ELECTRIC, WITH AN EDGE

Supply Ability: 20 Set/Sets per Month Three phase low-loss nltc oil immersed 66kv 5mva power transform

Packaging Details: Wood case or according to client’s requests

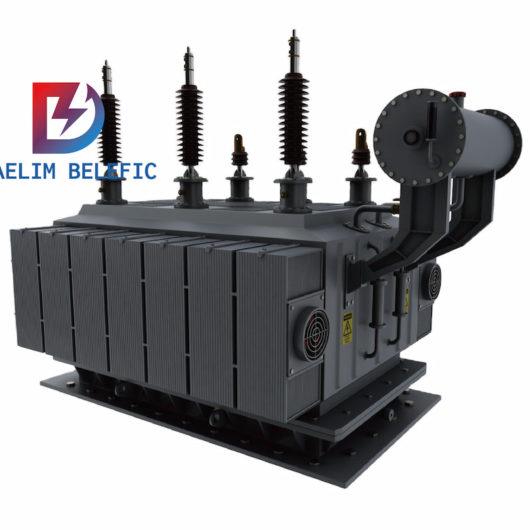

Three-phase low-loss nltc oil-immersed 66kv 5mva power transformer

Daelim brand 220kv,110kv, and 66kv low-loss series transformer is our independently developed new generation of transformers on the basis of absorption of China and foreign advanced technology, which features low local discharge, low loss, high reliability, strong protection against abrupt short circuit.

220kv,110kv and 66kv low loss series transformer if our independently developed new generation of transformer on the basis of absorption of domestic and foreign advanced technology,which features low local discharge ,low loss,low noise,high reliability ,strong protection against abrupt short circuit,its excellent performence has been recognized ny wide users and high appeaised by experts.the full sealed suspending cover free product sell well nationwide.

Amount of local discharge :the apparent discharge amount under 1.5 times if rated voltage is less than 80pc.

Noise:product of 63mva and below is lower than 58db(an)

Power loss:no-load loss is 30% lower than that of IEC stanard.

Reliability:all in service product have no damage or oil leakage occurred;

Short circuit withstanding :model SFZ11-50000/132 smoothly passed the short circuit withstanding test of the national transformer quality supervision and inspection center and also passed holland KEMA quality control systom.

COIL

The high voltage aoil adopts an interleaved continuous structure to improve the voltage characteristica under impact voltage and make voltage evently distrivuted.all stays and pads are chamfered to keep highly reliable insulation.

In the transformer winding there is a zigzag oil guide structure so as to fully cool all areas inside the winding ,lower the temperature rise of the winding and the hot points of the winding and [rolong the service life of insulation.the HV and MV regulation system are independently provide with voltage regulating winding to balance the ampere turn of each winding effecticely lower the axial electrodynamic force generated at short circuit of transformer and improve abrupt short circuit withstanding capacity.

The winding adopts radial 0 margin design ,between the core and the paper sleeve of LV winding ,and between the LV,HV,voltage regulating windings ,as well as before insertion of stays and shround plate they are fully dried and tightly matched to ensure extremely good compactness and concentricity of the entire winding.

CORE

The core is made of high permeable grain orientated top quality coid rolled silicon sheet and the materical is cut with advanced germany geoge gmbh automatic shear line with the cut burrs controlled within 0.002mm.

The sillicon sheet fabrication adopts no-upper yoke lapped technology and all lapped joints of the sillicon sheet are 45 c full miters.the laminated core sheets are integrally pressed and adhered with epoxy resin to make the three leg two yoke core a strong and flat integral one with good verticality precision ,this effectively improves no ;oad performance and reduces noises.

Bracing plates are used as support between coil leg and inner coil.the iron yoke is tied with wpoxy resin impregnated glass fiber band,and the lower iron yoke and the lower section of oil tank is tightened with counter pressure bolts.the upper iron yoke and the upper section of oil tank are fixed at 3 locations .hence the body inside the oil tank can withstand the vibration during transportation without any shift.

OIL TANK AND ACCESSORIES

The tank wall adopts wide steel sheet,which will be folded into corrugated structure without splicing,in this way welds are decreased and mechanical strength id enhanced ,meanwhile ,the corrugated wall has deverging effect ,and thus plays a role in dectease of noise .the routing troughs and control cabinets of the secondary circuit are all made of stainless steel.so the entire transformer has a simple and good looking .

All sealing surfaces use quality sealing material and are precision machined.

On the edge of the tank there are double sealing grooves,and the outer sealing materical is used to shade the atmosphere and ultra ray to protect the inner seaing being damaged,thus at utmost prolinging service life and enhancing reliablity of the seal.

SUBASSEMBLY

As we have good cooperation tie with many subassembly manufactures of famous transformer brands,we are able to provide different subassemblies as per users requrments .the whole procedure of manufacture ,R&D and sales services are carried out strictly in accordance with interational stanards and ISO quality management system.

Dalin’s transformers can be assembled with internationally renowned brand accessories such as Qualitrol remote installation thermometers and tap changers, ABB bushings..

