How to Choose Pad Mounted Transformer?

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical

ELECTRIC, WITH AN EDGE

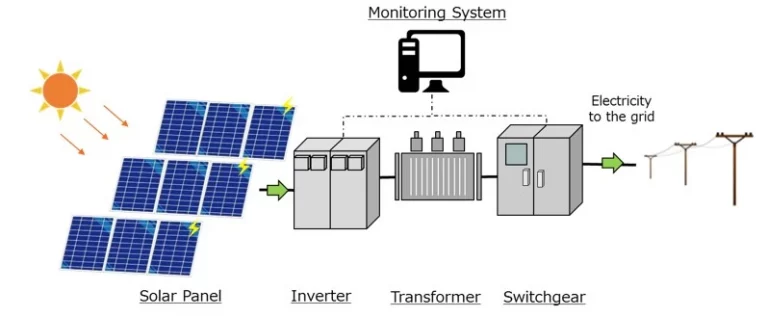

In large grid-connected Solar power plants with centralised inverters, a Solar power plant pad mounted transformer with a three-phase double secondary winding structure is generally used to convert the AC output from the inverter to a suitable voltage level for connection to the grid.

Lorem ipsum dolor sit amet, consectetur adipiscing elit。Ut elit tellus、luctus nec ullamcorper mattis、pulvinar dapibus leo。The three-phase double secondary winding solar transformer has good impedance characteristics and low voltage ride-through capability according to the operating characteristics of the inverter configured on its low voltage side, which is essential for the safe, stable and economic operation of the photovoltaic power generation system. In view of the faults encountered in the actual production of Solar power plant, such as single phase grounding, high voltage disconnection and high and low voltage short circuit, the causes of the faults are analysed and the handling methods are discussed, which have certain guiding significance for the production operation and maintenance of Solar power plant.

The Solar power plant where the Solar power plant pad mounted transformer fault occurred has a total installed capacity of 50 MWp, the PV modules are EG-255P60-C modules, the inverter is a centralised inverter with a single rated capacity of 500 kW, and the solar transformer is T-1000/38.5 double secondary winding solar transformer of type ZGS11-Z.T-1000/38.5, rated capacity 1 000 kVA, coupling group D-y11, y11.

One solar three phase pad-mounted transformer with two central inverters, a total of 50 solar 3 phase pad mounted transformers for the whole station, connected to the 35 kV bus side of the solar power plant by five 35 kV lines via buried cables.

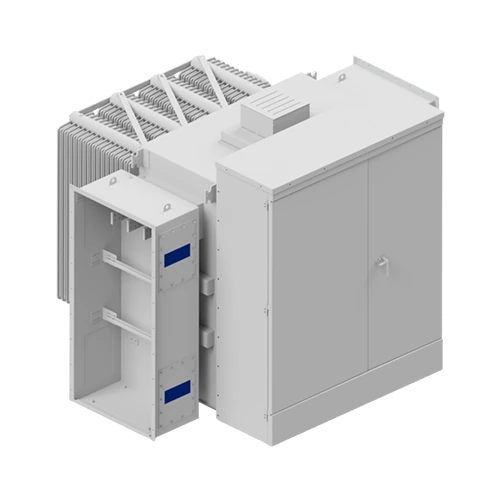

The solar transformer is equipped with a three-phase, three-column core, with the core column and yoke made of stacked steel sheets and lapped by diagonal joints in the form of a five-step lap joint, which effectively reduces the losses between the core column and yoke joints.

The solar transformer has a double winding on the low voltage side, with two low voltage windings wound in a double spiral arrangement close to the core in turn, insulated by insulating paper between the windings, with the two low voltage winding head bushes arranged at the upper and lower ends of the solar transformer.

The high voltage winding is wound on a hollow insulating paper tube and finally the whole set is placed on the low voltage winding.

On October 29, 2018, Solar power plant operation and maintenance personnel conducted preventive tests on the whole station Solar power plant pad mounted transforme, and when doing insulation inspection tests on the No. 1 Solar power plant pad mounted transforme with power outage, they found that the No. 1 The insulation resistance of the low-voltage side of Solar power plant pad mounted transforme No. 1 a1, b1 and c1 was 0, and there were traces of burnt black and loose bolts on the incoming bus bar connection of the circuit breaker on the low-voltage side of Solar power plant pad mounted transforme No. 1.

Before the power outage, the power generation unit was generating electricity normally. Subsequently, the operation and maintenance personnel conducted a DC resistance test on the Solar power plant pad mounted transforme and found no abnormality.

It was initially determined that there was a fault inside the low voltage side of Solar power plant pad mounted transforme 1 that required opening the cover for inspection.

