How to Choose Pad Mounted Transformer?

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical factors, as these ground-mounted distribution transformers play a vital role

ELECTRIC, WITH AN EDGE

Dry-type transformers use air to dissipate heat, and oil-immersed transformers use oil as a medium to dissipate heat. When it comes to the difference between dry-type transformers and oil-immersed transformers, we must also pay attention to the power comparison between the two.

The former has low power and poor moisture resistance, while oil-immersed transformers have high power and are better than dry-type transformers in terms of moisture resistance.

Generally speaking, oil-immersed transformers are low in cost and easy to maintain, but their disadvantages are flammable and explosive. Because of its good fire resistance, the dry transformer can be disassembled for transportation, clean, and easy to maintain.

It does not require a machine base for installation and has no oil seepage pool. It can be installed in the center of the load to reduce voltage loss and power loss. However, dry transformers are expensive, large in size, poor in moisture and dust resistance, and are noisy.

Oil-immersed transformers are generally installed indoors or outdoors in separate transformers due to the need for fire protection, while dry-type transformers must be installed indoors.

Generally, they are installed in low-voltage power distribution rooms and installed side by side with low-voltage power distribution cabinets.

Price: Dry-type transformers are more expensive than oil-immersed transformers. From the perspective of transformer capacity, oil transformers generally have a larger capacity than dry transformers. Dry-type transformers are generally suitable for power distribution. Most of the capacity is below 1600KVA, the voltage is below 10KV, and some have 35KV voltage levels; while oil-type transformers can achieve full capacity and voltage levels from small to large. Voltage.

Application: Generally speaking, comparing two types of transformers, such as the difference between dry-type transformers and oil-immersed transformers, the place of use of the transformer must be considered. Dry-type transformers are generally used in comprehensive buildings (basements, floors, Roofs, etc.) and crowded places. Oil-immersed transformers are used in independent substations. Transformers in box substations generally use dry transformers, and oil transformers are generally used for outdoor temporary electricity use.

Volume: The size of the transformer determines the place where the transformer is used. Comparing the difference between dry-type transformers and oil-immersed transformers, it can be seen that the volume of oil transformers is larger than that of dry transformers. When using oil transformers, more space is required. Can use dry change.

Heat dissipation effect: The heat dissipation effect of oil transformer is better than that of dry transformer. Dry-type transformers are generally insulated by resin and are cooled by natural air. The large capacity is cooled by fans, while oil-type transformers are insulated by insulating oil. The circulation of insulating oil inside the transformer transfers the heat generated by the coil to the radiator (sheet) of the transformer. To dissipate heat.

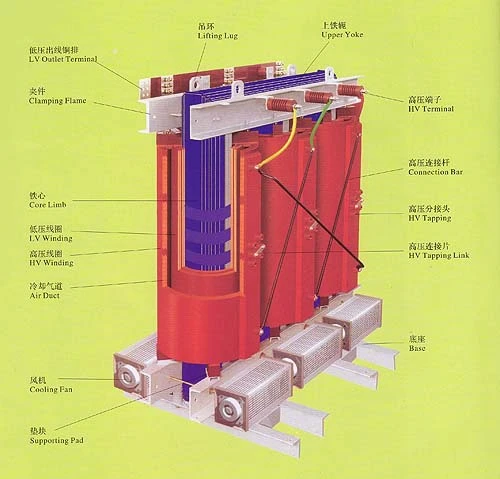

Appearance: It can be known that the difference between dry-type transformers and oil-immersed transformers is mainly in the form of packaging. Dry-type transformers can directly see the iron core and coil, while oil-type transformers can only see the outer shell of the transformer.

Lead form: dry-type transformers mostly use silicone rubber bushings, while oil-type transformers mostly use porcelain bushings.

Endurance: Generally, dry-type transformers should be operated under rated capacity, while oil-type transformers have better overload capacity.

Cooling medium: Oil-type transformers use transformer oil (of course, other oils such as β oil) as the cooling and insulating medium, while dry-type transformers use air or other gases such as SF6 as the cooling medium. The oil change is to place the body composed of iron core and windings in an oil tank filled with transformer oil. Dry-type transformers often encapsulate the iron core and windings with epoxy resin. There is also a non-encapsulated type, which is more used now. The windings are impregnated with special insulating paper and special insulating varnish, etc., to prevent winding or The iron core is damp.

Insulation Materials:

Oil-immersed transformer insulation is Class A insulation. It is made of natural textiles such as wood, cotton, paper, fiber, acetate fiber and polyester amine-based textiles, and plastics that are easy to thermally decompose and have a low melting point. They work in minerals. In oil, or immersed in oleoresin compound glue, its limit working temperature is 105℃;

Dry-type transformers commonly used H-class insulating materials, that is, mica products without reinforcement or with inorganic materials as reinforcement, thick F-level materials, composite mica, silicone mica products, silicone organic paint, silicone organic rubber polyimide The limit working temperature of composite glass cloth, composite film, polyimide paint, etc. is 180°C.

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical factors, as these ground-mounted distribution transformers play a vital role

The primary function of the pad mounted transformer is to serve as a critical distribution transformer that steps down higher primary voltage from utility distribution

A pad mounted transformer operates through electromagnetic induction, serving as a crucial distribution component that converts high voltage electricity to lower, usable voltages for residential

When looking for the best pad-mounted transformer manufacturer, it’s important to find industry leaders known for reliability and innovative solutions. Pad-mounted transformers are essential in

After filling in the contact information, you can download the PDF.

2 Responses

Which one recommended by OSHA dry transformers OR oil transformers ,

Please tell me your usage scenarios and power consumption so that I can recommend a suitable transformer for you.