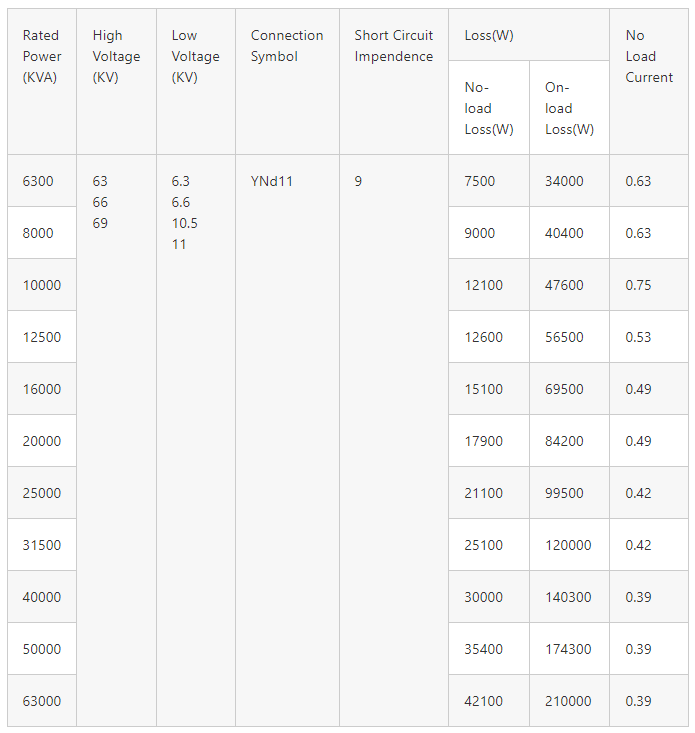

Note: The above data is only subject to our standard design, special requirements can be customized.

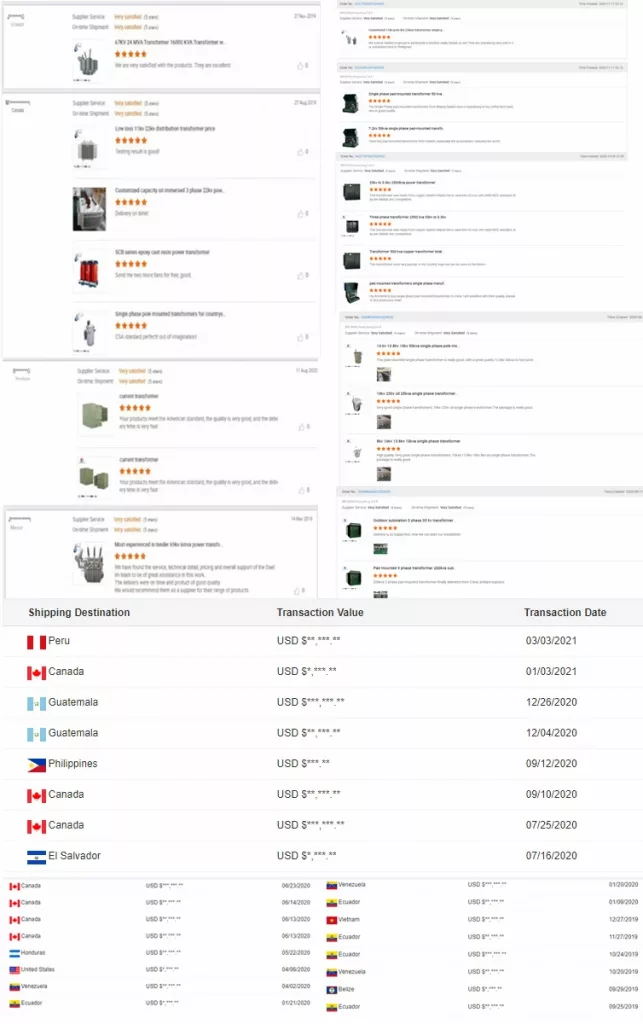

Here is some of comments from our world-wide customers.

[ TRUST YOU WILL LIKE OUR SERVICES, QUALITY AND PRICE ]

Q: Are you a trading company?

A: No. We are a transformer manufacturer. We have our own transformer factory in Jiangsu province.

Q: How long is your delivery time?

A: Generally it is 20 days if the goods are in stock, or 30 days if the goods are not. It is according to the quantity.

Q: What is the standard of package?

A: Export standard package or special package according to customer’s requirement.

Q: Which markets have you already sold your products to?

A: South America, North America, Europe, Middle East, Africa, etc.

Q: How long have you been worked in the electric industry?

A: We have been worked in the electric industry for nearly 25 years.

Q: Why should I choose Daelim?

A: After comparing the quality, delivery, and price of the same products, you will find out the answer.

BEIJING DAELIM GREEN EP TECHNOLOGY CO., LTD. Locates in Beijing, China,is a professional transformer manufacturer and international electrical engineering contraction company. The expert team of DAELIM controls each process from product development to design , production and manufacturing in order to achieve its goals. They have strong R&D team and they have more than 20 years of transformer design experience and are familiar with lots of international transformer standards, such as IEC, IEEE / ANSI,CSA, etc. The technical team of DAELIM are experts, electrical engineers, CAD first-class draftsmen, etc. They also use the latest technology, machines and other modern facilities to produce transformers, but meanwhile DAELIM transformers are made of qualified standard materials which meets the standards of world-renowned suppliers through international procurement as well.