere) and VA (volt-ampere) . Rather than kilowatts, transformers are rated in kVA or VA.

Furthermore, electric loads such as motors, lamps, and heaters are all rated by their power consumption (kW) rather than their output (kVA), which is the case for equipment used to generate and transmit power (generators and transformers).

Equipment is rated according to the amount of current it can handle at a given voltage and the number of losses that occur in it.

For power transformers as well, the same holds. A transformer’s rating is determined by its ability to transfer the highest electricity from its primary site to its secondary side while still incurring losses. Always refer to voltage ratings in terms of amperage, not kilovolts.

Transformers are made without considering the load they will be linked to. As a result, it can be used with any electrical load either resistive, capacitive, inductive, or combination loads.

Confusion can occur over what type of load is connected to the transformer rated in KWs.

This is the reason for the KVA rating on the transformer. This will clear any misunderstandings about what kind of load is being connected.

Losses in the transformer determine the rating it can achieve because of temperature rise. However, the temperature can be kept below acceptable ranges with the correct cooling system.

To specify, the higher the transformer’s rating, the more efficient the cooling system must be, and vice versa. The losses in an electrical machine determine a machine’s rating in a cooling system.

The maximum power a gadget can use, create, or transfer determines its rating. Even though they’re not all the same, they’re all different when it comes to kVA (kilo-volt-ampere) and VA (volt-ampere). Rather than kilowatts, transformers are rated in kVA or VA.

Furthermore, electric loads such as motors, lamps, and heaters are all rated by their power consumption (kW) rather than their output (kVA), which is the case for equipment used to generate and transmit power (generators and transformers).

Equipment is rated according to the amount of current it can handle at a given voltage and the number of losses that occur in it. For 125 kva distribution transformer as well, the same holds. A transformer’s rating is determined by its ability to transfer the highest electricity from its primary site to its secondary side while still incurring losses. Always refer to voltage ratings in terms of amperage, not kilovolts.

Transformers are made without considering the load they will be linked to. As a result, it can be used with any electrical load either resistive, capacitive, inductive, or combination loads. Confusion can occur over what type of load is connected to the 125 kva distribution Transformer rated in KWs. This is the reason for the KVA rating on the 125 kva distribution Transformerr. This will clear any misunderstandings about what kind of load is being connected.

Download Resource

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical

The primary function of the pad mounted transformer is to serve as a critical distribution

A pad mounted transformer operates through electromagnetic induction, serving as a crucial distribution component that

After filling in the contact information, you can download the PDF.