On November 2, 2018, after returning to the factory, the core was lifted out by opening the cover and it was found that the insulation paper between the a1 phase winding out copper row and the support clamp block on the No. 1 low-voltage side had discharged through, resulting in the a1 phase bus bar and the fixing bolt of the core bracket being tightly attached, forming a ground point.

Due to the Solar power plant pad mounted transforme the coupling group is D-y11, y11, low-voltage side using the neutral point is not grounded mode, when a single-phase ground fault occurs, according to the characteristics of photovoltaic power generation, the fault situation from two aspects of the analysis.

First, when the inverter works in off-grid state, i.e. at night or when the irradiance is insufficient, the inverter works in standby state.

At this time, the Solar power plant pad mounted transforme works in the distribution state, and the inverter is supplied by the grid through the Solar power plant pad mounted transforme as a power load to maintain the inverter in the standby state.

The insulation between the a1 phase copper row on the low voltage side of No. 1 and the core holder fixing bolt is damaged forming a grounding point, but the system three-phase line voltage remains unchanged and can supply power to the inverter normally. This state is not found in time and continuous operation may lead to two or more points of grounding on the low-voltage side.

Secondly, when the inverter works in the grid-connected state, because the inverter topology is a three-phase three-wire ungrounded inverter system without neutral lead, the inverter control system can only measure or control the line voltage at the grid-connected point, and the zero sequence current is zero.

According to the inverter three-phase steady-state model analysis, the three-phase three-wire unearthed system cannot form an electrically closed circuit after a single-phase grounding occurs, so no grounding current is generated and the equivalent position generates a grounding impedance at the neutral point.

For the output circuit of the three-phase inverter this corresponds to a series of impedances in the output circuit of each phase, without destroying the system steady-state model. The inverter can work in a grid-connected state, but the output efficiency is reduced.

At 16:24 on 4 April 2019, the inverter in zone 36 of the Solar power plant tripped with a fault message for a low voltage ride-through and grid undervoltage alarm fault, the inverter reset was invalid, and the unit failed to shut down. The backend monitoring showed that the three phase AC voltages on the low voltage side of Solar power plant pad mounted transforme 1 and 2 were: ac phase 280 V AC, bc phase 250 V AC and ab phase 46 V AC.

On-site inspection revealed a slight discharge sound inside the solar transformer and a distinct rotten egg smell in the air around the solar transformer. The operation and maintenance personnel immediately carried out fault investigation after the collector line where the solar power plant pad mounted transforme was located was de-energised, measured that the solar power plant pad mounted transforme high voltage fuse insurance was normal, measured the solar power plant pad The insulation resistance between phase A winding and the other two windings was found to be infinite when measuring the phase insulation on the high-voltage side of Solar power plant pad mounted transforme, and the preliminary judgment was that the insulation resistance of phase A on the high-voltage side of Solar power plant pad mounted transforme was infinite. The initial judgement was that there was a disconnection in phase A on the high-voltage side of the transforme.

The DC resistance of the winding on the high-voltage side of the Solar power plant pad mounted transforme was tested further, and the DC resistance of phase BC was normal, while the DC resistance of phase AC and phase AB was infinite.

After returning to the factory and opening the cover on April 6, 2019, it was found that the connection line between the A-phase high-voltage load switch and the high-voltage insurance was burnt off, and the connection line was discharged and flamed inside the Solar power plant pad mounted transforme during the process from insulation damage to burnt off, causing serious pollution of the solar transformer oil.

Solar power plant pad mounted transforme high voltage side disconnection is generally divided into high voltage lead disconnection and high voltage winding disconnection.

In this paper, the fault solar transformer high-voltage side winding using triangle wiring, in the fault measurement, AC phase and AB phase DC resistance for infinity, BC phase DC resistance is small, in line with the fault characteristics of a phase of high-voltage lead disconnection.

After the high-voltage winding is disconnected, the DC resistance of the disconnected phase and the adjacent winding will increase by a factor of two, while the DC resistance of the remaining two phases will remain unchanged.

In terms of electrical changes, the line voltage of the high-voltage side without disconnection remains unchanged, and the size of the two line voltages of the disconnected phase becomes half of the original line voltage.

Low-voltage side has two phases of line voltage equal and slightly less than the original line voltage, a phase of line voltage theoretically reduced to 0, but the actual measurement due to the presence of induction voltage, the measured value in the tens of volts or so.

At 14:05 on 14 May 2019, No. 10 Solar power plant pad mounted transforme low voltage side circuit breaker tripped, Solar power plant operation and maintenance personnel immediately went to the accident site to check the fault situation, and upon arrival at the site, they found that the solar transformer sounded abnormal and the site sprayed A large amount of solar transformer oil was sprayed from the site.

At this point, the 35 k V collector II line 353 switch overcurrent section where the faulty Solar power plant pad mounted transforme was located operated and the 353 circuit breaker tripped. After the line tripped, operations and maintenance personnel immediately transferred the 35 kV collector II line 353 switch from operation to maintenance, unlisted the faulty Solar power plant pad mounted transforme from the line and carried out a fault check. The 353 switch protection device reported three-phase overcurrent and phase-to-phase overvoltage.

On-site inspection revealed that the Solar power plant pad mounted transforme had a three-phase to ground short circuit in the low-voltage side winding, the high-voltage side insurance was fused, the pressure relief valve was operated and a large amount of blackened solar transformer oil was sprayed out at the site. A serious fault occurred inside the transforme and it was necessary to return to the factory to open the cover for inspection and repair.

On 17 May 2019, after returning to the plant and opening the cover, it was found that the low-voltage side b1 and b2 phase windings were burnt, the high-voltage side B phase windings were burnt, the B phase column core was broken, and part of the core of the yoke iron under the core was broken. Low-voltage side a1, a2 two-phase winding damage, high-voltage side A-phase column iron core partial collapse.

View the fault recording wave (Figure omitted), the fault instant, 35 kV bus A-phase, B-phase voltage drop, resulting in 35 kV C-phase voltage suddenly increased, followed by No. 2 PV inlet A-phase, B-phase overcurrent generation, overcurrent value exceeds the system fixed value, protection start, No. 2 PV line 353 circuit breaker tripped.

From the fault filtering can also be found, the initial phase of the fault occurred A, B-phase short circuit grounding, C-phase insulation is not damaged, C-phase fault current lags behind A-phase, B-phase, when the high-voltage fault into the steady state, due to Solar power plant pad mounted transforme high-voltage side of the three-phase wiring group for the angle connection, the performance of high-voltage three-phase short circuit grounding, at this time C-phase to generate Fault current.

From the internal fault situation of the solar transformer after disintegration, the short circuit of the b1 and b2 phase windings on the low voltage side is the cause of the fault, the short circuit discharge leads to insulation breakdown between the low voltage winding and the high voltage winding, which expands the fault and leads to a short circuit of the high and low voltage windings. The solar transformer oil is heated up and the pressure relief valve is flushed open.

The solar power plant pad mounted transforme was disassembled and the high and low voltage windings were found to be badly burnt in the B-phase low voltage windings.

Considering that the solar transformer was subjected to a large short-circuit impact after a high-voltage short-circuit fault, the disassembly showed that the core and yoke of the solar transformer were deformed to varying degrees, the B-phase windings were all burnt, and the A-phase windings were also deformed and slightly damaged. The transformer was scrapped.

(1) The low-voltage side of the solar transformer with star wiring and no neutral point lead wire, when a single-phase ground fault occurs, because there is no zero-sequence current generation, and the three-phase line voltage has not changed, the inverter can still work in the power generation state, on the one hand, is not conducive to fault detection, on the other hand, will lead to the expansion of the fault, there are large security risks.

In combination with the actual situation on site, an insulation monitoring device has been added to the AC output of the inverter, and a start-up condition of qualified insulation has been added before the system is connected to the grid. For the new Solar power plant, it is recommended to choose a three-phase four-wire inverter when selecting equipment, padmounted solar transformer matching D-yn11,yn11 wiring group solar transformer.

(2) Daily operation and maintenance of solar power plants should pay attention to the insulation monitoring of solar transformers and carry out regular insulation inspection work.

In particular, for solar power plants with star wiring and three phase padmounted solar transformers without neutral point lead-in, the frequency of insulation inspection should be increased, and it is recommended to conduct insulation inspection on the low voltage side of the solar power plant pad mounted transforme once a month. It is recommended that the solar power plant pad mounted transforme be insulated once a month.

(3) To prevent internal insulation faults in solar power plant pad mounted transforme, oil sample testing should be emphasized.

From the two high-voltage faults in this paper, it can be seen that both broken wires and shorted windings were caused by the presence of internal insulation weaknesses.

Regular oil sample testing can help to detect the process of insulation deterioration and intervene in advance to reduce fault losses. For solar transformers with significantly high oil temperatures in daily operation, it is particularly important to strengthen daily inspections and increase the frequency of oil sample testing.

(4) Attention should be paid to the technical selection of the solar power plant when it is put into operation. When selecting the solar transformer, the overall electrical design, local grid operating characteristics and the natural environment of the site should be taken into account, with special attention to the core materials, winding specifications and insulation materials, and increased technical communication with the manufacturer to ensure the conformity and reasonableness of the chosen products. The technical communication with the manufacturer should be increased to ensure the conformity and reasonableness of the selected products.

Download Resource

Table of Contents Selecting the right pad-mounted transformer requires careful consideration of several critical

The primary function of the pad mounted transformer is to serve as a critical distribution

A pad mounted transformer operates through electromagnetic induction, serving as a crucial distribution component that

After filling in the contact information, you can download the PDF.